Risk assessment form - Faculty of Medicine

advertisement

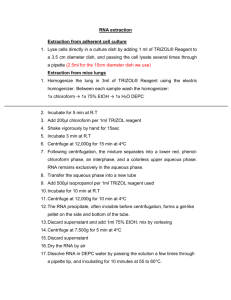

OHS017 Risk assessment completed by:P Peake OHS Risk Assessment and Control Form School/Unit: nephrology Faculty/Division: Medicine Document number Initial Issue date 15.5.2010 Current version 1.0 Current Version Issue date 15.5.2010 Next review date 15.5.2010 RRNAEXT.RA For additional information refer to the OHS Risk Assessment and Control Procedure, the OHS Risk Rating Procedure and the Hierarchy of Risk Controls. Risk Assessment title: Extraction and purification of RNA from cells or tissues using TRI REAGENT (Sigma). Step 1: Identify the activity Describe the activity: 1A. Tissue: Homogenize tissue samples in TRI Reagent (1ml per 50–100 mg of tissue) in a Polytron or other appropriate homogenizer. 1B. Monolayer cells: Lyse cells directly on the culture dish. Use 1 ml of the TRI Reagent per 10 cm2 of glass culture plate surface area. After addition of the reagent, the cell lysate should be passed several times through a pipette to form a homogenous lysate. 1C. Suspension cells: Isolate cells by centrifugation and then lyse in TRI Reagent by repeated pipetting. One ml of the reagent is sufficient to lyse 5– 2. Phase Separation: To ensure complete dissociation of nucleoprotein complexes, allow samples to stand for 5 minutes at room temperature. Add 0.1 ml of1-bromo-3-chloropropane or 0.2 ml of chloroform per ml of TRI Reagent used. Cover the sample tightly, shake vigorously for 15 seconds, and allow to stand for 2–15 minutes at room temperature. Centrifuge the resulting mixture at 12,000g for 15 minutes at 2–8 °C. Centrifugation separates the mixture into 3 phases: a red organic phase (containing protein), an interphase (containing DNA), and a colorless upper aqueous phase (containing RNA). RNA Isolation 1. Transfer the aqueous phase to a fresh tube and add 0.5 ml of isopropanol (see item 4 for safety guidelines) per ml of TRI Reagent used in Sample __________________________________________________________________________________________________________________________________________________________________________ _________ Page 1 of 9 Risk Assessment and Control Form Date Effective: 15.5.2010 Uncontrolled document when printed Current Version: 15.5.2010 Preparation, step 1 and mix. Allow the sample to stand for 5–10 minutes at room temperature. Centrifuge at 12,000g for10 minutes at 2–8 °C. The RNA precipitate will form a pellet on the side and bottom of the tube. 2. Remove the supernatant and wash the RNA pellet by adding a minimum of 1 ml of 75% ethanol (see item 5 for safety guidelines) per1 ml of TRI Reagent used in Sample Preparation, step 1. Vortex the sample and then centrifuge at 7,500 g for 5 minutes at 2–8 °C. 3. Briefly dry the RNA pellet for 5–10 minutes by air drying or under a vacuum. Do not let the RNA pellet dry completely, as this will greatly decrease its solubility. Add an appropriate volume of RNAase-free water to the RNA pellet. To facilitate dissolution, mix by repeated pipetting with a micropipette at 55–60 °C for 10–15 minutes. Describe the location: Fume Hood And Laboratory Rm 501 in Wallace Wurth Step 2: Identify who may be at risk by the activity A number of people may be at risk from any activity. This may affect the risk controls needed. These people may include fellow workers, visitors, contractors and the public. The location of the activity may affect the number of people at risk. Operator and people nearby may be at risk from splash, spill or fumes from chemical reagents. Steps 3 to 7: Identify the hazards, risks, and rate the risks 1. An activity may be divided into tasks. For each task identify the hazards and associated risks. 2. List existing risk controls and determine a risk rating using the UNSW Risk Rating Procedure. 3. Additional risk controls may be required to achieve an acceptable level of risk. Re-rate the risk if additional risk controls used. __________________________________________________________________________________________________________________________________________________________________________ _________ Page 2 of 9 Risk Assessment and Control Form Date Effective: 15.5.2010 Uncontrolled document when printed Current Version: 15.5.2010 Tasks Hazards Associated risks (Step 3) (Step 4) Risk rating with existing controls * Additional risk controls required (Step 5) (Step 6) Existing risk controls C Homogenize tissue samples in TRI Reagent using a Polytron. Exposure to TRI Reagent Polytron TRI REAGENT Toxic by inhalation, in contact with skin and if swallowed. Harmful: contains phenol danger of serious damage to health by prolonged exposure through inhalation in contact with skin, and if swallowed. Contact with acids liberates very toxic gas. Causes burns. Possible risk of irreversible effects. Liquid handling and homogenization in fume hood. Standard PPE lab coat, goggles and double gloves. 4 L E R (Apply the hierarchy of risk controls) Risk Rating with additional controls * (Step 7) C L R M Homogenization in tall 15ml tubes to reduce danger of splash. Training Homogenization in tall 15ml tubes to avoid blade contact. Electrical equipment testing. Polytron or other homogenizer Electrical appliance – electrocution hazard Spinning blade physical injury hazard __________________________________________________________________________________________________________________________________________________________________________ _________ Page 3 of 9 Risk Assessment and Control Form Date Effective: 15.5.2010 Uncontrolled document when printed Current Version: 15.5.2010 Lyse cells directly on the culture dish. After addition of the reagent, the cell lysate should be passed several times through a pipette to form a homogenous lysate. Isolate cells by centrifugation and then lyse in TRI Reagent by repeated pipetting. Exposure to TRI Reagent Exposure to TRI Reagent TRI REAGENT Toxic by inhalation, in contact with skin and if swallowed. Harmful: contains phenol danger of serious damage to health by prolonged exposure through inhalation in contact with skin, and if swallowed. Contact with acids liberates very toxic gas. Causes burns. Possible risk of irreversible effects. TRI REAGENT Toxic by inhalation, in contact with skin and if swallowed. Harmful: contains phenol danger of serious damage to health by prolonged exposure through inhalation in contact with skin, and if swallowed. Contact with acids liberates very toxic gas. Causes burns. Possible risk of irreversible effects. Liquid handling and homogenization in fume hood. 4 E M 4 E M Standard PPE lab coat, goggles and double gloves. Training Liquid handling and homogenization in fume hood. Standard PPE lab coat, goggles and double gloves. Training __________________________________________________________________________________________________________________________________________________________________________ _________ Page 4 of 9 Risk Assessment and Control Form Date Effective: 15.5.2010 Uncontrolled document when printed Current Version: 15.5.2010 2. Phase Separation: Add chloroform, cover the sample tightly, shake vigorously. Centrifuge the resulting mixture at 12,000g for 15 minutes at 2–8 °C. Exposure to TRI Reagent Exposure to chloroform Centrifugation TRI REAGENT Toxic by inhalation, in contact with skin and if swallowed. Harmful: contains phenol danger of serious damage to health by prolonged exposure through inhalation in contact with skin, and if swallowed. Contact with acids liberates very toxic gas. Causes burns. Possible risk of irreversible effects. Chloroform Toxic by inhalation, in contact with skin and if swallowed. Carcinogenic and mutagenic Liquid handling in fume hood. 4 E M Standard PPE lab coat, goggles and double gloves. Homogenization in tall 15ml tubes to reduce danger of splash. Electrical equipment testing. Training Note: Chloroform rapidly degrades Latex and Nitrile gloves . In the event of a spill replace both layers of gloves immediately. __________________________________________________________________________________________________________________________________________________________________________ _________ Page 5 of 9 Risk Assessment and Control Form Date Effective: 15.5.2010 Uncontrolled document when printed Current Version: 15.5.2010 Transfer the aqueous phase to a fresh tube and add isopropanol. Centrifuge at 12,000g for10 minutes at 2–8 °C. Exposure to TRI Reagent Exposure to chloroform Exposure to isopropanol Centrifugation TRI REAGENT Toxic by inhalation, in contact with skin and if swallowed. Harmful: contains phenol danger of serious damage to health by prolonged exposure through inhalation in contact with skin, and if swallowed. Contact with acids liberates very toxic gas. Causes burns. Possible risk of irreversible effects. Chloroform Toxic by inhalation, in contact with skin and if swallowed.Carcinogenic and mutagenic Wash the RNA pellet by adding 75% ethanol. Vortex the sample and then centrifuge at 7,500 g for 5 minutes at 2–8 °C. Remove supernatant. Exposure to ethanol Isopropanol (Propan-2ol or 2-propanol). Flammable liquid and vapor. May cause central nervous system depression. Causes severe eye irritation. Causes respiratory tract irritation. Causes moderate skin irritation. Ethanol Flammable liquid and vapor. May cause central nervous system depression. Causes severe eye irritation. Causes respiratory tract irritation. Causes moderate skin irritation. Liquid handling in fume hood. 4 E M 2 D L Standard PPE lab coat, goggles and double gloves. Homogenization in tall 15ml tubes to reduce danger of splash. Electrical equipment testing. Training Note: Chloroform rapidly degrades Latex and Nitrile gloves . In the event of a spill replace both layers of gloves immediately. Avoid flames. Only small volumes of Isopropanol stored on bench. Liquid handling in fume hood. Standard PPE lab coat, goggles and double gloves. Training Avoid flames. Only small volumes of Isopropanol stored on bench. __________________________________________________________________________________________________________________________________________________________________________ _________ Page 6 of 9 Risk Assessment and Control Form Date Effective: 15.5.2010 Uncontrolled document when printed Current Version: 15.5.2010 Briefly dry the RNA pellet for 5–10 minutes by air drying. Add an appropriate volume of RNAase-free water to the RNA pellet. To facilitate dissolution, mix by repeated pipetting with a micropipette at 55–60 °C for 10–15 minutes. Use of a 55–60 °C Heating block Electrical equipment shock Burn * C = consequence Electrical equipment testing. 2 D L Training L = likelihood R = risk rating from the UNSW Risk Rating Procedure Step 8 Documentation and supervisor approval Completed by: (name) P PEAKE (signature) Authorised by: (signature) Date: Step 9: Implement the additional risk controls identified Indicate briefly what additional risk controls from Step 6 above were implemented, when and by whom. Risk control: Date: Implemented by: Risk control: Date: Implemented by: Step 10: Monitor and review the risk controls It is important to monitor risk controls and review risk assessments regularly. Review is required when there is a change in the process, relevant legal changes, and where a cause for concern has arisen. Reviews could be scheduled on an annual basis. If the risk assessment has substantially changed a new risk assessment is warranted. Review date: Reviewed by: Authorised by: Documentation It is a requirement that legal and advisory documentation that supports this risk assessment be listed. Such documentation includes Acts, Regulations, Australian Standards and Codes of Practice, where applicable. __________________________________________________________________________________________________________________________________________________________________________ _________ Page 7 of 9 Risk Assessment and Control Form Date Effective: 15.5.2010 Uncontrolled document when printed Current Version: 15.5.2010 NSW OHS Act 2000 NSW OHS Regulation 2001 Code of Practice for the Labelling of Workplace Substances AS/NZS 2243.2:2006. Safety in laboratories. Part 2: Chemical aspects AS/NZS 2243.3-2002. Safety in laboratories. Part 3: Microbiological aspects and containment facilities. AS/NZS 2243.4: 1998 Safety in Laboratories Part 4; Ionising Radiations AS/NZS 2243.6-1990. Safety in laboratories. Part 6: Mechanical Aspects. AS/NZS 2243.7-1991. Safety in laboratories. Part 7: Electrical Aspects. AS/NZS 2161.1:2000 Occupational Protective Gloves – Selection, Use and Maintenance AS/NZS 1336:1997 Recommended Practices for Occupational Eye Protection UNSW Hazardous Waste Disposal Procedure __________________________________________________________________________________________________________________________________________________________________________ _________ Page 8 of 9 Risk Assessment and Control Form Date Effective: 15.5.2010 Uncontrolled document when printed Current Version: 15.5.2010 UNSW Concise OHS Risk Rating Table OHS697 What you need to do 1. Consider what can go wrong that can hurt someone 2. Determine what the most likely outcome would be - Consequences 3. Determine how likely those consequences are - Likelihood 4. Calculate the risk rating 5. Required action CONSEQUENCES: How severely could someone be hurt death or permanent disability to one or more persons hospital admission required medical treatment required first aid required injuries not requiring first aid Severe Major Moderate Minor Insignificant How likely are those consequences? expected to occur in most circumstances will probably occur in most circumstances could occur at some time is not likely to occur in normal circumstances may occur only in exceptional circumstances LIKELIHOOD: Almost certain Likely Possible Unlikely Rare CONSEQUENCES Insignifica nt 1 Minor 2 Moderate 3 Major 4 Severe 5 M H H VH VH M M H H VH Possible C L M H H VH Unlikely D L L M M H Rare E L L M M M LIKELIHOOD Almost certain A Likely B Risk level Very high High Medium Low Required action Act immediately: The proposed task or process activity must not proceed. Steps must be taken to lower the risk level to as low as reasonably practicable using the hierarchy of risk controls. Act today: The proposed activity can only proceed, provided that: (i) the risk level has been reduced to as low as reasonably practicable using the hierarchy of risk controls; (ii) the risk controls must include those identified in legislation, Australian Standards, Codes of Practice etc. (iii) the risk assessment has been reviewed and approved by the Supervisor and (iv) a Safe Working Procedure or Safe Work Method has been prepared. (v) The supervisor must review and document the effectiveness of the implemented risk controls. Act this week: The proposed task or process can proceed, provided that: (i) the risk level has been reduced to as low as reasonably practicable using the hierarchy of risk controls; (ii) the risk assessment has been reviewed and approved by the Supervisor and (iii) a Safe Working Procedure or Safe Work Method has been prepared. Act this month: Managed by local documented routine procedures which must include application of the hierarchy of controls. _______________________________________________________________________________________________________ ________ Page 9 of 9 UNSW Concise OHS Risk Rating Table Effective date: 01/01/2007 Uncontrolled document when printed Current Version: 2.6,16/07/2008