L11-13416_SI

advertisement

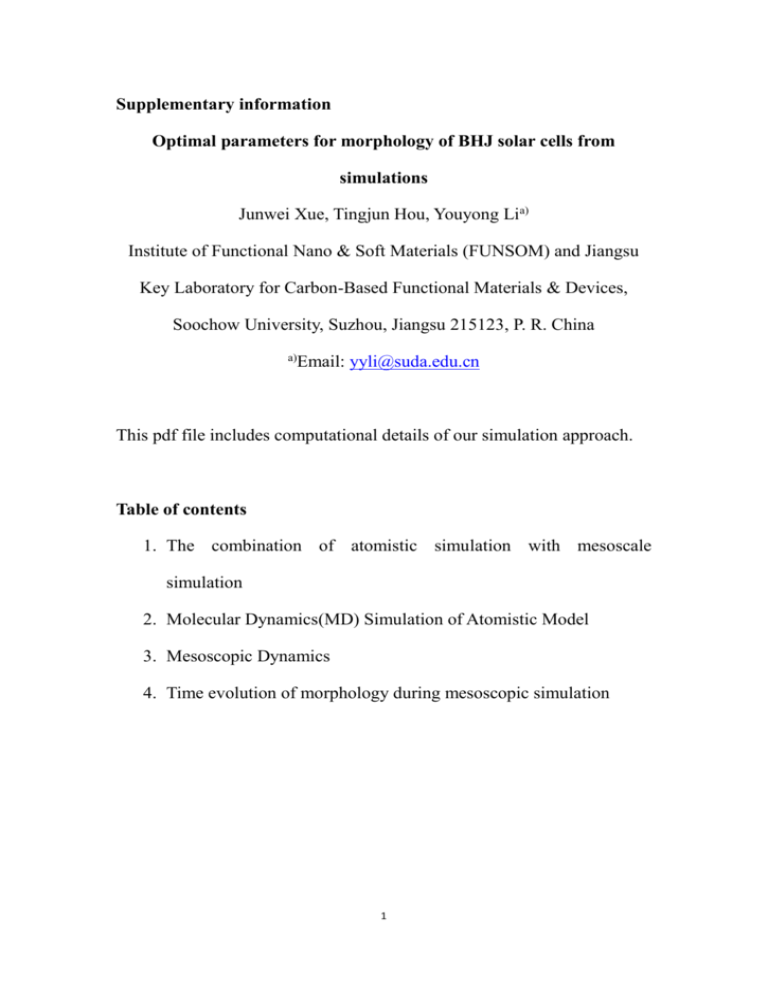

Supplementary information Optimal parameters for morphology of BHJ solar cells from simulations Junwei Xue, Tingjun Hou, Youyong Lia) Institute of Functional Nano & Soft Materials (FUNSOM) and Jiangsu Key Laboratory for Carbon-Based Functional Materials & Devices, Soochow University, Suzhou, Jiangsu 215123, P. R. China a) Email: yyli@suda.edu.cn This pdf file includes computational details of our simulation approach. Table of contents 1. The combination of atomistic simulation with mesoscale simulation 2. Molecular Dynamics(MD) Simulation of Atomistic Model 3. Mesoscopic Dynamics 4. Time evolution of morphology during mesoscopic simulation 1 1. The combination of atomistic simulation with mesoscale simulation Molecular dynamics(MD) simulation of atomistic models in combination with quantum chemical calculations have been employed to study the microstructure, electronic structure and charge mobility of organic semiconductors in crystalline or amorphous states.1 However, atomistic simulation of phase domains on the length scale of a few of nanometers would be too expensive to perform. Coarse-grained models in which collection of atoms from an atomistic model are mapped onto a smaller number of “superatoms”, decrease the number of force sites and thus reduce computational requirements and increase the time and distance accessible in molecular simulation.2 Huang et al3 developed coarse-grained simulation model to study the structure and dynamic evolution of poly(3-hexylthiophene) (P3HT)/fullerene-C60 bulk heterojunction(BHJ) at the molecular level for systems approaching the device scale. On the mesoscopic scale, some other methods such as dissipative particle dynamics (DPD)4 and dynamic density functional theory (DDFT)5 have been applied to simulate the self-assembling behavior of mixtures, typically for dilute or semi-dilute polymer solutions.6 These mesoscopic models form a bridge between fast molecular kinetics and the slow thermodynamic relaxation of macroscale properties. Here we combine atomistic simulation with mesoscale 2 simulation (dynamic density functional theory) to predict the morphology of BHJ solar cells. 2. Molecular Dynamics Simulation of Atomistic Model The cubic boxes of pure P3HT, [6,6] -phenyl C61-butyric acid methylester (PCBM) and their blends are constructed with the Amorphous package of Materials Studio 5.0, followed by geometry optimization with the energy convergence threshold of 110-4 kcal∙mol-1. An amorphous cell of P3HT/PCBM blend at 50% PCBM by weight is shown in Figure S1. Preliminary runs of 1.5 nanoseconds(ns) in Isothermal-Isobaric (NPT) ensemble at a constant pressure of 1 atm are performed to bring the system to equilibrium stage. Sequentially, production runs of 200 picoseconds(ps) in the NPT ensemble are followed, during which trajectories are stored per 2 ps for later analysis. The interactions are modeled with the COMPASS7 force field. The initial velocities are generated by Maxwell distribution and the temperature and pressure are normalized by Nose and Berendsen method respectively. The Ewald summation is adopted for the Coulomb interactions with an accuracy of 0.01 kcal·mol-1, and the atom-based summation is applied for the van der Waals interactions with a cut-off distance of 9.5 Å, a spline width of 1 Å, and a buffer width of 0.5 Å. For each configuration, MD simulation is conducted by Forcite package of 3 Materials Studio 5.0. The temperature of all MD simulations is set to 298K, with time step 1 femtosecond. The size of oligomers used in model calculations is important to calculate thermodynamic parameters. We use 3HT 12-mers to represent the real long-chain P3HT as reported previously3. Figure S1. Simulation cell of weight ratio = 1:1 P3HT/PCBM blend constructed by Amorphous Builder of Materials Studio 5.0. The carbon and sulfur atoms are colored in brown and blue respectively. The hydrogen atoms are not displayed for clearness. Solubility parameter (δ) is a characteristic of a polymer used in predicting the solubility of that polymer in a given solvent. The solubility parameter is related to each component’s volumetric cohesive energy density Ecoh/V of the system via the definition: 4 (1) For a substance of low molecular weight, the value of the solubility parameter is often estimated from the enthalpy of vaporization; for a polymer, it is usually taken to be the value of the solubility parameter of the solvent producing the solution with maximum intrinsic viscosity or maximum swelling of a network of the polymer. Molecular dynamics simulations of the two pure systems are carried out to estimate the solubility parameters. The solubility parameters for P3HT and PCBM are estimated to be 16.788 and 20.527 (J∙cm-3)0.5 based on our simulation results. Similarly, the Hansen solubility parameters for C60 have been found to be 20.09 MPa1/2 (δD, δP, δH = 19.7, 2.9, 2.7, respectively)8. MD simulation with COMPASS force field provides us reasonable solubility parameters. The Flory-Huggins χ parameter could be estimated from: (2) where Vmono is a monomer unit volume. Here we use the average molar volume of 3HT and PC60BM as the volume, and Flory-Huggins interaction parameters between P3HT and PCBM is calculated to be 2.155. 3. Mesoscopic Dynamics 5 The phase behavior of the P3HT/PCBM blends at the mesoscopic level is simulated by using dynamic density functional theory (DDFT) with MesoDyn of Materials Studio 5.0. MesoDyn is based on a dynamic variant of mean-field density functional theory,5 in which there is a one to one mapping between the distribution functions of the system, the densities and an external potential field. In dynamic density functional theory, the optimal distribution function is such that the free energy F[] is minimized. Hence is independent of the history of the system, and is fully characterized by the constraints that it represents the density distribution and minimizes the free energy functional. This constraint on the density fields is realized by means of an external potential UI. The molecule is defined as a string (Gaussian chain) of beads which represent groups of atoms such as one or a few monomers of a polymer chain. Chemically specific information can be used to define the properties of the bead type such as the self-diffusion coefficients of the bead components, the Flory-Huggins interaction parameters, the bead sizes and the molecular architecture (chain length, branching, etc). The dynamic process of the system is the Langevin equation of motion, which describes the evolution of the bead density field. In Mesodyn, the method used to model the time evolution of a mesoscopic system is the time-dependent Ginzburg-Landau model. The polymer chains are mapped to Gaussian chains by demanding 6 the mean square end-to-end distance and the length of a fully extended chain. Thus, the number (Nb) and the length (αb) of the Gaussian chain segments are estimated by the following formulas: (3) (4) where Nmon is the polymerization degree of the polymer molecule, and is the characteristic ratio. Empirical methods implemented in Synthia, Materials Studio 5.0, provide a value of 3.49 for P3HT. In this study, Mn(P3HT) is assumed to be 50000 g∙mol-1, the polymerization degree is equal to 300. A P3HT chain is represented by A85. B bead represents PCBM molecule. αb is equal to 1.4 nm. The dimensions of the simulation lattice are 323232, and the cell size (h) has an optimal value of α/1.1543. The diffusion coefficients of all beads are assumed to be equal to 1.010-7cm2∙s-1. The time step is set to 20 ns for numerical stability. The noise scaling parameter is 75 and the compressibility is 10. 4. Time evolution of morphology during mesoscopic simulation After setting up the initial configurations, the systems are subjected to 10000 time steps, i.e. 200microseconds(μs), run to approach the equilibrium. The isosurface of the density fields for P3HT at θP3HT= 0.56 with time evolution at T = 298K for 1:1 P3HT/PCBM blend is shown in 7 Figure S2. In order to show the microstructure more clearly, only the P3HT domains are colored with red and PCBM is not shown. The green curved surface stands for the interface between P3HT and PCBM. Unlike molecular dynamics simulation, which provides details of small-scale fluctuating motion of atoms, mesoscale modeling focuses on physical processes in microsecond and is able to simulate the system with a large size (e.g. 39.8nm × 39.8 nm × 39.8 nm as shown in Figure S2). Figure S2. The isosurface of the density fields for P3HT at θP3HT=0.56 at different time stages from simulation. (T = 298K for 1:1 vol% P3HT/PCBM blend) 8 (a) (b) Figure S3 Time evolution of (a) free energy density and (b) order parameters of P3HT and PCBM for 1:1 vol% P3HT/PCBM blend at T = 298K Over the course of a simulation, the free energy asymptotically approaches a stable value. Phase separation is characterized by the order parameters for each of the beads. The order parameter, Pi, is defined as the volume average of the difference between the local density squared and the overall density squared, ( 5 ) where ηI is a dimensionless density volume fraction for species I, defined as ηI(r) = ν ρ(r). Large order parameter indicates strong phase segregation. Small value indicates a relatively homogenous system. The time evolution of the free energy and order parameters for the 9 1:1 vol% P3HT/PCBM system at T = 298K are shown in Figure S3. The dynamic process can be divided into two stages. During the first 2000 time steps, free energy of the system decreases rapidly and the order parameters surge, which shows that the microphase separation is performed mainly during this stage. After the first 2000 time steps, the free energy fluctuates and approaches to the equilibrium slowly. The density profiles in Figure S2 show that the domains grow coarsely by phase transfer as well as by coalescence. Reference 1 V. Coropceanu, J. Cornil, D. A. da Silva, Y. Olivier, R. Silbey, and J. L. Bredas, Chem. Rev. 107 (4), 926 (2007); David L. Cheung, David P. McMahon, and Alessandro Troisi, The Journal of Physical Chemistry B 113 (28),4679 (2009); David L. Cheung, Alessandro Troisi, Phys. Chem. Chem. Phys. 10,5941 (2008); Alessandro Troisi, David L. Cheung, and Denis Andrienko, Phys. Rev. Lett. 102 (11), 116602 (2009); Lett. 9 (12), 3996 (2009); (2010); Nenad Vukmirovic and Lin-Wang Wang, D. L. Cheung and A. Troisi, J. Phys. Chem. C 114 (48), 20479 K. Do, D. M. Huang, R. Faller, and A. J. Moule, Physics 12 (44), 14735 (2010); Nano Physical Chemistry Chemical Claudio Melis, Luciano Colombo, and Alessandro Mattoni, The Journal of Physical Chemistry C 115 (2), 576 (2011). 2 W. Tschop, K. Kremer, J. Batoulis, T. Burger, and O. Hahn, Acta Polym. 49 (2-3), 61 (1998); J. Baschnagel, K. Binder, P. Doruker, A. A. Gusev, O. Hahn, K. Kremer, W. L. Mattice, F. Muller-Plathe, M. Murat, W. Paul, S. Santos, U. W. Suter, and V. Tries, Advances in Polymer Science: Viscoelasticity, Atomistic Models, Statistical Chemistry 152, 41 (2000); C. X. Chen, and J. K. Maranas, P. Depa, Journal of Chemical Physics 134 (1),014903 (2011). 3 Huang D. M., Faller R., Do K., and Moule A. J., J. Chem. Theory Comput. 6 (2), 526 (2010). 4 R. D. Groot and T. J. Madden, 5 Journal of Chemical Physics 108 (20), 8713 (1998). J. G. E. M. Fraaije, B. A. C. van Vlimmeren, N. M. Maurits, M. Postma, O. A. Evers, C. Hoffmann, P. Altevogt, and G. Goldbeck-Wood J. Chem. Phys. 106 (10), 4260(1997). 6 Y. Y. Li, T. J. Hou, S. L. Guo, K. X. Wang, and X. J. Xu, (12), 2749 (2000); 7 H. Sun, J. Phys. Chem. B 102 (38), 7338 (1998); Eichinger, Physical Chemistry Chemical Physics 2 Y. M. Lam and G. Goldbeck-Wood, Polymer 44 (12), 3593 (2003). David Rigby, Huai Sun, and B. E. polymer international 44 (3), 311 (1997). 8 Charles M. Hansen and Allan L. Smith, 9 W. L. Ma, C. Y. Yang, X. Gong, K. Lee, and A. J. Heeger, Carbon 42 (8-9), 1591 (2004). 10 Advanced Functional Materials 15 (10), 1617 (2005); Richard M. Beal, Alexandros Stavrinadis, Jamie H. Warner, Jason M. Smith, Hazel E. Assender, and Andrew A. R. Watt, 11 Macromolecules 43 (5), 2343 (2010).