Fabrication of Electrodes with Nano-Size Gap - UROP

advertisement

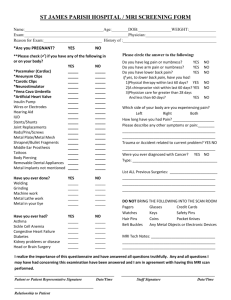

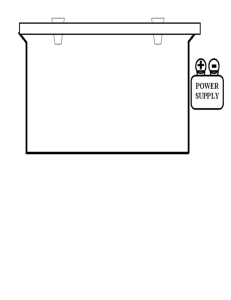

Fabrication of Electrodes with Nano-Size Gap Brian A. Higa University of California, Irvine Electrical Engineering Mentor: Professor Peter J. Burke Graduate Students: Lifeng Zheng and Sungmu Kang University of California, Irvine Department of Electrical Engineering and Computer Science Engineering Gateway Funded in part by the National Science Foundation and the Undergraduate Research Opportunities Program -1- Abstract: As of now, the presence of intense study in nanotechnology suggests that the future will need electronic devices that can measure the electrical properties of atoms and molecules. Current fabrication methods of these devices require abstruse techniques and expensive equipment. We propose a simple and inexpensive method of fabrication by electroplating metal onto electrodes with a large gap (0.25 microns) in between them. We hypothesized that the deposition rate can be controlled by monitoring the electronegativity of the electrodes and the electrolyte concentration. We found that during a specific stage in metal deposition there was rises in the conductance between electrodes by increments of 2e2/h. This stage shows the quantization of conductance which can be interpreted as the first atoms closing the gap between electrodes. With this result we conclude that metal deposition can be controlled which can be used as an alternative fabrication method of electrodes with nano-size gap. Key Terms: Cation, electronegativity, electroplating, deplating, metal deposition rate, Ohm’s law, quantization of conductance (QOC) -2- Introduction: The purpose of my research is to explore a method of fabricating electrodes with nanosize gap. The many disciplines of nanotechnology are being forestalled due to the lack of an effective and inexpensive method to fabricate these devices at a large-scale. Current fabrication methods require scanning probe microscopy, advanced lithography and special contacts. These methods produce fragile devices at an exorbitant cost. The exorbitant cost results from the method’s inefficiency to produce devices with punctilious gap sizes. They also need to be produced in a remote and quiescent environment because even the slightest vibrations from an iterant truck can stymie the fabrication process. The pith of my method of fabrication involves starting out with electrodes with large gaps of 100nm to 2um and allowing metal ions to adhere to the surface of the electrodes by electroplating and metal deposition. As metal ions accrete to the surface it also shrinks the size of the gap between the electrodes. This process is called metal deposition which is depositing metal ions onto the surface of a metal. Electroplating is making the electrodes negatively charged in respect to another metal so that the metal ions will be attracted to the electrodes and metal deposition can occur. Fig. 1 shows two electrodes before and after electroplating. Fig. 1: Left is before electroplating and right is after electroplating. Notice that the gap between the electrodes decreases after electroplating. -3- In comparison to current methods, my method is cheaper and simpler because my method does not require expensive equipment nor to be located in a remote and quiescent area. Controlling the metal deposition rate, which is done by regulating the electronegativity of the electrodes and how many metal ions are present, is not convoluted and it is the cardinal reason why my method can produce accurate Fig 2: Key before and after electroplating gap sizes efficiently. Another reason that adds to the simplicity of my method is that electroplating is observable without the need of optical devices (Fig. 2). These devices prove to be essential to measuring the electrical properties of atoms and molecules and they can be implemented in molecular electronics (Fig. 3). These devices can also be implemented as electronic switches that can consume less power than the inimitable metal-oxide-semiconductor-field-effect transistor (MOSFET). The MOSFET (Fig. 4) is a three terminal device where a specific Fig. 3: Molecular Electronic Spectroscopy terminal called the gate regulates the formation of an inversion layer on the substrate that allows the conductance between the other two terminals called the drain and source. The gate needs to be kept at the required voltage to maintain the desired inversion layer. Fig 4: MOSFET Unlike the MOSFET my device only needs the required voltage for a finite amount of time to obtain the desired conductance between the two electrodes. Other applications for these devices include operating as a chemical detector. Due to the fact that these devices are designed to measure the electrical properties of atoms and molecules they can also be implemented to allow specific atoms and molecules to bind to the surface of the -4- electrodes. Chemicals in an unknown solution (Fig. 5) can easily be identified from observing if a specific atom or molecule is extant to bridge the gap between the electrodes. These devices can also brook astringent and acidic solutions which can broaden its utilization. Fig 5: Chemical Spill These devices are also applicable to serve as metal collectors. They have a proclivity to allow metal ion to adhere to their surface by electroplating and metal deposition. At high metal deposition rates these devices can effectively collect metal ions from aqueous and viscous solutions. This can improve modern metal recycling techniques (Fig. 6) and prolong Fig 6: Metal Recycling the ineluctable depletion of raw metals and alloys. The research of Krahne et al. gave me inspiration for my research by demonstrated how a network of electrodes with nano-size gaps can be fabricated for use in integrated circuits. Their method of fabricating is not by electroplating but by lithography. Although their work is not apposite to mine, they showed me how these devices can be used in integrated circuits to study the properties of nano-size objects. Since I am an electrical engineering major this really got me interested in my research. My Method: My research incorporates the methods used in the research of Morpurgo et al. Their research involves fabricating electrodes with nano-size gaps by electroplating using potassium cyanaurate [KAu(CN)2] and a buffer (pH 10) composed of potassium bicarbonate (KHCO3) and potassium hydroxide (KHO). In other words, the metal they used for electroplating is gold. My method is to experiment to see if electroplating works for a different metal, copper. Although -5- gold and copper have similar electric conductivity, they are quite disparate from each other. For example, a gold atom is much bigger and heavier than a copper atom which means that the Brownian motion of gold is slower than copper. This means that copper moves faster than gold and could possibly mean electroplating is faster with copper than with gold. On the other hand, copper has an inherent tendency to form copper oxide (CuO) very easily. This can create problems when electroplating for a long period of time. I also adopted methods from the research of Li et al. They used copper for electroplating, but it wasn’t used for fabricating electrodes with nano-size gaps. It was used to show the quantization of tunneling current which is not related to my research. What I learned from them is the chemicals that they used for electroplating. They used 1mM copper sulfate (CuSO4) and 10mM sulfuric acid (H2SO4). I learned that H2SO4 prevents the formation of CuO and it is the cardinal reason why they used it. This colored me to add an acid in my solutions. The process that is the nexus of my research is electroplating. Electroplating is making the electrodes negatively charged in respect to a metal so that the metal ions will be attracted to the electrodes. This happens because metal ions are cations which are ions that are positively charged due to having lost electrons by ionic bonding. This is why metal ions have a propensity to be attracted to Vd c Metal (Cu Wire) negatively charged objects. Electronegativity is how much a metal is at a lower voltage than another metal. Controlling the electronegativity of the electrodes is accomplished by using a DC voltage supply (Fig. 7). The positive pole is connected to a metal and the negative pole is connected to an electrode. -6- Electrodes Fig. 7: DC voltage supply controls electrodes’ electronegativity In my experiments I have proven that there is a direct relationship between electronegativity and metal deposition rate. Metal deposition rate is the average number of metal ions being deposited on a surface of the electrodes per unit of time. At low electronegativity, metal deposition is slow resulting in gradual and uniform electroplating. Complete closing of the gap between electrodes occurs after several hours or longer. At high electronegativity, metal deposition is fast resulting in capricious and non uniform electroplating. Complete closing of the gap between electrodes occurs within seconds or minutes. Fig. 8 is a sample of electrodes after electroplating at a low metal deposition rate and Fig. 9 is a sample of electrodes after electroplating at a high metal deposition rate. Fig 8: Low metal deposition rate Fig 9: High metal deposition rate Another factor that affects the metal deposition rate is the amount of metal ions available for electroplating. Higher concentration of metal ions results in more metal ions available for electroplating and faster metal deposition. Lower concentration of metal ions results in less metal ions available for electroplating and slower metal deposition. However, unlike electronegativity it is not pragmatic to easily adjust the metal ion concentration. It is also very untoward to know the exact concentration because the solution is always evaporating and concentrations are never completely uniform. Therefore adjusting the metal ion concentration to control the metal deposition rate is not feasible. -7- The goal for running experiments is to aver that my method can control the gap size between electrodes. I can do this by determining a metal deposition rate that results in a constant decreasing gap size rate. A constant decreasing gap size rate allows fabrication of electrodes with precise gap sizes. This rate can be shown by 5 4 G (2e^2/h) observing the quantization of conductance (QOC) in the gap between the electrodes. 3 2 1 QOC is defined as conductance (G) 0 2 increasing by increments of 2e /h in 0 50 constant time intervals (∆t) (Fig 10). “e” is elementary charge constant and “h” is Planck’s constant. The unit of conductance is 100 150 Time (second) 200 250 Fig 10: QOC Y axis – Conductance (G) X axis – Time (sec) 2e2/h because this is the approximate conductance of an atom. QOC is the stage in electroplating when the very first metal ions bridge the gap between the electrodes. In other words, what is observed is one metal ion being - Metal Ion Quantization of Conductance - Electrodes deposited onto a surface of the electrodes per ∆t (Fig. 11). QOC is not observed at high Fig 11: Going up to down then left to right. Electroplating with gap size decreasing at a rate of 1atom per ∆t. The region that is dark green is QOC which is what I observe. conductance values because the -8- bridge of metal ions between the electrodes has a large surface area (Fig. 12). This results in exponential and erratic increases in conductance. Deplating is when the metal ions are repelled from the electrodes. This is done by making the electrodes positively charged in respect to a metal. This process results in reversing the effects of electroplating. Unfortunately in my research, I was unable to Fig. 12: Top – low G values Bottom – high G values return a sample back to its intrinsic state after electroplating. An abundant amount of metal ions do not come off the electrodes. This is something that I look forward to working on in the future. Methods and Materials: The first step is to design the program on LabVIEW that will read the data from the lockin amplifier, analyze the data and record it on a spreadsheet file. The data read from the lock-in amplifier is the AC voltage difference between two nodes. This data can be converted into conductance by Ohm’s law: V = I * R (1). The program should also take data every second for a given amount of time. The second step is to prepare the solutions that I used in my research. Before doing anything it is recommended to wear safety gloves and glasses. I put into three containers 20uM CuSO4, 40uM hydrochloric acid (HCl) and 200uM sodium hydroxide (NaOH) (Fig. 13). CuSO4 is the electrolyte that contains metal ions for metal deposition and it is directly proportional to the metal Fig. 13: From left to right. CuSO4, HCl and NaOH deposition rate. HCl is an acid used to occlude the formation of CuO. CuO is not conductive and sticks to the electrodes which engenders failure in an experiment. NaOH is for neutralizing the -9- acid after I finish an experiment so that I can discard the solution in the sink. Next I get a beaker and fill it with 2liters of water. I use a pipette to add the desired amount of CuSO4 and HCl into the beaker. I prefer to add in discrete amounts of 5milliliters. That way each 5milliliters of CuSO4 corresponds to adding 50uM CuSO4 into the beaker and each 5milliliters of HCl corresponds to adding 100uM HCl into the beaker. I would advise that the beaker be placed in area that is not susceptible to vibrations. My research is about measuring the conductance between a very small gap and it is sensitive to noise and vibrations. The next step is to make the circuit and to set up necessary connections. I start by soldering metal contacts onto the electrodes using indium. An effective way to prevent the contacts from breaking off is to spread the indium across a large area (Fig. 14) because the strength of the adhesion is directly proportional to the contact surface area. Then I hook up the lock-in amplifier to the computer via a GPIB cable and I also take Fig. 14: Soldered contacts note of the GPIB address of the amplifier so that the computer can read it. I set the frequency and amplitude of the signal generator of the lock-in amplifier to 13Hz and 3mV respectively. Then I connect it to input A of the lock-in amplifier. I also connect it to a 10kohm resistor. The resistor is connected to input B and to one of the electrodes. The other electrode is grounded. Fig. 15 shows all the connections made to the lock-in amplifier except the GPIB cable. A simple method to check to see if the connections and Fig. 15: Connections to Lock-in Amplifier LabVIEW program are correct is to connect a 13kohm resistor to input B and observe the data recorded on the computer. It should read very close to 1 because 2e2/h is equal to the reciprocal of 13,000. Then I hook up a DC power supply and connect the - 10 - positive pole to a copper metal and the negative pole to the grounded electrode. The copper metal should be clean because if it is dirty it can introduce problems that can hinder the result of an experiment. Then the electrodes and metal are submerged in the beaker containing known concentrations of CuSO4 and HCl (Fig. 16). The beaker is covered with aluminum foil to prevent contamination. After this the setup is complete and it should look like Fig. 17. Fig. 16: Beaker with electrodes and copper metal DC Supply Lock-In Amplifier B Vd c 10 k A Copper Wire Va c Electrodes Beaker Fig. 17: Schematic of the experiment - 11 - For deplating I reverse the DC voltage by switching the connections. The positive pole is connected to the grounded electrode and the negative pole is connected to the copper metal. Analyzing data from the spreadsheet file made from LabVIEW is done using the IGOR program. This program can convert the spreadsheet file into limpid tables and graphs. It can also do histograms which are very useful for compressing all of my results into one graph. Results: Before doing actual experiments to progress in my research I ran experiments to Conductance vs. HCl Concentration 0.30 come up with reasonable parameters for sundry 0.25 amplitudes for the signal generator and came up G (2e^2/h) variables. I tested different frequencies and 0.20 0.15 with 13Hz and 3mV. I learned that higher 0.10 frequencies and amplitudes results in little or no 0.05 metal deposition at the surface near the gap and 0 50 100 150 200 250 300 350 uM HCl lower frequencies and amplitudes results in the Fig. 18: Conductance vs. uM HCl experiment being too sensitive to noise. I also have done an experiment of the contribution HCl has to conductance (Fig. 18). I learned that too high a concentration of HCl results in very high background conductance and therefore the experiment becomes AC amplitude: 3mV Frequency: 13Hz HCl: 300uM CuSO4: 50 or 100uM very sensitive to noise. I came up with 300uM as a reasonable concentration of HCl. Table 1 summarizes my setup parameters. - 12 - Table 1: Setup Parameters Fig. 19 and 20 are QOC that I observed in my research. Note that Vdc means the DC voltage which is the electronegativity strength. 12 11 10 9 8 G (2e^2/h) 7 6 5 4 3 2 1 0 1000 1100 1200 1300 1400 1500 Time (second) Fig. 19: Sample D37 at 2Vdc and 50uM CuSO4 6 5 G (2e^2/h) 4 3 2 1 0 500 1000 1500 2000 Time (second) Fig. 20: Sample D29 at 2Vdc and 100uM CuSO4 - 13 - Fig. 21 is a histogram of the occurrences of conductance for all the experiments in my research. Notice that there are peaks in conductance near 1, 2, 3, 4, and 6. This supports that the conductance of atoms is in units of 2e2/h. On the next page, there are images taken using a scanning electron microscope (SEM). Fig. 22 is my devices before electroplating and Fig. 23 is my devices after electroplating. The green circle that appear on the images is the approximate size of 2000 atoms. Fig. 21: Conductance vs. Occurrence - 14 - 2000 Atoms Fig. 22: SEM image of electrodes before electroplating 2000 Atoms Fig. 23: SEM image of electrodes after electroplating - 15 - Discussion: My empirical data from my research proves that my method of fabricating electrodes with nano-size gap is controllable. By observing QOC right after there is a connection between the electrodes, it can be interpreted that the metal ions are being electroplated on the surface of the electrodes at a rate of one atom per ∆t. By looking at Fig. 24 it can be shown that each jump in the conductance results in the thickness of the connection between the electrodes to increase by an atom. In other words, the metal deposition rate is one atom per ∆t. Since the metal deposition rate only depends on the electronegativity and metal ion concentration it can be concluded that this rate occurs throughout the entire experiment. 6 3 Atoms thick G (2e^2/h) 5 4 3 2 1 2 Atoms thick 0 500 1000 1500 Time (second) - Metal Ion 1 Atom thick - Electrodes Fig. 24: Each jump in conductance corresponds to the connection between the electrodes increasing by an atom. By observing the QOC, the connection thickness is increasing by 1atom per ∆t. Therefore the metal deposition rate is controlled. - 16 - 2000 With more time I should be able to improve my results of conductance vs. occurrence in Fig. 21. Specifically, I should be getting a peak at 5. I noticed in many of my experiments when the gap size is very small that it sometimes skips some jumps in conductance such as from 1 to 4 in Fig. 19 and sometimes there are gradual increases in conductance such as from 4 to 5 in Fig. 20. These problems can be prevented my lowering the metal deposition rate. By looking at my samples using a SEM I noticed that electroplating is not uniform. The web-like impurities (Fig. Fig. 25: SEM picture of electrodes after electroplating 25) are chunks of metal ions that got deposited. I have tried experiments with very low electrolyte concentration and low electronegativity, but it would take a long time for the gap between electrodes to close. I also encountered new problems at low metal deposition rate that required me to change my setup parameters in Table 1. I needed to lower the AC amplitude, frequency and HCl concentration. This made my experiments very sensitive to noise and vibrations. I wasn’t able to get deplating to work in my experiments. As I said before, many metal ions do not come off the surface of the electrodes when the DC voltage is Fig. 26: SEM picture of electrodes after deplating reversed (Fig. 26). I believe that there might be impurities in the solution that prevent metal ions from coming off the surface of the electrodes. - 17 - Acknowledgements: I would like to use this opportunity to thank the National Science Foundation (NSF) for funding the IM-SURE program at UCI. I would like to sincerely thank Said M. Shokair, Edward M. Olano, Sarah Martin, and the rest of the UROP team for their meritorious efforts in making this edifying experience possible. I would also like to give special thanks to John Porter for arranging me to use the SEM provided by Carl Zeiss, Inc. As a final point, I would like to express my gratitude to Professor Peter J. Burke, graduate students Lifeng Zheng and Sungmu Kang, and the rest of the Burke research group. - 18 - Work Cited Krahne, R., Yacoby, A., Shtrikman, H., Bar-Joseph, I., Dadosh, T., and Sperling, J. “Fabrication of nanoscale gaps in integrated circuits.” Applied Physics Letters 81.4 (2002): 730-732. Li, C. Z., He, H., and Tao, N. J. “Quantized tunneling current in the metallic nanogaps formed by electrodeposition and etching.” Applied Physics Letters 77.24 (2000): 3995-3997. Morpurgo, A. F., Marcus, C. M., and Robinson, D. B. “Controlled fabrication of metallic electrodes with atomic separation.” Applied Physics Letters 74.14 (1999): 2084-2086. - 19 -