Section 203A - Road Storm proofing

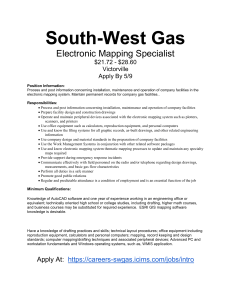

advertisement

METRIC SPECIAL PROJECT SPECIFICATION SECTION 203A --- ROAD STORM PROOFING April 24, 2000 Description 203A.01 Work. This work will consist of preparing the road to better withstand storm events and to be less dependent on recurrent road maintenance. It will include construction items SHOWN ON THE DRAWINGS, designated in the SCHEDULE OF ITEMS, and other associated incidental work. For the purpose of this specification the project Work List is considered part of the Drawings. Construction 203A.02 Clearing and Slash Treatment. Clearing may be necessary in order to complete a work item. Remove vegetation from roadway prior to excavation and placement of excavated material. Unless otherwise shown on SCHEDULE OF ITEMS, clearing is incidental to other pay items and will not be paid separately. (a) Performance. When clearing is needed, it shall be accomplished as follows: (1) Clearing slash shall be scattered on disturbed areas and shall not be incorporated in embankment material unless otherwise SHOWN ON THE DRAWINGS. (2) Unless otherwise SHOWN ON THE DRAWINGS, the materials generated will not need to be limbed and lopped. (3) Materials shall be positioned in a stable position to prevent rolling. (4) Generated Materials that create such a deep or thick mat that they will prevent seeding, ripping, or other ground surface treatments called for shall be further scattered or moved off disturbed areas. (5) Any timber encountered and commonly considered merchantable shall be treated under “Utilization of Timber.” (b) Utilization of Timber. Merchantable timber is timber that meets utilization standards as follows: (1) Logs and poles that are at least one third sound, having a minimum diameter of 250 mm under the bark and a minimum length of 2.5 m (plus trim) shall be considered merchantable timber. R6/SPS 203A ROAD STORMPROOFING 4/24/00 1 (2) Merchantable timber shall be decked at locations SHOWN ON THE DRAWINGS or marked on the ground. Decks shall be stable and relatively free from brush and soil. 203A.03 Salvaging Aggregate. When shown on the SCHEDULE OF ITEMS suitable existing aggregate shall be salvaged as SHOWN ON THE DRAWINGS and marked on the ground. Salvaged aggregate shall be hauled to and placed in approved stockpiles at designated sites SHOWN ON THE DRAWINGS. Rocks larger than 100 mm, and woody material larger than 50 mm in diameter or more than 600 mm long, and concentrations of finer woody material shall be removed as much as practicable prior to salvaging. This work is incidental to salvaging aggregate and will not be paid separately. Salvaging aggregate shall be accomplished to within 600 mm of the cut slope or ditch and 600 mm of the outer edge of the road surface unless otherwise SHOWN ON THE DRAWINGS. Haul will only be measured and paid when Cubic Meters is shown as a pay unit on SCHEDULE OF ITEMS, and meets the requirements for Haul under 203A.18 Method, paragraph (e). 203A.04 - Rolling Dip. Rolling Dips are drivable. Rolling dips shall be constructed and located as SHOWN ON THE DRAWINGS and as specified below. Dip construction shall include up to 10 m of leadoff ditch where required and the restoration of any surfacing and base course existing prior to dip construction. Lead-off ditch, and salvaging and replacing base course and surfacing will be considered incidental to Rolling Dip construction and will not be measured or paid separately. 203A.05 - Drainage Dip. Drainage dips may or may not be drivable; refer to THE DRAWINGS for construction details and dimensions. Drainage dips are similar to Rolling Dips except they may or may not be drivable when completed. Drainage dips shall be constructed and located as SHOWN ON THE DRAWINGS. Dip construction shall include up to 10 m of lead-off ditch where required and when SHOWN ON THE DRAWINGS, and the restoration of any surfacing and base course existing prior to dip construction. Leadoff ditch, and salvaging and replacing base course and surfacing will be considered incidental to Drainage Dip construction and will not be measured or paid separately. Construction requirements for both Rolling Dips and Drainage Dips: (a) Construction. Often, existing aggregate will need to be removed, stockpiled, and relayed after subgrade of dip is constructed, compacted, and approved. Unless otherwise SHOWN ON THE DRAWINGS, when road has existing aggregate, the dip shall be finished with at least 150 mm thickness of surface aggregate when completed. This total thickness shall include salvaged aggregate and new aggregate as needed. New aggregate will only be measured and paid separately when shown on SCHEDULE OF ITEMS. All suitable material excavated shall be used in the construction of the dip. Widths shall be as SHOWN ON THE DRAWINGS, and not less than those in adjacent areas of the roadbed. R6/SPS 203A ROAD STORMPROOFING 4/24/00 2 When watering is specified on the SCHEDULE OF ITEM (Section 207) or in these specifications, material being worked shall be surface damp throughout the mixture. The Contractor may use any water source approved by the Contracting Officer (CO). Any special access and operating procedures will be SHOWN ON THE DRAWINGS or contract provisions. Contractor shall furnish all equipment, labor and materials needed to load, haul and apply the water. Unless otherwise SHOWN ON THE DRAWINGS, no unsuitable material, including vegetative material, shall be used in dip construction. All unsuitable material, including minor clearing slash, shall be scattered with no concentrations on fill slopes, unless otherwise SHOWN ON THE DRAWINGS. The CO shall approve the sub-grade in writing before placing base or surface course. Unless otherwise SHOWN ON THE DRAWINGS, and when the road is paved in the area of dip construction (chip-seal or asphalt concrete paving), the asphalt portion shall be removed or pulverized prior to dip construction and the dip shall be paved when finished. When pulverized it shall be reused as part of the base course, unless otherwise SHOWN ON THE DRAWINGS. When the paving is removed it shall be disposed of in locations SHOWN ON THE DRAWINGS. (b) Compaction. When the surfacing is native or aggregate, compact the subgrade by operating spreading and hauling equipment over the full width of each layer of the subgrade. When the surface will be paved, moisten or dry the material to a uniform moisture content suitable for compaction. Operate rollers that meet the requirements specified in Subsection 203.15(b), (c), or (d) over the full width of each layer until visual displacement ceases, making no fewer than three complete passes. Aggregate under pavement shall be compacted as specified above for a paved surface. The CO shall approve the base-course in writing before placing paving material. (c) New Aggregate. New aggregate shall be certified to meet the requirements of Subsection 703.05, grading C, D, or E for bases; and grading C, D, E, F or G for Surface Courses, as SHOWN ON THE DRAWINGS. When crushed aggregate is from a Government source the Government certifies its quality and gradation, but the contractor is responsible to maintain that quality and gradation into the work. (d) Paving. When the original paving was a chip seal over aggregate, the finish shall be either a double chip seal meeting the requirements of Subsection 410 Asphalt Surface Treatment; or a 50 millimeter thickness of cold mix or hot mix meeting the requirements of Subsection 403 Minor Hot Asphalt Concrete Pavement or 405 Minor Cold Asphalt Concrete Pavement over the base, unless otherwise SHOWN ON THE DRAWINGS. When paving was hot or cold mix asphalt, the finish shall be either hot or cold mix asphalt, unless otherwise SHOWN ON THE DRAWINGS. The thickness of asphalt shall be the thickness of the original asphalt, but in no case less than 50 mm. R6/SPS 203A ROAD STORMPROOFING 4/24/00 3 (e) Finishing. Finish the surface of rolling dips, outsloping, and drainage dips to be reasonably smooth, uniform, and shaped to conform to the typical sections as SHOWN ON THE DRAWINGS. Remove unsuitable material from the roadbed and replace it with suitable material. Finish roadbeds to a reasonable tolerance and smoothness that matches that in adjacent areas of the road. 203A.06 Cross Ditches. When cross ditches are specified in the schedule of items, they shall be constructed as SHOWN ON THE DRAWINGS. Special treatment of the existing aggregate is not required, but caution must be used to avoid loss, or unnecessarily displace or damage the existing aggregate. 203A.07 Waterbars. When waterbars are specified in the SCHEDULE OF ITEMS, they shall be constructed as SHOWN ON THE DRAWINGS. Special treatment of the existing aggregate is not required, but caution must be used to avoid loss, or unnecessarily displace or damage the existing aggregate. 203A.08 Flared End Sections. When flared end sections are specified in the SCHEDULE OF ITEMS, they shall be furnished and installed as SHOWN ON THE DRAWINGS and in accordance with manufacturer’s instructions. When SHOWN ON THE DRAWINGS existing culverts shall be cut off as indicated and flared metal end section installed. In all cases backfilling and compaction is required to fully support the installation. Backfill material shall be obtained from sources SHOWN ON THE DRAWINGS or within 300 m of installation as directed by CO. End Section material shall match the material of the culvert upon which it is installed. 203A.09 Drop Inlets. When Drop Inlets are specified in the SCHEDULE OF ITEMS, they shall be furnished and installed as SHOWN ON THE DRAWINGS. In all cases backfilling and compaction is required to fully support the installation. Backfill material shall be obtained from sources SHOWN ON THE DRAWINGS or within 300 m of installation as directed by CO. Drop Inlet material shall match the material of the culvert upon which it is installed, unless otherwise approved by the CO. 203A.10 Earthen Barrier. Earthen Barriers shall be constructed as SHOWN ON THE DRAWINGS. 203A.11 Recontouring. Recontouring shall be completed and located as SHOWN ON THE DRAWINGS. Recontouring is replacing the excavation material with the embankment material to approximate the original shape of the ground prior to road construction. It is not intended to import material to fill the excavation area. 203A.12 Outsloping. Designated roads or segments shall be outsloped by pulling material from the road fill section towards the backslope. Pullback material shall be spread over the roadbed and ditch forming a minimum outslope equal to the grade and dimensions SHOWN ON THE DRAWINGS. Any existing ditches at the toe of the backslope shall be filled with material excavated for outsloping. Unless otherwise SHOWN ON THE DRAWINGS aggregate shall be removed and replaced after construction and compaction is finished to restore the R6/SPS 203A ROAD STORMPROOFING 4/24/00 4 finished roadbed. Reshaping and resurfacing, except paving, shall be handled according to Construction requirements of paragraph 203A.05 (a), (b), (c), and (d). Pavement sections to be outsloped will be SHOWN ON THE DRAWINGS. Existing asphalt shall be swept clean, a suitable tack coat applied, and asphalt of the type SHOWN ON THE DRAWINGS applied to the inside edge to form the slope, lengths, and tapers of outslope SHOWN ON THE DRAWINGS. Surfacing, and compaction shall be handled according to Construction requirements shown in paragraph 203A.05 (d) above. 203A.13 Embankment Pullback. Designated roads or segments shall have embankment pulled back to limits and slopes SHOWN ON THE DRAWINGS. Excavated material shall be placed at designated locations SHOWN ON THE DRAWINGS, sloped to drain, and left in an uncompacted condition, unless otherwise SHOWN ON THE DRAWINGS. When shown on SCHEDULE OF ITEMS, haul over 0.2 km will be paid for entire distance hauled, one-way. 203A.14 Riprap. Riprap shall be furnished and installed at locations and to dimensions and thickness SHOWN ON THE DRAWINGS. Use sources SHOWN ON THE DRAWINGS or commercial sources. (a) Material. Material shall meet requirements in the following subsections: Geotextiles, Type IV (A, B, C, D, E, or F; Table 714-4) ........... Riprap Rock ................................................................................... 714.01 705.02 Provide certification that the material meets the material quality requirements of these specifications, unless material is from Government Sources. The Government assumes responsibility for material quality when Government Sources are specified. (b) Construction. Control gradation by visual inspection. Rock shall be placed on a prepared surface to form a well-graded mass. Place riprap to its full thickness in one operation to avoid displacing the underlying material. Do not place riprap material by methods that cause segregation or damage to the prepared surface. Place or rearrange individual rocks by mechanical or manual methods to obtain a compact uniform blanket with a reasonably regular, even surface. (c) Geotextile. When SHOWN ON THE DRAWINGS, place geotextile in accordance with Section 241.11 and as SHOWN ON THE DRAWINGS. Geotextile is considered incidental to riprap and will not be measured or paid separately. 203A.15 Leadoff Ditch. Install Leadoff Ditches as SHOWN ON THE DRAWINGS. 203A.16 Slide or Slump Repair. When SHOWN ON THE DRAWINGS, remove slides, slough, loose rock, and debris to provide a clean and safe roadbed to adjacent widths as SHOWN ON THE DRAWINGS. Material shall be disposed of as SHOWN ON THE DRAWINGS, or within 300 m as directed by the CO. Washouts or slumps in the roadbed shall be repaired where, and as SHOWN ON THE DRAWINGS. R6/SPS 203A ROAD STORMPROOFING 4/24/00 5 203A.17 Culvert Cleaning. When SHOWN ON THE DRAWINGS, the inlet and outlet ends, as well as one half meter inside each end of existing culverts, shall be cleaned to provide unobstructed flow of water. Excess material further inside the culvert shall be noted and the CO shall be notified with a location of the problem. (a) Ditch Relief Culverts Clear trees, brush, and debris that restrict the flow of water for 3 pipe diameters in length and 2 pipe diameters in width from each end. Scatter slash without concentrations below the road, but at least 10 m from any stream. Catch basins shall be cleaned of excess material above the invert of culvert or above floor of culvert basin to dimensions shown above. Excess material shall be used in ditch block, or as SHOWN ON THE DRAWINGS. (b) Natural Drain Culverts When SHOWN ON THE DRAWINGS, channels shall be cleaned and shaped to natural streambed with constant grade at the inlet and outlet ends. This channel shall be cleared of all trees, limbs, brush, stumps, rocks and other debris that restrict the flow of water for 3 pipe diameters in length and 2 pipe diameters in width from each end. Slash shall be scattered so as not to enter the channel, drainage ditch, or the roadbed. Measurement 203A.18 Method. Use the method of measurement that is designated in the SCHEDULE OF ITEMS. Only those items listed in the SCHEDULE OF ITEMS will be measured. (a) Measurement for Pay Items with Pay Unit as EACH will be the actual count of the number of items of those designated by the Government, and installed or constructed by the Contractor. (b) Measurement for Pay Items with Pay Units as KILOMETERS will be measured along the centerline of the roadway from the beginning of that work to the end of that work. Distance will be measured to the nearest one-hundredths (0.01) kilometer as measured with a FS odometer. (c) Measurement for Pay Items with Pay Units as CUBIC METER will be by the Design Quantity cubic meter compacted in place and specified in the SCHEDULE OF ITEMS and will be measured by any standard method used to measure this unit to the nearest whole cubic meter for areas calling for 3 cubic m or more and to the nearest one-tenth (0.1) cubic meters for those areas calling for less than 3 cubic m. (d) Measurement for Pay Items with Pay Units as METER will be measured along the centerline of the roadway from the beginning of that work to the end of that work. Distance will be measured to the nearest one meter. (e) Haul will not be computed when the total haul distance is equal to or less than 0.2 km. But when that distance exceeds 0.2 km, measurement for Haul Pay Items with Pay Units as R6/SPS 203A ROAD STORMPROOFING 4/24/00 6 CUBIC METER-KILOMETER will be the Design Quantity determined by the total number of km hauled times the cubic meters removed and hauled. Distance will be measured one way rounded to the nearest one-hundredth (0.01) kilometer. Measurement will be the centerline distance from center-of-mass of haul source to center-of-mass of designated waste area or stockpile. Units will be shown to the nearest whole cubic meter-kilometer. R6/SPS 203A ROAD STORMPROOFING 4/24/00 7 Payment 203A.19 Basis. The accepted quantities will be paid for at the contract unit price for each PAY ITEM DESIGNATED IN THE SCHEDULE OF ITEMS. Payment will be made under: Pay Item Pay Unit 203A(03)a Salvaging Aggregate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Kilometer 203A(03)b Salvaging Aggregate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cubic Meter 203A(04) Rolling Dip Constructed, Surfacing Type______. . . . . . . . . . . . . . Each 203A(05) Drainage Dip Constructed, Surfacing Type______. . . . . . . . . . . . Each 203A(06) Cross Ditch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Each 203A(07) Waterbar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Each 203A(08) Flared End Section - mm . . . . . . . . . . . . . . . . . . . . . . . . . . Each 203A(09) Drop Inlet, -mm . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . Each 203A(10) Earthen Barrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Each 203A(11)a Recontouring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Each 203A(11)b Recontouring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Meter 203A(12) Outsloping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . 203A(13)a Embankment Pullback. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Kilometer Kilometer 203A(13)b Embankment Pullback. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cubic Meter 203A(14) Meter Riprap, Class ..................................... 203A(15) Leadoff Ditch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cubic Meter 203A(16)a Slide or Slump Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cubic Meter 203A(16)b Slide or Slump Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Each 203A(17) Cleaning Culverts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Each 203A(18e) Kilometer Haul (over 0.2 km). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . R6/SPS 203A ROAD STORMPROOFING 4/24/00 8 Cubic Meter- INTENT AND USE GUIDE This specification is for use only on Road Storm Proofing projects. Other projects should use the standard specifications and/or Road Decommissioning Specification. 203A.03 Use Salvage Aggregate only on POC clean sites. If there is any chance of needing to change the stockpile site after contract is awarded, use Cubic Meter AND Haul as pay items. Consider salvage aggregate whenever making a road Level 1 and it has aggregate on it. Aggregate is a very valuable resource and is becoming harder to find and fund. We can restrict haul or use the next time that road is needed to avoid wet weather use. 203A.04 Rolling Dips. Rolling Dips are the “Rodney Dangerfield” of drainage structures. Rolling dips interrupt the wear rut, rill, wash, and the ditch, and allow rolling through by vehicles at 5-20 MPH depending on configuration. They can cut the need for recurrent maintenance and eliminate the risk of stream diversion in storm events. Dips are very sensitive to detail in design and construction. To function over time, they must drain water with a rut in the road. Even gravel will end up with a “wear rut” after a short time of use. Dips change looks & cost, drastically, with steeper grades. Use the provided guidelines for different critical vehicles needing to use the road. You may also want to consult the Engineering Applications (dips) in the IBM server (“J” drive) library to help with unusual vehicles’ dimensions and Dip taper distances. Rolling Dips and Drainage dips can be very costly to install, especially when specified on aggregate and particularly on paved sections of roads. A cost/benefit and risk analysis should be used in determining areas to construct dips on a priority basis with these scenarios. The history of a drainage crossing, whether trouble or success over time, can be valuable in any risk analysis. In POC areas without root-rot, caution is warranted in locating outlets of dips to avoid concentrations onto healthy POC. Avoid concentration of surface water on dips, but when unavoidable consider using riprap at the outlet. Suggest we assure water goes across riprap, not around, by utilizing a short berm on either side of the drain line on outlet side. Dips are an optical elusion paradise -- be sure to use a hand level to determine the drain line. Suggest utilizing Waterbars on Level 1 roads. They don’t require dealing with aggregate and are MUCH cheaper. Disconnect the ditches, and maintenance will be needed very little. There is a chart to help determine waterbar spacing in the “library” on the IBM server. On paved roads, see suggestions under Outsloping for another alternative. R6/SPS 203A ROAD STORMPROOFING 4/24/00 9 203A.05 Drainage Dips. Drainage dips are similar to rolling dips except that they are typically used at major drainages, may or may not be drivable (depending on intended Maintenance Level), and may be shaped differently because of grades or need to hold more water. Suggest you use the OPEN-CHANNEL application in the IBM server “Engineering Applications” in the Library to help determine quantity any given dip configuration is capable of holding. Usually, if you want to pay separately for watering use Section 207, Developing Water Supply & Watering. 203A.06 Cross Ditches. Cross Ditches can be used to interrupt wear ruts in relatively high use, high speed roads without dealing with the gravel. They can be inboard or outboard in direction. They are still dependent, somewhat, on recurrent maintenance. They are very sensitive to drain-line slope. We suggest matching the grade of the road very carefully with the drain-line slope to avoid either silting up or excess down-cutting of the drain-line. 203A.08 Flared End Sections. Flared End Sections can force more water through the same diameter culvert when combined with a headwater situation. But probably the biggest benefit of a Flared End Section is its ability to direct sticks and debris to better pass through the culvert. End Sections have been shown to decrease risk of plugging up to 50%. However, they will not help much in large debris-flow situations. 203A.09 Drop Inlets. Drop inlets fit in the ditch line without need of a catch basin. When the opening is as large as the CMP into which it drains, can help prevent need for recurrent maintenance. A standard ditch block should back the DI. 203A.11 Recontouring. A short section of recontouring (usually 15-20 m) is a more natural way to stop traffic on a Level 1 road, and is harder to breach when natural cross-slope exceeds about 40%. Recontouring can help disguise the beginning of a road and can look “friendlier” than an Earthen Barrier. 203A.12 Outsloping. Outsloping coupled with dips or waterbars can get away from maintenance dependent ditches and cross drain culverts, but outsloped roads still need dips or waterbars to drain the wear ruts on open roads. Even on closed roads we suggest using waterbars to back up the outsloping. Some would say you don’t need outsloping, just disconnect the ditches with waterbars or dips. On Pavement we suggest using a section of outsloping to prevent the road capturing the stream during a storm event. It is much less expensive to build, easier to drive, will not wear rut like native or gravel, and look more credible than dips on pavement. The length required can be calculated for roadgrades and widths. Use a ditch-block to prevent water from running down the ditch-line. R6/SPS 203A ROAD STORMPROOFING 4/24/00 10 Gates. Use spec 640 for gates. Gates should very rarely be used to close a level 1 road. But sometimes gates can be used to close a level 1 road so private land can be accessed by the permittee, only. Gates are normally used on Level 2 or 3 roads for seasonal closures. 203A.14 Riprap. When riprap is specified with geotextile backing, specify a thickness at least 1.5 times the maximum size of stone. Without geotextile, specify a thickness at least 2.5 times the maximum size of stone. Use Riprap Sizing program in Library to assist in sizing riprap to resist movement with expected velocity. 203A.17 Cleaning Culverts. We will almost always want to assure Type 1 culverts are cleaned. Type 2 & 3 culverts or ditches need not be cleaned on level 1 roads since we want to avoid need for recurrent maintenance, and we recommend intercepting any ditch with Waterbars often enough to avoid any concentration of water. Level 2 roads can follow the same scenario if we construct enough dips, but costs of dip construction can be high on surfaced roads. Ditch Cleaning and Road Blading. Use spec 306 Reconditioning Existing Road for any required ditch cleaning and road blading. Keep in mind a Level 2 road, at least at the entrance, must look, feel, and quack like a level 2 or it has to meet the Highway Safety Act like a Level 3. We suggest not blading level 2 roads. 203A.18 Haul. Use haul as a pay item when you think a pay item may need to change in borrow, waste, or stockpile location during the contract. Allows easier and more economical change-order involving hauling of materials. Notice haul is not paid until distance exceeds 0.2 km. Then, haul is calculated using the TOTAL, weighted average haul distance. Use the various culvert installation specifications for needed culverts or culvert replacements. As much as practicable, work items to be "marked on the ground" should also be indicated on THE DRAWINGS (Work Lists), or the location indicated on maps. This will better facilitate “bidding” by contractors. Typical Drawings can have a list included to show locations by km, station, or other. The Drawing, "OUTSLOPING TYPICAL (storm proofing)" should be used only in storm proofing due to the flatness of outslope that is specified. It is not enough to assure drainage for Decommissioning without plenty of waterbars. Requirement indicated for Project Work List (DRAWINGS): Check all “capitalized” reference in Specification for direction AS SHOWN ON THE DRAWINGS and SCHEDULE OF ITEMS. R6/SPS 203A ROAD STORMPROOFING 4/24/00 11