Existing Arcs

advertisement

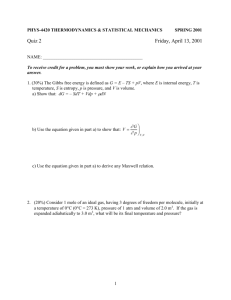

3/14/07 Rev A 1.3.4.1.1 Existing Arcs Scope For Installation and Alignment Existing Arcs include the matching sections, arcs 1 through 9, and the lines to Hall A, B, and C downstream of the lambertson to the Hall targets. This is defined by the CEBAF songsheets; East Arc 28405E0009, 0010, 0012-0016 West Arc 28405E0023-0029 and part of 28405E002 (Arc Dipoles and MQC2A40) Halls A, B, &C 28405E0031-0038 1. Please provide all labor estimates in Person-Weeks. Separate line items for each group, i.e. Vacuum or Installation. 2. Labor codes are Mechanical Engineering (ME), Mechanical Design (MD), and Mechanical Tech (MT). Purchased labor (ME, MD, MT) Others by request. 3. List all procurements in 2007 dollars. Identify if needed prior to Acclerator Installation down. 4. Include planning time for 1yr down in estimates as a separate line item. 12th Hour request from PM. Assuming we get a 6 month down in the year prior to the major 1 year down. 1. 2. Cost the effort to pull dipoles, modify, remeasure, and reinstall by Arc. Guidelines from below apply. 16 dipoles in Arc 1 and 2. 32 Dipoles in Arcs 3 through 9. Other suggestions for this time are appreciated. a. Arc 10 b. Re-plumb 20 amp quads for increased flow c. Other? Global 1. Please cost all labor, consumables, tooling, new equipment and supplies. 2. Include estimates to maintain vacuum quality in the arcs. 3. Need vacuum work for all arcs before magnets are removed and after reinstallation. 4. Penetration work and LCW manifold changes as required. 5. Quadrupoles 1. Add klixons to 59 quadrupoles to be powered with 20 amp power supplies. 2. 3. 4. 5. 6. Re-plumb LCW on ~20 of those quadrupoles for increased water flow. Install one additional QA on a simple separate pedestal in Hall B. No BPM or correctors. Will be located between MQA2C22 and MQA2C23. Relocate MQA2C22 just upstream of present location. Pull 14 QA girders and rebuild as QR girders. Assume all hardware and girders are reused. Reinstall and align. QR magnets will have klixons preinstalled. There will be no changes in drift tubes between the quad girders. No changes to stand. Pull 5 QA girders and rebuild as QAQA girders. Assume most hardware is reused and installed on new girders. Reinstall and align. Will need new drift tubes both upstream and downstream sides. Please cost drift tube modifications assume no RADCON issues. No changes to stand. Contingency Estimate - Separate line item - Cost of pulling quad girders, replacing cartridge caps and reinstalling quad girders. Cost per arc. 40 girders in Arc 1, Arcs 2 through 9 have 32 girders. Dipoles 1. Pull all ARC dipoles and relocate to Mag. Meas for rebuild and remeasurement. Install new Beam Style cartridge heads. Store old alignment cartridge caps for reuse elsewhere. Reinstall. Store Vacuum Chambers for ARC 1 and 2 and reinstall later. Arcs 3 through 9 vacuum chambers will travel with magnets. Arcs 1 and 2 16 Dipoles each Arcs 3 through 9 32 Dipoles each 2. Pull all Hall A, B, and C dipoles and relocate to Mag. Meas for rebuild and re-measurement. Install new Beam Style cartridge heads for Hall A and C only. Store old alignment cartridge caps for reuse elsewhere. Reinstall. Vacuum chambers will travel with magnets. Not touching the BSY dump dipoles. Hall A One 1m, and eight 3m dipoles Hall B Eight 1m dipoles Hall C Two 1m, and eight 3m dipoles [one of the 1m dipoles is in Hall C as part of the GEN[?] chicane. Need to review this dipole to see if or when it needs to be upgraded] 3. Does the new alignment plan require special fiducialization of the magnets with the H- steel added? Arcs 3 through 9, Hall A, and Hall C lines. Scope For Magnet Measurment Includes all work to rebuild and measure dipoles. Measurement of the Hall A and C magnets need separate line items and are to be budgeted in the Hall A and C budgets. 1. QC check of new H Steel and hardware prior to one year down 2. Split magnet 3. Add klixons (~176 dipoles) 4. Remove old urethane 5. Install new EPDM 6. Install new coil wedge system 7. Install corrector coil (~88 dipoles) 8. Rebuild and mount H steel 9. Clean and silver polish terminal flags 10. Add Belleville washers 11. Perform Magnet Measurement Procedure 12. Remove H steel 13. Install vacuum chamber 14. Remount H steel 15. Close out assembly/testing traveler and store documentation