CH 465 Biochemical Engineering Spring 2009

advertisement

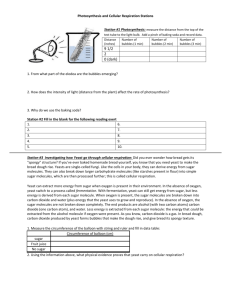

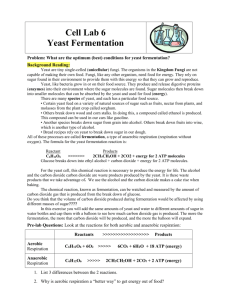

CH 465 Biochemical Engineering Spring 2009 Baker’s Yeast Fermentation Introduction The objective of this experiment is to learn about the kinetics of cell growth by examining the growth rates of baker’s yeast. A Zulauf or fed-batch process is generally employed by the baker’s yeast industry. Nutrients and sugar are fed incrementally to the fermenter at an increasing rate during the growth period so that the amounts of nutrients and sugar per cell remain roughly constant. The temperature and pH are maintained at constant values throughout the process. The concentration of cells is measured as a function of time. If all of the sugar supply is added initially with the yeast, the yeast follows the typical growth curve for batch cell cultivation: a lag phase, exponential growth phase, stationary phase, and death phase. If, however, the yeast is activated and the sugar fed incrementally, only the exponential growth phase is observed. Apparatus The fermentation apparatus consists of a jacketed fermenter with a stirrer, a constant temperature circulation bath and an air pump. The total volume inside the jacketed fermenter is 2 L. The working volume (i.e., the volume into which we can place the fermentation broth) is 1.5 L. A spectrophotometer is used to measure the yeast concentration. A calibration curve that relates cell concentration to the percent light transmitted is attached. The wavelength has been set to approximately 660 nm. Do not change the wavelength of turn off the spectrophotometer while you are conducting the experiment. Experimental Procedure Lin Wu will prepare a nutrient medium for each group. The composition of the medium is: 10g/L ammonium sulfate 6g/L potassium phosphate 3g/L magnesium sulfate 0.1 g/L calcium chloride 0.1 g/L sodium chloride A multivitamin First, 1000 mL of a solution containing the salts is placed in the reactor. Then 100 mL of a solution of the multivitamin is added to the fermenter and brought to an appropriate temperature (e.g., 37 C). Then, 100 mL of a suspension containing 0.8 grams of yeast is prepared and added to the reactor. You can then measure light transmittance of the suspension. Next, you will also need to prepare a 50 wt% of table sugar in water to add to the reactor to initiate the fermentation; the sugar solution will contain 5 grams of sugar. 1 After adding the sugar solution, turn on the air bubbler by plugging into the outlet (there is no on/off switch). At equally spaced time intervals, samples should be collected and analyzed to determine the yeast concentration. You can recalibrate the spectrophotometer before each sample measurement using water. With water in the cuvette, press the calibrate button and %T will be set to 100%. It is important to use the same cuvette for all of your measurements to obtain consistent results. You should wash the cuvette out after each measurement. The total volume of the liquid suspension will be 1.2 Liters; this corresponds to 100 mL of yeast suspension, 100 mL of multivitamin dissolved in water, and 1000 mL of water with the salts dissolved in it. We will already have the 1000 mL of water and salts in the reactor and at a temperature close to 37 C. We have a Mettler balance near the apparatus that can be used to measure the amounts of yeast and sugar. The motor speed is set to 617 rpm. Please don’t change the motor speed. The calibration curve relating yeast concentration to logarithm of % light transmitted follows a linear relationship (Beer’s Law) for concentrations up to ~0.5 wt% (% light transmitted > 2.5%. If the yeast concentration becomes greater than this (i.e., the % light transmitted < 2.5%), you can dilute the collected sample with a known amount of medium accurately monitor yeast concentration. The calibration curve is shown on the following page along with a least squares fit. Data Analysis The collected data should be used to determine the specific growth rate during the exponential growth phase, the yield and the doubling time. A growth curve (yeast concentration as a function of time) should be prepared. By using the glucose meter, monitor the sugar concentration as a function of time and calculate a yield coefficient. 2 3