Paper

MECHANOCOMPOSITES

ORGANIC SUBSTANCE – LAYERED SILICATE

N.Z. Lyakhov, T.F. Grigorieva, I.A. Vorsina, A.P. Barinova

Institute of Solid State Chemistry and Mechanochemistry of SB RAS,

Kutateladze str., 18, Novosibirsk 630128, Russia.

E-mail: Lyakhov@solid.nsc.ru

The mechanochemical approach is very efficient for the surface chemical reactions, e.g for grafting organic compounds to the surface of other substances, either organic or inorganic ones.

Mechanical activation of organic compounds causes rupture of intermolecular and intramolecular bonds; radicals are formed at break points, and the substance becomes able to interact with other compounds forming composite structures with chemical bonding between components.

Mechanochemical preparation of composites

It is known that the molecules of organic compounds containing

OH-, NH- or SH groups are bound to each other through hydrogen bonds. Hydrogen bonds are broken during mechanical activation of individual compounds but they recover very soon after the load is removed. When one carries out activation of mixtures with other compounds in which mechanical activation liberates functional groups able to react with the functional groups of organics, chemical reaction takes place on the contact surface.

Mechanochemical formation of the composites of organic acids with layered silicates was investigated.

It is known that organic acids are dimeric and form cyclic pairs with very strong hydrogen bonds between carbonyl and hydroxide groups of both molecules. The cyclic pairs of monocarboxylic acids contact each other be means of electrostatic interaction between oxygen atoms of hydroxide groups forming planar nets with motif (1)

(Scheme 1). Packets of these nets are hold together due to interplanar bonds of two types, (2 a) and (2 b).

In the plane, aromatic acids have a packing motif in which carboxylic groups of the dimers are located close to the phenyl ring with the С-Н

О distance equal to 3,5 Å; so, the molecules are bound not only

75

in cycles through hydrogen bonds of the С-О-Н

О type but also form chains due to the side С-Н О bonds; because of this, acids have layered crystal structure. These bonds result in close packing. Interlayer contacts of the types (З a) and (3 b) are typical for these acids (Scheme 1).

Scheme 1.

Mechanical activation of individual higher carboxylic acids

(including aromatic ones) does not result in any changes in the crystal and molecular structure [1, 2]. Such a behaviour was also observed for dicarboxylic, unsaturated and hydroxo acids [3, 4]. The situation for low-molecular amino acids is somewhat different; it was considered for

-glycine as an example [5]. Its molecules exist in the form of a zwitter ion; they are bound to each other with two relatively short and therefore rather strong N-Н

О hydrogen bonds to form netlike layers paralleled to the ac plane. The changes in IR spectra of

-glycine after activation are attributable to the presence of

-glycine in

-glycine. However also possible is disordering of hydrogen bonds between the double layers [6].

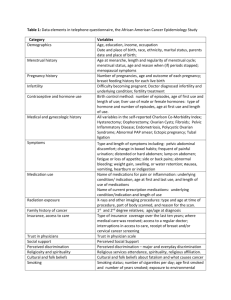

These acids exhibit quite a different behaviour in the presence of natural silicates. For instance, mechanical activation of stearic acid with kaolinite (Fig. 1) causes rather fast decrease in the intensity of bands related to the carboxyl group:

ОН 2750

2450 cm

–1

, 3300

3000 cm -1 ;

С=О 1690 cm -1 , 1710 cm -1 (shoulder), and the bands related to the vibrations of hydroxo group: 1430 cm -1 , 1300 cm -1 – deformation vibrations

(ОН + СО). At the same time, a broad diffuse band related to

ОН of water molecules appears within the range 3550

3300 cm -1 with the deformation vibration in the form of a weakly exhibited shoulder 1630 cm -1 of the 1590 cm -1 band. The bands at 1590 and 1460 cm -1 appear (the latter one appears as a shoulder of the 1475 cm -1 band); taking into account a decrease in the intensity of OH group vibraiton bands, these bands can be assigned to antisymmetric and symmetric

76

stretching vibrations of carboxylate ion, respectively. Similar changes occur in the IR spectra of the mixtures of kaolinite with other solidphase organic acids. It should also be noted that after a definite time of

Fig. 1. a- IR spectra of mixture kaolinite with stearic acid, b – these spectra in region of absorption of carboxylate ion. 1 – initial; 2 – 3 min MA;

3 – 10 min MA. activation of the mixture of kaolinite with the acid (up to 20 wt.% of the organic acid) the bands related to the vibrations of carboxyl group disappear almost completely; clear bands

ОН, ОН of water molecules

(3550

3300, 1630 cm -1 ) and carboxylate ion

as

,

s

1590, 1460 cm

–1 appear. Since mechanical activation of kaolinite causes the formation of surface centres of basic character on the newly liberated surfaces, and mechanical activation of organic acids may result in their depolymerization, then, the joint mechanical treatment of these compounds results in neutralization of the surface hydroxo groups of kaolinite by the protons of acids, and the ionized acid anion gets grafted

77

to the kaolinite surface. Mechanocomposite kaolinite – organic acid anion is formed. A similar behaviour of the solid-phase organic acids was observed during their joint activation with talc, pyrophyllite and other layered silicates [1-4, 6-9].

An evidence of the possible mechanochemical grafting of the anion to the silicate surface can be the fact that after the joint activation the crystal structure of a silicate is conserved (Fig. 1), while in the IR spectra there are bands not of organic acid, but of carboxylate ion. The diffraction patterns of a mixture of succinic acid with talc and the samples after activation for different time are shown in Fig. 2.

After treatment for 1 min, only the reflections of talc are observed. The IR spectra of the same products reveal the presence

Fig. 2. X-Ray patterns of mixture of talc with succinic acid. (a) – initial, (b) – after 10 s MA, (c) – 1 min MA. 1 – talc;

2 – succinic acid. of absorption related to carboxylate ions (Fig. 3).

High-resolution electron microscopy provides evidence of similar morphology of talc and the products of its mechanochemical interaction with succinic acid (Fig.

4) [3].

Fig. 3. IR spectra of of mixture of talc with succinic acid. (1) – initial, (2) – after 10 s

MA, (3) – 1 min MA.

Mechanocomposites of this kind are formed also between layered silicates and higher alcohols.

Alcohols, similarly to organic acids, form polymeric associations due to hydrogen bonds which are destroyed during

78

grinding and restored after the load is eliminated. This is confirmed by the IR spectra and X-ray diffraction patterns that remain almost unchanged.

During mechanical activation of a mixture of kaolinite with cetyl alcohol, the intensity of

X-ray reflections of the latter decreases sharply, while the IR spectra exhibit the formation of a new chemical bond of the type of the alcoholate one

4

, that is, not only carboxylic but also hydroxyl groups of the organic compound can interact with active surface centres

Fig. 4. Micrograph of composite of talc + succinic acid formed on kaolinite. It was noticed for the joint activation of kaolinite with hydroxy acids, for example with tartaric acid, which contains both the carboxylic and hydroxyl functional groups, that chemical interaction of kaolinite with the acid is realized only through the carboxylic group

4

.

A similar mechanochemical interaction of layered silicates as an example of talc was also observed with the salts of organic acids [10] including those with complicated cations: substituted ammonium – tertbutylamine succinate and polycation – natural mucopolysaccharide chitosan (chitosan succinate).

The X-ray diffraction patterns of the mixtures of talc with sodium benzoate, succinate, oxalate and stearate, unlike for individual compounds, even after activation for a short time (

а

= 10 s) all the reflections of salts are absent; the intensity of talc reflections decreases.

1. Sodium succinate + talc

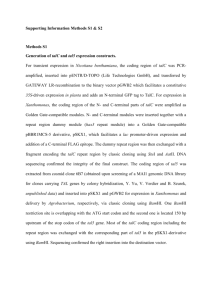

A comparison of the IR spectra of the initial and activated (

а

> 3 min) mixtures of sodium succinate with talc (Fig. 5a) reveals that: 1) in the region of antisymmetric stretching vibrations of carboxylate ions (

as

79

СОО ) a band with the maximum at 1590 cm

–1

appears instead of the band with the maximum at 1560 cm -1 (for sodium oxalate); 2) the shape and position of the band of deformation vibrations of СН

2 groups (

СН

2

) 1370

1500 cm -1 change under the action of changes in the adjacent СО groups. The position and shape of these bands are fully identical to those in the IR spectra of the activated mixture (

а

> 3 min) of succinic acid with talc (Fig. 5b).

At the same time, we observe: 1) a decrease in the intensity of the bands of stretching vibrations of

ОН groups of talc (

ОН, 3670 cm -1 ) till their complete disappearance for

Si-O of

s

-

а

Si-O-Si (670 cm -1 ), for

Fig. 5. IR spectra of mixtures of sodium succinate (a) and succinic acid

(b) with talc: 1 – initial; 2 - 5 min MA;

3 – 3 min MA.

> 3 min; 2) broadening of the bands related to

and Si-O-Si bonds (1200

850 cm -1 ) and a decrease in the intensity

а as

> 3 min the band disappears. The shape of the band of deformation vibrations of the silicon-oxygen layer of talc

(the region below 500 cm -1 ) changes substantially, which is an evidence of the deformation of talc lattice, because these vibrations are modified by the lattice vibrations.

The data obtained, including the similarity of the

IR spectra of activated mixtures of sodium succinate with talc and succinic acid

Fig. 6. IR spectra of mixtures of sodium benzoate (a) and benzoic acid (b) with talc:

1 – initial; 2 – 5 min MA. with talc within the region of

as

СОО and

СН

2 vibrations allow assuming that the mechanochemical activation of sodium succinate with talc involves substitution of hydroxyl groups of talc with the

80

succinate anion with the formation of a product similar to that formed in the interaction of succinic acid with talc. In addition, the character of changes in the parameters of IR bands related to talc in a mixture of the salt with talc activated for

3 min allows us assuming that a chemical bond is formed between the surface active centres of acidic type in talc and Na + cations, similar to the interaction between natural silicates and a basic oxide [6]. Water is formed as a result of interaction. We discovered similar mechanochemical substitution reactions resulting in the formation of chemical bonds between talc and not only acid carboxylate ion but also Na + cation when investigating the joint mechanochemical activation of talc with sodium benzoate, oxalate and stearate. The IR spectra of the mixtures of talc with sodium benzoate, the initial one and that activated for 7 min, are shown in Fig. 6; for comparison, the IR spectra of the initial and activated (

а

= 5 min) mixtures of talc with benzoic acid are shown in the same Figure. One can clearly see in Fig. 6 that the spectra of activated mixtures are identical within the regions of cm -1

as

and

s

(1570

1500 and 1500

1450

) and within the region of benzene ring vibrations 1700

1570 cm -1

.

2.Chitosan succinate + talc

It follows from the analysis of the IR spectra of the initial and activated mixtures of chitosan succinate with talc (Fig.

Fig. 7. IR spectra of mixtures of chitosan succinate (a) and TBA succinate (b) with talc: 1 – initial; 2 - 3 min MA.

7) and their comparison with the

IR spectra of activated mixtures of succinic acid and sodium succinate with talc (Fig. 5) that mechanochemical interaction of chitosan succinate with talc occurs during mechanochemical activation. The IR spectra of activated mixtures (

а

30 s) exhibit: 1) gradual shift of

СН

2 bands 1400

1450 (for

а

= 3

81

min) and

as

СОО band (carboxylate ion of succinic acid) 1560

1580 cm -1 ; 2) a decrease in the intensity of all the bands related to talc, especially the bands of ОН groups (3700

3650 cm -1 ); 3) changes in the shape of the band of deformation vibrations of talc lattice within the range 550

400 cm -1 for

а

1 min. The IR spectrum of a mixture of chitosan succinate with talc, activated for 3 min, within the spectra regions 3750

3000, 1800

1400 cm -1 , and talc vibration bands below

1200 cm -1 is almost identical with the IR spectrum of a mixture of succinic acid with talc (

а

= 1 min) and sodium succinate with talc (

а

=

3 min) (Fig. 5). The X-ray diffraction patterns of activated mixtures of succinic acid with talc and chitosan succinate with talc are almost identical, too, they differ only by an amorphous halo with a maximum about 6

, which is likely to be due to amorphized chitosan. These data allow assuming that the joint mechanical activation of chitosan succinate with talc involves substitution of hydroxyl groups of talc with the carboxylate ions of succinic acid. According to the data of highresolution electron microscopy, the product of this interaction is composed of agglomerates of plate-like particles, that is, the product conserves the structure of initial talc, similarly to the case of the product of interaction of succinic acid with talc.

Chitosan bands in the IR spectra (Fig. 7a) of the activated mixtures of chitosan succinate with talc (

а

3 min) are not observed, since, according to the data of XPA, chitosan succinate, being initially poorly crystallized, amorphizes very rapidly during activation (

а

30 s).

3.Tert-butylamine succinate + talc

The possibility for substitution reaction to proceed during mechanochemical activation of the salts of organic acids with talc is confirmed by the data of analysis of the IR spectra of activated mixtures of tert-butylamine (TBA) succinate with talc. It follows from Fig. 7b that after the activation of the mixture for 3 min, instead of the bands of initial TBA succinate in the region 1800

1300 cm -1 bands with the maxima at 1580 and 1450 cm

–1

there are two broad

, similarly to the spectra of activated mixtures of talc with sodium, chitosan succinates and with succinic acid (compare Fig. 7 and Fig. 5).

82

Capacity of silicates in the reaction with organic acids

Thus obtained nanocomposites can be used as nutrition additives and active components in curative cosmetics. In this case, the question concerning the capacity of silicates becomes urgent; silicate capacity is here understood as the silicate : acid molar ratio (m.r.) with which the mechanochemical neutralization proceeds till completeness. This ratio defines maximal possible concentration of the active substance in the composite. It is also important to study the return of grafted biologically active substances.

Mechanochemical interaction of organic acids with talc

It follows from the analysis of spectra (Fig. 8) that the capacity of talc in mechanochemical reactions with monocarboxylic acids with the talc to the acid m.r.

1 : 1 is defined by the nature of acids. This means that only 50 % or less of hydroxyl groups of talc can participate in mechanochemical interaction with the protons of carboxylic groups of saturated and aromatic acids. For unsaturated crotonic acid, the capacity of talc is maximal, m.r. talc : acid = 1 : 2, that is, almost all the hydroxyl groups of talc participate in neutralization with the protons of carboxylic groups. Indeed, bands related to the vibrations of carboxylic groups of acids are absent from the IR spectra:

1800

1650 cm

–1

, but there are the bands related to carboxylate ions:

- 1650

1550 cm -1 ;

ОН - 3000

2450 cm -1 ;

С=О -

as s

- 1400

1300 cm -1

1-3, 6, 10

. At the same time, the intensity of

ОН band of talc at 3670 cm -1 decreases. The parameters of characteristic bands of talc do not exhibit substantial changes. Clear changes in the shape of the band of deformation vibrations of the layer at 550

440 cm -1 provide evidence that definite deformation of lattice occurs in the reaction product. The x-ray diffraction patterns of these mixtures do not contain reflections corresponding to acids; reflections of talc are broadened and shifted but no more than by 5 % with respect to the position in the X-ray diffraction patterns of the initial talc. According to the data of electron microscopy, the mechanocomposite formed as the reaction product is composed of plate-like nanometer-sized particles in which Ме ions of the silicate are chemically bound with carboxylate ions of the organic acid

1-3, 6

.

The IR spectra of activated mixtures of talc with monocarboxylic saturated and aromatic acids at the m.r. > 1 : 1 and 1 : 2, along with

83

vibration bands of carboxylate ion ,

as

,

s

COO , contain the bands characteristic of carboxylic group:

С=О and

ОН, as well as

ОН of talc (Fig. 8, b, d). The X-ray diffraction patterns of these samples contain reflections belonging not only to talc and to mechanocomposite but also rather intensive reflections of unreacted acid. These facts provide evidence that mechanochemical reaction in these mixtures proceeds not till completion.

Fig. 8. IR spectra of mixtures of talc with acids: stearic (a), lauric (b), crotonic

(c), salicylic (d). M.r. talc : acid 1 : 0,5 (a), 1 : 2 (b), 1 : 2 (c), 1 : 1 and

1 : 2 (d). Time MA, min: 1 – 0, 2 – 5, 3 – 7, 4 – 9.

84

Dicarboxylic acids, independently of their nature (saturated, unsaturated, hydroxy), interact with talc for m.r. = 1 : 1, that is, for the molar ratio of such a kind with which the number of hydroxyl groups of

Fig. 9. IR spectra of mixtures of talc with acids: succinic (a), suberic (b), fumaric (c), citric (d). M.r. talc : acid 1 : 1; for citric acid 3 : 2. Time

MA, min: 1 – 0, 2 – 3, 3 – 5, 4 – 13.

85

Mg

3

(Si

4

O

10

)(OH)

2

silicate is equal to the number of carboxyl groups of R(COOH)

2

. For tricarboxylic citric acid (OH)C(CH)

2

(COOH)

3 such an interaction with talc occurs for m.r. = 3 : 2. Indeed, the IR spectra of activated mixtures (Fig. 9) contain no bands characterizing the vibrations of carboxyl group of the acid

ОН - 3250

2450 cm -1 ,

С=О

– 1800

1650 cm -1 ; the band of stretching vibrations of talc hydroxyl groups disappears almost completely:

ОН – 3670 cm -1 . The IR spectrum of the product of mechanochemical interaction of talc with multicarboxylic acid contains the bands of carboxylate ion:

1650

1550 cm -1 ,

s

СОО as

СОО -

- 1400

1300 cm -1 ; the bands corresponding to the stretching vibrations of Si-O and Si-O-Si bonds of talc, respectively,

- 1020, shoulder at 1040 and a band at 670 cm -1 somewhat broaden; while their maxima shift by 10-15 cm -1 . The participation of weakly acidic Si-OH groups of talc along with Mg-OH groups in neutralization with multicarboxylic acids is likely to cause some strengthening of Si-O bonds and weakening of Si-O-Si bonds with the corresponding obvious shift of

Si-O and

as

Si-O-Si bands to higher-, and

s

Si-O-Si to lowerfrequency regions of the spectrum.

Since deformation vibrations of the silicon-oxygen layer are modified by lattice vibrations, changes in the parameters of the band corresponding to these vibrations (the region within 550

400 cm -1 ) are more important in this case since they provide evidence of the deformation of talc lattice in the mechanocomposite.

In the diffraction patterns of these samples, the reflections related to acids are absent, while the reflections of talc are substantially broadened and shifted (depending on the nature of an acid) but not more than by 4 % with respect to the position in the initial talc. A similar picture is observed for a mixture of talc with crotonic acid for m.r. = 1 : 2. The data obtained allow us to assume that a mechanocomposite retains the type of crystal structure of the initial talc

(Fig. 9). This assumption is confirmed by the data of high resolution electron microscopy according to which the composite of talc with succinic acid is composed of agglomerates of plate-like particles

10

.

The differences in the interaction of talc with mono- and multicarboxylic acids during their joint activation can be understood if we take into account the following considerations. Talc belongs to layered silicates of 2 : 1 type having the only kind of Oh groups which

86

are interlayer hydroxy groups: weakly acidic Si-OH and basic Mg-OH, which are situated only at the side faces and edges of plate-like particles.

It is necessary to note that under definite conditions, namely, for рН < 2,

Si-OH groups can play the part of basic ones. Because of this, it may be assumed that the acidity of reaction medium becomes pH < 2 during mechanical activation of multicarboxylic acids and monocarboxylic unsaturated acid due to dissociation of the acids. As a result, Si-OH groups can participate in neutralization as basic groups. Alcohol hydroxyl groups of acids do not participate in chemical reactions of neutralization with talc as they are typical ol-groups. The duration of mechanochemical interaction

а

of talc with carboxylic acids is determined by the nature of an acid.

Mechanochemical interaction of organic acids with kaolinite

Unlike talc, kaolinite which is an octahedral mineral of 1 : 1 type has at least four kinds of ОН groups; four bands in the region of

ОН vibrations correspond to them: 3695 cm -1 – intralayer ОН groups, 3670,

3650, 3620 – ОН groups of the external net of a layer; they form hydrogen bonds of different energy with oxygen atoms of the adjacent layer.

Unlike talc, both the basic Al-OH and acid Si-OH groups are situated not only on the side faces but also on the basal (001) ones. It is important to note that the side faces account for only 10-15 % of total surface, depending on the disperse state of particles; hence, more than

80 % of all the OH groups are on the basal faces of kaolinite.

It follows from the analysis of the IR spectra of initial and activated mixtures of kaolinite with carboxylic acids that mechanochemical neutralization of the OH groups of kaolinite by the protons of СООН groups of acids takes place for saturated monocarboxylic and aromatic acids for the m.r. of kaolinite to an acid

1 : 0,25, for di-, tricarboxylic acids and for unsaturated monocarboxylic acid m.r.

1 : 0,5. This is confirmed by the fact that the IR spectra of reaction products do not contain the bands characteristic of the carboxyl group of the acid:

ОН - 3400

2450 cm -1 ,

С=О - 1800

1650 cm -1 , but contain the bands of carboxylate ion:

as

1620

1550 сm -1 ,

s

1450

1300 сm -1 and

ОН - 3700

3000 cm -1 of molecular water. At the same time, the intensity of

ОН and

ОН bands of kaolinite decreases noticeably, within the ranges 3750

3600 cm -1 and 950

900 cm -1 ,

87

respectively; their shape changes [10]. The intensity and shape of the characteristic bands of kaolinite in the regions 1150

950 and 850

750 cm -1 change significantly (Figs. 10 and 11).

The X-ray diffraction patterns of activated mixtures of kaolinite and monocarboxylic acids, saturated and aromatic ones with the m.r.

1 : 0,25 contain only kaolinite reflections. In the case of mixtures of kaolinite with acids (monocarboxylic unsaturated and multicarboxylic ones) the reflections of acids are absent from the diffraction patterns for m.r.

1 : 0,5, while for kaolinite we observe a sharp decrease in intensities, shift and broadening of reflections.

Taking into account the above considerations, we may assume that mechanical activation of kaolinite with saturated and aromatic monocarboxylic acids involves neutralization of only Al-OH groups of the side faces of the silicate by acid protons. The hydroxyl groups of basal faces, being typical ol-groups, do not participate in the mechanochemical neutralization in this case.

Fig. 10. IR spectra of mixtures of kaolinite with acids: succinic (a), maleic (b), tartaric (c). M.r. kaolinite : acid = 1 : 1 and 1 : 0.5 (a); 1 : 0.25 and 1 : 2 (b);

1 : 0.75 (c). Time MA, min: 1 – 0, 2 – 1, 3 – 3, 4 – 5, 5 – 7.

88

Fig. 11. IR spectra of mixtures of kaolinite with acids: lauric (a), crotonic (b), benzoic (c). M.r. kaolinite : acid = 1 : 0.25 (a) and (c); 1 : 0.5 (b). Time

MA, min: 1 – 0, 2 – 1, 3 – 3, 4 – 5, 5 – 7.

Dissociation of unsaturated monocarboxylic and multicarboxylic acids in the reaction mixture with kaolinite during their joint activation and the presence of water as a product of mechanochemical interaction between components results in pH differing from the neutral one (a similar picture is observed during mechanical activation of the indicated acids with talc). It may be assumed that this creates conditions for the participation of Al-OH groups (001), as well as ( hkl ) faces of kaolinite, in mechanochemical neutralization with soluble monocarboxylic

89

unsaturated acid and with multicarboxylic acids. In this case m.r. kaolinite : acid

1 : 0,5. The presence of four types of hydroxyl groups, strong hydrogen bonds of different energies, and the location of acid and basic OH groups not only on edges and side faces (~ 10-15 %) but also on basal planes (more than 80 %) excludes the possibility to change the behaviour of acidic Si-OH groups, that is, to make them play the part of basic groups, as it was the case for talc. That is why even for MA with well dissociating multicarboxylic acids the maximal capacity of kaolinite m.r. kaolinite : acid

1 : 0.5.

Solubility of mechanocomposites

In order to investigate the solubility, 0.4 g of a mechanocomposite was placed into 25 ml of an aqueous solution of hydrochloric acid (рН

1) at room temperature. The mixture was stirred continuously (the frequency of rotation of the magnetic mixer was ~ 80 rpm). Dissolution was performed within a definite time interval 1.0

d

120 min. After that, the sample was centrifuged; concentration (%) of acid anions was determined in the aqueous fraction by means of voltammetry [13].

Relative error of the determination of A, %

100 concentration of acids does not exceed

7 %.

No effect of talc and

99

98

97 kaolinite on the signal height has been detected. Specific

96

95

94

1

2

3

4 surface of the

93 composites was

92 determined by means

91 of argon desorption at

Т = 77 K (liquid

90

0 1 2 3 4 5 6 7 8 9 10

Dissolution time, min nitrogen) from the powder surface

Fig. 12. The dynamics of dissolution of talc-based mechanocomposites of succinic (3, 4) and tartaric

The dynamics of the transition of acid

(1, 2) acids with various activation time, min: 1 – 1;

2 – 3, 3 – 5, 4 – 7. anions from composite

90

into solution is shown in Fig. 12 and 13 (

А

is concentration of acid anions, %;

d

is dissolution time).

It follows from Fig. 12 that in the case of talc-based mechanocomposites the acid anions get detached and pass into solution almost completely within

s

1 min, both for the samples containing free acid and for the samples containing no free acid, i.e., taken before or immediately after the mechanochemical reaction [3]; activation time was

а

5 min and

а

3 min мин for succinic and tartaric acid, respectively

(

а

is activation time).

Quite a different phenomenon is observed for kaolinite-based mechanocomposites. In the case of composites of succinic acid sampled at the initial stages of mechanochemical interaction, at

а

1,0 min, containing substantial amount of the unreacted acid

3

, the anions of the free acid pass into solution almost from the very beginning of dissolution process (Fig. 13, curve 1). With a decrease in the concentration of unbound acid in the samples (i.e., with an increase in activation time), the transition of the ions into solution slows down. For samples containing no free acid (i.e., sampled after the completion of the mechanochemical reaction) and further activated,

а

= 5 and 7 min, the rate of the transition of acid anions into solution depends both on dissolution time and on activation time (Fig. 13, curves 3, 5). The disperse state (specific surface) of the samples increases during activation. It reaches its maximum after the completion of the mechanochemical reaction (

а

= 5 min). However, these samples exhibit the lowest solubility (Fig. 13, curve 3). With longer activation time, the solubility of samples increases (Fig. 13, curves 4, 5). The observed decrease in specific surface is likely to be connected with the secondary aggregation which does not affect the solubility, because the dissolution was performed under continuous agitation.

While the [А] = f( d

) dependencies for the talc-based mechanocomposites of succinic and tartaric acids are almost identical

(Fig. 12), they are substantially different from each other for kaolinitebased mechanocomposites (Fig. 13). For the samples taken before completion and immediately after completion of the mechanochemical interaction (

а

3 min) the tartaric anions pass into solution almost completely within 1 min, similarly to the case of talc-based mechanocomposites.

91

The character of dissolution of the talc- and kaolinite-based

100

A, %

70

60

50

90

80

40

30

20

0

3

4

5

1

2

20 5 10 15

Dissolution time, min

Fig. 13. The dynamics of dissolution of kaolinite-based mechanocomposites succinic (1, 3-5) tartaric (1, 2) acid with various activation time, min: -

1 – 1, 2 – 3, 3 – 5, 4 – 7, 5 – 9. mechanocomposites of succinic and tartaric acids is due both to the features of the crystal structure of silicates determining the structure and composition of mechanocomposites, and to the features of structure and properties of acids.

Mechanocomposites can be conventionally represented as the compounds: talc – succinic acid: [Mg

3

(Si

4

O

10

)] 2+

(COO )

2

R; talc – tartaric acid: [Mg

3

(Si

4

O kaolinite – succinic acid: [2Al

10

2

)]

(Si

2+

(COO )

2

(ОH)

2

R;

2

O

5

)(OH)

3

] kaolinite – tartaric acid: [2Al

2

(Si

2

O

5

)(OH)

3

] 2+

2+

(COO -

(COO )

2

)

2

R;

(ОН)

2

R.

92

It may be assumed that the anions of succinic and tartaric acids in talc-based composites are bound with the cation mainly by electrostatic forces and can be easily extracted into the low acidic solution (within 1 min) dissociating almost completely according to the strong electrolyte type. In kaolinite-based composites of succinic acid, the bonding strength of the bond between cation and anion can be increased due to the formation of hydrogen bonds between the OH groups of kaolinite and acid anions. Because of this, anions pass into solution slower; they do it gradually within 20 min. The presence of hydroxy groups in the structure of tartaric acid is likely to prevent the formation of hydrogen bonds with kaolinite. As a result, the anions of tartaric acid pass into solution easily, similarly to talc-based composites. This assumption is confirmed by the fact that acid anions pass into solution within 1 minute independently of activation time in the presence of unreacted acid in composite (kaolinite: tartaric acid m.r. = 1 : 2).

Investigation of the dissolution of mechanocomposites

(detachment of acid anions and their transition into solution ) was carried out for the example of composites containing the anions of succinic and tartaric acids.

Conclusions

1.

It is demonstrated that mechanochemical activation of organic acids, their salts and polyhydric alcohols with natural layered silicates

(kaolinite, talc) is accompanied by substitution of hydroxyl groups of silicates with the anions of organic acids. As a result, homogeneous nanocomposites are formed, in which the support, i.e. natural silicate, is chemically bound with the biologically active compound.

2.

The capacity of a silicate (the maximal amount of the biologically active substance that gets attached to the silicate) depends both on the silicate nature and on the nature of the biologically active additive.

3.

The capacity of talc is maximal in the reactions with well dissociating acids. The molar ratio talc : acid = 1 : 2; 1 : 1 and 3 : 2 for the composites with mono-, di- and tribasic acids.

4.

The molar ratio of kaolinite to an acid with well dissociating acids is

1 : 0,5.

93

5.

For the composites with saturated and aromatic acids, the molar ratio talc : acid ≤ 1 : 1, while the molar ratio kaolinite : acid ≤ 1 :

0,25.

6.

The dynamics of dissolution of mechanocomposites depends both on the nature of an acid and on the nature of the silicate. For talc-based composites containing succinic and tartaric acids, detachment of acid anions and their transition into solution occur within ~ 1 minute.

In the case of kaolinite-based composites, the anions of tartaric acid pass into the solution within the same time (1 minute), while the anions of succinic acid do this much slower: within 20 minutes.

7.

The data obtained can be used as a basis for the development of new medical products and biologically active nutrition additives, including multi-functional ones and those possessing prolonged action, using a rapid and ecologically safe mechanochemical procedure.

References

1.

Grigorieva T.F., Vorsina I.A., Barinova A.P., Boldyrev V.V.

Mechanochemical synthesis of dispersed composites on base of kaolinite and high carbon acids. Doklady Akademii nauk, 1995, v.

341, № 1, p. 66-68.

2.

Grigorieva T.F., Vorsina I.A., Barinova A.P., Boldyrev V.V.

Mechanochemical synthesis of dispersed composites on base of kaolinite and organic and inorganic acids. IR Spectroscopy investigation. Neorganicheskie materially. 1996, v. 32, № 2, p.

214-220.

3.

Vorsina I.A., Grigorieva T.F., Barinova A.P., Lyakhov N.Z.

Mechanochemical obtaining of succinic acid preparate. Chemistry for sustainable development, 2000, v. 8, № 6, p. 783-788.

4.

Grigorieva T.F., Vorsina I.A., Barinova A.P., Lyakhov N.Z.

Mechanocomposites – a new materials for solid cosmetics.

Chemistry for sustainable development, 2004, v. 12, № 2, p. 139-

146.

5.

Jonsson P.-G., Kvick A. Precision Neutron Diffraction Structure

Determination of Protein and Nucleic Acid Components. III. The crystal and molecular structure of the amino acid

-glycine. Acta

Crystallogr., B, 1972, N 28, p. 827-1833.

94

6.

Grigorieva T.F., Vorsina I.A., Barinova A.P., Lyakhov N.Z.

Interaction in system kaolinite + aminoacetic acid at joint activation. Neorganicheskie materially, 1997, v. 33, N 8, p. 997-

1000.

7.

Grigorieva T.F., Vorsina I.A., Barinova A.P., Boldyrev V.V. Solid state interaction of kaolinite and acids during joint mechanical activation J. Mater. Synth. and Proc.,1996, v. 4, No 5, p. 299-305.

8.

Grigorieva T.F., Vorsina I.A., Barinova A.P., Boldyrev V.V.

Mechanochemical synthesis of dispersed composites on base of kaolinite. «Mechanochemistry and mechanical activation», reports on International Workshop. Sankt-Peterburg, 1995. P. 6.

9.

Grigorieva T.F., Vorsina I.A., Barinova A.P., Boldyrev V.V.

Mechanochemical activation of the kaolinite with the solid state acids. XIII Int. Symp. on Reactivity of Solids, Hamburg, 1996.

Abstracts. I-PO-132.

10.

Vorsina I.A., Grigorieva T.F., Barinova A.P., Lyakhov N.Z.

Mechanochemical interaction in systems with biologically active substances. Chemistry for sustainable development, 2000, v. 8, №

5, p. 679-684.

11.

Vorsina I., Barinova A., Lyakhov N. About “capacity” of layered silicates in mechanochemical reactions with organic acids.

Chemistry for sustainable development, 2004, v. 12, № 3, p. 303-

311.

12.

Vorsina I., Tarasova V., Barinova A., Lyakhov N. The solubility of nanocrystalline mechanocomposites with biologically active substances in the aqueous medium. J. Mater. Sci., 2004, v. 39, N

16-17, p. 5357-5359.

13.

Kletenik Yu., Polyakin L., Bek R., Zamyatin A. Izvestiya SO AN

SSSR, ser.khim. 1985, N 1, p. 93-96.

95