AAN for G-DELF, UK CAA document

1.

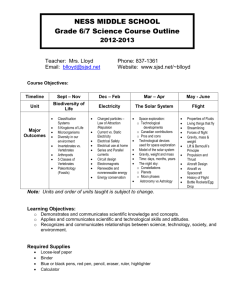

AIRWORTHINESS APPROVAL NOTE NO: 26120

APPLICANT: P A Greenhalgh & B Green, Fast Jets Ltd

AIRCRAFT TYPE:

REGISTRATION NO:

Aero Vodochody, L-29 Delfin

G-DELF

CONSTRUCTOR'S NO:

OPERATOR:

CERTIFICATE CATEGORY:

194555

Fast Jets Ltd

Permit-to-Fly

To approve Aero L-29 Delfin registered G-DELF for the issue of a Permit-to-Fly.

Introduction

The L-29 Delfin is a two seat jet trainer which was designed and manufactured by Aero Vodochody, at Kunovice,

Czechoslovakia. The turbojet engine designated the M701c - 500 was also designed and manufactured in

Czechoslovakia by Walter at its Motorlet works.

The first studies leading to the Aero L-29 was made in 1955 by a team under K. Thomas and Z. Rublic. Known as the XL-29, the prototype flew for the first time on 5 April 1959, powered by a Bristol Siddeley Viper turbojet.

The second prototype, which made its initial flight in July 1960 and a small pre-production batch of L-29s for service evaluation, had the M 701 turbojet. A year later the Delfin was subjected to competitive evaluation against the Yakovlev Yak-30 and PZL-Mielec TS-11 Iskra. As a result, all Warsaw Pact countries (except

Poland, which decided to continue supporting its own TS-11) decided to adopt the Delfin as their standard basic and advanced jet trainer. The first production Delfin was completed in April 1963, and approximately 3,600 had been built before the run ended some 12 years later to be replaced by the L-39 Albatros.

2. Description

The L-29 Delfin is a tandem two-seat basic and advanced jet trainer with tapered wings and a horizontal stabiliser mounted on top of the vertical stabiliser. The design concept of the L-29 is based upon a straight-forward, easy-to-build structure which is simple to fly and uncomplicated to operate. Runway requirements are modest, and it can operate from grass, sand or water-logged airstrips.

Flight controls are manual, with generous wing flaps and a solid airbrake on each side of the rear fuselage. The

Delfin does not readily stall or spin, and its safety and reliability are said to be high. There is an emergency manual backup for carriage extension and the lowering of landing flap.

Both cockpits are pressurised and are provided with ejection seats with canopy jettison being performed by pneumatically operated piston actuators.

A detailed description of the aircraft may be obtained by reference to the publications listed in section 6.

3. Approval Basis

The aircraft was designed to Russian military requirements broadly equivalent to Def Stan 00-970 although not directly comparable. CAA approval is based on the satisfactory service history of the type and investigation carried out in accordance with policies agreed by ARB during the meeting of 23 rd April 1992 appropriate to its classification in the intermediate category. The aircraft's safety record is acceptable to CAA.

Technical Investigation 4.

The applicants have submitted information on type safety record based on extracts from official DOSAAF documents in accordance with BCAR A3-7 Appendix 1 para 2.1 and this record is acceptable to the CAA 1 . The applicants engaged J S Chillingworth to establish conformity to type (BCAR A3-7 Appendix 1 para 2.2.) and support submission of this aircraft to the CAA for Permit issue. The aircraft was surveyed for potentially hazardous features in accordance with BCAR Section B3-7 para 3(d) and the results are described below.

Unusual features of the aircraft include simulated failure modes selectable from the rear seat. These features were intended as training aids but these facilities are not accepted for Permit issue as the pilot-in-command must be sure of retaining full authority throughout flight. These modes have been disabled under the applicant’s modification actions described in Section 4.1 (b).

L-29 Delfin, serial number 194555 was delivered to the Soviet Air Force in October 1971 where it remained in service until May 1991 when it was placed in long term storage and preserved. This aircraft was purchased in

1995 together with four other Delfins by Mr Ravio Susi an Estonian aircraft dealer.

These aircraft were dismantled and shipped to Tartu Airport in Estonia where they were re-assembled by Russian technicians under the supervision of Mr S Gorokh who is the Chief Engineer at Zaporozhye, a Ukrainian airbase which still operates 105 L-29 Delfins. After re-assembly, a full military flight-test profile was conducted by Mr V

Gorak who is the Flying Standards Officer at Zaporozhye. A submission was made to the Estonian CAA and

194555 and the other aircraft were granted civilian Airworthiness Certificates in the Normal/Aerobatic category in

December 1995.

In July 1996 the aircraft was ferried to the UK from Tartu by Mr Gorak and the aircraft subsequently operated until October 1996 from RAF Manston.

At the time of this permit application, the airframe and engine hours are shown in table 1.

Airframe

Service Use

2678.30

Civilian Use

36.50

Total

2715.20

Engine 1310.40 38.55 1349.35

Table 1: Aircraft Utilisation

4.1. Modification State

The applicants have ascertained that no alterations have been made, damage incurred or significant repairs to the main structure of the aeroplane. Unlike Western aircraft which have ongoing modification programmes. Aero Vodochody ‘freeze’ the modifications at build standard. It has been determined that any modifications issued after the time of build in 1971 and the last airframe overhaul in 1984 have been implemented. Some minor modifications were made to the aircraft during the period of Estonian registration and subsequently some other modifications were made by the applicants

______________________________

1

Flight Safety Analysis: L-29 Delfin

4.1(a) Estonian Modifications 2

The modifications made during the period of Estonian registration were not of a structural nature. No formal record of these modifications is available but a survey of these modifications indicates that these were carried out to a satisfactory standard. The modification were:

(i) Exchange of front & rear metre reading altimeters for units calibrated in feet.

(ii) Installation of King KN76A transponder and altitude encoder.

(iii) Removal of front cockpit tank jettison switch.

(iv) Removal of gun sight and camera from front cockpit.

(v) Removal of military 0

2

0 IFF transponder.

4.1(b) Applicants Modifitions 3

Applicants modifications have been carried out, as follows:

(i) Inhibition of simulated failure modes from rear seat

Simulated Failure

Pitot & static pressure: failure by 2 switches

How Inhibited

Attitude indicator: failure by 2 switches

Undercarriage lowering: failure by switch

Landing light over-ride switch

Isolation valve switch

Instrument, intercom and Master switches on main panel

Drop tank jettison switch

Lock switches with 20 swg wire to Normal position

Lock switches with 20 swg wire to Normal position

Lock switches with 20 swg wire to Normal position

Lock switches with 20 swg wire to Off position

Lock switches with 20 swg wire to Normal position

Lock switches with 20 swg wire to On position

Lock switches with 20 swg wire to Safe position and cover with guard

(ii) Removal of redundant military equipment

Equipment

APK9 ADF receiver & twin turner units

ADF inverter & transformer

ADF Gonio

Flight data recorder

(iii) Oxygen system

Oxygen system was disabled and the 3 four litre Oxygen bottles used to enhance the capacity of the

Nitrogen based braking system.

(iv) Braking system

The capacity of the braking reservoir was increased from 8 litres to 20 litres by connecting unused Oxygen bottles to the Nitrogen system.

________________________________

2 TG Modification Reference TGM/Mod1/98

3

TG Modification Reference TGM/Mod2/98

4.2.

Structure - Fatigue State

A manufacturer’s communication states that the airframe life is nominally 5000 hours provided that all airframe overhauls have been carried out.

4 All such overhauls have been performed by factory agreed agencies for

194555 with the last one at 2010:10 hours in March 1984. An extension beyond 5000 hours is permissible on an on-condition basis. The maximum interval between overhauls is 1200 hours. This information is derived from the logbook front page for this aircraft, which is series 9.

The remaining airframe fatigue life at permit application is therefore:

5000 - 2715: 20 = 2284 hours: 40 minutes

Remaining airframe time before overhaul is therefore:

1200 - 705:10 = 494 hours: 50 minutes

Load factors are up to +7/-3.5g with external tanks fitted. An aural tone is heard when these limits are approached,

A single g-meter is fitted to the front cockpit but is clearly visible from the rear.

4.3. Engine

The aircraft is powered by a Walter Motorlet M70c-500 turbojet engine. It has a single-sided centrifugal compressor and a single stage axial flow turbine. Compressor bleed air is taken from the engine to provide cabin pressurisation, de-icing, air-conditioning and pressurisation of the external fuel tanks.

Engine driven accessories are the HP fuel pump, hydraulic pump, generator and a tacho-generator for the dual RPM indicators.

The engine fitted to 194555 serial number c63131 which prior to flight test had completed a total of 1349 hours: 45 minutes and 161 hours: 45 minutes since overhaul. Time between overhauls is stated as 500 hours and a service life of 4000 hours (to be confirmed by applicant).

5

The remaining life left to run on the engine at permit application is therefore:

500 - 161:45 =338 hours: 15 minutes.

The limitations stated in the engine Technical Manual 6 are consistent with those contained in the Flight Manual 7 and are quoted in Section 8, Limitations.

Fire warning and extinguisher systems are provided and operational. The HP fuel control system consists of a fully automatic governor which provides the correct fuel flow for any demanded throttle position. The fuel control system ensures controlled acceleration during the start cycle, limits the maximum RPM achievable under all conditions and provides barometric compensation. To accommodate a failure in the HP fuel system there is a pilot activated valve duplicated in both cockpits which bypass the fuel around the fuel metering devices. The activation of this valve is indicated in the cockpit by a warning on the Caution and

Warning Panels.

The engine is equipped with an electrically driven starter, located in the air intake nose cone. A clutch connects the starter with the engine and automatically disconnects when the rotor RPM is higher than the starter revolutions. A starting control box applies the appropriate signals to the ignition unit and the starter motor to provide fully automatic control over the start sequence. The duration of this automatic cycle is 17 seconds with the engine becoming fully self sustaining 30 seconds later.

A separate air starter button is also provided which supplies continuous ignition for 19 seconds but no starter engagement.

_________________________________

4

Manufacturers Communications

5 Engine Logbook II page 167

6 TG110 M701c-500 Service instructions

7 TG 100 L-29 Delfin Flight Manual

___________________________

4.4. Controls

All primary flight controls are mechanically operated through control rods. The angle of attack of the tailplane moves electrically in response to the flap setting selected. This feature is intended to minimise pitch changes as flap is lowered and raised. Guidance from the Flight Manual suggests that if failure of the actuator motor leaves the tailplane in the incorrect position, then the aircraft can be safely flown with manual trim and acceptable stick forces.

4.5. Systems General

In general all systems in the aircraft are operational with the exception of the oxygen system which has been disabled to provide a greater reservoir capacity for the brakes. As a consequence of this the owner has elected not to operate the aircraft above 10,000 feet, and this is now listed as a limitation. The cabin pressurisation has not been disabled however as it is combined with the cabin air-conditioning and heating system which is to be retained.

Undercarriage

The undercarriage is hydraulically extended and retracted and has a extension and operating speed limit of 290 kph.

An hydraulic accumulator provides emergency pressure for undercarriage extension in the event of a pump failure.

Brakes

The braking system is actuated by a ground replenishable source of Nitrogen or air at a pressure of 150 Bar. The brakes are differently controlled by rudder bar deflection and applied by a lever mounted on the control column. When the undercarriage is raised the brakes are automatically applied briefly.

Flaps

The flaps are hydraulically operated with an extension and operation speed limit of 270 kph. The flaps will retract automatically if this speed is exceeded. An hydraulic accumulator provides emergency pressure for flap and undercarriage extension in the event of a pump failure.

Air brakes

The air brakes are hydraulically extended and automatically open when the speed exceeds MACH 0.7.

Pitot/static

Duel selectable systems are provided.

Fire Warning

Multi-sensor fire detectors are placed in the rear fuselage and are activated by excessive rate-of-change of temperature.

Fire Protection

A pyrotechnically discharged fire bottle can be activated from the cockpit directly into the engine bay in case on of a fire.

4.6. Ejection Seats

Ejection seats based on pyrotechnic cartridges are fitted in both front and rear cockpits. The seats can be operated above heights of 1500’ AGL and speeds below 800 km/h. The canopies are jettisoned by pneumatically powered pistons raising the leading edges of the canopies in to the airstream. Canopy separation removes a blocking pin allowing the seat firing handle to be squeezed. Simultaneous ejection is prevented by an electro-pnematic blocking circuit which prevents the second occupant ejecting until the first has left the aircraft. This sequencing may be disabled in special circumstances by pulling a de-blocking D-ring.

Vital seat checks will be performed at annual inspections of the seats and after each installation. Duplicate inspections of the seat locking to the airframe will also be performed after each installation.

4.7. Fuel System and Drop Tanks

The fuel tank consist of two main fuselage tanks mounted between the rear cockpit and the engine. They are interconnected by two balancing hoses. Fuel to the engine is drawn from the rear tank through an inverted flight reservoir which provides fuel for 15 seconds of inverted flight. An electrically driven LP fuel pump is mounted at the base of the rear fuselage tank and the whole fuel system may be isolated at the tank base by activating the LP fire-cock. This is closed by compressed Nitrogen and is controlled by operating the fire cock handle from either cockpit.

Total usable capacity of the two fuselage tanks which are filled through a single filler cap is 1000 litres. Two additional external tanks are mounted on pylons under the wings. These tanks hold 150 litres each and the fuel is transferred to the main tanks by compressed air obtained from the engine. Fuel transfer is controlled by a float valve in the main tanks. Although aircraft 194555 has a total usable capacity of 1300 litres.

A low-fuel light activated when 200 litres remains is included on both front and rear caution and warning panels.

The switch that jettisons the drop tanks has been removed from the front cockpit and a similar switch in the rear cockpit has been wire-locked into the safe position.

4.8. Weight and Balance

The aircraft is accepted by the CAA at 3550 kg MTWA. Maximum landing weight is 3285 kg. A weight and balance schedule reference 98MAR111 dated 6 th March 1998 has been prepared by Steve Cook Aircraft

Loading and Trim Services and appended to the Flight Manual. The acceptable centre of gravity range has been determined by the manufacturer to be between 20.5% and 25.5% of the Mean Aerodynamic Chord

(MAC) which is 2.04m and the datum is at Fuselage Frame 11. These figures have been re-established in report 98MA111 and schedule 98MA111 using units of mm relative to a new datum declared at 4300 mm forward of Frame 11.

The weight schedule referenced above calls for 19 kg ballast at 1163 mm. The applicant has, however, opted to use 15 kg ballast at 163 mm which yields the same forward and aft CG positions. This has been recorded in the Flight Manual Supplement.

4.9. Electrical system

A battery master switch is provided and a generator warning in both cockpits indicates when operating on internal battery power alone. The battery endurance in an emergency meets the requirements of Airworthiness

Notice 88. Load shedding procedures will be added to the Flight Manual

The 28VDC system is provided by a single lead-acid charged by an engine driven 3 kW generator. A volt-ammeter is provided in both cockpits. AC power for flight and remaining radio systems is provided by two, 36V

400 Hz inverters and one 115v 400 Hz inverter.

4.10. Avionic System

The original military equipment has been rendered inoperative or removed with the exception of the Baklaw5 VHF communications transceiver. The only avionics fitted and operable are as follows:

Qty Type Function Approval

1

1

Baklan 5

King KT76A

760 Channel VHF Comms Tranceiver

Transponder

LA301034

LA208

7.

5.

6.

4.11. Operational Aspects

The operators Operational Control Manual has been submitted to the CAA Sports and Recreational

Department for approval to CAP 632. Approval by CAA letter T10Z/13/018/G-DELF was granted.

Maximum duration for inverted and negative g flight is 15 seconds following which a period of 30 seconds of positive g flight must be flown to allow the inverted fuel reservoir to refill.

The aircraft may take-off and land on grass surfaces.

Flight Test

The aircraft was flight tested by the applicant on 8 & 10 April 1998 to L29 FLIGHT TEST CERTIFICATE and concludes that the aircraft is acceptable for the issue of a Permit to Fly.

A CAA handling assessment has been carried out and reported in FTR/10421P. The performance and handling was acceptable to CAA.

Manuals

The applicants have a complete set of technical manuals which were produced in English by Aero Vodochody.

The flight manual is essentially that prepared by Dornier for the Nigerian Air Force. The following manuals are available; the documents marked * have been authored by personnel of Fast Jets Ltd or TG Aviation Ltd.

Title Book

Reference

TG100

TG100/G-DELF

TG101

TG102

TG103

TG104

TG105

L-29 Delfin Flight Manual (includes Pilot’s Check List)

L-29 Delfin Flight Manual Supplement for G-DELF

General Data of the L-29 Aircraft

Technical Description of the Airframe

Technical Description of the Electrical, Instrument Oxygen & Radio Systems

Technical Description and Instruction for Operation of Aircraft Armament

Servicing and Maintenance of Canopy Jettison and Ejector seats*

Periodic Inspection of the L-29 Aircraft TG106

TG107

TG108

TG Aviation Maintenance Schedule for L-29 Aircraft*

Airframe Parts Manual Volume 1

TG109

TG110

TG111

TG112

Airframe Parts Manual Volume 2

M701c -500 Service Instructions

M701c -500 Parts Manual

TG Aviation Maintenance Schedule for M701c -500 Engine*

Noise Certificate

A noise certificate is not required for this aircraft as it operates on a Permit to Fly.

8.

9.

Limitations and Concessions

Airframe and engine limitations are given in the Flight Manual TG100. Key limitations and concessions are shown below. Items marked * are to be placarded or marked on instruments

Reference Limitations /concession

1

2

3

4

5

6

7

8

9

Maintenance

Aerbatics are permitted in accordance with the Flight Manual. Flick manoeuvres, intentional stalling and spinning are prohibited.*

Load factor +7.5\3.5g. Negative g limited to 15 seconds.*

C of G to be between 20.5% and 25.5% of MAC. MAC is 2.04m and datum is at Fuselage

Frame 11.

Max take-off weight -: 3550 kg, Max landing weight -: 3285 kg

Airspeed Limitations:

Max Speed* 820 km/h

M max

* 0.7 Mach

Undercarriage lower/raise* 290 km/h

Flaps 15

or 30

lower 270 km/h

Maximum crosswinds 43 km/h (23kts)

Engine limitations

Conditions RPM(%)

Maximum Speed*

Normal rated speed*

100

97

Maximum continuous* 94

Idle* 35

Oil pressure minimum 0.5kg/cm 2 at idle 35%.*

Oil pressure maximum 2.5kg/cm 2 at full power 100%.*

Oil pressure minimum 20

C*

Oil pressure maximum 110

C.*

JPT (

C)

700

700

700

550

Day VMC only*

No Smoking*

Maximum altitude 10,000 ft

Duration

6 minutes

30 minutes

No limit

No limit

The manufacturers servicing schedule for the L-29 is defined in book reference TG106 and TG107. Inspections are called for at 50, 100 and 200 hours and multiples thereof up to the 1200 hour overhaul. These times have allowable margins of - 10% /+20%. Due to the expected low utilisation under the Permit to Fly, the applicant has proposed the following calendar maintenance check cycle:

Permit to Fly issue

First year Permit renewal

200 hr inspection

100 hr inspection

Second year Permit renewal

Third year Permit renewal

Fourth year Permit renewal

200 hr inspection

100 hr inspection

200 hr inspection and so on

This maintenance check cycle is acceptable to the CAA provided the flying hours called up in the manufacturers servicing cycle are not exceeded.

This aircraft must be maintained by a company approved under BCAR A8-20 with a rating for the aircraft type and experience in the maintenance of the ejection seats. The aircraft is to be kept hangared and inhibiting/short term care and maintenance procedures observed.

This aircraft has been inspected and found to conform to the requirements of the AAN and to be in a satisfactory and airworthy condition.

10. Approval

This aircraft G-DELF Constructors Number 194555 is approved for issue of a Permit to Fly provided that it is operated accordance with the limitations and procedures in documentation in documentation referred to in Section

6 above, and in Section 8 above, and the conditions of the Permit to Fly and that it is maintained in accordance with all appropriate manuals and schedule including publications referred in Section 6.

R J Hardy

..........................................................

For the Civil Aviation Authority

Date 28 April 1998