REQUEST FOR PROPOSAL - WisBuild

advertisement

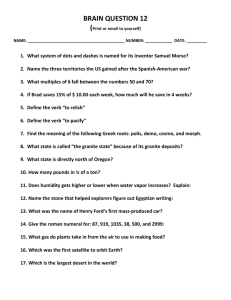

WISCONSIN STATE CAPITOL DOME MOISTURE STUDY Department of Administration Project No. 03K3Q Provide professional architectural and engineering services to perform a close inspection of the dome of the Wisconsin State Capitol. The purpose of the inspection is to identify conditions at joints between granite units that may be allowing water to enter the dome and to identify any other possible causes for the moisture related problems observed. In 2000 repairs were made to the dome that included pointing and sealing of joints between granite units and granite repairs. Since then we have observed paint degradation around the perimeter of the dome, consistent with high moisture in the plaster, on the interior plaster finishes at the 10th level, at the base of the dome. The deterioration is not symmetrical or uniform in pattern and is generally above the windows and 90% of it is below the interior gutter. There is additional recent moisture damage just below the interior coffer dome area at the 8th level. We also observed corrosion on the steel trusses that was not observed previously. Water penetration through deteriorated or open exterior joints between granite units of the dome may be causing the moisture related problems. Inspection of the exterior of the dome is being done to determine if it is possible that water is entering through the granite dome’s joints. We suspect that the dome area and the pipe gallery areas suffer from entirely different problems. The investigation of the moisture at the 8th level should probably focus on the exterior deck above the pipe gallery. DESCRIPTION OF THE DOME The dome of the Capitol extends from 175 feet above the ground floor elevation to 236 feet above the ground floor elevation and consists of 24 radial segments and 14 courses of granite between the skirt course located below the lantern and the scroll course at the base of the dome. The granite of the dome is supported on the top chords of 24 steel trusses and at the base of the dome the granite between the trusses is supported on a brick masonry wall. Granite infill units that are widest at the base of the dome and taper toward the top of the dome are set between projecting granite rib units. 24 ribs are made up of granite units 1 foot 8 inches thick and are located directly over each built-up steel truss. The granite infill units between the ribs are 8 inches thick and are connected to the adjacent steel truss at alternating horizontal joints. The units are connected to trusses by a bent rod attached to a continuous horizontal angle that spans between the trusses and is connected directly to the trusses. All horizontal joints are keyed together by a one inch lap cut into the ends of the units. The top surface of each panel between the ribs is cut to create a reveal that slopes down from the inner edge. The space between the trusses and directly behind the granite units is infilled with clay tile. The original drawings show a 2 inch air space between the inside face of the granite and the outside face of the clay tile. The top of the dome consists of a granite skirt course, starting at 231 feet above the ground floor elevation, a balustrade, starting at 235 feet above the ground floor elevation, and a lantern, starting at 235 feet above the ground floor elevation. These elements are supported by the 24 steel trusses. On top of the lantern stands the three ton Daniel Chester French gilded bronze statue, Wisconsin. At the base of each granite rib of the dome, 183 feet above the ground floor, there is a decorative carved granite scroll with masonry backup. Masonrybacked granite spandrel units are set between the scrolls. At the top the steel trusses are connected to a steel compression ring that is 10 feet in diameter. At the bottom each steel truss is connected to a steel column that is connected to a steel tension ring that is 80 feet in diameter. Original building documents, Drawing 518-2017, dated 28 June 1910, and Drawing 5182016, dated 29 June 1910, show the connection of the trusses to the column and the connection of the column to the tension ring. The bottom chord of each steel truss, back-to-back, 5 x 3 ½ x 7/16 angles separated by a 3/8 inch plate, is connected to a steel columns by a 4 ½ inch diameter steel pin inserted through a 3/8 inch thick steel plate that is riveted to the web of the column. The tension ring, a built-up steel girder consisting of two 5 x 3 ½ x 3/8 inch angles riveted to a 3/8 inch thick web plate, is riveted to the inner flange of each column. SCOPE OF WORK Be responsible for project administration, coordination of contract, billings, budget, and schedule for the Project. Review original documents related to the construction of the drum and dome. Review Wiss, Janney, Elstner Associates, Inc.’s study of the dome and west wing. Review documents related to repairs to the dome, including, but not limited to, recaulking in 1996, repairs made in 1997, and repair and conservation of exterior granite project in 2000. Review maintenance records to obtain information on the performance of the dome and adjacent interior construction. Interview building management staff and various contractors. Meet with building maintenance personnel to discuss the ongoing maintenance issues with the dome and adjacent construction. Create field inspection data sheets of the dome from existing documents to document conditions observed. Closely inspect the exterior of the dome from a boatswain’s chair using industrial rope access techniques. The inspection shall extend from the base of the lantern down to the base of the dome scrolls. It will include granite units and joints as well as roofing, sheet metal and flashing. The inspection will be done by trained engineers using appropriate equipment for inspection of the dome employing industrial rope access techniques. The extent of the inspection shall be limited to visual inspection and sounding as necessary, detailed field notes, plus photographic and video recording. Document conditions observed relative to distress and deterioration of granite units, mortar and sealant in joints, roofing, sheet metal, and flashing materials on inspection data sheets and record the conditions with photographs and by video. Each video will be reviewed thoroughly by professional architectural and engineering staff during inspection so any re-inspections can be completed as necessary. DSF staff intends to review video tapes during the inspection. Document other visible distress conditions observed on the inspection data sheets and record the conditions with photographs and by video. Meet and discuss results of all observations with building management. Prepare a report presenting the results of the inspection and conditions observed. Recommend immediate remedial repairs if appropriate. Recommend repairs and long term maintenance procedures. Work with Capitol staff to plan the work, include them on an ongoing basis with respect to all observations. Schedule regular team meetings that will include Capitol staff. STAFF Identify staff and subconsultants to be used to execute the work. Use only highly qualified personnel, experienced in the work they are assigned and who have experience working on significant historic buildings. If we do not know individuals proposed to do the work we may request resumes. We reserve the right to approve all personnel who are to work on the Capitol. FEE AND SCHEDULE After a Consultant is selected, the A/E shall submit a fee on a time and material, not to exceed basis, clearly breaking down the work as described above and as required to thoroughly inspect the dome. Breakdown show hours associated with each task, the hourly rate associated with those hours and include all personnel and subconsultants. Submitted fee shall include all labor, materials, and equipment, (including rope access), and all expenses for food, travel, lodging, printing, reviewing of submittal documents, research, logs, correspondence, scaffolding, material testing, data loggers, interior and exterior access, and any other expenses required to complete the work. Submitted fee shall not include any fees or expenses to make repairs that may be recommended based on observations. With the fee proposal, the A/E shall submit a schedule identifying earliest start date and an estimated duration for the work in number of calendar days. Recognize weather delays based on average weather conditions for Madison. AGENCY CONTACT Dan Stephans, dan.stephans@doa.state.wi.us, 608.266-1417