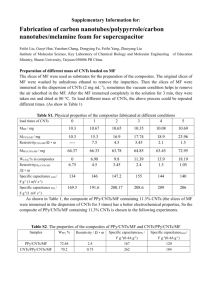

Cheryl_research

advertisement

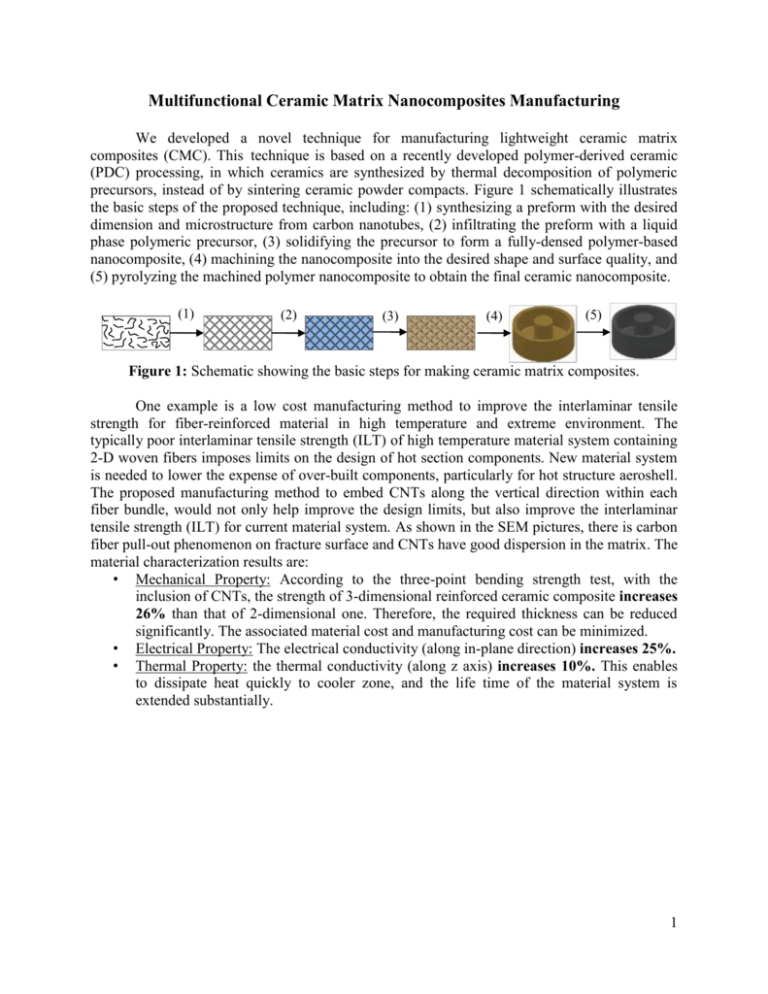

Multifunctional Ceramic Matrix Nanocomposites Manufacturing We developed a novel technique for manufacturing lightweight ceramic matrix composites (CMC). This technique is based on a recently developed polymer-derived ceramic (PDC) processing, in which ceramics are synthesized by thermal decomposition of polymeric precursors, instead of by sintering ceramic powder compacts. Figure 1 schematically illustrates the basic steps of the proposed technique, including: (1) synthesizing a preform with the desired dimension and microstructure from carbon nanotubes, (2) infiltrating the preform with a liquid phase polymeric precursor, (3) solidifying the precursor to form a fully-densed polymer-based nanocomposite, (4) machining the nanocomposite into the desired shape and surface quality, and (5) pyrolyzing the machined polymer nanocomposite to obtain the final ceramic nanocomposite. (1) (2) (3) (4) (5) Figure 1: Schematic showing the basic steps for making ceramic matrix composites. One example is a low cost manufacturing method to improve the interlaminar tensile strength for fiber-reinforced material in high temperature and extreme environment. The typically poor interlaminar tensile strength (ILT) of high temperature material system containing 2-D woven fibers imposes limits on the design of hot section components. New material system is needed to lower the expense of over-built components, particularly for hot structure aeroshell. The proposed manufacturing method to embed CNTs along the vertical direction within each fiber bundle, would not only help improve the design limits, but also improve the interlaminar tensile strength (ILT) for current material system. As shown in the SEM pictures, there is carbon fiber pull-out phenomenon on fracture surface and CNTs have good dispersion in the matrix. The material characterization results are: • Mechanical Property: According to the three-point bending strength test, with the inclusion of CNTs, the strength of 3-dimensional reinforced ceramic composite increases 26% than that of 2-dimensional one. Therefore, the required thickness can be reduced significantly. The associated material cost and manufacturing cost can be minimized. • Electrical Property: The electrical conductivity (along in-plane direction) increases 25%. • Thermal Property: the thermal conductivity (along z axis) increases 10%. This enables to dissipate heat quickly to cooler zone, and the life time of the material system is extended substantially. 1 CNTs are aligned along the vertical direction to ensure the 3rd-dimensional bonding strength. Carbon nanotubes (CNTs) are reinforced along the vertical direction in between of each carbon fiber bundle CNTs CNT/PDC Cf CNT/PDC Cf PDC (a) surface area (x-y plane); polished surfaces Cf (b) cross-section area (vertical plane); fracture surface Stack of multiple layers of carbon fiber sheets (Patent applied) • • • • In summary, the advantages of such manufacturing method are summarized as below: Low cost, and the manufacturing procedure can be scaled up in size. This manufacturing process can produce parts with curvatures or other complex geometries. The volume fraction of the fiber reinforcement and CNTs reinforcement can be adjusted based on design needs. In our experiment, the volume fraction of Carbon fiber is 45 Vol.% and that of CNTs is 10 Vol.%. This manufacturing process is generic – can be applied to different types of fiberreinforced high temperature material systems. 2