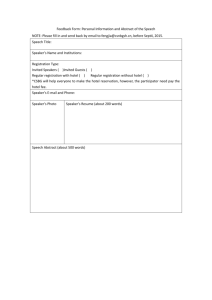

BEST PRACTICES OF TOURIST ACCOMODATIONS IN CRETE

advertisement

BEST PRACTICES OF TOURIST ACCOMODATIONS IN CRETE AND IN GREECE USING RENEWABLE ENERGY SOURCES Solar Energy Solid Biomass Geothermal Energy Incubator of New Enterprises of Chania Vourdoubas John Papanikolaou Joanna Email: incubator@cha.forthnet.gr DATE 17-02-2009 SUMMARY Renewable energy sources find various applications in buildings for power generation and for heat and cool production. Currently in Greece solar energy is used for power generation and for heat and cool production. Solid biomass is used for heat production and geothermal energy for heat production. The present work concerns various good examples of hotels and tourist accommodations in Crete and in Greece which are using the abovementioned RES for covering part of their energy needs. The most of them are in Crete and low enthalpy geothermal energy is used from a hotel in the region of thrace for heat production. The following hotels are presented 1. ATRION [SOLID BIOMASS FOR HEATING] 2. ELOYNDA [PHOTOVOLTAICS] 3. MILIA [SOLID BIOMASS AND PHOTOVOLTAICS] 4. LOUTRA TRAIANOUPOLIS [GEOTHERMAL ENERGY FOR HEATING] 5. LENTZAKI [SOLAR COOLING] 6. RETHYMNO VILLAGE [SOLAR COOLING] 7. CANDIA MARIS [SOLAR THERMAL HEATING] Apart from that, the fried vegetable oils from the restaurants of various hotels in Crete are collected and used as raw materials for the production of biodiesel. The collected used vegetable oils are sent from Crete to Continental Greece, where the processing plants are operating. LOUTRA TRAIANOUPOLIS HOTEL HOTELS LENTZAKIS, RETHIMNON VILLAGE HOTELS ATRION,CANDIA MARIS HOTEL MILIA HOTEL ELOYNDA Picture 1: Locations of the hotels (best practices) in Greece HOTEL ATRION IN HERAKLION-CRETE 1. Hotel details Name of Hotel : ATRION Location : HERAKLION-CRETE Class : C Client Activity : Tourism Geopraphy : Urban Area Operational Season : All Year Occupied area : 2000m2 Number of beds : 117 Staff numbers : 30 2. Description of technology Atrion Hotel uses two hot water boilers, which are burning olive husks. The boilers produce hot water at 95oC. The two boilers are connected in series and the hot water that is produced, is heating, through a serpetine, the water, which in contained into two water tanks of 3000 lt each. The hot water from these tanks caters all the needs of the hotel, from space heating during the winter to hot water for the showers or the kitchen and the laundry. During the winter, both the boilers are working in order to cater the needs for space heating, as it is mentioned before. At summer time one boiler is enough to serve the needs of the hotel for hot water. Each boiler consists of the heeding hoper, the biomass hearth, the piping section, and the chimney with the cyclone for the collection of the particulates from the flue gases. The feeding hoper holds a load of olive husks capable to feed the boiler for at least three hours of continuous operation. A screw conveyor brings the biomass into the bottom of the hearth. A blower supplies the combustion air at the bottom of the heart where the combustion takes place on a fixed bed. The combustion air, as well, assists the entrance of biomass into the hearth. The flue gases produced from the biomass combustion are passing through the piping section and they heat the water up to 95oC. Then they are released to the atmosphere though the chimney and the cyclone. The hearth has to be cleaned from the ashes once a day since there is no system for automatic ash removal. The feeding hoper has to be refilled two or three times per day from the main storage bin of the olive husks depending on the boiler’s operating time. Particulates are collected at the bottom of the cyclone in a special bin. The piping section and the chimney are cleaned from shoot and ashes annually, during the maintenance period. The two boilers have 150 and 120 Gcal/h nominal thermal power. The produced hot water circulates by a circulating pump into a closed circuit and through the serpentines of the two water tanks and keeps the water temperature in the tanks over 60 oC. If the temperature of the water in the tanks drops below 60oC then the circulating pump starts and if the closed circuit water temperature drops below 75oC starts the biomass feeding screw and the combustion begins in the boiler’s hearth. 3. Photos Picture 2: Hotel ATRION- Combustion of biomass (Heraklion-Crete) TOURIST ACCOMODATION IN ELOUNDA 1. Hotels details Name of Hotel : Elounda- Crete Location : CRETE Class : C Client Activity : Tourism Geography : Rural Area Operational Season : All year Number of beds : 60 2. Description of technology The photovoltaic system at Elounda, at the north coast of Crete, was the first autonomous PV installation in Greece for the electrification of a tourist resort. The tourist facility was established in 1978 in Crete and the bungalow complex consists of 12 individual villas and one restaurant. Bioclimatic design of the buildings was undertaken and, in the way, summer interior comfort and energy saving were achieved. The PV system was installed in June 1996 and operates satisfactorily since then. Until then, the electrical demand was covered by two diesel generators, which consumed approximately 18tn of light diesel fuel between May and September in a typical tourist season. The expenses for fuel and regular engine maintenance exceeded 13Kecu in the 1995 tourist season. The environment was also burdened from emissions and noise pollution. Grid connection was not economically feasible due to the archaeological character of the site and the associated expenses required for underground cabling. Therefore, the installation of a stand-alone PV system was considered. 3. Photos Picture 2: Hotel at Elounda–South Crete. Photovoltaic system MILIA ACCOMODATION IN CHANIA 1. Hotel details Name : Milia Location : Chania Prefecture Activity : Agrotourism Geography : Rural Area Operation : All Year Capacity : 13 houses-studios 2. Description Milia is consisted of an isolated renovated village neighborhood which was abandoned approximately 100 years ago. The old houses were refabricated and the visitors live in an old way of village life. Space heating is provided with fire places feeded with local wood. Electricity is produced from photovoltaics and a small diesel engine. For cooking and for hot water production LPG is used. The accommodation is isolated and it is not interconnected with the electricity grid. The electricity consumption in the accommodation is very low and candles are also used for lighting, so the visitors have a sense of the old way of life, in a traditional Cretan village. 3. Photos Picture 3: Rural Lodgings in Milia (Chania-Crete) LOUTRA TRAIANOUPOLIS HOTEL 1. Hotel details Name of hotel : Intermunicipal company of Loutra Traianoupolis – Alexandroupolis (D.E.L.T.A.) Location : Loutra Trainoupolis, Alexandroupolis [Region of Thrace] Class : C Client Activity : Tourism, Spa bathing Geography : Rural area, plains near the delta of Evros river Operational Season : All year Occupied Area : 4,5 ha Number of beds : 120 in 44 rooms in 4 buildings Staff numbers : 30 2. Description of technology This hotel uses the heat energy of a low enthalpy geothermal field to produce heat covering its own needs. An under floor heating system utilizes the warm water to heat the various rooms of the hotel. Heating/cooling needs : 1.050KW Description of technology : Geothermal circuit : production of 520C mineral water from a geothermal well, heats a closed loop water through a heat exchanger and reinjection at 370C, plate heat exchanger (estimated capacity of 450KW), PP piping. Closed loop circuit : buried transmission lines to the buildings. Heating system : under floor pipes at 40/300C Accumulation apparatus : water boiler, coil to coil, geothermaly fed & electric heating for peaks. 3. Photos Picture 4: Loutra Traianoupolis Hotel HOTEL LENTGAKI IN RETHYMNON 1. Hotel details Name : Lentzakis Location : Rethymno Activity : Apartments Geography : Urban area Operation : All year Capacity : 23 appartments 2. Description Lentzakis hotel has a capacity of 150 beds and it is occupied 100% in the summer and 45% in the winter. The solar cooling system has a power of 105 KW and hot water is produced with 450m2 flat plate collectors placed on the roof of the building. During the summer, cool is produced with an absorbtion cooling system and during the winter heat for space heating and for hot water production. The system was installed during 2002 and it was subsidized by the Greek Government in a rate of 50%. This solar cooling system is one of the few existed solar cooling systems in Crete at the moment. 3. Photos Picture 5: Establishments of solar cooling system RETHYMNON VILLAGE 1. Hotel details Name : Rethymnon Village Location : Rethymno Activity : Apartments Geography : Urban area 2. Description of technology The hotel has a capacity of 260 beds. The solar cooling system has a power of 105 KW(water’s temperature 70-75 oC) and hot water is produced with 450m2 flat plate collectors placed on the roof of the building. The solar cooler uses the hot water like a source of energy and the water (instead of Freon or Ammonia) like coolant resource to produce cold water (water’s temperature 8-10oC). The technology is simple and it is based on the process of condensation and vaporization of the coolant resource (the water) under vacuity. During the winter the collectors warm the water to 550C that is used for the heating of the rooms. The cold water (during summer) and the hot (during winter) leads to the local fan-coils in the rooms. With the same technology the natatorium is warmed (surface of natatorium 250m2- surface of collectors 200m2).The system was installed during 2000 and it was subsidized by the Greek Government in a rate of 50%.The positive consequences of the environment are the avoidance of the followings: CO2 SO2 CO NOX HC PARTS 871.182Kg/year 15.175 Kg/year 183 Kg/year 34.207 Kg/year 53 Kg/year 783 Kg/year 3. Photos Picture 6: Establishments of solar cooling system HOTEL CANDIA MARIS IN HERAKLION-CRETE 1. Hotel details Name of the hotel : CANDIA MARIS Location : Heraklion Crete Class : A Activity : Tourism Geography : Urban Area Operation : All Year Number of beds : 257 rooms 2. Description of technology This large hotel complex has installed a very large solar thermal field with flat collectors, producing heat all over the year and covering the most of the heating needs of the resort. Apart from that, the hotel is using EMS to optimize its energy utilization. The characteristics of the solar heating system are presented below: Water temperature in the swimming pools : 32-35oC Warm water temperature requirements in the Jacuzzi : 53 M3/day in temperatures 35-40oC Shower with consumption of 5M3/day at 48oC Consumption in the rooms and the kitchen of 30 M3/day at 48 oC Total heating requirements : 2166 MWh The solar system covers the heating needs at 70,26% producing 1522 MWh Inclination of flat collectors :27 0 Total surface of the solar collectors : 2.397 M2 Before the installation of the solar heating system, the hotel consumed 47.630 lt of oil per year and 449.651 lt of gas per year Most of the oil and the gas are now substituted by solar energy after the installation of the solar heating system State subsidies of the investment cost : 50% Manufacturing company : SOLE SA, GREECE 3. Photos Picture 6: Hotel Candia Maris- View of Solar heating system and general view of the hotel USE OF FRIED VEGETABLE OILS AS RAW MATERIALS FOR BIODIESEL PRODUCTION The fried vegetable oils from restaurants of various hotels in Crete are picked up, stored and sent to various plants in Continental Greece where they are co-processed with various vegetable oils for biodiesel production. Currently there are few biodiesel producing plants in Greece but non of them is located in Crete.