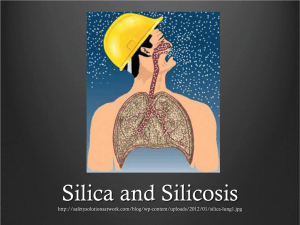

the Silicosis Fact Sheet

Hazards in the Workplace

Fact Sheet: Silicosis

WHAT IS SILICOSIS?

Silicosis is a specific form of

pneumoconioses

International Labor Organisation (ILO) as "an accumulation of dust in the lungs and the tissue reaction to it's presence". The ILO reports several thousand new diagnosis of silicosis each year.

Silicosis is caused by the inhalation of airborne crystalline silica dust in sufficiently high concentrations over a period of time. The silica dust enters the lungs and is deposited in the small air sacs known as the

alveoli

, a serious lung condition which is defined by the

, where the exchange of gases occur. This causes the formation of fibrous tissue around the dust particle: a process known as

fibrosis

. The fibrous tissue does not allow for the easy exchange of oxygen and carbon dioxide, causing an obstruction to breathing.

The most common form is the chronic form, which develops after long exposure to relatively low concentrations of dust. With the possible exception of some breathlessness during exercise the disease may remain free of symptoms for ten to twenty years after exposure. The disease progresses slowly but relentlessly.

A less common form is acute silicosis, which may develop three to five years after a heavy exposure to dust, particularly in enclosed spaces.

In all cases, there is no medical treatment. Furthermore, once the disease has begun, the progression continues even if the worker is removed from further exposure.

SILICA DUST & DISEASE

Silica is the most common element found in the earth's crust, being the major component of beach sand and granite for example. When combined with other substances, silica is relatively harmless and certainly does not cause silicosis. It is the airborne particles of the crystalline form of free silica found in quartz, tridymite and cristobalite that causes the damage. Quartz is the most important form of crystalline silica in the Australian context.

The size of the silica particles is important in causing the disease. Larger particles are usually prevented from reaching the lung's small air sacs and it is therefore the smaller particles (less than five thousandths of a millimetre) that are the most dangerous.

Page 1 726884843

The development of silicosis depends on a number of factors including:

-amount and kind of dust inhaled -percentage of free silica in the dust -the form of silica -the size of the silica particles -the duration of exposure -the individual's natural body resistance -presence or absence of complicating factors (such as infection).

DETECTION OF DISEASE

The disease is difficult to detect in the early stages because of the absence of symptoms.

Frequent dry coughing, shortness of breath, wheezing and increasing tiredness are possible early indicators.

There are three main methods of diagnosis:

1.

Chest x-rays are the most reliable and the earliest means of detection. An x-ray can show the fibrous tissue mentioned earlier.

2.

Work history is particularly useful in differentiating silicosis from other dust related diseases with similiar symptoms and formation such as asbestosis.

3.

Lung funtion tests performed using a lungs.

spirometer

, which assesses the performance of the

COMPLICATIONS

Tuberculosis: People with silicosis are known to be much more susceptible to tuberculosis.

Though the incidence of this is decreasing, it is still the most common complication of silicosis.

Heart Effects: In severe cases the fibrous tissue can so hinder the flow of blood in the vessels of the lungs that the heart expands; endeavouring to pump more blood. This is known as

cor pulmonale

. Death can result from these complications.

Cancer: A link between silicosis and cancer has been speculated on for some time. In a study published in December 1990, no conclusive proof of this link could be shown. The possibility was not definitely excluded, however, in the authors' words "(it) would seem unlikely".

Though silicosis is not known to cause any other diseases it may be aggravated by other conditions. Emphysema and asbestosis can cause an additive crippling effect on the lungs when coupled with silicosis, as can cigarette smoking. Needless to say, people with these known lung conditions should not be exposed to silica dust.

WORKERS AFFECTED

726884843 Page 2

Obviously, the workers at risk are the large variety of occupations in contact with silica dust.

These include: -

Underground mining, tunnelling and excavation work

Extraction and cutting of quartzite, gneiss, granite and slate

Foundaries

Glass manufacturing plants

Brick making

Manufacture of pottery, porcelain, refractory materials and siliceous abrasives

Road building

Demolition work where potential sites of silica exist eg. breaking up concrete

Explosive blasting work

Although silicosis differs from the pneumoconiosis afflicting coal miners, some coal dust, particularly from anthracite coal, can contain free silica and therefore cause silicosis.

It is important to note that silicosis is not a naturally occurring disease; it's occurrence is directly associated with work place exposure to silica dust. Its earlier names demonstrate its connection to various occupations such as miners' asthma, grinders' consumption, miners' phthisis, potters' rot and stonemasons' disease.

PREVENTION

The only protection against silicosis is prevention of dust exposure. The basic methods of prevention are:

Substitution: Where possible, less toxic substances should be substituted for silica sand.

Olivine and zircon sand should be used in moulds and cores in foundaries. Metallic shot, slag products or grit should be used for abrasive blasting (It is now illegal to use sand for abrasive blasting). Alumina should be substituted for flint in china placing in pottery.

Engineering Controls: Tools causing dust eg. grinders, saws etc should be fitted with dust extraction devices. Where possible, dusty processes should be fully enclosed and have an exhaust hood attached. Local ventilation system with hoses as close as possible to the head of cutting tools.

Using tools fitted with a water attachment to suppress dust e.g. on power saws, jackpicks and scabbling picks. Spraying with water in processes such as grinding or drilling can reduce the amount of dust by as much as 75%. An American study of foundries showed that

726884843 Page 3

overexposure to silica dust was the result of poorly designed and/or poorly maintained ventilation systems.

Good Housekeeping: Regular vacuuming and wet sweeping of floors, machinery etc. to remove settled dust, is particularly important to stop dust being kicked back into the air.

Work clothing should be vacuumed before removal. Under no circumstances should dry sweeping take place in areas where silica dust could be present

.

Posters and signs warning of the presence of free silica should be prominently displayed.

Respiratory Protective Equipment: This should be looked at as a last resort when all other preventative solutions possible, have been put in place. These vary from a simple disposable mask to a full respirator supplying clean air for particularly high concentrations of dust. In all cases, the equipment should fit properly and be regularly cleaned and checked.

Dust masks are unsuitable for use with a beard, and in these cases, an air supplied respirator with a hood or a helmet and visor should be used.

All these preventive measures should not be looked at in isolation but in combination with each other. It is very important that workers potentially exposed to silica dust have a chest x-ray every two years, to allow for early diagnosis.

The American Conference of Governmental Industrial Hygenist (ACGIH) has set an exposure limit for respirable quartz of 0.1 mg/m 3 . This is the limit recommended in Worksafe Australia's

Exposure Standards for Airborne Contaminants in the Workplace

; however, this standard is currently under review.

Under the

N.S.W Occupational Health and Safety Act

that silica dust is involved.

Associated legislation includes:

, workers' health and safety committee members can call for a WorkCover inspection if they suspect that dust levels are too high or

Section 41 of the Factories, Shops and Industries Act which aims to prevent the accumulation of fumes and dust in workrooms. Exhaust appliances must be provided where practicable.

Regulation 95A of the Construction Safety Act Regulations which sets out procedures for dust control during building and construction work and insists on regular testing of sites.

The Factories Shops and Industries Act sets out procedures for abrasive blasting including the outlawing of silica substances in abrasive blasting.

726884843 Page 4

Regulations 158A to 158F of the Construction Safety Act Regulations which again discusses the use of silica compounds in abrasive blasting.

Mines Inspection Act covering people working in mines, quarries and processing plants as well as people working on dredges.

Foundary Regulations in the Factories Shops and Industries Act which sets out restrictions on the use of silica in foundaries.

This Fact Sheet is courtesy of the Workers Health Centre

726884843 Page 5