JPhalen - Boris Jeremic

advertisement

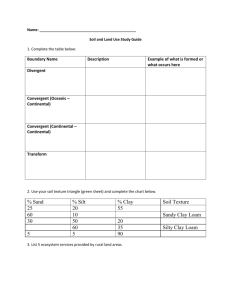

Kansai International Airport: A Foundation Case Study University of California, Davis Department of Civil and Environmental Engineering ECI 284: Theoretical Geomechanics Professor: Boris Jeremic By: Justin Phalen March 21, 2002 Introduction: In the early 1960’s Japan was advancing with technology at a fast rate. Their economy finally stabilizing after World War II, Japan’s exports had become high in demand as well as their imports, which were crucial to maintaining a booming population growth. At this time, the largest international airport was in Tokyo; the middle of the island. Business owners had to ship their goods hundreds of miles so they could be exported out of the country. This was both costly and time-consuming. 300 miles south of Tokyo was a region being burdened with this heightened sense of growth. The Kansai region was becoming a major industrial area but had little means necessary to move its goods and capitalize on its potential for expansion. The idea of building an international airport in the area was developed in the late 1960’s, but radical landowners and angry farmers violently revolted and the project was forced to shut down. Soon the Kansai region, which included the large cities of Kobe and Osaka, became a sprawling metropolis. City designers were forced to find a solution as to where to put an airport. With the majority of land yielding to the inhabitants of Kansai, the only practical solution was to build on water. Osaka Bay is now the home of an immense 2.5-mile long man-made island, the largest of its kind. The mile-long terminal of Kansai International Airport (KIX) opened in 1994, only eight years after construction began. This is not to say that the project was flawless. Inexperience with building on the soft seabed gave engineers problems with settlement both during and after construction. This report focuses on the methods the engineers used to mitigate the anticipated problems of a sinking island as well as the unexpected issues that trouble designers even today. 2 Subsurface Investigation: The first step to solving any geotechnical application is to gather as much information as possible about the soil and the environment in which the soil will be used. This may include soil types, strength parameters, compressibility issues, stratigraphy, groundwater conditions, and other parameters relevant to the project. For a task the scale of Kansai, an extensive investigation was necessary to characterize the subsurface since very little was known about the soil conditions below the bay. Using large barges and rigs, engineers were able to bore deep into the seabed and gather information about the types of soil they would be resting their airport on. Not a surprise to the investigators, the upper 60 feet was a soft alluvial clay. Comprised of loosely placed sediment, this Holocene layer was thought to give engineers the most problems in terms of settlement. They were not worried, however, since they were used to building on similar deposits off the shores of the bay and had means to control it. More unexpected and threatening was below the alluvial clay layer. An old, diluvial deposit of stiff clay, which had never been built on before, was seated approximately 1000 feet below the Holocene layer. Scientists could only guess how it would respond to the tremendous weight of the airport. Figure 1 shows a schematic of the subsurface. Dimensions are approximate. Figure 1: Subsurface of The Kansai Airport Foundation 3 Island Construction: Engineers outlined three main stages of the island construction: remediation of the seabed, placement of a seawall, fill. Seabed Remediation The largest concern of building an island on clay is settlement. The loose Holocene layer is comprised of small soil particles with many small voids between them. Because of their small size, clay particles can be packed very close together, and thus, have small pore spaces. Small pores mean low permeability, which causes fluid to move very slowly through a clay matrix. When an external load from a building, soil structure, or fill is applied to a deposit or stratum of clay, the particles condense and try to reduce the voids between them. If these voids are filled with water, the water needs to escape before the soil matrix can reach its fully consolidated state. Depending on the thickness, the drainage conditions at the boundaries, and the intrinsic properties of the clay layer, this procedure can take anywhere from hours to hundreds of years. In the case of the Kansai Airport, the upper alluvial layer was highly compressible. Engineers could somewhat predict the magnitude of settlement from laboratory testing of samples and experience. Because of its thickness, it would take years to consolidate under the immense loads of the airport. To mitigate this problem, designers used a very simple technique (in terms of theory). To allow the water to drain quickly, one must shorten the length it takes for a molecule to exit the system. Approximately one million sand columns were inserted into the Holocene clay layer to improve drainage conditions. This system allows the water to flow horizontally to a column and then exit relatively quickly in a vertical direction since the sand has a high permeability. It also strengthens the soil during construction, which is essential to maximize the productivity given their time frame. The sand draining method is illustrated in Figure 2 below. 4 Figure 2: Sand Draining Technique to Increase Settlement Rate of Consolidating Clays Seawall Much like the boards that create a confining area for a child’s sandbox, the island needed a sturdy perimeter to retain the fill and act as a buffer for any tidal activity. For a period of 2 years, divers individually placed large concrete boulders to form a seawall for the airport. Within a couple of inches from the plans, the 2-ton blocks slowly arose from the seabed creating a ring of concrete 40 ft above sea level. Special “tripod” blocks were used on the seaward side to dissipate the energy of any harsh waves generated by typhoons or any other natural disaster. Figures 3 and 4 show different perspectives of this wall. Figure 4: Typical Cross Section of Seawall 5 Figure 3: Completed Seawall Fill Once the seawall was completed, workers started on the body of the island. The source of their fill material, which was comprised of three distinct grades of sand, gravel and rock, was from three nearby mountains. Trucks steadily transported the soil to the bay where large barges collected it and shipped it three miles to the site. Once systematically positioned by GPS tracking, the bottoms of the barges opened, allowing their load to fall to the bottom of the bay. When the surface of the soil became too shallow for this method, soil-heaping machines placed the fill in these areas. Four years and 750 million cubic feet of fill later, the island was complete and three mountaintops had disappeared. 6 How Low Will It Go? Once the fill was in place, it was only a matter of time before the foundation would settle and engineers would see exactly how accurate their predictions were. The following is an excerpt from a report the author had written earlier. It is a look at consolidation theory: how engineers might predict how much and how long it takes a soil to settle under loading conditions knowing certain properties of their soil. Hopefully it will give the reader a better sense of what engineers have to tackle in this type of project. Consolidation Settlement In a way, fine-grained soils have a “memory” when it comes to their stress histories. A clay stratum will consolidate to a higher degree when subjected to an unfamiliar stress state than it will if it has previously experienced it. Soils that are currently at their highest stress state in history and are not settling are termed normally consolidated. If there haven’t been any drastic changes to the physical conditions of the subsurface (including groundwater fluctuations, excess surface loads, etc.), soil is generally considered to be in this state. In short, a soil is less compressible during reloading than during virgin loading. It would be useful to engineers if the magnitude of settlement were known so precautions could be made to insure structural stability of their projects. For ideal homogeneous subsurface conditions (and infinite uniform loading scheme), soils can be expected to consolidate uniformly over the area of the site. This makes design for the engineer relatively simple, as there will be no differential settlement issues at different areas of the project. This ideal condition is rarely attainable, however, so empirical methods have been developed to calculate the consolidation settlement of fine-grained soils. Considering normally consolidated clay with layer thickness H, the ultimate consolidation settlement c,ult due to an applied stress increment , can be estimated by: c,ult ' H Cc log vo 1 eo vo ' 7 Where: Cc is the compression index of the clay, from oedometer testing or estimation, vo’ is the initial effective stress at the middle of the soil layer, and eo is the initial void ratio corresponding to vo’ (Terzaghi and Peck 1967). This equation allows for analysis at various areas of the project site while altering thickness, stress increments, and initial effective stress values to accommodate the changes in subsurface stratigraphy. Furthermore, it can be used to find the settlement of a clay stratum at a sub-layer level. Accuracy of the settlement equation increases when separating a large deposit of clay into smaller divisions and summing the individual settlements at different levels. This is extremely useful when dealing with very thick clay deposits or applied loads of limited areal extent, which influence those sub-layers closer to the surface more than those further below. Time-Rate Settlement Even more important than how much a soil consolidates is how long it takes to reach ultimate settlement. As in the case of Kansai International Airport, if a project site has not reached full settlement under the loads applied by the structure, it will continue to deform (most likely nonuniformly) and cause unwanted disturbances in the foundation. This leads to high maintenance costs and sometimes failure of the structure. When a saturated, low-permeability soil is subjected to an increase in stress, the soil matrix tries to reduce its volume by forcing the clay particles closer together. Since water cannot escape the pores of the soil matrix quickly, it bears the majority of the stress until it can be discharged. The excess pore water pressure, ue, is what defines the time-rate settlement of a fine-grained soil. When a clay deposit has zero excess pore water pressure, it is fully consolidated. Terzaghi (1925) suggested that the rate of consolidation settlement is governed by the differential equation: 2ue ue c v 2 t z 8 Where: cv is the coefficient of consolidation ue is the excess pore water pressure at z, the depth below the upper surface of the clay layer under consideration at t, the time coordinate With the following assumptions: Voids are completely filled with water Both water and soil particles are incompressible Coefficient of permeability k does not change as soil consolidates Time lag of consolidation is due entirely to the low permeability of the clay Clay is laterally confined Clay is homogeneous and isotropic Using a number of boundary conditions, the solution for ue at any time t can be solved using a Fourier series: ue 4 1 2 N 1 z ( 2 N 1) 2 2 T / 4 sin e 2H N 0 2 N 1 N and T cv t Hd 2 Where: T is a dimensionless time factor, Hd is the length of the longest drainage path in the soil layer The term Hd describes the longest distance a water molecule must travel to escape the clay layer. In the case where the layer is restricted on one side by an impervious boundary and free to drain on the other side (single drainage), then Hd is the thickness of the layer. If the water is free to seep out of either end (double drainage), Hd is taken to be one half of the thickness. This procedure allows one to estimate the time for excess pore water pressure dissipation at any level in the clay layer if the above intrinsic properties can be quantified. From these expressions, plots have been created to aid engineers in determining the degree of consolidation for their specific subsurface conditions. Figure 5 is an isochronal map in terms of dimensionless parameters Z (depth factor), T (time factor), and U (consolidation ratio). T, defined above, is heavily dependent on the drainage path of the pore water. Simply doubling the thickness of a clay layer increases the time for consolidation by four. Z, defined as z/Hd, describes a depth location in the soil layer with respect 9 to the drainage path. At depth Hd, the depth ratio is 1.0. This is the location of the maximum excess pore water pressure at any time. Note that for the single drainage condition, the depth ratio is never greater than 1.0, so only the top half of Figure 5 is used. The consolidation ratio U is a percentage of how much excess pore water pressure exists at any time in terms of the initial excess pore water pressure. This value is synonymous with how much the soil has consolidated at any time. The consolidation settlement c,t at time factor T, corresponding to time t, at depth z is expressed as: c , t U c ,ult Notice that U is independent of load. This means that the time-rate of consolidation is constant, regardless of the magnitude of applied loading (i.e. a soil that takes 20 years to fully consolidate under a 200 psf applied load will take 20 years to consolidate completely under a 1000 psf load). Figure 5: Isochrones of Excess Pore Water Pressure for Uniform Initial Excess Pressure 10 Settlement Predictions and Why They Were WRONG: Scientists debated over how much the island would ultimately settle. Since this was the first time anyone had worked with the deep deposit of diluvial clay it was almost anyone’s guess as to how it would behave under the immense load of the fill. Most scientists were confident it would only sink between 19 and 25 feet. Interestingly enough, the airport was designed for an island that would settle only 19 feet. By the time the island was completed in 1990, it had already settled 27 feet and was continuing at a rate of 2 inches per month. This prompted designers to put an extra ten feet of fill on top to compensate for the difference, adding even more stress to the seabed. The deep clay layer was not a homogeneous material. Imbedded in the clay were horizontal seams of sand at random intervals (Figure 6). Researchers hoped these seams would help dissipate the excess pore water pressure relatively quickly since there was no conceivable way of Figure 6: Sand Seams Interbedded with Pleistocene Clay Layer remedying the situation themselves. Careful monitoring of the pore pressure in these sand beds led engineers to believe that only parts of the clay were consolidating quickly. Other areas with thin seams or non-continuous layers would take years to drain. Figure 7 illustrates an average excess pore pressure over time. The airport opened in 1994, near the peak of the curve. A 11 steadying trend means the soil will continue to consolidate for many years, perhaps past the life of the airport. Figure 7: Average Excess Pore Pressure vs. Time Figure 8 shows the pore pressure distribution with depth as well as the location and relative sizes of the sand layers (nine years after completion of the island). Notice that both the top and bottom of the Pleistocene have drained well while the center is largely under consolidated. The sand draining method is not easily implemented at these depths. 12 Figure 8: Excess Pore Pressure with Depth 13 Differential Settlement: Of possibly even more concern than how much the airport would settle is how evenly the island would recede into the bay. Ideally, engineers would like to design their foundations considering a homogeneous material. These are easily modeled and propose that the foundation will settle at the same rate at all points below. Certainly with a plan the size of Kansai Airport, coupled the mystery of the deep-seated clay, this island is not an ideal case. Without proper precautions, differential settlement can cause unwanted disturbances in the foundation and even catastrophic failure in the structure itself. To account for anticipated differential settlement between the island and the terminal, workers lined the basement of the terminal with a quarter of a million tons of iron ore. At first it would seem counter-intuitive to make the terminal heavier than it already is. After all, the idea is to reduce the amount of settlement, not increase it. However, designers calculated that the structure actually weighed about one half of the soil it displaced. This would cause the island to sink faster than the building it is trying to support. The additional weight of the iron ore allows the terminal to settle at approximately the same rate as the rest of the island. Local differential settlement issues were corrected in a different manner. The runways were paved with asphalt so they could easily patch holes if needed. Concrete would have the tendency to crack in this situation. The terminal was built on 900 columns, which supported the weight of the building. A computer monitored each column for any vertical displacements as the earth below subsided. If any differential settlement occurred the columns could be raised or lowered my means of a hydraulic jack. Steel plates were slid under the columns to stabilize them once the jacks were removed. 14 Earthquakes and Other Natural Disasters: A certain amount of risk comes with building anything in a seismically active region. Historically, Japan has played host to some of the most violent earthquakes in the world. Catastrophic death tolls, however, are caused by human creations, not the actual motion of the quake. The majority of structural failures are due to a sudden loss in strength in the soil foundation. Liquefaction is always a threat in regions where buildings are built on loose, saturated sands and landfills. Recall that the fill under Kansai Airport was placed by dumping barges of sand and gravel into the bay and letting it settle in a very loose state. The performance of the fill during an earthquake worried designers for this reason. Hopefully, they would not have to test it. In 1995, just 15 months after the terminal opened, an earthquake rocked the Osaka Bay area in the early morning. Kansai Airport was just 18 miles from the epicenter near Kobe on the northern rim of the bay. When officials arrived at KIX, they were surprised to find minimal damage to the island. With the exception of a few cracked sidewalks and some shaken tourists, the terminal was visibly in perfect condition. They concluded that there were enough large rocks in the fill to absorb the energy released from the waves of the earthquake to prevent liquefaction. The ingenious design of the terminal also helped maintain structural stability. Trouble areas were fitted with sliding joints, allowing various sections to move independent of one another. Also, the roof was not rigidly connected to the walls. This allowed no transfer of energy between the heavy roof and the sensitive, glass-laden walls. The airport remained open during rescue efforts and was a staging yard for emergency procedures. Earthquakes weren’t the only disaster to threaten the island. Three years later, a powerful typhoon stormed into Osaka Bay. At that time the elevation of the island was 17 feet above sea level. High winds and the threat of flooding caused officials to close the terminal until the storm had passed. Luckily, the typhoon caused no serious damage and KIX was re-opened later that evening. 15 Conclusion: Currently there are plans for two more phases of the KIX project. This will include adding another island and an expanded runway, both larger than the first and both in deeper waters. From the experience of the first phase, engineers have estimated approximately 60 feet in total settlement with the next two. This is about the depth of the current seabed from the water surface. The seawall of the second phase has already been constructed and filling will commence over the next six or seven years. To date, the largest concern the designers face is flooding. If the island continues to settle at the rate it is, the next typhoon could ultimately swamp the 2.5-mile marvel. Perhaps once the second phase is complete, they will have to tear down the existing terminal and add more soil to compensate for the unexpected consolidation, then rebuild. Although many precautions were taken to ensure the livelihood of the island, being unconservative in their estimates of settlement will ultimately cost designers billions of dollars in repair as well as the humility of an engineering blunder. 16 References Holtz, Robert D. and Kovacks, William D. (1981) An Introduction to Geotechnical Engineering. Prentice Hall, Englewood Cliffs, New Jersey. Terzaghi, Karl (1943) Theoretical Soil Mechanics, John Wiley & Sons, Inc., New York. Terzaghi, Karl and Peck, Ralph B. (1967) Soil Mechanics in Engineering Practice, 2nd Edition. John Wiley & Sons, New York. Kansai International Airport Land Development Company, Kald Information Center: URL: < http://www.kald.co.jp/index-e.html> Takenaka Corporation, Modification Method for Differential Settlement: URL: < http://www.takenaka.co.jp/takenaka_e/quake_e/fudo/fudo.htm> The Learning Channel, “Super Structures of the World: Kansai International Airport”, Original Broadcast, 1999. 17