This product is a new environmentally friendly deicing salt, snowy

advertisement

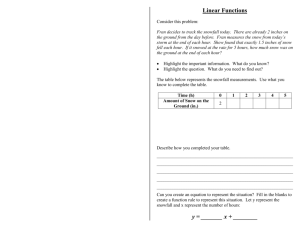

NON-Chloride Plant-Based Environment Friendly Deicing Introduction The product was produced by state of the art biological technology with plant raw materials. It contains multivariable organic acid salts and polyol except any kind of chloride、sulfate and nitrite. The product is non-toxic and harmless. All Performance index meet the national environment protection authority requirements and in accordance with the national standard GB/T23854-2009 and Beijing Olympics Standard DBII/T161-2002 completely。 The product is a new-type environment friendly snow-melted liquid, It is suitable for any snowy and icing place and it will not be frozen again within 24 hours after spraying. It has 2-5 times melting capacity than the normal snow-melted liquid, especially in the low temperature region. The product has obvious effect on snow-melt and ice-melt under the circumstance of the failure of the normal salt. If it is sprayed in right amount and right time in some dangerous sections, such as the icy bridge、curve、turning, ice can be melted quickly to ensure road friction and safety. Properties and models models Freezing point Properties scope City roads SM-1 -15℃ Light-color, SM-2 -25℃ clear SM-3 -35℃ barreled canned liquid High way or Airport Product features GBT non-chloride environment friendly deicing includes the following characteristics: 1 High Snow or Ice Melting Capacity: It is proved to be 200% more effective than sodium chloride snow melting agents in terms of melting capacity. 2 Unique Low-temperature Snow or Ice Melting Capacity: It still remained high snow melting capacity under low-temperature environment(-15 ~ -30℃), However, snow melting effect of normal snow-melted liquid reduced greatly or failed when the temperature was lower than -15℃. 3 Long Function Duration: The product is proved to reach 300% melting capacity after 1 hour compare to salt and reach to 400% melting capacity after 2 hours. Meanwhile salt melting capacity reduces greatly or lost after spraying 30 minutes. 4 Super Low Corrosion: Test results have shown that the corrosion rate of the product on the 20 # steel is 0.015mm / y; the corrosion rate on copper and aluminum is less than 0.005mm / y. Much lower the normal deicing. 5 Non chloride、sulfate and other inorganic salts. 6、 It can be decomposed by soil microorganism or absorbed by plants Technical Index Item National Standard Test Result (GB/T23851-2009) Snow melting capacity/(g/min)≥ 90% snow melting capacity 200% of sodium chloride Freezing point/℃ ≤ PH SM-1 -15 -20 SM-2 -25 -28 SM-3 -35 -38 6.5-9.0 7.8 Carbon steel corrosion rate/(mm/y)≤ 0.19 0.015 Concrete corrosion rate/(kg/m2) ≤ 0.1 0.02 Roadway friction damping 10 9 ratio % 15 14 ≤ Mercury(Hg) mg/L ≤ 0.0001 ≤0.0001 cadmium(Cd)mg/L ≤ 0.001 ≤0.001 Chromium(Cr)mg/L ≤ 0.05 ≤0.05 Lead(Pb) mg/L ≤ 0.01 ≤0.01 Arsenic(As)mg/L ≤ 0.007 ≤0.007 Seed Victimization rate % ≤ 70 12 Use 1、Select Model Select an appropriate model of deicing in accordance with outdoor temperature and road conditions . 2、Spraying Method The best time to spray is when thickness of snow is between 5 and 10 mm, and to adjust spraying amount according as the snowfall amount. Spraying amount should be increased appropriately when spraying after snowing. When road is covered with firm ice or snow and a little harder to clean with machines, a small quantity of deicing is sprayed first, spraying once or twice again after a period of car passing. 3、Amount of usage The amount of usage should be determined by the volume of snow and ice. The frequency and the amount of application can be increased depending on specific conditions when heavy snow falls. Reference on Usage Ice volume Applied Amount. g/m2 Light Snowfall About Medium Snowfall About 60-80 Heavy Snowfall About over 100 30-60 Cautions 1、Snow should not be piled on the lawn or around the trees in large quantities after spraying. 2、Skin contact is allowed when operating, but after eye contact, rinsing out with water immediately and require immediate treatment if the situation is serious. 3、Keep it at dark place and away from high temperature or fire .