Manufacturing Engineering Tech Career Guide | UNT

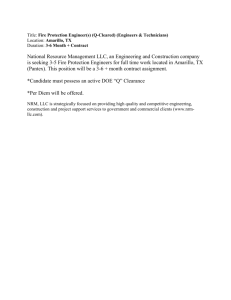

advertisement

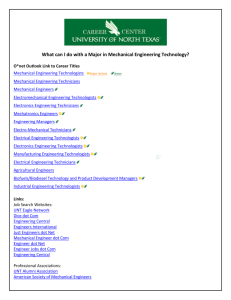

What can I do with a Major in Manufacturing Engineering Technology? O*net Outlook Link to Career Titles Industrial Engineering Technicians Green Industrial Engineers Industrial Engineering Technologists Bright Outlook Manufacturing Engineering Technologists Manufacturing Engineers Mechanical Engineering Technicians Mechanical Engineers Engineering Teachers, Postsecondary Industrial Safety and Health Engineers Industrial Machinery Mechanics Electrical and Electronics Repairers, Commercial and Industrial Equipment Electrical Engineers Electronics Engineers, Except Computer Electrical Engineering Technicians Industrial Production Managers Engineering Managers Environmental Engineering Technicians Materials Engineers Electronics Engineering Technicians Manufacturing Production Technicians Links: Job Search Websites: UNT Eagle Network Engineer Jobs dot Com Engineer dot Net Engineering Central Dice dot Com Engineers International Just Engineers dot Net Global Energy Jobs Professional Energy Jobs dot Com Professional Associations: UNT Alumni Association Texas Board of Professional Engineers Institute of Industrial Engineers The Society of Manufacturing Engineers The Association of Technology, Management, and Applied Engineering (ATMAE) Examples of Employers Recruiting This Major: Advanced Lightning Technology Aerotek Professional Services Alpha Industries, Inc. ALT Fabrication American Locker Amphenol Fiber Systems International Amtex Acquisition dba Amtex Corp. Applied Concepts, Inc. ARKRAY USA, Inc. AVTEQ, Inc. Barton Enterprises, Inc Best Brands Corp Cardinal FG CP&Y, Inc Crisp Industries, Inc. Custom Nutrition Laboratories Daisy Brand Derse Exhibits Dexas International, Ltd. Dymatize Nutrition Marketing Dept. Ecolab EFJohnson Emoteq Corporation Employer Organization Name Exeltech Flow Design, Inc. G&K Services Gale Pacific USA General Dynamics Genlite Controls GRIMCO H&K Dallas Hollman, Inc. ID Technology ILC Dover LP Insight Merchandising Inc. Insul-Fab Integrated Test Corporation JTEKT Automotive Texas, L.P. L-3 Communications ComCept Division L-3 Communications Infrared Products L-3 Communications, Unmanned Systems LG Electronics LGS Technologies Megger Molded Fiber Glass Companies/Texas MultiCam, Inc National Envelope NCH Corp. Oklahoma Steel & Wire Pacific Northern, Inc. PCI Industries, Inc. Presco Printpack Inc. Product Support Services Quest Medical, Inc. Quiltcraft Industries, Inc. Ranpak Corp Samsill Corporation Samsung | GVI Security, Inc. SandenVendo America SecuritySolutions Sherwin-Williams Garland Manufacturing Spraylat Corporation Stemco LP Tidel Engineering Titan Specialties Ltd. Tyco Healthcare United McGill Variosystems Inc. Ventura Foods, LLC Watson & Chalin Mfg. Westmoor Mfg Williams-Pyro, Inc. Knowledge, Skills and Abilities learned in this Degree: Knowledge: Engineering and Technology Production and Processing Mathematics Administration and Management Mechanical Computers and Electronics Design Education and Training Skills: Critical Thinking Active Listening Complex Problem Solving Mathematics Judgment and Decision Making Active Learning Abilities: Deductive Reasoning Problem Sensitivity Mathematical Reasoning Inductive Reasoning Information Ordering Visualization Majoring in Manufacturing Engineering Technology: A major in manufacturing engineering technology prepares you to design, develop, test, install, operate and maintain industrial automation and manufacturing systems, including robots and other tools used in automated manufacturing. In this program, you will study fluid mechanics; manufacturing processes and materials, including plastics, ceramics and metals; materials testing; statistics and quality assurance; industrial robot programming; component design; welding; and adhesive bonding. The major focus of the curriculum is manufacturing processing and factory automation in durable goods production. The manufacturing engineering technology program is accredited by the Technology Accreditation Commission of the Accreditation Board for Engineering and Technology [ 111 Market Place, Suite 1050, Baltimore, Md. 21202, telephone (410) 347-7700]. This accreditation means the program has passed strict academic standards for excellence in education. Faculty members have degrees in electrical, mechanical, metallurgical and nuclear engineering. They average 10 years of industrial experience. Faculty members have worked for organizations such as Airgas Inc., Boeing Military, Electrotest, General Dynamics (Lockheed Martin), General Electric, Houston Engineering and Research, Integrated Technologies Inc., Los Alamos Scientific Laboratory, among others. Career Potential: As manufacturing engineering technology major, you will be preparing for a career in the manufacturing/production environment. Manufacturing engineering technologists apply scientific and engineering technology in support of engineering activities. Graduates may find employment in research and development, process and equipment specification and design, reliability/quality assurance and tool design. To advance in the field of manufacturing engineering technology, you may want to earn a master’s degree. UNT has one of the largest engineering technology graduate programs in the United States. To teach manufacturing engineering technology at a university, you likely will need a doctoral degree. UNT’s Career Center can help you prepare to pursue your career. The center has information about jobs and employers with resume and letter writing, job search strategies and interview preparation. Getting Hands on Experience: The engineering technology department receives thousands of dollars per year in research projects and grants. Current faculty research interests include conceptualized systems, corrosion, cryogenic power sources, curriculum development, engineering/operations management, environmental concerns, finite element techniques, fluid dynamics, highway illumination, industrial adhesives, industrial training, materials engineering, metal and ceramic matrix composites, non-traditional propulsion systems, plastics processing, process control systems, space nuclear reactors, surface coatings, transportation studies, and welding and joining. For a senior project, you may work in one of these areas with a faculty member and/or for an industrial sponsor.