Final_s02_431_soln

advertisement

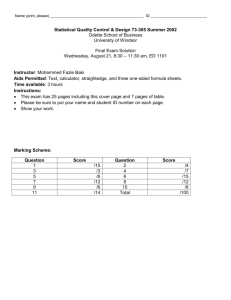

Last Name ________________________ First Name ________________________ ID __________________________

Operations Management II 73-431 Summer 2002

Odette School of Business

University of Windsor

Final Exam Solution

Tuesday, August 16, 12:00 – 3:00 pm ED Gym Area 1-3

Instructor: Mohammed Fazle Baki

Aids Permitted: Calculator, straightedge, and 3 one-sided formula sheet.

Time available: 3 hours

Instructions:

This exam has 26 pages including this cover page and 6 pages of table

Please be sure to put your name and student ID number on each page.

Show your work.

Marking Scheme:

Question

1

3

5

7

9

11

13

15

Score

/15

/4

/8

/4

/5

/3

/5

/2

Question

2

4

6

8

10

12

14

Total

Score

/6

/8

/14

/10

/6

/5

/5

/100

Name:_________________________________________________

ID:_________________________

Question 1: (15 points)

1.1 For which of the following should we use an X control chart to monitor process quality?

a. Windshield cracked or not

b. Flash lights work or not

c. Number of flaws in a paint job

d. Weight errors in cans of soup

e. All of the above

f. None of the above

1.2 For which of the following should we use an R control chart to monitor process quality?

a. The volume of scrap parts

b. Lengths of boards cut in a mil

c. The ounce of beer poured in a can

d. Errors in the length of pencils produced

e. All of the above

f. None of the above

1.3 You want to develop a three-sigma X control chart with subgroup size 4. You know that the

standard deviation of the sample means is 4 and the average of the sample means is 24. Which

of the following is the resulting UCL

a. 40

b. 36

c. 30

d. 24

e. 12

f. 4

1.4 Consider the problem of economic design of X control chart. If k is increased keeping

n unchanged

a. Searching cost increases

b. Searching cost decreases

c. Cost of operating in out-of-control state increases

d. Cost of operating in out-of-control state decreases

e. a and d

f. b and c

1.5 Which of the following is sampling cost?

a. Personnel cost for scrap or repair

b. Personnel cost for the fixing the problem

c. Cost of item

d. Cost of warranty claims

e. All of the above

f. None of the above

2

Name:_________________________________________________

ID:_________________________

1.6 Consider a single sampling plan with sample size n and acceptance number c . The producer’s

risk increases if

a. only n increases

b. only c increases

c. both n and c increase proportionately

d. a and c

e. all of the above

f. none of the above

1.7 What is AOQ?

a. Proportion of good items in the outgoing lot

b. Proportion of defective items in the outgoing lot

c. The maximum proportion of good items in the outgoing lot

d. The maximum proportion of defective items in the outgoing lot

e. Proportion of items inspected

f. Proportion of items replaced by the good items

1.8 Reliability increases if

a. the components are in series and the number of components increases

b. the components are in series and the number of components decreases

c. the components are in parallel and the number of components increases

d. the components are in parallel and the number of components decreases

e. a and d

f. b and c

1.9 The average life is called

a. Mean Time Between Failure (MTBF) if the system is repairable

b. Mean Time Between Failure (MTBF) if the system is non-repairable

c. Mean Time To Failure if the system is repairable

d. Mean Time To Failure if the system is non-repairable

e. a and d

f. b and c

1.10 Failure rate

a. decreases during the normal operating period

b. is the inverse of average life

c. is constant during the wear-out period

d. increases during the infant-mortality period

e. all of the above

f. none of the above

1.11 Process layout is used if

a. product is standardized

b. volume is high

c. efficiency is more important than flexibility

d. demand is fluctuating

e. all of the above

f. none of the above

3

Name:_________________________________________________

ID:_________________________

1.12

a.

b.

c.

d.

e.

f.

Cellular layouts

group machines into cells that resemble small assembly lines based on part families

identify families of parts with similar flow paths

may provide poorly balanced cells

all of the above

a and b

none of the above

1.13

a.

b.

c.

d.

e.

f.

In a job shop

every job visits all the machines in the same order

special purpose equipment is used

scheduling is part of line balancing

aisles are narrow

all of the above

none of the above

1.14

a.

b.

c.

d.

g.

h.

A scheduling problem is called stochastic if

jobs are processed on two or more machines in series

jobs are processed on two or more machines in parallel

all the jobs are not available for processing at time zero

processing times are not known at time zero

a and d

b and c

1.15

a.

b.

c.

d.

e.

f.

A critical path is the

longest path

one along which ES = LS for every activity

one along which EF = LF for every activity

one along which slack time = 0 for every activity

all of the above

none of the above

Question 2: (6 points)

An amplifier has a constant failure rate of 4% per 500 hour.

a. (2 points) What is the probability that the amplifier will survive 2000 hours?

Plife 2000 1 1 0.04 0.8493

t

4

b. (2 points) What is the average life?

1

1

25 in 500 hours = 12,500 hours

0.04

4

Name:_________________________________________________

ID:_________________________

c. (2 points) What failure rate is required to have a probability of survival of 95% at 2000 hour?

1 4 0.95

or, 1 0.951 / 4

or, 1 - 0.951 / 4 0.0127

Hence, the failure rate is 0.0127 1.27% per 500 hour

Question 3: (4 points)

Two components A and B are used to make a subassembly in a circuit board. The reliabilities of A

and B are 0.60 and 0.75 respectively.

a. (2 points) Find the reliability of the subassembly, if the components are in parallel.

R p 1 1 0.601 0.75 0.90

b. (2 points) Find the reliability of the subassembly, if the components are in series.

Rs 0.60 0.75 0.45

Question 4: (8 points)

The next-door neighbours are currently installing a new cistern that will provide water for their

household. The different components for the system and their reliability are described in the diagram

below. Determine the reliability of the system.

0.65

0.80

0.75

0.50

0.95

0.75

0.70

0.85

0.85

0.75

0.60

0.70

Consider the following subsystems:

3

0.80

7

0.65

1

4

0.75

0.75

0.95

0.50

6

5

2

0.85

0.85

0.75

0.70

0.60

0.70

5

Name:_________________________________________________

ID:_________________________

R1 0.75 0.75 0.5625, R2 0.85 0.85 0.7225

R3 1 1 0.651 R1 1 R2 1 1 0.651 0.56251 0.7225 0.9575

R4 0.95 0.751 0.95 0.9875

R5 1 1 0.701 0.70 0.91, R6 0.60 R5 0.60 0.91 0.546

R7 1 1 0.501 R6 1 1 0.501 0.546 0.773

Rsy stem 0.80 R3 R4 R7 0.80 0.9575 0.9875 0.773 0.5847

Question 5: (8 points)

In one of the acceptance sampling plans, 15 items were to be tested for 100 hours with replacement

and with an acceptance number of 2. Plot an Operating Characteristic curve showing probability of

acceptance as function of average life. Consider average life, = 250, 500, 1000, 2500, and 5000

hours. For each average life compute and plot the probability of acceptance.

T 15100 1,500 hours, n 15, c 2

250

1

0.004

T

1 PNumber of defective c 1 3 | T

1 p

where p is obtained from Table A - 3 for x' 3, m T

1500(0.004)

=6

500

0.002

1500(0.002)

=3

1000

0.001

1500(0.001)

=1.5

2500

0.0004

1500(0.0004)

=0.60

5000

0.0002

Pa PNumber of defective c 2 | T

1500(0.0002)

=0.30

Pa PNumber of defective c 2 | 6

1 PNumber of defective c 1 3 | 6

1 0.9380 0.0620

where 0.9380 is obtained from Table A - 3 for x' 3, m 6

Pa PNumber of defective c 2 | 3

1 PNumber of defective c 1 3 | 3

1 0.5768 0.4232

where 0.5768 is obtained from Table A - 3 for x' 3, m 3

Pa PNumber of defective c 2 | 1.5

1 PNumber of defective c 1 3 | 1.5

1 0.1912 0.8088

where 0.1912 is obtained from Table A - 3 for x' 3, m 1.5

Pa PNumber of defective c 2 | 0.60

1 PNumber of defective c 1 3 | 0.60

1 0.0231 0.9769

where 0.0231 is obtained from Table A - 3 for x' 3, m 0.60

Pa PNumber of defective c 2 | 0.30

1 PNumber of defective c 1 3 | 0.30

1 0.0036 0.9964

where 0.5768 is obtained from Table A - 3 for x' 3, m 0.30

6

Name:_________________________________________________

ID:_________________________

Probability of acceptance,

Pa

Operating Characteristic Curve, Question #5

1.2

1

0.8

0.6

0.4

0.2

0

0

2000

4000

6000

Average life

Question 6: (14 points)

A film processing service monitors the quality of the developing process with light-sensitive

equipment. The accuracy measure is a number with a target value of zero. Suppose that an X chart

with subgroup of size four is used to monitor the process and the control limits are UCL = 1.10 and

LCL = -1.10. Assume that the process mean is zero and the process standard deviation is 0.80.

a. (2 points) What is the Type I error probability, for this control chart?

1.1 0

2 P X 1.1 | 0, 0.8, n 4 2 P z

2 Pz 2.75 20.50 0.4970 0.006

0.8 / 4

b. (3 points) Suppose that the process mean shifts to 1.00. What is the probability that the shift is

detected on the first subgroup after the shift occurs?

1.1 0

1.1 0

P 1.1 x 1.1 | 1, 0.8, n 4 P

z

0.80 / 4

0.80 / 4

P 5.25 z 0.25 P 5.25 z 0 P0 z 0.25 0.5 0.0987 0.5987

Pshift is detected 1 1 0.5987 0.4013

c. (2 points) Suppose that there is a probability of 0.05 that the process shifts from an in-control

state to an out-of-control state in any period. What is the expected number of periods per cycle

that the process remains in control? Assuming each search costs $10, compute the expected

searching cost per cycle.

1 1 0.05

19

0.05

Search cost per cycle a 2 1 E T 101 0.006 19 $11.14

E T

7

Name:_________________________________________________

ID:_________________________

d. (2 points) Assume that when the process shifts out of control, the process mean shifts to 1.00.

What is the expected number of periods per cycle that the process remains in an out-of-control

state until a detection is made? If the cost of operating in an out-of-control state is $100 per

period, what is the expected cost of operating in out-of-control state per cycle?

E S

1

1

2.4919 periods

1 1 0.5987

Cost of operating in out-of-control state = a3 E S 1002.4919 $249.19

e. (3 points) What is the expected number of periods per cycle? If the cost of sampling is $10 per

unit, what is expected cost of sampling per cycle? What is the expected total cost of sampling,

searching, and operating in out-of-control state per period?

E C E T E S 19 2.4919 21.4919 periods

Sampling cost per cycle a a nE c 10 4 21.4919 $859.68

Total cost per period

11.14 249.19 859.68 1120.01

$52.11 per period

21.4919

21.4919

f. (2 points) Find the UCL and LCL based on three-sigma control limits.

UCLX 3

LCLX 3

n

n

03

03

0.80

4

0.80

4

1.2

1.2

Question 7: (4 points)

An R chart is used to monitor the variation in the weights of packages of chocolate chip cookies

produced by a large national producer of baked goods. An analyst has collected a baseline of 200

observations to construct the chart. Suppose the computed value of R is 5.068.

a. (2 point) If subgroups of size six are to be used, compute the value of three-sigma limits for the

R chart.

n6

UCLR d 4 R 2.00 5.068 10.136

LCLR d 3 R 0 5.068 0

b. (2 points) If an X chart based on three-sigma limits is used, what is the difference between UCL

and the LCL? (You can compute UCL X LCL X without knowing X )

UCLX X 3

LCLX X 3

n

n

R

5.068

Hence, UCLX LCLX X 3

X 3

6

6

6

4.8990

n

n

n

d2 n

2.534 6

Question 8: (10 points)

8

Name:_________________________________________________

ID:_________________________

Consider a single sampling plan with n 20 , c 2 , AQL=0.01, and LTPD=0.2.

a. (2 points) Compute producer’s risk . Use Poisson probability table.

Producer’s risk = PRejection | p AQL 0.01

= Pc 1 or more defective | n 20 items are drawn, p 0.01

= P3 or more defective | np 20 0.01 0.20

= 0.0011

(Table A-3 gives Poisson cumulative probabilities for x' or more defectives. The value 0.0011 is

obtained from x' 3, m np 0.20 )

b. (3 points) Compute consumer’s risk . Use Normal probability table.

Consumer’s risk = PAcceptance | p LTPD 0.2

= Pc or fewer defective | n 20 items are drawn, p 0.20

= P 2 or fewer defective | np 20 0.20 4, 20 0.20 0.80 1.7889

2.50

| 4, 1.7889 (continuity correction)

= P z

2.50 4

P z

P z 0.84 P z 0 P 0.84 z 0 0.5 P0 z 0.84

1.7889

0.50 - 0.2995 (From Table A-1) = 0.2005

The following questions refer to the sampling plan stated above: n 20 , c 2 .

c. (4 points) Compute the probability of acceptance, Pa at proportion of defective, p 0.3 . Use

Binomial probability formula.

Pa

= P2 or fewer defective | n 20 items are drawn, p 0.30

= P0 defective | n 20 , p 0.30 + P1 defective | n 20 , p 0.30 + P2 defectives | n 20 , p 0.30

20

0

20 0 20

1

201 20

2

20 2

= 0.30 1 0.30 + 0.30 1 0.30 + 0.30 1 0.30

0

1

2

20!

0.300 1 0.30200 + 20! 0.301 1 0.30201 + 20! 0.302 1 0.30202

=

0!20 0!

1!20 1!

2!20 2!

20!

0.300 0.7020 + 20! 0.301 0.7019 + 20! 0.302 0.7018

=

0!20!

1!19!

2!18!

1

19

0

20

2

18

= 10.30 0.70 + 200.30 0.70 + 1900.30 0.70

=0.000798+0.0006839+0.027845873

= 0.0355

d. (1 point) Use the result of part c. Compute AOQ at p 0.3 if the lot size, N is 500.

AOQ

pN nPa 0.30500 200.0355

0.01022

N

500

9

Name:_________________________________________________

ID:_________________________

Question 9: (5 points)

A large national producer of cookies and baked goods uses a c chart to monitor the number of

chocolate chips in its chocolate chip cookies. The company would like to have an average of six

chips per cookie. One cookie is sampled each hour. The results of the last 12 hours were:

Hour

Number of chips per

cookie

Hour

Number of chips per

1

7

7

3

2

4

8

6

3

3

9

3

4

3

10

2

5

5

11

4

6

4

12

4

a. (2 points) Using the above data, set up a c -chart with z 3.

c

7 4 3 3 5 4 3 6 3 2 4 4 48

4

12

12

UCL c c 3 c 4 3 4 10, LCL c c 3 c 4 3 4 2 0 (negative)

b. (2 points) A purchaser of a bag of chocolate chip cookies discovers a cookie that has no chips in

it and charges the company with fraudulent advertising. If the expected number of chips per

cookie is four, what is the probability that a cookie would have no chips? Use Poisson probability

table.

Px 0 | 4 1 Px 1 | 4 1 0.9817 (from Table A - 3 for x' 1, m 4)

0.0183

c. (1 point) Suppose that the company produces 300,000 cookies per year. How many cookies

baked each year would have no chips?

E X np 300,000 0.0183 5,490 cookies

Question 10: (6 points)

Frank Brown, an independent TV repairman, is considering purchasing a home in Ames, Iowa, that

he will use as a base of operations for his repair business. Frank’s primary sources of business are 5

industrial accounts located throughout the Ames area. He has overlaid a grid on a map of the city

and determined the following locations for these clients as well as the expected number of calls per

month he receives:

Client

Grid Location

Expected Calls per Month

1

(6,4)

6

2

(8,3)

4

3

(5,9)

5

4

(4,5)

3

5

(7,8)

2

Find the optimal location of his house, assuming the goal is to

10

Name:_________________________________________________

ID:_________________________

a. (3 points) minimize weighted squared of the Euclidean distances.

Client, i

ai

bi

wi

wi ai

wi bi

1

6

4

6

36

24

2

8

3

4

32

12

3

5

9

5

25

45

4

4

5

3

12

15

5

7

8

2

14

16

w

i

w a = 119/20 = 5.95

w

w b = 112/20 = 5.60

w

X*

i

w a

20

i

i

119

w b

i

i

112

i

i

Y*

i i

i

Optimal location = (5.95, 5.60)

b. (3 points) minimize the maximum rectilinear distance to any client.

Client

ai

bi

ai bi

ai bi

1

6

4

10

-2

2

8

3

11

-5

3

5

9

14

4

4

4

5

9

1

5

7

8

15

1

Min

c1 9

c3 -5

Max

c2 15

c4 4

c5 max c 2 c1 , c 4 c3 max 15 9,4 5 max 6,9 9

x1 c1 c3 / 2 9 5 / 2 7.0

y1 c1 c3 c5 / 2 9 5 9 / 2 6.5

x 2 c 2 c 4 / 2 15 4 / 2 5.5

y 2 c 2 c 4 c5 / 2 15 4 9 / 2 5.0

Any point along (7.0, 6.5) and (5.5, 5.0) is optimal.

11

Name:_________________________________________________

ID:_________________________

Question 11: (3 points)

Activities of a project and their immediate predecessors are shown below:

Activity

Time (Weeks)

Immediate Predecessors

A

5

---

B

7

A

C

3

A

D

2

B,C

E

6

C

F

5

B,E

Construct a network for the project. Use activity on arc methods.

D

4

6

B

1

A

F

2

C

5

3

E

Node 1 = starting node

Node 6 = finish node

Question 12: (5 points)

Following network shows PERT time estimates (a,m,b)

in weeks:

4

(2,5,9)

C

a. (3 points) Determine a critical path based on most

likely times. What is the mean and standard

deviation of the length of the critical path?

There are only 4 paths from the start node 1 to the

finish node 7. These paths ad their lengths are listed

below:

Path

ACEG

ABEG

ABDG

ABFH

Length

6+5+7

+3=21

6+12+7

+3=28

6+12+1

1+3=32

6+12+5

+6=29

The longest path, ABDG is the critical path.

12

(5,7,9)

E

1

A

(4,6,8)

2

5

P1

(1,3,7)

G

D

(10,11,12)

B

(9,12,14)

3

F

(3,5,7)

6

7

H

(4,6,9)

Name:_________________________________________________

Critical activity

ID:_________________________

a 4m b

6

2

4 46 8

6

6

A

B

b a 2

8 42

14 92

10 411 12

11

6

12 102

36

0.6944

0.1111

36

1 43 7

3.33

6

G

0.44

36

9 412 14

11.83

6

D

36

7 12

6

6 11.83 11 3.33 32.16

1.0

2 0.44 0.69 0.11 1.0 2.25

2 2.25 1.5

b. (2 points) Assuming that the critical path is the one identified in a, find the probability that the

project will be completed in 35 days.

35 32.16

P x 35 | 32.16, 1.5 P z

P z 1.89

1. 5

P z 0 P0 z 1.89 0.50 0.4706 0.9706

Question 13: (5 points)

Shop starts at 8:30 am. Following are the information about two jobs.

Job

Time when the job

arrives

Time when the job is

completed

Time when the job is

due

A

8:30 am

12:30 pm

1:30 pm

B

11:30 am

4:30 pm

2:30 pm

Find

a. (1 point) completion time of each job.

Set t 0 at 8:30 a.m.

C A 12 : 30 8 : 30 4 hours

C B 4 : 30 8 : 30 8 hours

b. (1 point) flow time of each job.

FA C A rA 4 0 4 hours

FB C B rB 8 3 5 hours

c. (1 point) tardiness of each job.

13

Name:_________________________________________________

ID:_________________________

TA max 0, C A d A max 0,4 5 0 hours

TB max 0, C B d B max 0,8 6 2 hours

d. (1 point) total completion time.

C C

A

CB 4 8 12 hours

e. (1 point) makespan.

Makespan = max C A , CB max 4,8 8 hours

Question 14: (5 points)

Jobs processed through Percy’s machine shop pass through milling, grinding and turning in the

stated order. The hours required for each of these operations is as follows:

Job

Milling

Grinding

Turning

A

7

2

2

B

2

1

7

C

4

1

1

D

5

2

6

E

3

1

8

a. (2 points) Determine a sequence to minimize makespan.

First, consider the following fictitious 2-machine problem:

Job

Machine 1’

Machine 2’

A

7+2=9

2+2=4

B

2+1=3

1+7=8

C

4+1=5

1+1=2

D

5+2=7

2+6=8

E

3+1=4

1+8=9

Iteration 1: Min{processing times} = 2 for Job C on Machine 2’. Assign Job C to Position 5 (near

end). Eliminate Job C.

C

Position 1

Position 2

Position 3

Position 4

Position 5

Iteration 2: Min{processing times, except Job C} = 3 for Job B on Machine 1’. Assign Job B to

Position 1 (near beginning). Eliminate Job B.

B

C

Position 1

Position 2

Position 3

Position 4

Position 5

Iteration 3: Min{processing times, except Jobs B,C} = 4 for Job A on Machine 2’. Assign Job A to

Position 4 (near end). Eliminate Job A.

B

C

Position 1

Position 2

Position 3

Position 4

Position 5

Iteration 4: Min{processing times, except Jobs A,B,C} = 4 for Job E on Machine 1’. Assign Job E

to Position 2 (near beginning). Eliminate Job E.

B

E

A

C

Position 1

Position 2

Position 3

Position 4

Position 5

Iteration 5: Assign Job D to the only remaining position 3.

B

E

D

A

Position 1

Position 2

Position 3

Position 4

14

C

Position 5

Name:_________________________________________________

ID:_________________________

Final sequence: B, E, D, A, C.

b. (2 points) Draw a Gantt chart illustrating your solution.

Milling

B

E

B

Grinding

D

E

Turning

A

A

D

B

2

4

C

C

E

6

8

10 12

Time

A

D

14

16

18

20

22

24

C

26

28

30

c. (1 point) What is the optimal makespan? 27.

Question 15: (2 points)

A production facility assembles inexpensive telephones on a production line. The assembly requires

7 tasks with precedence relationships and activity times in minutes are shown below:

5

E

5

A

3

G

7

C

6

B

F

8

D

12

a. (1 point) Consider a solution with station 1: {A,B}, station 2: {C,D}, station 3: {E,F,G}. Is the

solution feasible? If so, find the cycle time given by the solution.

Yes. Cycle time = max 5 6,7 12,5 8 3 max 11,19,16 19 min

b. (1 point) Using eye inspection, provide a line balancing solution with cycle time at most 23

minutes and minimum number of workstations.

Station 1: {A, B, C, E}, time = 5+6+7+5 = 23 min

Station 2: {D, F, G}, time = 12+8+3 = 23 min

Cycle time = max{23, 23} = 23 min as required.

15