JMF MOLD COATINGS - JMF Precision Welding

advertisement

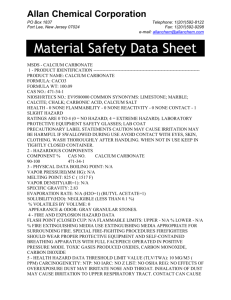

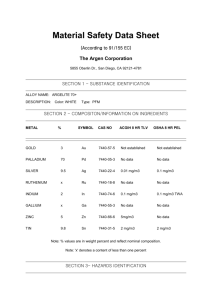

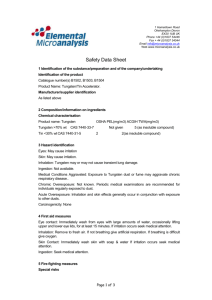

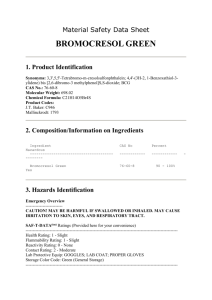

JMF MOLD COATINGS 2415 Harbin Springs Cove Dacula , GA 30019 Voice (770) 367-7320 Fax (770) 822-0651 Jim French http://www.jmfmicroweld.com jmfmicroweld@earthlink.net We are now offering mold coatings as an added service to insure the longest life for all your molds and dies. We have two products that offer increased lubricity to any surface treated. Based on your needs we will recommend which one is best suited for you. M1 material is our primary coating. M1 has an operating temperature of up to 750 degrees. For some die casting applications ,M2 can be used when an operating temperature of up to 950 degrees is required before some oxidation begins to occur. The coatings are reasonably priced based on quantities and required masking of areas. Surface wear ratings ( f c = friction coefficient mentioned henceforth) can be increased dramatically in many cases with our coatings. There are always considerable gains in f c noted. As an added benefit, there is no dimensional difference after our coatings are applied, as is the case with many surface treatments. Once applied to surfaces, it is a permanent application and will last for extended periods. Whenever deemed advisable by your regular maintenance, or if diminished performance is noted, or upon recommendation by JMF Mold Coatings, the parts can be reexamined and stripped and reapplied for premium performance. What If maintenance is required on tooling or engineering changes are required? Operations like grinding, milling and EDM can be accomplished without consideration for the coatings. If however, welding or other surface applications i.e. (plating) are to be a part of the maintenance, the parts should be sent back to JMF Precision Welding for stripping. This is a very low cost procedure and can quickly and easily be accomplished prior to the welding procedure. We recommend its application to bearing surfaces , slide by shut-offs, leader pins, gibs, slides, horn pins, parting lines that receive wear or may be prone to galling, etc…our coatings have been used successfully on all types of steels, Inconels, and even plastics and rubber compounds. Additionally, perishable tooling can be coated to increase f c which can increase tool life and even surface finishes. The uses for these coatings are limited only by the users imagination and specific engineering considerations. The fc of standard 10W30 motor oil is supplied below to allow customers to compare petroleum lubricants coefficients of friction to our coatings. This amply demonstrates the vast improvement M1 and M2 allow for wear applications. 10W30 motor oil: 0.15-0.20 M-1 0.03-0.06 M-2 0.03-0.04 MSDS - M1 General Mfg. IAW: MIL-M-7866 CAS No: 1317-33-5 EINECS No: 215-263-9 Physical data Appearance: dark grey or black Melting point: 1185 C, but sublimes from around 500 C Boiling point: NA Vapor density: NA Vapor pressure: NA Density (g cm-3): 5.06 Flash point: NA Explosion limits: NA Auto-ignition temperature: NA Water solubility: insoluble coefficients of friction M-1 0.03-0.06 Stability Stable. Incompatible with oxidizing agents, acids. Toxicology Harmful if swallowed or inhaled, eye and respiratory irritant. Typical STEL 10 mg/m3. Toxicology not fully investigated. Harmful by inhalation. Harmful if swallowed. Irritating to eyes. Irritating to respiratory system. Possible risk of irreversible effects. Transportation Non-hazardous for air, sea and road freight. Personal protection Safety glasses. Do not breathe dust. Wear suitable protective clothing. Wear suitable gloves. Wear eye / face protection. In case of accident or if you feel unwell, seek medical advice immediately (show the label whenever possible.) MSDS M-2CAS# 12138-09-9 M-2 coefficients of friction 0.03-0.04 M2 99. 90000 min Tungsten 74.14000 avg Sulfur 25.65000 avg H20 0.05000 max Iron 0.00100 max Aluminum 0.00040 max Silicon 0.00060 max Copper 0.00050 max Magnesium 0.00020 max Calcium 0.00100 max Nickel 0.00070 max Carbon 0.00130 max Molybdenum 0.00200 max Other Impurities 0.04230 max Screen Analysis FSSS: 1.1 Microns Average Particle Size: 0.8-2 Microns Chemical Family: REFRACTORY METAL SULFIDE CAS Number: 12138-09-9 Formula: M-2 Molecular Weight: 248.02 PHYSICAL DATA Appearance & Odor: GRAYISH-BLACK , NO ODOR Boiling Point: N/A Vapor Pressure: (mm HG) N/A Vapor Density: (air=1) N/A Solubility in Water: INSOLUBLE Specific Gravity: (H2O=1) 7.4 Percent Volatile by Volume: 0 Evaporation Rate: N/A How Best Monitored: AIR SAMPLE HAZARDOUS INGREDIENTS Percent by Weight: 100 ACGIH TLV: 5MG/M3 LIMIT IS FOR INSOLUBLE COMPOUNDS AS "W" HEALTH HAZARD DATA ROUTES OF EXPOSURE: material can be inhaled, swallowed, or come in contact with the skin or eyes. EFFECTS OF OVEREXPOSURE: dust and inhalation may cause mild irritation of the nose and throat. With the exception of TOW Russian studies that found early signs of pulmonary fibrosis in some workers exposed to tungsten trioxide, tungsten metal, and tungsten carbide, most studies have shown that insoluble tungsten compounds to be toxicologically inert. Skin and eye contact may cause irritation due to the abrasiveness of the dust. Recent scientific evidence indicates no adverse effects are likely from accidental ingestion of small amounts of the material. EMERGENCY AND FIRST AID PROCEDURES: inhalation- if symptoms of pulmonary involvement develop, remove from exposure and seek medical attention; skin contact- if irritation occurs, thoroughly wash affected area with mild soap and water and prevent further contact, contact medical help if irritation persists; eye contact- if irritation occurs, flush with copious amounts of a water, contact medical help if irritation persists; ingestion- if substantial quantities are swallowed, give person (if conscious) a large quantity of water to drink, induce vomiting, and seek medical attention; carcinogenic assessmentNTP Annual Report, IARC monographs, et. al.) this material has not been identified as a known or suspected carcinogen by NTP, IARC, or OSHA. FIRE & EXPLOSION HAZARD DATA Flash Point: N/A Flammability Limits: N/A NO FIRE HAZARD, USE EXTINGUISHING AGENTS SUITABLE FOR SURROUNDING FIRE. SPECIAL PROCEDURES: USE A SELFCONTAINED BREATHING APPARATUS TO PREVENT INHALATION OF DUST, MIST OR FUMES THAT MAY BE GENERATED DURING FIRE FIGHTING ACTIVITIES. NO UNUSUAL FIRE OR EXPLOSION HAZARDS. REACTIVITY DATA Stability: STABLE Conditions to avoid: N/A Incompatible Materials to Avoid: CONTACT WITH STRONG ACIDS MAY GENERATE HYDROGEN SULFIDE Hazardous Decomposition Products: OXIDES OF SULFUR AND TUNGSTEN MAY BE EVOLVED AT EXTREME TEMPERATURES SPILL & LEAK PROCEDURES IF SPILLED OR RELEASED- VENTILATE AREA OF SPILL, CLEAN-UP USING METHODS WHICH AVOID DUST GENERATION, SUCH AS VACUUMING WITH APPROPRIATE FILTER, WET DUST MOP, OR WET CLEAN-UP. IF DUST IS GENERATED, USE APPROVED NIOSH RESPIRATOR. DISPOSAL-DISPOSE OF IN ACCORDANCE WITH APPROPRIATE FEDERAL, STATE, AND LOCAL REGULATIONS RESPIRATORY PROTECTION- USE AN APPROPRIATE NIOSH APPROVED RESPIRATOR IF AIRBORNE DUST LEVELS EXCEED THE TLV, APPROPRIATE REQUIREMENTS SET FORTH IN 29 CFR 1910.134 SHOULD BE MET VENTILATION- USE LOCAL EXHAUST WHICH IS ADEQUATE TO LIMIT EXPOSURE LEVELS BELOW TLV GLOVES-GLOVES ARE RECOMMENDED EYE PROTECTION- RECOMMENDED SPECIAL PRECAUTIONS Handling and Storage: MAINTAIN GOOD HOUSE KEEPING PROCEDURES TO PREVENT ACUMULATION OF DUST; USE CLEAN-UP METHODS WHICH MINIMIZE DUST GENERATION Other Precautions: WASH THROROUGHLY AFTER HANDLING AND BEFORE EATING, SMOKING, AND END OF WORK SHIFT; DO NOT SHAKE CLOTHING TO REMOVE DUST; AVOID INHALATION, INGESTION, AND DIRECT SKIN CONTACT