Paper

advertisement

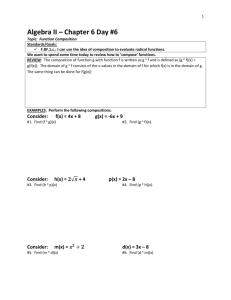

DIRECTED SYNTHESIS OF FINE-LAYER COATINGS, HERMETICS AND NANOCOMPOSITES BY MEANS OF CHEMICAL REACTIONS IN OXIDE MELTS V.Zhabrev Grebentshikov Institute of the Chemistry of Silicates RAS St.-Petersburg. Russia Grebentshikov Institute of the Chemistry of Silicates RAS is the fundamental scientific center of Russia in the field of nanostate. Scientific directions concerning of synthesis and study of nanoparticles and nanocomposits is developed. There are the investigations of structure and properties of high temperature oxide compounds, phase equilibriums, nanocrystals and nanocomposites based on oxides and hydroxides and organo-inorganic hybrid compositions. Other directions are investigation of chemical bonds and structure of compounds in glassy and crystal state, new methods making materials with certain properties.(glass, piroceramics, coatings). Now the synthesis of nanoparticles and nanocomposites is realized by or hydrothermal or zol-gel methods. Complexity and multistage this methods is known because it is necessary to make methods of synthesis on nanoparticles and nanocomposites. Two aspects of making of nanosize material is considering in this paper – synthesis of oxide nanocompounds using the chemical reaction in oxide melts and any kinetic questions on formation of high temperature coatings basing infusible oxides and nanosize reagents. 1. Synthesis nanocrystal mixed titanates of barium and strontium by means of reaction of crystal modification of titanium dioxide with KNO3 + Ba(NO3)2 or KNO3 + Sr(NO3)2 mixed melts. Titanates of barium and strontium are used as segnetoelectrics. Monocrystal segnetoelectrics usually are fabricated growing from both melt or solution and gas phase, polycrystal segnetoelectrics – under ceramic technology, film ones – vacuum evaporation or extrusion technology. Usually materials in system BaTiO3-SrTiO3 are produced as solid state reaction between carbonates and titanium dioxide at 1300-1400оС: 323 BaCO3+TiO2 = BaTiO3+CO2 SrCO3+TiO2 = SrTiO3+CO2 At 1400оС BaCO3, SrCO3, TiO2 are solid powders and to make equal mixed solid solutions it is necessary too large annealing time – up to ten hours. Solid state synthesis has very many limitation to produce nanosize materials as dispersion of productes of reaction is increasing in comparison with dispersion of original components. High temperature annealing reduces to tendency to cake. This factor do not give possibility of fabrication of equal dispersion low size materials. At last time new methods of production of titanates are developed. It is methods using hydrolysis of metallorganic compounds ( Si(OC2H5)4 + Ba(OH)2) or TiCl4 + BaCl2 etc. The mainly this methods is low temperature of reactions (up to 200оС), that guarantees well qualify of products. However ones have a lot of difficulties - toxicity and large price of reagents, necessary to keep technology. Thus it is needed to work out simply methods of making equal alloying oxide materials at more low temperature. Those methods must guarantee possibility to regulate dispersion of samples including ultraand nanosize crystals and high degree of purity. It may be the synthesis of materials in melting salts. Temperature of melting of nitrates of potassium, barium, strontium is given on Table 1: Таble 1 Melting temperature of compounds, оС Ba(NO3)2 595 Sr(NO3)2 645 TiO2 1840 KNO3 337 Potassium nitrate is used as reaction medium. In the medium certain portions of other reagents are adding. During reaction the particles of titanium oxide are solid ones and they do not solve in mixed 324 salt melts. To make nanosize materials in system BaxSr1-xTiO3 it is necessary to use high dispersion particles of titanium oxide. Preparing of powder TiO2 may be realized by hydrolysis of sulfate solution: Ti(SO4)2 + 4NH4OH 2(NH4)2SO4 + Ti(OH)4 with following annealing of hydrates Ti(OH)4 TiO2 + 2H2O The synthesis of titanates is carried out at 700-800оС: Ba(NO3)2+TiO2 = BaTiO3+2NO2+1/2O2 Sr(NO3)2+TiO2 = SrTiO3+2NO2+1/2O2 After this the products of reaction are washing off water soluble nitrates. Phase analysis of products of reaction is realized using RFA. At pictures 1 and 2 you can see diffractogrammes of powder materials BaTiO3 and SrTiO3 after reaction. It is seen only peaks of products of reaction. Fig.1. Diffractogramme of BaTiO3 prepared at 800oС from mixed salt melt 325 Fig.2. Diffractogramme SrTiO3 prepared at 825оС from mixed salt melt. Thus the synthesis of nanosize materials of BaxSr1-xTiO3 into mixed nitrate melts permits to make ones at 700-900оС, that lower on 200-400оС then we use solid state reaction from carbonates. Processes of migration into melt are intensified and reaction time is smaller. This method permits to regulate the dispersion of compounds up to nanosize value. Picture 3 shows the results of study of preparing particles by AMS set. Fig.3. Structure of nanoparticles of barium titanate. Next step of our investigation is the synthesis of new segnetoelectric compositions (table 2). To prepare of film carriers of 326 information those nanoparticles are deposited on hybrid organoinorganic coatings making by zol-gel method. Table 2. Some reactions in KNO3 melt Reaction t, С о Time, min 2Bi2O3+3TiO2Bi4Ti3O12 900 15-60 — 8Bi2O3+4LaCl3+15TiO2 5(Bi0.8La0.2)4Ti3O12 900 15-60 — 900 15-60 1:1 15-180 1:2 240 1:2 15-120 1:0.5 15-120 1:1 15-120 1:2 8Bi2O3+4LaCl3+15TiO2 5(Bi0.8La0.2)4Ti3O12 1000 8Bi2O3+4LaCl3+15TiO2 5(Bi0.8La0.2)4Ti3O12 2.The kinetics of heterophase interactions under formation of temperature stably coatings. In this part of paper influence of composition and condition termoannealing in air to prepare temperature stably porousless coating based on ZrB2 – SiC is discussed. The original reagent are powders with size of particles near 63 mkm. As binder water solution of carbometilcellulose or zol of silica is applied. Particles of silica is 20 nm. For comparing the compositions with addition of glass SiO2 –80, B2O3 – 17.5, Al2O3 – 2.5 (mаss.%) is used. Study cоmposition is given in table 3. Porosity coating termoannealing for one hour at 1400˚С is 30%. The velocity of all reactions under formation of coating is determined as increase or decrease of mass of samples ( ∆m, mg/cm2) during experiment at 800,1200 и 1400оС. 327 Таble 3 Study compositions Name 1а 2а 3а 4а 1б 2б 3б 4б 1в ZrB2 100 95 90 70 100 95 90 70 90 Соmposition, mаss.% SiC SiO2 5 10 30 7.5 5 7.5 10 7.5 30 7.5 - АБС 10 In table 4 the results of RFA of surface of some composition after thermoannealing at 1400С and different time of treatment are shown. It is seen that new phases are formed on surface of samples namely ZrO2 monoclinic modification, ZrSiO4 и -crystabolit. Table 4 Crystal phases on surface of samples after annealing at 1400С in air Name Phase composition after annealing for different time, min. 5 60 1а ZrB2,ZrO2 ZrB2,ZrO2 2а 4а ZrO2 ZrO2 1б ZrB2,ZrO2 3б ZrB2,ZrO2, ZrSiO4 1в ZrO2 ZrO2 ZrO2 ZrB2,ZrO2, ZrSiO4 ZrO2, ZrSiO4 ZrO2, - crystabolit 328 300 ZrB2(следы), ZrO2 1020 ZrO2, ZrSiO4 ZrO2, ZrSiO4 ZrO2, ZrSiO4 ZrO2, ZrSiO4 ZrO2, ZrSiO4 ZrO2, ZrSiO4 ZrO2 This results show point of chemical reactions passing under oxidation zirconium diboride and silicon carbide. It is possible to suppose that at high temperature oxidation this composition passing next reactions: - oxidation zirconium diboride and silicon carbide in air at 8001400оС as: ZrB2(s) + 2.5O2 = ZrO2(т) + B2O3(l) SiC(s) +2 O2=SiO2(s) + CO2 ↑ - - solution in liquid B2O3 zirconium dioxide and silica: B2O3(ж) + ZrO2(т) + SiO2(т) к ZrO2 mB2O3.nSiO2 and resulting product is anionic matrix of melt. crystalisation of melt with precipitating of zircon ZrSiO4 и crystabalit Kinetic curves of oxidation compositions 1а, 2а, 3а и 4а is shown Fig.1 at 800оС (1а),1200оС (1б) и 1400оС (1в).Alone ZrB2 is oxidized at 1400оС very strong. It is possible to suppose that produced melt of B2O3 is not protected layer because its viscosity is small. Introduction in composition of increasing portions of SiC leads to Fig.3 shows kinetic curves of oxidation of compositions 3а, 3б, и 1в during long time. For 17 hours at 1400С ∆m of samples is not more then 25 mg/sm2. It is needs to know that kinetic curves show summary result of different chemical reactions spring from annealing of samples in air – oxidation of initial components, interactions between oxides, forming of liquid borosilicate glassy melt, evaporation of small part of B2O3 and full evaporation of CO2. Therefore it needs to sort out them with point of view of interphase interactions. In common mechanism of interphase reaction of oxidizing of study compositions may be describe by means of forming of reaction boundary of division of phases and future processes of interaction of solid phase with products of dissociation of melt: migration ionic associates of oxide melt to surface of separation and insertion of products of reactions into structure of melt. 329 1а m 200 150 2а 100 3а 50 4а 0 0 20 40 60 80 100 t,min m (mg/sm2) 1б 50 40 2а 30 3а 20 4а 10 0 0 20 40 60 80 100 t,min 1в m (mg/sm2) 40 1а 30 2а 20 3а 10 4а 0 0 20 40 60 80 t, min Fig.1 Dependence of increasing of mass ∆m (mg/sm2) samples 1а-4а after annealing in air at 800оС (а), 1200оС (б) и 1400оС (в) vs time t (min). 330 20 2б 18 16 3б m мг/см привес, 2 14 4б 1в 12 10 8 6 4 2 0 -2 0 20 40 60 80 100 t, время, min мин Fig.2. ∆m of samples 2б-4б,1в vs t after annealing at 1400 ºС in air. 35 mмассы привес 30 25 1в 20 3а 15 3б 10 5 0 0 5 10 15 20 25 t,ч t, hours Fig.3. Dependence of ∆m (mg/sm2) of samples 3а, 3б и 1в after annealing in air at 1400оС for t (min). Processing rate is determines by diffusion in drowing layer of reaction products and three-dimensional decreasing of volume of reagents as result of moving of reaction boundary of separation. 331 Oxidation of any studied compositions on base of ZrB2 and SiC is complexity process and there is no possibility to fixe of variation of comcentration of each from all component of composition. To avoid indefiniteness in determination of rate of chemical interphase reactions ( without certain component at which determined common rate) It is needs to give the definition of degree of conversion as value that indicates the quantity reacted or formed substance (without to origin or final ones). Farther this value will mark and race of reaction will be d/dt. The degree of conversion is unsize relation of maximal increasing of mass on kinetic curves (Fig.1 and 2) to current increasing of mass. ( = mi/ mmax). We also admit the possibility of parallel ( А+В С и А+В D) and consecutive ( А + В С D ) reactions. Kinetic equations for reaction with advance of boundary of division of phases are taken out by summation the volumes of all nuclei of new phases: dα V(t) = o V(titj) ----- ) dtj dt t (1) where: V(t) – volume of product of reaction for time t. As V(t) is proportional to degree of conversion, integration of (1) gives: α = (kt)n (2) where: к – constant of race of reaction, n – order of the reaction. The equation (2) is named by power law of growth of product of new phase and its is right for any combination of laws of nucleation and growth of new phase. Estimation of regularity of variation of degree of conversion as function of time lets to predict the rate of reaction under certain composition of reagents and certain value of constant of rate. In this prediction analyzing the order of reaction it is possible to make conclusion about mechanism of reaction. Constant of rate is equal the rate of reaction if concentrations are 1 and depends from temperature as Arrenius equation: к= A exp(-E/RT) 332 (3) where: А – preexponential member; Е – activation energy; R –gas constant; Т- temperature. Fig.4-6 show the dependence of degree of conversion (a) and rate of reaction (б) as function of time of interaction at 800,1200 и 1400оС for compositions 1а,2а,3а,4а. For all compositions and at all temperatures rate of reaction falls sharply for first 10 minutes and after this we can see low decreasing of rate of reaction. Also introduction rising quantity of SiC leads to gradual decreasing of oxidation rate. For kinetic analysis of topochemical reactions are used large quantity of equations α = f(t). Those equations are take into account different points of view about formation and moving of boundary of separation, diffusion of reagents in layer of products of reactions. First treatment of experimental data are maken by AvraamiErofeev equation: α = 1- exp (-ktn) (4) This equation describes common dependence of degrre of conversion from time. Transformation of (4) gives: lg[-ln(1- α)] = lgk +nlgt (5) 1,2 1 0,8 0,6 0,4 0,2 0 0 20 40 60 t, min Fig.4а. Dependence of degree of conversion from time at 1400 оС for compositions: ● – 1а, - 2а, - 3а, ▲- 4а. 333 80 1400 0,04 0,035 0,03 0,025 da/dt 0,02 0,015 0,01 0,005 0 0 10 20 30 40 50 60 t Fig.4б. Dependence of rate of reaction from time at 1400 оС for compositions: – 1а, - 2а, - 3а, ▲- 4а. 1200 1 0,8 0,6 0,4 0,2 0 0 10 20 30 40 50 60 70 80 t, min Рис.5а. Dependence of degree of conversion from time at 1200 оС 334 90 for compositions: - 2а, - 3а, ▲- 4а. 1200 0,04 0,035 0,03 0,025 da/dt 0,02 0,015 0,01 0,005 0 0 20 40 60 80 t Fig.5б. Dependence of rate of reaction from time at 1200 оС for compositions: - 2а, - 3а, ▲- 4а. 1 0,9 0,8 0,7 0,6 0,5 0,4 0,3 0,2 0,1 0 0 10 20 30 40 50 60 70 80 min Fig.6а. Dependence of degree of conversion from time at 800 оС for compositions: - 3а, - 2а, ▲- 4а. 335 90 0,035 0,03 0,025 da/dt 0,02 0,015 0,01 0,005 0 0 10 20 30 40 50 60 70 80 t Рис.6б. Dependence of rate of reaction from time at 800 оС for compositions: - 2а, - 3а, ▲- 4а. The value of angular coefficient of linear dependence lg[-ln(1- α)] = lg(t), gives n (order of reaction). In Fig. 7a,b,в are shown the dependences lg[-ln(1- α)] vs lg (t) at 800,1200 и 1400оС for compositions 1а-4а. At 800оС for 2а и 3а linear part of dependence is observed only at small time of interaction, FOR 4а equation ( 4 ) is applicated in all times. The value of angular coefficient of linear part of dependence is 0.65±0.10. This value of n answers by model of diffusion – controlled reaction. 0,6 lg|-ln(1- ) 0,4 0,2 3a 0 2a -0,2 4a -0,4 -0,6 0,9 1,1 1,3 1,5 1,7 1,9 2,1 lgt Fig.7а Dependence lg[-ln(1-)] vs lgt at 800оС for compositions: ▲- 4а, - 2а, ■- 3а. 336 In first steps of oxidation 2а и 3а quantity of silica is not sufficiently to prevent motion of oxygen. Forever there are two reactions: oxidation of components and forming glassy film and we can see deflecton from ( 4 ). For composition ( 4a ) only diffusion – controlled process is observed. 0,8 0,6 0,4 2a 0,2 4a 3a 0 -0,2 -0,4 0,9 1,1 1,3 1,5 1,7 1,9 2,1 Fig.7б Dependence lg[-ln(1-)] vs lgt at 1200оС, composition: ■- 3а, ▲ - 4а, - 2а. 0,8 0,6 0,4 1a 3a 0,2 2a 4a 0 -0,2 -0,4 1 1,25 1,5 1,75 Fig.7в Dependence lg[-ln(1-)] vs lgt at 1400оС:–1а, - 2а, - 3а, ▲- 4а. Now it is needs to consider the chemical aspect of reactions. Zirconium in structure of borate melt may form groups [ZrO4/2] and those groups enter in ionic associates of melt: 337 ZrO2 + 2[ВO3/2] [ZrO4/2] 2[ВO3/2] (6) The same reaction for silica: SiO2 + 2[ВO3/2] [SiO4/2] 2[ВO3/2] (7) As result of two parallel reactions common matrix of melt is formed [SiO4/2] [ZrO4/2] 2[ВO3/2]. Those reactions determine common kinetics of process. In Table 3 the values of lgk is given for composition 2а-4а at all temperature range. Table 3 Values of lgk for compositions 2а-4а at 800, 1200 и 1400оС Состав 2а 3а 4а о 800 С -1.15 -1.05 -0.90 1200оС -0.95 -0.70 -0.85 1400оС -0.75 -0.70 -.0.95 Fig.8 show results of kinetic analysis for composition 1б – 3б. 0,7 lg[-ln(1-a) 0,6 0,5 1б 0,4 2б 0,3 3б 0,2 0,1 0 1 1,2 1,4 1,6 1,8 2 lgt Рис.8. Dependence lg[-ln(1-)] vs lgt at 1400оС for composition: ♦–1б, 2б, ▲- 3б. In conclusion it is fact that formation of glassy matrix of melt is important part of protection of material. 338