Supplementary material_v2

advertisement

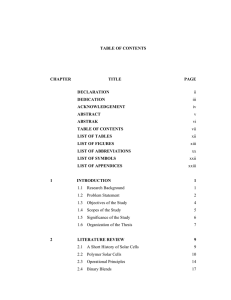

Supplementary material – Modelling transport in nanoparticle organic solar cells using Monte Carlo methods K. Feron,a,b,* S. Ulum,b N. Holmes,b A. L. D. Kilcoyne,c W. J. Belcher,b X. Zhou,b C. J. Fell,a,b P. C. Dastoorb a CSIRO b c Energy Technology, Newcastle, NSW 2300, Australia University of Newcastle, Centre for Organic Electronics, Newcastle, NSW 2308, Australia Advanced Light Source, Lawrence Berkeley National Laboratory, Berkeley, CA 94720, USA * Corresponding author email address: Krishna.Feron@csiro.au (Krishna Feron) A. Simulation parameters Table I. Simulation parameters used in the DMC model. Values are mostly tuned to describe a P3HT:PCBM device. Property Value Temperature (T) 300 K Relative dielectric constant 3.1 Reference 1 Standard deviation density of states electron donor and 0.05 eV 2 acceptor 3.65 nm (equivalent to 1D 3 Forster radius PCBM diffusion length of 40 nm) 2.15 nm (equivalent to 1D 4 Forster radius P3HT diffusion length of 8.5 nm) (C60 diffusion length) Exciton lifetime PCBM 11 µs 5 Exciton lifetime P3HT 400 ps 4 3 x 1012 s-1 6,7 3 x 1012 s-1 6,7 1 x 104 s-1 2 Reorganization energy 0.5 eV 2 Lattice constant 1 nm 6,8 Anode work function (ITO) -4.8 eV 9 -4.08 10 -5.3 9 -4.3 9 Charge hopping rate constant electron acceptor Charge hopping rate constant electron donor Charge carrier Recombination rate Cathode work function (aluminium) HOMO electron donor (P3HT) LUMO electron acceptor (PCBM) B. Film thickness – NP size relationship A series of nanoparticle dispersion were prepared with the aim of determining the film thickness – NP size relationship. NP size could be controlled through the P3HT:PCBM concentration in water. A more concentrated solution would give a thicker film when deposited using the same spin-coating conditions. The size of NPs in solution was determined using DLS. The film thickness was measured using a profilometer. Figure S1 shows the thickness as a function of NP size together with a linear fit that was forced to go through the origin. The slope of the fit was approximately 3 indicating that each film consisted of 3 layers of NPs. FIG. S1. Film thickness as a function of NP size (red dots). A linear fit forced through the origin (black solid line) had a slope of 2.92 ± 0.12 (standard deviation). C. Optimisation of annealing conditions Annealing conditions were optimised for efficiency. As shown in Fig. S2 an annealing temperature of 140 ˚C and duration of 4 min. was found to be optimal. Figure S2. Efficiency as a function of (a) annealing temperature while the annealing time is fixed at 4 min. and (b) annealing time while the annealing temperature is fixed at 140 ˚C. Blue dots indicate the average of 6 devices with standard deviation shown (error bars). The black dots correspond to the maximum value of each set of devices. References 1 P. Yu, D. Mencaraglia, A. Darga, A. Migan, R. Rabdbeh, B. Ratier, and A. Moliton, Phys. Status Solidi C 7, 1000 (2010). 2 K. Feron, C.J. Fell, L.J. Rozanski, B.B. Gong, N. Nicolaidis, W.J. Belcher, X. Zhou, E. Sesa, B. V. King, and P.C. Dastoor, Appl. Phys. Lett. 101, 193306 (2012). 3 P. Peumans, A. Yakimov, and S.R. Forrest, J. Appl. Phys. 93, 3693 (2003). 4 P.E. Shaw, A. Ruseckas, and I.D.W. Samuel, Adv. Mater. 20, 3516 (2008). 5 S. Cook, H. Ohkita, J.R. Durrant, Y. Kim, J.J. Benson-Smith, J. Nelson, and D.D.C. Bradley, Appl. Phys. Lett. 89, 101128 (2006). 6 R.A. Marsh, C. Groves, and N.C. Greenham, J. Appl. Phys. 101, 083509 (2007). 7 L. Meng, Y. Shang, Q. Li, Y. Li, X. Zhan, Z. Shuai, R.G.E. Kimber, and A.B. Walker, J. Phys. Chem. B 114, 36 (2010). 8 K. Feron, X. Zhou, W.J. Belcher, and P.C. Dastoor, J. Appl. Phys. 111, 044510 (2012). 9 Y.S. Eo, H.W. Rhee, B.D. Chin, and J.-W. Yu, Synth. Met. 159, 1910 (2009). 10 J.S. Foresi and T.D. Moustakas, Appl. Phys. Lett. 62, 2859 (1993).