GeE 477 Term Project 1 Higgins Paper

advertisement

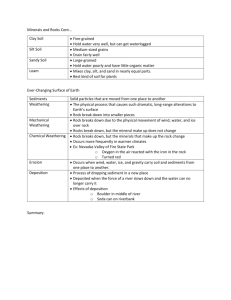

Evaluation of the State of the Practice: Effects of Jointed/Discontinuous Rock on Drilled Shaft Design By Karl A. Higgins, III, P.E. Missouri University of Science and Technology (MS&T) Course GeE 477 – Discontinuous Rock Fall Semester 2011 ABSTRACT Title: Evaluation of the State of the Practice: Effects of Jointed Rock on Drilled Shaft Design Author: Karl A. Higgins, III, P.E., MS&T Graduate Student The author will examine the current state of the practice for evaluating drilled shaft capacity for shafts socketed into rock of varying quality (from severely jointed and weathered poor quality rock to unweathered, widely jointed, good quality rock). Characterization of rock using varying methods of unconfined compressive strength, Rock Quality Designation (RQD), Rock Mass Rating (RMR) and Geological Strength Index (GSI) will be examined in the context of drilled shaft capacities. The author will compare and contrast how drilled shafts bearing in soil or highly weathered rock versus a rock socket behave. The author will compare the current practice state methods with actual load tests of drilled shafts bearing in rock of varying quality for a recent engineering mega-project, the $3 billion Northern Virginia High Occupancy Toll (HOT) Lanes project currently under construction that resulted in the replacement of 40 bridges many supported on drilled shafts. Table of Contents 1.0 Introduction .............................................................................................................. 1 2.0 Description of Drilled Shafts ..................................................................................... 1 3.0 The Geomaterials Drilled Shaft Bear In .................................................................... 2 4.0 How Drilled Shaft Create Capacity ........................................................................... 3 5.0 Shaft Friction in Rock Sockets.................................................................................. 6 6.0 End Bearing in Rock Sockets ................................................................................... 8 7.0 State of the Practice ............................................................................................... 11 8.0 Case Study ............................................................................................................. 12 8.1 Test Shaft in IGM ................................................................................................ 13 8.2 Test Shaft in Rock .............................................................................................. 15 9.0 Closing ................................................................................................................... 17 1.0 Introduction Engineers use drilled shafts as deep foundations to support a variety of civil infrastructure projects and buildings. Drilled shafts are robust deep foundation elements capable of carrying high axial compression, uplift, and lateral loads and thus are ideal for certain unusual loading conditions such as traffic breaking, wind and seismic forces on bridges. At times, the loads required of drilled shafts are very significant, and engineers seek to found the base of the drilled shafts into rock where capacities are generally higher. The challenge with this objective is that relatively competent rock (rock that is not severely jointed or weathered) may not be present at reasonable depths for drilling and constructability purposes. As such, engineers are often required to form the base of the drilled shafts into closely jointed and weathered rock. The objectives of this paper are to examine the geologic factors that affect drilled shaft capacity, compare and contrast the differences in shaft behavior for shafts bearing in soil/weathered rock and rock. The author will compare the current practice state methods with actual load tests of drilled shafts bearing in rock of varying quality for a recent engineering mega-project, the $3 billion Northern Virginia High Occupancy Toll (HOT) Lanes project currently under construction that resulted in the replacement of 40 bridges many supported on drilled shafts. 2.0 Description of Drilled Shafts Drilled Shafts are broadly described as a cast-in-place deep foundation whereby the shaft is stabilized to permit the installation of reinforcing steel and concrete. Drilled Piers are synonymous with Drilled Shafts, but “Caissons” are not. Page 1 Drilled shafts generally have larger diameters as compared to drilled, continuous flight, hollow stem auger piles or “Augercast Piles,” but this distinction is changing as maximum Augercast pile diameters are upwards of 48 inches. Drilled shafts are perhaps the most robust of deep foundation types, and they are used for bridges, large buildings and major Civil infrastructure projects due to their unique ability to resist high axial and lateral loads. The design capacity of drilled shafts can vary between 30 to 6,000+ tons with diameters from 30 to 120+ inches. The only limit on drilled shaft diameter is equipment capability. Typical drilled shafts lengths are 20 to 90+ feet; however, exceptions as deep as 200 feet+. 3.0 The Geomaterials Drilled Shaft Bear In Shaft bear in what engineers categorize as three material types: 1. Soil, 2. Intermediate GeoMaterials (IGM), and 3. Rock. Soil is further broken down into two types, cohesionless and cohesive. Cohesionless materials include Sands and Gravels, and non-plastic Silts that are deposited or weathered in place (i.e., residuum). Cohesive materials are clays and sandy/gravelly clays with undrained shear strengths less than 5,000 psf and Liquid Limits greater than 50. The geologic weathering process can change rock into soil. This transition between soil and rock is generally vertical in the geologic lithology, with the degree of weathering decreasing with depth. As the earth’s materials transition from rock to soil, engineer’s have characterized the transitional materials as Intermediate GeoMaterials (IGM) or weathered rock. IGM is stronger than soil and weaker than rock and posses both soil and rocklike properties. IGM is subdivided into Cohesionless and Cohesive groups. Cohesive IGM is defined as materials that exhibit unconfined compressive strengths in Page 2 the range of 10 ksf < qu < 100 ksf. Cohesionless IGM is defined as very dense granular geomaterials with SPT N60 values between 50 and 100 blows per foot. Lastly, rock, a material with no consensus definition in geology or geotechnics, is defined by engineers in drilled shaft design as a cohesive, cemented geomaterial that can be identified on the basis of geologic origin. This definition of rock was provided by the National Highway Institute (NHI) in their publication Drilled Shafts: Construction Procedures and LRFD Design Methods dated May 2010. In the author’s opinion, this NHI definition of rock is too vague. 4.0 How Drilled Shaft Create Capacity For this discussion, the author will subdivide the explanation into two categories: shafts bearing in soil/IGM and shafts bearing in rock. Shafts that bear in these two groups of materials behave fundamentally different. For shafts that bear in soil/IGM, engineers sum the side shear resistance based on differing soil/IGM layers and then add the end bearing to determine capacity. Two important equations are Rtot = ΣRSN + RBN and Rtot > F.S. X QTN. provides a schematic of this equation. Page 3 Figure 1 below Figure 1 For cohesionless materials, engineers calculate the side shear resistance (shaft to soil/IGM) by determining overburden pressures, converting these pressures into horizontal pressures via earth pressure coefficients, and then determining the shearing resistance between soil and the shaft concrete by estimating frictional interface coefficients. Side shear in cohesive soils are estimated by determining the undrained shear strength of the clay, determining the appropriate alpha factor (a reduction coefficient), then multiplying the shear strength and the alpha factor by the circumferential area of the shaft. End bearing for cohesionless or cohesive soils is calculated conventionally per Terzaghi’s original theories on bearing capacity modified for deep foundation effects. Shafts with bases founded in soil/IGM require “movement” to mobilize side shear and end bearing support. The shafts first engage side shear resistance, as relatively small amounts of downward shaft movement are required to mobilize these resistances. Once the side shear is fully mobilized, the end bearing becomes significantly engaged, however, considerably more movement is required to mobilize full end bearing resistance. At times, the amount of movement required to fully mobilize end bearing (i.e., bearing shear) is excessive and cannot be tolerated structurally; hence, total Page 4 capacity is not a function of the full end bearing resistance. Figure 2 below explains the basic relationship between shaft response to top loading. Maximum side resistance occurs Maximum base resistance at relatively small displacement occurs at relatively large and is displacement independent of shaft diameter Figure 2 Drilled shafts with bases formed in rock sockets behave quite differently than described for soil/IGM above. The primary differences are that the overburden pressures do not affect the side shear of the concrete in the rock socket, and that axial support from the soil overburden above the rock socket is ignored. Further differences include ultimate capacity of the shaft being either from side shear in the socket, or end bearing, but not the sum of both. So why do we not sum end bearing and side shear from the socket for capacity for rock supported shafts? The answer lies in the differences between soil and rock. Side shear in the socket is developed by engaging the rock’s asperities (or the roughness of the socket) with the cast-in-place concrete. Once the load is increased and the asperities are sheared, the load is transmitted to the base. Unlike soil or IGM, that may remold and re-adhere around the concrete after significant movement, rock does not behave this way. The volume/shape of the socket is not appreciably affected by horizontal overburden pressures and thus the “residual” socket side shear cannot re-engage. Further, the asperities are sheared and thus if still resistive, are lower than the peak strength. Page 5 Why are the frictional side shear resistances of the soil overburden (residual or deposited soil) and IGM above a rock socket ignored? The answer lays in strain compatibility differences between soil and rock. As explained above, relatively small amounts of downward shaft movement are sufficient to engage and then mobilize fully side shear resistance in soil/IGM. To mobilize the side shear in a rock socket, even smaller amounts of movement are required. Since the shaft is concrete and stiffer (much higher modulus) than the soil overburden/IGM, as load is applied to the top of the shaft, the shaft responds by load shedding top down. The less stiff upper soils ultimately yield and transfer stress to the stiffer materials comprising the rock socket. This load shedding characteristics of rock socket will be demonstrated in the case history portion of the paper. For these reason, engineers either design shafts bearing in rock sockets as side shear or end bearing only, but not a combination of the two. Further, the side shear from soil/IGM above the socket is ignored from a capacity perspective due to load shedding. As explained, shafts bearing in rock sockets behave fundamentally different than for shafts bearing in soil/IGM. 5.0 Shaft Friction in Rock Sockets Drilled shafts are large, highly loaded elements that are difficult (and expensive) to load test. As such, there is not frequent field testing of drilled shafts to confirm design assumptions. What engineers are ultimately interested in is the frictional resistance between the concrete and the shaft rock socket. The engineering design process results in some basic assumptions or characterizations: roughness coefficient, jointing of the rock, and soil materials of in filled joints. The drilling process itself can affect rock socket roughness and obviously the rock type is a factor. Cleanliness of shaft sockets Page 6 prior to concrete pouring is also a concern. Despite all these challenges, some researchers have presented theories and empirical relationships for other more easily measured properties to estimate shaft socket roughness. Two of the more common procedures for estimating socket roughness are from O’Neill and Reese’s research and from Horvath and Kenney’s research. These authors choose different, more easily measured rock properties to indirectly estimate socket roughness. O’Neill and Reese suggest socket roughness is a function of unconfined compressive strength, qu, and a term called alpha, a, which in turn is a function of rock jointing (measured by the RQD process). The more severely jointed the rock is, the lower the RQD and alpha values are respectively. The weaker the rock is, the lower the qu value. Since alpha and qu are directly proportional in the equation, the weaker and more jointed the rock is, the lower the socket friction. Since RQD and qu are common engineering measurements on boring/coring logs for cored rock, this correlation is significant in engineering practice. O’Neill and Reese Equation for socket shaft resistance. Pa = atmospheric pressure, qu = unconfined compressive strength of the rock, aE is the reduction factor. Horvath and Kenney suggested socket friction, fSN = 2.5(qu)0.5, is related only to the rock’s unconfined compressive strength, qu, also an engineer property that is often measured in the lab and reported on boring/coring log reports. There are undoubtedly more research and correlations related to estimating socket shaft resistance in rock. What is interesting about the above author’s work is that neither introduce the basic rock type into the equation. One can imagine that a finegrained siltstone (sedimentary rock), that is not significantly jointed and has reasonably high qu value (say 4,000 psi) would have a lower socket roughness than a coarse Page 7 grained granite (igneous rock) with similar properties of jointing and strength. However, neither equation above takes rock mineralogy into consideration. 6.0 End Bearing in Rock Sockets Like shaft resistance, there are several notable authors who have conducted research into base support for drilled shafts with rock sockets. Prakoso and Kulhaway used a series of load tests for shafts bearing in rock to determine a relatively simple empirical equation qBN = Nc* qu. Nc=2.5 is recommended when qu alone is used to Fig. 3 characterize rock mass, Nc is not a F.S. Base diameter does not appear to affect the equation (different than for soil/IGM supported shafts) and again rock type is not part of the equation. For Kulhaway’s equation to be valid, the rock must either be massive or tightly jointed to a depth of at least 1D below base, and the base must be clean base and visually verified. When data are available on the spacing and condition of discontinuities in rock beneath the base, the method described in the Canadian Foundation Engineering Manual (Canadian Geotechnical Society, 1995) provides a more refined estimate of N c Page 8 (Nc=3Kspd) but uses the same equation qBN = (3Kspd) qu. For this method to be valid, discontinuity spacing is at least 1 ft, and discontinuity aperture does not exceed ¼ inch. Canadian Geotechnical Society Method relies on knowledge of spacing an d discontinuities below shaft base. The NHI/Federal Highway Administration’s recent publication addresses end bearing in yet another equation, this time relying on the engineering geology properties of Rock Mass Rating (RMR) and qu to determine end bearing. NHI/FHWA Method for base resistance in rock Lastly, Hoek and Brown have developed their own methodology for determining base resistance, but this time it relies on the Geologic Strength Index (GSI) as the socket Page 9 characterization tool. Hoek believes that GSI is a better method for determining engineering properties of rock than is the RMR method. According to Hoek, GSI is based upon an assessment of the lithology, structure and condition of discontinuity surfaces in the rock mass. What is appealing about Hoek’s ideas is that for the first time, the roughness of the rock mass (a characteristic of mineralogy) and weathering are factors. The basic premise of Hoek’s GSI theory is shown graphically below in Figure 4. Decreasing Surface Quality Decreasing interlocking of rock pieces 10090 10-0 Fig. 4 A GSI of 100-90 would describe a massive, widely jointed rock with rough, fresh surfaces whereas a GSI of 10-0 would describe a rock that had indistinguishable blockiness and weathered, slickensided surfaces. Hoek’s equations for end bearing: S, a and mb are Hoek strength parameters based on GSI Page 10 7.0 State of the Practice The National Highway Institute (NHI) and the Federal Highway Administration (FHWA) have long been at the forefront of geotechnical research and publication. The two organizations have combined and prepared many geotechnical, practice based design manuals intended to help ensure the nation’s infrastructure is designed adequately. A recent, 2010 NHI/FHWA Publication titled Drilled Shafts: Construction Procedures and LRFD Design Methods does a good job in synthesizing the cumulative research and design approaches for drilled shafts. One of the appealing items of this publication is that it presents several author’s perspectives allowing the practitioner to determine which theories to apply. Some of the more commonly referenced authors are O’Neill and Reese (combined research) and Kulhaway. The manual provides specific equations and reference materials for shafts bearing in differing materials. After conducting research, Prof. Reese (University of Texas) went on to form a software company called Ensoft Inc. The design procedures captured in the FHWA manual(s) were converted into software for geotechnical engineering analysis purposes. One notable software for analyzing the axial behavior of shafts is Ensoft’s Shaft® program. The Shaft program is capable of analyzing shafts bearing in a variety of soil and IGM materials, and rock of differing type and weathering. Pertinent input parameters for shafts bearing in rock include rock unconfined compressive strength (qu), Young’s Modulus, RQD, spacing and thickness of the discontinuities. Kulhaway’s method for shafts bearing in rock sockets is utilized by Shaft® and is summarized below. 1. Calculate required socket length based on side friction alone 2. Compute settlement of shaft by adding elastic shortening (PL/AE) of the shaft itself to the amount of settlement required to mobilize end bearing, q p assuming the full load of the shaft is taken by end bearing Page 11 3. If computed settlement < 0.4 inches, side resistance will dominate and little end bearing will be engaged 4. If computed settlement > 0.4 inches, bond in socket will be broken and end bearing will be engaged The concept is that side resistance and end bearing will not be developed simultaneously, and that Qult ≠ Qside friction + Qend bearing (different than IGM shafts), rather Qult = Qside friction or Qend bearing depending on settlement amount. While Kulhaway’s methods are cited for “rock” (which is presumably hard rock as the software manual describes), there are alternative methods for weak rock as presented by O’Neill. The software manual uses the term IGM (previously described) synonymously with weak rock. Input parameters for weak rock/IGM include qu, RQD, core recovery percentages, Young’s modulus, a description of the joints (open or closed), and whether or not the socket would “smear” during drilling. In summary, one can use the FHWA manual and perform hand calculations or use Ensoft’s Shaft® program which is based on this manual, both of which appear to be the most progressive state of the practice for drilled shaft design. 8.0 Case Study The author was fortunate enough to be one of several principal geotechnical engineers involved with the design and construction of the I-495 High Occupancy Toll (HOT) lanes project, a Civil Engineering mega project. This $3billion project included the first modernization of the DC Capitol Beltway since its initial construction, and resulted in the replacement or addition of more than 40 bridges. Many of the bridge piers were supported by Drilled Shafts bearing in IGM and Rock. Because of the size and complexity of the project, there was sufficient money to do several sacrificial test shafts using an Osterberg Load Cell (or O-Cell). The author reviewed the test data and there Page 12 are examples that support the theories on the differences between shafts bearing in IGM and rock presented in this paper. 8.1 Test Shaft in IGM As previously mentioned, shafts with bases founded in IGM require “movement” to mobilize side shear and end bearing support. The shafts first engage side shear resistance, as relatively small amounts of downward shaft movement are required to mobilize these resistances. Once the side shear is fully mobilized, the end bearing becomes significantly engaged, however, considerably more movement is required to mobilize full end bearing resistance. The graphic in Figure 5 below depicts the load settlement graphs of a test shaft with the base bearing in IGM. Note the significant amount of movement on both sides of the O-cell which represent the development of shaft friction and base resistances. Page 13 Fig. 5 Note significant base of shaft movement in IGM during load test Page 14 Table A above is the corresponding summary table showing the side shear resistance developed in the shaft during the test. Note that there is significant side shear (1.26 to 3.45 ksf) in the residual soil above the O-cell, and even higher shaft resistances at and below the O-cell where denser residual soil and IGM are present. Further, the base of the shaft was in the process of shear engagement, but did not likely experience full base resistance shear mobilization (typically thought to be 10% of the shaft diameter, which would be over 5 inches in this example). In summary, the O-cell test data fits nicely with the theories of shafts bearing in IGM whereby first side shear resistance is mobilized, then ultimately the base of the shaft, and that both side friction and end bearing are added to determine shaft capacity. 8.2 Test Shaft in Rock Side shear in the rock socket is developed by engaging the rock’s asperities (or the roughness of the socket) with the cast concrete. Once the load is increased and the asperities are sheared, the load is transmitted to the base. Unlike soil or IGM, that may remold and re-adhere around the concrete after significant movement, rock does not behave this way. The volume/shape of the socket is not affected by horizontal overburden pressures and thus the “residual” socket side shear cannot re-engage. Further, the asperities are sheared and thus if still resistive, are lower than the peak strength. To mobilize the side shear in a rock socket, even smaller amounts of movement are required. Since the shaft is concrete and stiffer (much higher modulus) than the soil overburden/IGM, as load is applied to the top of the shaft, the shaft responds by load shedding top down. The less stiff upper soils ultimately yield and transfer stress to the stiffer rock socket. This load shedding characteristics of rock socket is demonstrated in the load test below (Figure 6). Page 15 Fig. 6 No upward movement of Shaft Note small base of shaft movement in Rock during load test (<0.10 inch). Side shear in socket is dominating capacity. Page 16 Table A above is the corresponding summary table showing the side shear resistance developed in the shaft during the test. Note that this time, there is no mobilization of side shear in the residual soil above the O-Cell (there is one segment (strain gauge level 1-2) where 2.7 ksf of shear is mobilized, but this location is very near the top of the socket in more competent IGM. Since the settlement amounts of the socket are small (less than 0.10 inch), side shear in the socket is dominating resistance, and in fact end bearing is not likely even engaged. There is insufficient shaft movement upward to engage side shear in the residual soil above the socket (hence why it is ignored). This shaft behavior corresponds very well with the theories on shaft loading in sockets presented in the FHWA manual. 9.0 Closing Shafts bearing in discontinuous rock (IGM and highly jointed rock) behave fundamentally different than shafts bearing in rock sockets. One must appreciate these behaviors when designing shafts for support. It would be a mistake, for example, to include side shear from the residual soils above the socket to a shaft’s capacity. The current state of the practice is adequately captured in NHI/FHWA’s 2010 publication on the design of drilled shafts. C:\UM S&T\GE 477 Discontinuous Rock\Assignments\Term Project 1\GeE 477 Term Project 1 Higgins Paper.doc Page 17 References (1) “Drilled Shafts: Construction Procedures and LRFD Design Methods,” NHI Course 132014, FHWA-NHI-10-016, FHWA GEC 010, U.S. Dept. of Transportation, Federal Highway Administration, May 2010 (2) “Computer Program Shaft Version 6.0”, by Lymon Reese, et al, 2007 (3) “Analysis and Design of Drilled Shaft Foundations Socketed into Rock”, prepared by Cornell University for the Electric Power Research Institute, EPRI EL-5918, August 1988, by Authors Carter and Kulhaway (4) Power point presentation, “Determination of Unit Tip Resistance for Drilled Shafts in Fractured Rock using the Global Rock Mass Strength”, by Truzman, Corley and Lipka (undated) (5) “Improving Foundation Design in Rock: Load Test at Burma Road Overpass”, FHWA-WY-09/10F, University of Wyoming, December 2009, Author John Turner, Ph.D.