PS Tube Cleaning - University of Toronto, Particle Physics and

advertisement

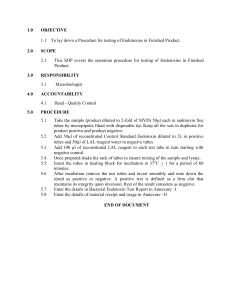

FCAL2 Process Sheet University of Toronto ATLAS Project Process Spec: Procedure for Tube Cleaning Components: Copper Tubes Materials: Latex Gloves, Heavy Chemical Gloves Citranox Cleaner, LPS Cleaner Reverse Osmosis Water, Foam swabs Tooling: Ultrasonic Cleaners Cleaning Racks, Rinsing Tanks, Bag heat sealer QC Data Sheet: Quality Control of Tube Cleaning Materials Cleaning Report Tube Processing Tag Process: Wear gloves whenever tubes are being handled. Heavy chemical gloves can be worn when handling hot objects, or when handling mineral spirits. 1. - Preparation Stage 1.1. Pre-soak the tubes in mineral spirits for a minimum 7 days. 1.2. Swab out the tubes, 2 swabs each tube. 1.3. Load 124 tubes into the washing rack, and stand to dry. 1.4. Place the rack of tubes into 1st ultrasonic cleaner. Agitate with ultrasound for 60 minutes in LPS (20% soln., 65o C). 1.5. Soak the tubes in LPS solution for 12 hours (overnight). 2. - 1st Cycle – 2.1. Agitate with ultrasound for 30 minutes in LPS (20% soln., 65o C). Lift and plunge the tray of tubes 3 times every 10 minutes. 2.2. RO water rinsing: 2.2.1. Plunge and lift the rack in the large rinsing tank (plastic), 10 times for a total time of 1 minute. Repeat rinse in 2nd tank. 2.2.2. Hang the rack in the large ultrasonic cleaning tank. Agitate with ultrasound for 15 minutes. Lift and plunge 5 times every 5 min. 2.3. Citranox bath, (10% soln., 65C) with US for 30 min. Lift and plunge the tray of tubes 3 times every 10 minutes. 106727735 Version: 02 Page 1 of 2 Date: 24 July 2001 Authorizing Signatures Production Manager QA Manager Research Scientist FCAL2 Process Sheet University of Toronto ATLAS Project 2.4. RO water rinsing: 2.4.1. Plunge and lift the rack in the large rinsing tank (plastic), 10 times for a total time of 1 minute. Repeat rinse in 2nd tank. 2.4.2.Hang the rack in the large ultrasonic tank. Agitate with ultrasound for 15 minutes. Lift and plunge 5 times every 5 min. 3. – 2nd Cycle – 3.1. Agitate with ultrasound for 30 minutes in warm (65o C) 20% LPS. Lift and plunge the tray of tubes 3 times every 10 minutes. 3.2. RO water rinsing: Plunge and lift the rack in the large rinsing tank (plastic), 10 times for a total time of 1 minute. Repeat rinse in 2nd tank. 3.3. Hang the rack in the large ultrasonic cleaning tank. Agitate with ultrasound for 15 minutes. Lift and plunge 5 times every 5 minutes. 3.4. Prepare a fresh Citranox bath, (0.5% soln., 65C) in the insert tray. Place this tray in the deep ultrasonic tank. Process with US for 1 min. Remove the insert tray when finished. 3.4.1. RO water rinsing: Rinse with RO in the large ultrasonic tank for 1 minute. 3.4.2. Re-fill the 2 plastic rinsing tanks with RO. Plunge and lift the rack in 10 times in each tank. 3.5. Final Step: Dip the rack in Ethanol Bath 1 for 30 seconds. Lift and allow to drain. Dip the rack in Ethanol Bath 2 for 30 seconds. Stand to drain. Blow down each tube with nitrogen, and then blow off exterior of tubes. 4. Stand to dry. 5. Perform Quality Control of Tube Cleaning procedure. 6. Package passed clean tubes for storage by carefully placing the batch of tubes in a polybag, fill the bag with nitrogen gas, and then seal the bag closed. Label the bag with Date, & Batch Number. Store the bag in the cleanroom on the shelf designated for tube storage. 7. Complete the Tube Processing Tag and ensure the Materials Cleaning Report is completed. 106727735 Version: 02 Page 2 of 2 Date: 24 July 2001 Authorizing Signatures Production Manager QA Manager Research Scientist