Hearth, Patio & Barbecue Association Searches

advertisement

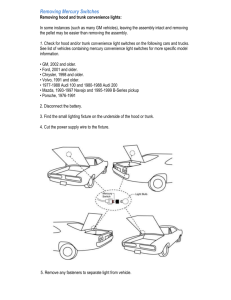

Hearth, Patio & Barbecue Association Searches April 16, 2007 HPBA Outdoor kitchen trend raging through Indy **HPBA** Indianapolis Star - Indianapolis, IN April 15, 2007 HPBExpo What's Hot in Grilling; Gadgets at Recent Expo Whet Appetites of Outdoor Chefs **HPBA** Reno Gazette-Journal – Nevada Johnathan L. Wright March 21, 2007 Hearth Trends Oregon Can Be A Leader In Pellet And Biofuel Production Statesman Journal – Salem, Oregon March 28, 2007 (Opinion) Pellet power MaineToday.com - Portland, ME TUX TURKEL April 15, 2007 Outdoor kitchen trend raging through Indy **HPBA** Indianapolis Star - Indianapolis, IN April 15, 2007 As the weather heats up and the coats come off, Indiana residents turn their thoughts toward finagling ways to spend more time outdoors. Fortunately, appliance manufacturers are making it easier than ever to do just that. There are many factors to consider when buying a grill for your outdoor kitchen. Outdoor living According to the Hearth, Patio & Barbecue Association, the concept of outdoor living is a rapidly growing phenomenon. In fact, the “leisure lifestyle” segment represents a $6.2 billion industry and is growing. “The outdoor kitchen concept is becoming really popular, more so every year,” said B.J. Clark of Clark Appliance Showcase. “People always have had freestanding barbecue grills, but now we’re seeing fully devoted built-in outdoor kitchens with refrigerators, kegerators and other appliances. Manufacturers are really making more products available.” Ancient picnic tables and folding chairs have been replaced with swanky outdoor dinettes and patio furniture that rivals anything homeowners might own indoors. In addition to a cooking appliance and a fridge, many homeowners opt for hearths, firepits or chimneys to extend the use of their outdoor Edens into the cooler months. Size doesn’t matter Homeowners who live in small homes or condos with limited space don’t need to abandon their dreams of an outdoor kitchen that cooks. Clark says size isn’t a factor. “You can create an outdoor kitchen in pretty much any space,” he said. “There are many different sizes of grills out there, from 27 inches up to 48 inches.” At his store, Clark says Viking, Wolfe, Monogram and DCS products seem to be popular choices for outdoor kitchens. Whatever appliances you put in your great outdoors, it pays to protect them from the elements. “If there’s a roof over them, that helps a lot,” Clark said. “Each appliance comes with its own cover, which is especially useful here in beautiful Indiana with all the changing weather. All outdoor appliances are UL-listed, so you can leave them outside through the winter. You just need to cover them up.” Great Grills The Hearth, Patio & Barbecue Association offers these considerations to help you pick the perfect grill: • Fuel Fuel for different grills comes from a variety of sources including liquid natural gas or propane, natural gas, charcoal, electricity and pellet fuel. • Size The square inches of cook surface determine a grill’s size. Thinking about how many people you plan to cook for on a regular basis helps you determine what’s most appropriate. • Style and aesthetics Gone are the days of basic black. Today’s grills come dressed in all sorts of finishes, colors and styles. Budget There’s a grill to meet any budget, from bargain versions that cost less than $50 to stateof-the-art monsters that run several thousand dollars. • Features Grills run the gamut from straightforward models to those with all the modern gadgets, bells and whistles such as rotisseries or smokers. It all depends on what you want and how much you plan to spend. What's Hot in Grilling; Gadgets at Recent Expo Whet Appetites of Outdoor Chefs **HPBA** Reno Gazette-Journal – Nevada Johnathan L. Wright March 21, 2007 Within five minutes of entering the Hearth, Patio & Barbecue Association's Expo 2007, which ran March 15 to 17 at the Reno-Sparks Convention Center, you realize you are surrounded by people dedicated to the proposition that no accessory is too specialized, no grill too powerful and no fuel too unlikely if it adds to the pleasure or performance of the ancient act of uniting food with flame. "There are so many options for so many pocketbooks," said Leslie Wheeler, spokeswoman for the Association, "How much do you want to spend?" Almost 500 vendors exhibited at the Expo, and about 12,000 people attended, according to Association officials. But amid fireplace inserts, ponds and patios sets, it was the barbecuing and grilling products (especially the grilling products) that stood out for sheer variety of inventiveness, price, function and, at times, glorious excess. Here are some highlights: * E-Z Que Caterer's Classic Rotisseries The stainless steel rotisserie cages — they could by no means be called baskets — stretch 5 feet in length and 11 or 14 inches in diameter. The smaller cage holds pigs up to 95 pounds, the larger cage pigs up to 165 pounds. Meat clamps hold the animal cavity open for quicker cooking than with spit grilling. The clamps can also hold several turkeys or other animals —"just line them up," said E-Z Que president Shane Kistler. When meat is done, rotate the cradle, unlock the clamps and ease it onto a tray. The rotisseries were made for caterers, but they've also been popular with home grillers, Kistler said. Details: From about $1,640; www.ezque.inc * Steve Raichlen Olive Wood Chunks or Branches; Rectangular Grill Basket Raichlen, one of America's foremost barbecue and grilling experts, brought much of his 2007 product line to the Expo. His olive wood chunks and branches, a nod to ancient Greek grilling, can be used with charcoal fires, gas grills or in smoker boxes. The wood imparts "a wonderful, fragrant, tart flavor," Raichlen said. The wire mesh, non-stick grill basket has four separate compartments, which allows grillers to keep flavors distinct and to remove food from the heat at different times. The mesh prevents food from falling between the bars of the grill grate. Details: Chunks or branches about $12.99, grill basket about $24.99; www.bestofbarbecue.com * Fire Magic Elite Magnum portable grill This gas behemoth would be more accurately described as a cooking center, not simply a grill. "Heat-zone separators" allow steaks to be seared on the same grill that fish or vegetables are cooking. An infrared back burner promotes even rotisserie cooking and eliminates flare-ups. There's also a built-in digital meat thermometer, a wood chip smoker, a wok ring and a charcoal basket "so you can get a nice char, even in a gas unit," said Elaine Remy, a Fire Magic representative. Details: About $12,000; www.rhpeterson.com/firemagic. * Bradley Digital Smoker and portable Propane Smoker Both units burn wood flavor pucks (Bradley calls them bisquettes) that are automatically fed every 20 minutes "so you don't have to worry about forgetting to change them," said Bradley's Jessica Dow. The short burn time means the pucks should produce only "good, clean" smoke. The digital version, which comes with four or six racks, enables custom combinations of smoking and cooking times; the smoker automatically shuts off when the temperature rises or falls too much. The portable smoker, which runs on propane and batteries, is "perfect for hunters and fishers and tailgaters," Dow said. "You can smoke your food right there." Details: Digital from about $479, portable from about $199; www.bradleysmoker.com * Grill Dog Rotisserie Hot Dog Cooker The raised, stainless steel rotisserie "platform" frees up grill space and eliminates the need to turn hot dogs. The cooker accommodates about a dozen dogs or sausages, depending on size. One model adapts to the existing rotisserie motor on a grill; the other models have electric and battery-operated motors. Horizontal and vertical adjustors allow the cooker to fit on grills of different sizes. Details: From about $39.99; www.grill-dog.com. * Cattleman's Brand personalized branding iron Who says meat can't be monogrammed? The branding iron head holds three letters or symbols or a single saying (like "Happy Birthday" or "Best Mom). The interchangeable, removable inserts are dishwasher-safe. The head pivots so that the inserts can be placed directly against the grill. That way, said Cattleman's president Adi Alphandary, "you don't have to hold it over the fire to heat it up." Details: From about $70 with insert; www.cattlemansbrand.com. * Eastman Outdoors Outdoor Gourmet Carbon Steel and Stainless Steel Wok Kits These kits aren't strictly barbecue or grilling items, but they're too cool not to mention. The carbon steel version comes with an 18- or 22-inch wok, the stainless still version with a 22-inch wok only. Both kits include a propane burner with adjustable legs, a propane regulator and hose, a thermometer and a large wok ladle and spatula. The woks can be used for classic stir-frys, of course, but they're also handy for making chili at tailgates or fajitas on camping trips. "We're trying to let people know that it's not just for Asian cooking," said Monica Whitburn of Eastman Outdoors. For outdoor use only. Details: Carbon steel from about $119, stainless steel from about $179; www.eastmanoutdoors.com. Oregon Can Be A Leader In Pellet And Biofuel Production Statesman Journal – Salem, Oregon March 28, 2007 (Opinion) Your viewpoint that Oregon should embrace biofuels is right on. But your editorial failed to recognize Oregon already has a "commercially practical" method for turning waste forest products into fuel. Meet the other biofuel -- pellets. Oregon produces about 200,000 tons of pellets a year, and the bulk of it is exported. What's more, thousands of Oregonians heat their homes with pellet stoves or pellet furnaces and have since they were pioneered in Oregon more than 20 years ago. The truth is you probably don't even know your neighbor has a pellet stove because they produce no visible smoke. These appliances are an environmentally sustainable home heating option and are recognized by the Oregon Department of Environmental Quality and Environmental Protection Agency as clean-burning and efficient home-heating appliances. Pellet stoves also are engineered to burn straw pellets, corn and even hazelnut shells. Gov. Kulongoski's energy package is a major step in helping Oregon to be a leader in biodiesel and pellet fuel production. With these incentives Oregon can increase production to prevent shortages caused by their rapid increase in popularity as a home heating option in the Northeast and Midwest. So give credit to Oregon's original biofuel - pellets. -- Harvey Gail, Salem Pellet power MaineToday.com - Portland, ME TUX TURKEL April 15, 2007 A North American wood pellet race has begun, and Maine is trying to get out of the starting gate. Developers are planning or building manufacturing plants that together could produce 1 million tons or more of wood pellets a year. Maine mills in Corinth and Athens are part of the rush. The pellets are made by compressing sawdust and other dried wood waste into a dense, high-combustion fuel source. Mainers may be familiar with stoves that burn these wood pellets for home heating. But a larger market is evolving in Europe, where regulations designed to combat global climate change have created incentives for power companies to boost their use of renewable resources. Europe already consumes nearly 8 million tons of wood pellets a year, to run factories and power plants, and to heat entire neighborhoods. The expected growth is leading entrepreneurs in timber-growing regions from Florida to Maine and Canada to build or expand pellet mills. Heavily forested and located close to Europe, Maine could become a player in the overseas wood pellet market. State officials see pellets as a way to generate new jobs and create export opportunities for a forest-products industry that's been losing its traditional manufacturing base. "It's just a perfect marriage," said John Richardson, the state's new economic development commissioner. As papermaking shrinks in Maine, officials are encouraging investment in innovative, niche enterprises, such as wood pellets. Three weeks ago, Richardson and Gov. John Baldacci attended the grand opening of the Corinth mill, which is located in an area that qualifies for state tax subsidies. But like other energy and trade ventures, wood pellets are a risky business. A warm winter in Europe this year hurt sales for existing producers. And it's still too early to say whether Maine plants can make and transport the pellets economically, and who will develop the port-side storage and loading systems needed for export. The larger Maine plant is Corinth Wood Pellets LLC. The venture represents $4 million in private investment. A dozen or so workers were ironing out some equipment kinks last week, to ramp up production. Corinth Wood Pellets has ambitious plans to become one of the nation's largest pellet makers, producing over 300,000 tons a year. Half the production will be sold domestically, the other half in Europe, according to Ken Eldredge, the company's president and co-owner. Eldredge declined to discuss efforts to secure deals in Europe, but said he's working with Sprague Energy, which has cargo piers at Portland and Searsport. Corinth Wood Pellets will benefit by being located in a Pine Tree Development Zone. That makes it eligible for sales tax exemptions and refunds that lower the cost of business, in exchange for creating jobs in a rural area. Another mill, Maine Wood Pellets Co., has been proposed at the site of former biomass power generator in Athens. It's a partnership between Linkletter & Sons, a local logging firm, and Maine Biomass Fuels of Belmont. The plant would process some of the waste wood generated by Linkletter & Sons. The partners want the Athens plant to be operating this summer, according to recent media reports, but say they need state and local grants to get going. It's not clear how many tons the plant would produce or the status of the project. One of the partners, George Rybarczyk, did not return repeated phone calls last week; the Linkletter family was vacationing and not available. One way to consider the challenges facing Maine's nascent pellet industry is to look at some of its competition. Energex Pellet Fuel Inc. currently bills itself as North America's largest pellet fuel maker, producing 200,000 tons a year from plants in Quebec and Pennsylvania. That output will easily be exceeded by a $100 million plant in Jackson County, Fla. Green Circle Bio Energy, owned by a Swedish company, is building what it calls the largest wood pellet plant in the world, capable of producing 560,000 tons a year. Much of it will be sent to Europe. Another venture that's also calling itself the world's largest pellet plant, Dixie Pellets LLC, is under way near Selma, Ala. European-bound pellets will be barged down the Alabama River and shipped out of Mobile. Near Baxley, Ga., Fram Renewable Fuels is building a 145,000-ton- a-year pellet plant, called Appling County Pellets LLC. It's all headed to Europe, shipping through Savannah and Brunswick, Ga. "There aren't too many of us exporting wood pellets successfully, but a lot of us are trying," said John Colquitt, Fram's president. Colquitt made European contacts while operating a pellet mill outside Halifax, N.S. The overseas market is poised to grow because of a directive in the European Union linked to the Kyoto Protocol, which requires participating countries to cut carbon dioxide and other greenhouse gas emissions. One strategy is to mix in wood pellets at coal-burning power plants. But the market can be fickle. A warm winter in Europe cut demand for all heating fuels, which hurt sales. " There has been a real shaking out this spring," he said. "Some companies couldn't weather the storm." Europeans are paying roughly $150 a ton wholesale for pellets landed there, Colquitt said. That's attractive, but exporters need to factor in the cost of wood supply, ocean freight, exchange rates and storage. Those issues are being studied carefully by Armand Demers, the forest products director at Sprague Energy. He's been working with Ken Eldredge at Corinth Wood Pellets. Corinth isn't near a rail line, so pellets would have to be trucked to Portland or Searsport. Pellets must stay bone dry, so they need special storage. And they degrade with heavy handling, so a conveyor system must be installed. Moving and storing wood pellets will require a multimillion-dollar investment, Demers said. "The challenge is going to be how to get them from the mill to Europe and not make it uncompetitive," he said. Charles Niebling hasn't been able to make the numbers add up. Niebling is the procurement and sales manager at New England Wood Pellets LLC in Jaffrey, N.H., which currently calls itself the nation's largest pellet maker. The nine-year old mill turns out 75,000 tons a year. The company also bags 80,000 tons a year of pellets shipped by rail from British Columbia, and is building a 100,000-ton plant in Schuyler, N.Y. Niebling has been selling bagged pellets for home heating in Europe, but saw sales drop this winter. And he hasn't been able to figure out an economic way to send bulk shipments to Europe, noting that American pellet makers also are competing with established companies in Scandinavia, Germany and Russia. Niebling laments that Americans don't burn more wood pellets. The only sizable commercial burner he's aware of in New England is a new manufacturing and office building in Hinesburg, Vt., owned by wind energy equipment maker NRG Systems. That pellet boiler burns roughly 30 tons a year, he said. Increased demand for pellets in American homes and businesses might boost supply and cut prices, said Matt Boucher, store manager at Yerxa's Lawn & Garden in South Portland. The company has a subsidiary that sells the Harman Stove Co. pellet stoves. One popular model, which is thermostatically controlled and can keep an average house warm for 24 hours with 40 pounds of pellets, sells from $2,695. Boucher was charging $250 a ton for pellets this year, up from $190 the previous winter. More domestic supply could drive prices back into the $200-a-ton range, he said, and that would make pellets more competitive with oil heat. By Niebling's estimate, if only 5 percent of the oil-fired boilers in New England were replaced by pellet burners, a 300,000-ton-a-year plant could sell all its output at home. But in the absence of aggressive policies to displace oil in the United States, it's not surprising that wood pellet developers see opportunity in Europe. "We're becoming a Third World nation, exporting our renewable resources," Niebling said. WOOD PELLETS typically are made by screening, compacting and drying sawdust and other wood waste. More than 60 mills across North America produce more than 680,000 tons a year, according to the Pellet Fuels Institute. MUCH OF IT is burned in stoves and fireplace inserts from two dozen manufacturers. Roughly 800,000 U.S. homes burn pellets, the trade group estimates. PELLETS ARE manufactured to a uniform size, roughly 1/4-inch in diameter, so they can be automatically fed into stoves and boilers. They are dried to a very low moisture content and leave behind little ash when burned. Combustion with quality hardwood pellets is in the 98 percent range, so the stoves can be directly vented without a chimney. A 40-POUND BAG of pellets can heat an average home for 24 hours. Some retailers sell wood pellets by the ton and deliver them on a 50-bag pallet. Stoves and pellets are available at many stove shops, hardware and home improvement stores. TO LEARN MORE about wood pellets, including a list of stove makers and pellet mills, visit www.pelletheat.org.