4.0 Air Management Plan - Bundaberg Regional Council

advertisement

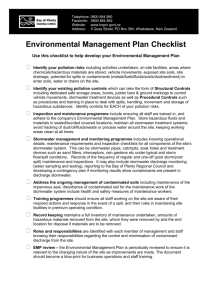

Environmental Management Plan 1.0 INTRODUCTION............................................................................................................ 3 2.0 ENVIRONMENTAL POLICY....................................................................................... 3 3.0 GENERAL ........................................................................................................................ 3 3.1 SITE DESCRIPTION .......................................................................................................... 3 3.2 FUTURE DEVELOPMENT .................................................................................................. 4 4.0 AIR MANAGEMENT PLAN ......................................................................................... 4 4.1 4.2 4.3 4.4 4.5 DUST............................................................................................................................... 4 EXHAUST EMISSIONS ...................................................................................................... 4 SOLVENT EMISSIONS ....................................................................................................... 4 AIR-CONDITIONING GAS RECOVERY/RECYCLING .......................................................... 4 WASTE STORAGE ............................................................................................................ 4 5.0 NOISE MANAGEMENT PLAN .................................................................................... 5 5.1 5.2 5.3 5.4 5.5 HOURS OF OPERATION .................................................................................................... 5 INSULATION .................................................................................................................... 5 LOCATION OF EQUIPMENT .............................................................................................. 5 TELEPHONE ..................................................................................................................... 5 NOISE MONITORING ........................................................................................................ 5 6.0 WASTE MANAGEMENT PLAN .................................................................................. 6 7.0 STORMWATER MANAGEMENT PLAN ................................................................... 7 7.1 EXCLUSION OF STORMWATER ......................................................................................... 7 7.2 STORMWATER ................................................................................................................. 7 7.3 TRADE WASTE ................................................................................................................ 7 8.0 ENVIRONMENTAL RISK & EMERGENCY MANAGEMENT PLAN ................. 8 8.1 STORAGE OF HAZARDOUS SUBSTANCES ......................................................................... 8 8.2 SPILL MANAGEMENT ...................................................................................................... 8 8.3 FIRE PROTECTION ........................................................................................................... 9 8.4 STAFF TRAINING ............................................................................................................. 9 9.0 ENVIRONMENTAL DUTY…………………………………………………………10 2 Environmental Management Plan 1.0 Introduction The following information comprises the environmental management plan under the Environmental Protection Act 1994 for …………………………………… located at ………………………………………. The environmentally relevant activity carried out on site is a motor vehicle workshop as defined under the auspices of the Environmental Protection Act 1994. 2.0 Environmental Policy ………….is committed to protect the environment in all of its day-to-day operations. ………….aims to conduct all of its activities not only in accordance with the requirements of the relevant legislation but also to demonstrate an environmentally responsible duty to both customer and industry alike. ………….believes that being an environmentally responsible business not only protects the environment in which we live, but also presents to the customer and general public a proud, responsible and reputable business. 3.0 General 3.1 Site Description The site is located at …………………………….., more accurately described as Lot ………. on …………………………………, Parish of …………………... The site is located in a primarily commercial area of ………………………. Other business located in this commercial are include: The workshop will be an annex to existing automotive businesses in ……………………………………. There are three (3) neighbouring properties to the site. To the east there is a ………………….(second hand car yard), to the west a ……………..… (residential dwelling). This dwelling is owned and occupied by an employee and future partner of the workshop and will act as a caretaker’s residence. To the north west there is another …………….……(residential building) some distance from the proposed workshop. 3 Environmental Management Plan 3.2 Future Development Should the need be required it is proposed that the future storage shed as shown on the site plan in Schedule I, will be used for the storage of parts and accessories for vehicles. This future area is not to be used for the servicing of vehicles. 4.0 Air Management Plan 4.1 Dust There are no anticipated dust nuisances on site as all driveway and car park areas are to be sealed in either concrete or bitumen. Refer to Appendix I – Site Plan. 4.2 Exhaust Emissions All work including tuning and testing will be conducted in the building. No odour nuisances are anticipated to adjoining premises. 4.3 Solvent Emissions All parts are to be cleaned in a Repco parts washer inside the workshop. The parts washer when not in use remains closed and non-operational to reduce evaporation. No odour emission related to solvents is anticipated. 4.4 Air-Conditioning Gas Recovery/Recycling All work done on air-conditioners will follow the Industry Code of Practice for automotive air-conditioning. Approved refrigerant gas recycling and storage equipment shall be used in these circumstances. 4.5 Waste Storage All waste is to be stored in either a <Council> supplied wheelie-bin or suitable recycling container. No odour nuisances are anticipated from this source. No other activities conducted on site are likely to cause environmental odour or dust nuisance. 4 Environmental Management Plan 5.0 Noise Management Plan The following measures are used to control noise on site: 5.1 Hours of Operation Proposed hours of operation of the workshop are: Monday – Friday #:##am – #:##pm Saturday – #:##am – ##:##pm Sunday – No trade 5.2 Insulation In accordance with Building and Fire Regulations the western wall of the workshop has been insulated with 3 layers of 13mm Gyprock® for both fire protection and noise attenuation. Details of construction are contained in Schedule I. 5.3 Location of Equipment All work and equipment including compressor is located within the insulated workshop. As such noise nuisances are not anticipated. Other noise sources contained within the building include grinding, welding and brake lathes. 5.4 Telephone Due to its location in the enclosed office within the workshop the ring of the telephone will not present a problem with respect to noise nuisance. A siren or industrial ring is not to be incorporated on this site. 5.5 Noise Monitoring The operators of the workshop will subjectively monitor noise levels on a three monthly basis. Where problems with noise are discovered action will be taken to rectify noise issues. 5 Environmental Management Plan 6.0 Waste Management Plan The treatment of waste generated on site is best described in the following table: Waste Product Liquids Waste Oil Brake Fluid Coolant Volume/Weight (per month) Contractor <Company> <Company> <Council> /<Company> <enter amount> As required Recycled Recycled Evaporation/Trade Waste Recycled Trade Waste <enter amount> <enter amount> Trade Waste Trade Waste <Council> <Council> /<Company> <enter amount> <enter amount> <enter amount> <enter amount> <enter amount> <enter number> Recycled Recycled Recycled Recycled Disposal Recycled (Metal) Steel <enter amount> Fan Belts, Hoses <enter amount> etc Paper <enter amount> Rags <enter amount> Absorptive As required? Material Other Recycled (Metal) Disposed <Company> <Company> <Company> <Company> <Company>/<Council> <Company> (Licence # CR####) <Company> <Company>/<Council> Recycled Disposed Bagged & Disposed <Company> <Company>/<Council> <Company>/<Council> Disposed <Company>/<Council> Solvents Wash Down Waters (floor) Detergent Degreaser Solids Cardboard Plastic Glass Aluminium Lunchroom Waste Oil Filters <enter amount> <enter amount> <enter amount> How Disposed <Company> <Council> Where licensed contractors are required, dockets/receipts are maintained for a period of seven (7) years. 6 Environmental Management Plan 7.0 Stormwater Management Plan The following measures have been incorporated in the design and construction of ………………………. to prevent water pollution. 7.1 Exclusion of Stormwater The workshop area is completely enclosed with all work carried out within the workshop. The workshop drains to a grated drain inside the front of the workshop where it drains to a 500 litre triple interceptor in accordance with Council’s Trade Waste Policy (see Schedule I). Where rain is likely to enter the workshop through open doors, standard procedure is to close the roller door as required to prevent stormwater from entering the sewerage system. 7.2 Stormwater The building is designed to divert the flow of all stormwater away from the workshop. The concrete driveway is sloped towards ………………………….with stormwater from the roof directed and piped to also ………………………….. 7.3 Trade Waste All discharges to the sewer shall be in accordance with the requirements of ……………………………………. Trade Waste Permit. The triple interceptor is checked on a monthly basis and cleared as required by <Company>. 7 Environmental Management Plan 8.0 Environmental Risk & Emergency Management Plan To reduce environmental risk and prevent emergency situations the following procedures are in place: 8.1 Storage of Hazardous Substances All fluids including waste oils are stored within the workshop. The workshop drains to a drain at the front of the building and then to a 500 litre triple interceptor. The maximum volume of hazardous substances stored on site as follows: Product Motor Oil Motor Oil Various Activities Degreaser Petrol Brake Fluid Solvent Coolant Waste Oil 8.2 Container Size <enter amount> eg.205 litres <enter amount> <enter amount> <enter amount> <enter amount> <enter amount> <enter amount> <enter amount> <enter amount> Number <enter quantity> Total Volume <enter total volume> <enter quantity> <enter quantity> <enter quantity> <enter quantity> <enter quantity> <enter quantity> <enter quantity> <enter quantity> <enter total volume> <enter total volume> <enter total volume> <enter total volume> <enter total volume> <enter total volume> <enter total volume> <enter total volume> Spill Management The above liquids are all stored undercover within the building. A spill kit comprising of rags, absorptive material, broom, shovel are kept in close proximity to the storage area. All large containers are frequently checked as they are repeatedly used. All liquid are stored in a constructed tray to contain any accidental spillage both for environmental protection reasons and workplace health and safety. In the event of a spill the following procedures will occur: 1. 2. 3. Minor The container is up-righted/checked and if required drained and the area spot cleaned with either absorptive material or rags. Major 8 Environmental Management Plan Where the unlikely event of a major spill occurs (>20 litres) the level in the interceptor is checked and if required <licence waste removalist’s name> contacted to empty the triple interceptor. 8.3 Fire Protection Fire extinguishers are located directly outside of the office and at the front opening of the buildings. These are regularly checked under contract with <Name> – <Company>. For location of the extinguishers see Schedule I. As described in Section 5.2 Insulation, the western wall of the workshop is insulated for both fore protection and acoustics. 8.4 Staff Training All staff are trained in accordance with the provisions of this Environmental Management Plan and the Environmental Authority. In particular staff are regularly briefed on : correct position of equipment; relevant environmental issues; proper waste disposal methods. 9 Environmental Management Plan 9.0 Environmental Duty ……………………… declare that I/we/it will comply with the issues and plans outlined within this Environmental Management Plan. Any proposed changes to the procedures or operation of this business will be submitted to the Health and Environmental Services Department at Bundaberg City Council for approval. ________________ ________________ Mr. Smith Date *Partner/Owner* **Insert Company Name** ________________ ________________ Mr Brown Date *Partner/Owner* **Insert Company Name** 10