MAINE SUBSURFACE WASTE

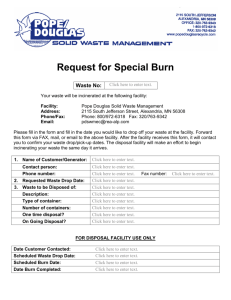

advertisement