Fluorescent and confocal microscopy

advertisement

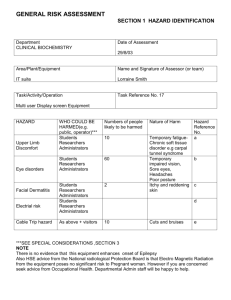

GENERAL RISK ASSESSMENT SECTION 1 HAZARD IDENTIFICATION Department CLINICAL BIOCHEMISTRY Date of Assessment 11th March 2003 Area/Plant/Equipment Microscope Rooms, Name and Signature of Assessor (or team) Margaret Blount Task/Activity/Operation Task Reference No. 8 Fluorescent and confocal microscopy-UV light emissions HAZARD WHO COULD BE HARMED(e.g. public, operator)*** Operator Observers Numbers of people likely to be harmed Nature of Harm 1-3 Exposure to mercury vapour UV emissions Operator Observers 1-3 Damage to eyes 8b Electrical faults Operator (mainly) Others in the area 1 50 (potentially most of the department in case of serious fire) Electric shock Burns to body Fire 8c Hazard from untidy cables Operator Others in the area 1 <10 Injury 8d Implosion ***SEE SPECIAL CONSIDERATIONS ,SECTION 3 Hazard Reference No. 8a SECTION 2 – RISK EVALUATION Note: Section 2 must be completed for each hazard identified in Section 1 Hazard from section 1 Implosion Reference No. 8a Make an assessment without taking into account current control measures (subjective) RISK = Probability of Harm X hurt) PROBABILITY 1 X 2 X 3 Most Likely Severity (will increase if large numbers will be 4 5 6 7 8 9 10 SEVERITY OF HARM 1 X 2 3 4 5 6 7 8 9 10 = RISK LEVEL 10 X 20 40 50 60 70 80 90 100 30 CURRENT CONTROL MEASURES Type Control at Engineering source controls (intrinsic) (guards, local exhaust ventIllation etc. Description Burner to be installed and centered by trained operator only. Procedural Personal controls protective (inc. training equipment and supervision) Use according to manufacturer’s directions Are they Adequate Additional Measures Required Yes Yes By who & When Operator Operator Other In the unlikely event of implosion, switch off controls, evacuate room for 30 min, inform lab management. Operator SECTION 2 – RISK EVALUATION Note: Section 2 must be completed for each hazard identified in Section 1 Hazard from section 1 UV emissions Reference No. 8b Make an assessment without taking into account current control measures (subjective) RISK = Probability of Harm X hurt) PROBABILITY 1 2 X 3 Most Likely Severity (will increase if large numbers will be 4 X 5 6 7 8 9 10 SEVERITY OF HARM 1 2 3 4 X 5 6 7 8 9 10 = RISK LEVEL 10 X 20 40 50 60 70 80 90 100 30 CURRENT CONTROL MEASURES Type Control at Engineering source controls (intrinsic) (guards, local exhaust ventIllation etc. Operate Description according to manufacturer’s instructions, check that correct filters are in place Procedural controls (inc. training and supervision) Personal protective equipment Other Disconnect from mains before replacing burner or bulb Never observe fluorescence or burner without appropriate barrier filter. Are they Adequate Additional Measures Required Yes Yes Yes By who & When Operator Operator Operator Observers SECTION 2 – RISK EVALUATION Note: Section 2 must be completed for each hazard identified in Section 1 Hazard from section 1 Electrical Reference No. 8c Also see Risk Assessment #40 Make an assessment without taking into account current control measures (subjective) RISK = Probability of Harm X hurt) PROBABILITY 1 X 2 X 3 Most Likely Severity (will increase if large numbers will be 4 5 6 7 8 9 10 SEVERITY OF HARM 1 2 3 4 5 6 7 X 8 9 10 = RISK LEVEL 10 X 20 40 50 60 70 80 90 100 30 CURRENT CONTROL MEASURES Type Control at Engineering source controls (intrinsic) (guards, local exhaust ventIllation etc. Before use, Disconnect Description Procedural controls (inc. training and supervision) visually inspect equipment especially cable. If it appears faultydo not use, put on an ‘OUT OF ORDER’ sign & tell lab management. from mains power before changing bulbs or burner Trained operator-only follow manufacture’s instructions Are they Adequate Additional Measures Required Yes Yes *Equipment should be PAT tested periodically and date label affixed, Yes By who & When Operator Operator *Qualified personnel Personal protective equipment Other Defective equipment should be replaced or repaired by engineers Yes Engineers Hazard from section 1 Untidy cables Reference No. 8d Make an assessment without taking into account current control measures (subjective) RISK = Probability of Harm X hurt) PROBABILITY 1 2 X 3 Most Likely Severity (will increase if large numbers will be 4 X 5 6 7 8 9 10 SEVERITY OF HARM 1 2 3 4 X 5 6 7 8 9 10 = RISK LEVEL 10 X 20 40 50 60 70 80 90 100 30 CURRENT CONTROL MEASURES Type Control at Engineering source controls (intrinsic) (guards, local exhaust ventillation etc. Keep leads Description Are they Adequate Additional Measures Required By who & When and connections tidy, but do not coil them too tightly (to prevent overheating). Yes Operator Procedural controls (inc. training and supervision) Personal protective equipment Other SECTION 3,SPECIAL CONSIDERATIONS 1. After carrying out the assessment and assuming adequate training, is this task one that can be carried out by a lone worker? This decision is one made by a group leader, please state their name and answer. Group leader name : Prof. S. O’Rahilly Answer: YES Answer: 2. Are there any special considerations for other groups of workers e.g Pregnant and new mothers, young people, cleaners etc. that you have not considered in your main assessment? If so, please make a comment below. SECTION 4- REVIEW Circumstances for Review Default Date review 12 Rules for Electrical Safety (University Health and Safety Division 2001) Electricity has the power to kill. Do a quick check of anything electrical before you use it: include the plug, lead, connections and the equipment. The University inspects and tests all electrical equipment regularly. Portable Appliance Testing (or PAT testing) is carried out to ensure that all electrical equipment is properly maintained. On each item of equipment there should be a 'Tested for Electrical Safety' label which will show a retest date. NEVER USE ELECTRICAL EQUIPMENT WHICH DOES NOT HAVE A CURRENT 'LATEST' LABEL. If the retest date has been passed, please contact the technician responsible for PAT testing and do not use the equipment. In the UK each year there are about 1,000 accidents at work involving electric shock or burns. Around 30 of these are fatal. Even non-fatal shocks can cause severe and permanent injury. In a serious incident in Cambridge in 2000, a student received an electric shock and at another University a student was electrocuted and died due to a badly wired mains plug. So here are your rules 1. Do not touch terminals to "see" if they are live. 2. Do not modify or work on "live" equipment. There are strict laws governing live working. No equipment should have exposed live terminals. 3. Do not obstruct plugs or other means of turning off the power in an emergency. A simple sign or label 'Please turn off in an emergency' may be useful. 4. Do not interfere with any University electrical installations or attempt to repair or alter them in any way. 5. If you make or adapt equipment in any way, it must be assessed by the person in your Department who is nominated as competent to do so. Never build or adapt equipment without their approval. 6. * * * Take action on faulty or damaged equipment switch off and unplug from the supply label to identify that it must not be used report it to the technician responsible. 4. Do not use extension leads unless you have to, never overload and never use where liquids are present. 5. Multiplug adaptors are banned in most departments. They mechanically strain the socket and when overloaded can cause fires. 6. Using an RCD (residual current device) detects some, but not all, faults in the electrical systems and rapidly switches the supply off. 7. Never disconnect an earth wire. 8. Always use the correct fuse. 9. Work safely. Make sure that you have read the instructions for the equipment. Even simple tasks such as wiring a plug can lead to danger - ensure you know what you are doing before you start. Help and advice are available so: Find out who is responsible for electrical safety in your Department. Need advice? First ask: Your Departmental Safety Officer or The University Health and Safety Division. An information leaflet for students and office staff, prepared by the University Safety Office with help from Tim Goldrein and Jane Blunt, Department of Physics. This leaflet forms part of the University Safety Policy July 2001 University Health and Safety Division