Lean Manufacturing Firm

advertisement

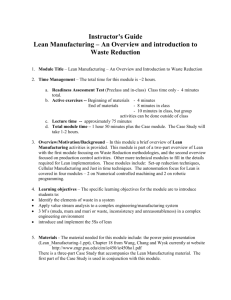

Redefining Optimal Manufacturing Operations: What it Means to be Competitive in the Global Economy Executive Summary Manufacturers today are under tremendous pressure to increase profitability and demonstrate stakeholder ROI. In order to meet these objectives and stay competitive in the global economy, executives are once again focusing on optimizing their manufacturing and supply chain networks. Now is the time to reinvest in operations because supply chain manufacturing has grown for 16 straight months. By redefining optimal manufacturing operations, businesses are meeting—and exceeding— business objectives. Proven metrics, case studies, and history show that a successfully optimized factory means implementing Lean techniques. However, to succeed in optimizing their supply chain networks, executives in complex, high-mix environments must first understand why Toyota Production System (TPS) Lean techniques do not always produce long-term or desired results. Companies have failed to generate savings for three main reasons: trying to implement Lean exactly as it was invented, failure to scale initial success and lack of technology to sustain positive results. By adapting Lean using a holistic approach of people, process and technology, companies are achieving sustained profitability. High-mix manufacturers that have won big have three common characteristics: a culture that promotes continuous improvement and employee involvement, a focus on customer needs, and leveraging technology to support the previous two characteristics. Bristol Myers Squibb, The CocaCola Company, and CP Kelco are ideal examples of manufacturers that have succeeded in achieving operational excellence because of their commitment to Lean using holistic methodologies (people, process and technology). To stay competitive and profitable in the global landscape, manufacturing executives must redefine optimal manufacturing operations. By investing in holistic Lean methodology and adopting new systems and processes that fit a high-mix environment, executives will meet and exceed their goals. Introduction: The 2011 Global Manufacturing Landscape Challenging economic times mean that manufacturing executives must do more with less. The recent downturn halted investment as companies slashed budgets, shuttered factories, reduced the number of employees, and delayed technology upgrades. Executives who once turned to manufacturing to improve execution and profitability instead focused on finance and marketing. But as the global economy recovers from the economic downturn, businesses are overcoming hesitation and emerging from the recession. Leading companies once again realize how important manufacturing and supply chain operations are to product quality and innovation. They are putting a strategic focus back on manufacturing and are using operations to innovate and regain profitability. Research shows that now is the time to reinvest in manufacturing. For 16 straight months, output has expanded and exports have grown steadily.1 The Institute of Supply Management reports that manufacturing in the U.S. rose in January at the fastest pace since May 2004. Justin Lahard and Kris Maher of The Wall Street Journal said “with demand for goods around the world continuing to rise . . . uncertainty is being trumped by concern about getting left behind.”2 Companies are transitioning from “the year of stability” to “the year of ROI” as management increasingly understands the need for investing in strategies that boost growth.3 Along with the increasing appetite for growth comes intense pressure for senior executives. Management must not only make up for lost time, they must restore an environment and funding for technical advancements and set the path for profitability and stakeholder return on investment (ROI). As exhibited in Figure 1, revenue, profitability and costs are top business concerns. Meeting profitability objectives is even more challenging given a global manufacturing landscape of fierce offshore competition, shorter product life cycles, demanding customers, and heightened regulatory compliance. According to research and advisory firm IDC Manufacturing Insights, the manufacturing industry as a whole is struggling with increasing complexity, rapidly changing business environments and volatile raw materials prices.4 To remain competitive in the global economy, manufacturers must become more productive, more FIGURE 1 efficient, and more responsive. According to “Business 2010: Manufacturing,” a white paper from The Economist, manufacturers can stay competitive by accelerating the pace of innovation and adapting swiftly to change.5 And, despite the recent pressure to reduce costs, a KRC Research survey of more than 300 senior manufacturing executives indicated that they have been investing in their companies, especially in the areas of quality improvement systems and research and development (R&D).6 Manufacturing executives must continue to invest in innovation. Optimizing manufacturing and supply chain network operations is not about improving operations—it’s about coming up with realistic solutions that contribute to the bottom line. Shortening cycle times, meeting customer deadlines, reducing inventory and shipping more products translates to meeting profitability objectives. The Evolution of Optimizing Efficiencies within Manufacturing History shows that an optimized factory and supply chain contribute to company-wide profitability. For this reason, many companies are once again focusing on their factories. They want to retain their core competency, guard intellectual property, and be near customers. However, C-level executives are hesitant to reinvest in Lean and Six Sigma techniques that have previously failed to generate results (namely, shareholder value and profits). Unfortunately, failure to produce less-than-stellar results is not uncommon. A survey from consulting firm Bain showed that only 19% of companies that had tried Lean were happy with the results.7 So where has Lean gone wrong for these manufacturers? Namely, it’s that traditional Lean is not effective or relevant to high-mix manufacturers in complex environments. According to Michael Mahoney, author of High-Mix, Low-Volume Manufacturing: The fundamental operational dynamics for high-mix manufacturing requires a different approach that TPSLean is ill equipped to address. In the original translation of the book, Toyota Production System from Industrial Engineering Viewpoint, it states that the TPS Kanban system could only be adapted only in the case of repetitive production and impossible to utilize for individual production. 8 Manufacturers that have applied traditional Lean principles for complex environments have ultimately failed to see results for three main reasons: 1. Companies are trying to implement Lean exactly as it was invented. The TPS principles that worked in the automotive industry won’t be successful without adapting techniques to work in a high-mix, complex environment. High volume doesn’t work well if you have multiple products on shared equipment, have a great deal of variability and manufacture products engineered to order. 2. Companies struggle to scale initial successes from pilot projects. Although manufacturers might have one line with tremendous results, they struggle to get the same success across all lines in a factory or all factories across the globe. 3. Companies cannot sustain initial success. Although companies may experience initial successes in the first three months, operations often gradually revert to the way they were. That’s why it’s imperative to automate use of these approaches and to measure performance. If manufacturers automate and use high-mix Lean techniques as scorecards, they are more likely to sustain results. So what is the answer? Sustainment using holistic Lean methodologies. Redefining Lean with People, Process, and Technology Manufacturers that have tried traditional Lean and Six Sigma have learned it’s not as straightforward as they expected it to be. Companies that use a holistic method—focusing on people, processes and technology—are winning big. Sath Rao, vice president at consulting and research firm Frost & Sullivan, says it’s these three things – people, process, and technology – that mitigate risk for complex manufacturing ecosystems.9 By optimizing the high-mix factory floor using this methodology, time to results is reduced, and companies are realizing significant savings in the second month of deployment. The matrix in Figure 2 compares these three characteristics at a company low on the maturity level scale of achieving holistic Lean results vs. a company that has accomplished competitive advantages through holistic Lean. Characteristic FIGURE 2 Maturity Levels Needs Improvement Competitive Advantage Through Holistic Lean Lack of employee engagement People Poor communications Significant investment in training Incompatibility with ERP systems Ideas from workforce Forecast-driven push Process Financial metrics based on Demand-driven pull internal efficiencies KPIs based on external customer satisfaction Lack of investment in equipment Focused investment in tools to support people and Technology Manual, adhoc decision support processes tools Automated, scalable business intelligence analytics As consumer demand fluctuates, holistic methodology gives manufacturers the competitive advantage of having the ability to respond to changes in the marketplace. The holistic methodology is based on three ideas: 1. Training and empowering employees 2. Refining plant processes with best practices 3. Implementing technology to improve responsiveness to the customers’ needs When companies leave out one of the three important characteristics, failure is inevitable. First, many manufacturers underestimate the importance of people and instead make technology investments that don’t yield any benefits. For example, some companies pour millions of dollars into enterprise resource planning (ERP) systems that aren’t well suited for the organizations or their people, leaving the company with a lot of expensive shelf ware. Second, some managers run into internal obstacles, such as traditional financial metrics that encourage them to produce tons of inventory. Or, short-term thinking leads executives to pursue investments that help them achieve quarterly goals, but doesn’t consider long-term investments in people or technology. The last missing critical component, which also is the easiest to fix, is using the right technology. Homegrown tools aren’t conducive to scaling and are difficult to maintain over time. The company may realize short-term results, but they cannot sustain those results and often abandon the process. Characteristics of Optimal, Profitable Plants Despite the fact that some organizations have failed to achieve positive, long-term results, many highmix manufacturers are succeeding using Lean methodologies to support increased efficiency and sustained profitability. Successful manufacturers share three characteristics: 1. Employee involvement and a culture that promotes continuous improvement 2. A focus on customer needs and value 3. Technology to support the Lean initiative Characteristic #1: Employee involvement and a culture that promotes continuous improvement. It’s never just about the technology. It’s about the people. Modern equipment or software is never sufficient. It’s the people who make good decisions and who identify improvements to operations and the supply chain. As Andrew Carnegie famously proclaimed, “Take away my people and leave the factories, and soon there will be grass growing on the factory floors, but take away my factories and leave my people, and soon we will have bigger and better factories.” Bristol Myers Squibb is an organization that’s done a great job of engaging their people and committing to a culture of continuous improvement. A new plant manager, who was determined to save his factory from shutdown, led a transformation that resulted in saving the plant and achieving industry-wide recognition for company performance. The plant manager hired consultants to help his people design and implement Lean techniques using software and pull, demand-driven replenishment. They used metrics that motivated their people to improve the flow of value and constantly looked for techniques and technology that would help them thrive.10 Characteristic #2: A focus on customer needs. This characteristic shifts the focus to customer needs and the value that the plant provides in order to eliminate waste, or non-value-added activity. The objective is to get value flowing to the customer as quickly and reliably as possible. Many maintain a forecast-driven push approach using sophisticated forecasting systems. They do this because, in theory, they’ll increase productivity and cut production costs. But only those who have transitioned to demand-driven pull are truly focused on customer needs. For example, The Coca-Cola Company recently embraced demand-driven pull replenishment. Working with a consulting firm, they designed pull processes that work in the face of high demand variability and rapid new product introductions. Characteristic #3: Leveraging technology to support the previous two characteristics. Software is a significant part of achieving sustainable, optimal manufacturing operations. Employees must be able to take the data collected by the software systems and make better decisions to support the customer. Management in turn, must be able to translate the data into business intelligence. CP Kelco, an Atlanta-based manufacturer, experienced great success in scaling demand-driven pull from a single pilot project across its global supply chain. Initially, the company applied the traditional TPS approach to Lean. Recognizing the need to adapt lean tools to their needs, they hired a consulting firm specializing in high-mix environments. Together they designed a pull implementation and then a pilot project. Using software to scale best practices to multiple plants around the world, CP Kelco has sustained results for three years and counting. Next Steps: Achieving Optimal Performance with Lean A commitment to a Lean approach for high-mix environments is required for a company to succeed at reaching optimal manufacturing operations. Prerequisites include leadership with Lean experience, a commitment to pull and an organizational culture that is receptive to change and disciplined enough to produce only when more inventory is needed. Helpful (but not necessary) characteristics include having accurate forecasts, stable demand, reliable equipment, on-time vendors, dedicated cells, fast changeovers and small lot sizes. Once executives are on board with refining optimal manufacturing operations to stay competitive in the global landscape, what is the next step? Invest time in learning. As proven with companies such as Bristol Myers Squibb, Coca-Cola and CP Kelco, Lean does work in high-mix environments when the right core components—people, process and technology—are in place. Conclusion Despite the pressures of a global economic landscape, manufacturers are staying competitive and profitable. For a business to reach its full profit and efficiency potential, it is imperative that the company redefine its operations. By adopting certain characteristics and employing the right mix of people, processes and technology, executives can sustain short-term and long-term profitability. At Invistics, we have the expertise and technology solutions that high-mix manufacturers need. We provide consulting services and supporting on-demand software solutions to help companies achieve the right inventory levels through advanced analytics and actionable insights. Where are you in the Lean journey? “We are already implementing Lean techniques . . . but need help scaling or sustaining.” If this sounds like your organization, our MachSix software is the quickest way to get you to your goals. For a demo of how MachSix can help your company, call us today at 1-800-601-3456 or email us here. “We have upper management support, but haven’t adopted Lean yet.” If this statement applies to your situation, resources are available to help you get to the next step. At Invistics, we offer lean coaching and consulting services and our highly effective Pull Design Workshop. The workshop teaches you how to build organizational consensus, and design a pilot project. Call us today at 1-800-601-3456 or e-mail us here to find out more. 1 Institute for Supply Management™, January 2011 Manufacturing ISM Report On Business. http://www.ism.ws/ISMReport/MfgROB.cfm 2 Lahard, Justin and Kris Maher, “Seeing Economic Rebound, Firms Step Up Spending,” The Wall Street Journal, June 25, 2010 3 “The Return of Manufacturing: Firms look to shore up operations and business systems as markets reemerge,” The MPI Group, 2010 4 Dahlgren, Megan and Pierfrancesco Maneti, “Beating Complexity, Achieving Operational Excellence,” IDC Manufacturing Insights, July 2010 5 The Economist Intelligence Unit, Business 2010: Manufacturing, Embracing the Challenge of Change, April 2005 6 Baker Tilly, Thoughts on the Economy and Global Business: Survey of U.S. Manufacturing Executives, July 2009 7 Jones, Del, “Toyota’s Success Pleases Proponents of ‘Lean’,” USA Today, May 4, 2007 8 Mahoney, Michael, “Lean when Based on Toyota Production System Fails for High-Mix Manufacturers,” July 20, 2007 9 Rao, Sath, “Can Manufacturers Drive the CEO’s Growth Agenda?” Managing Automation, October 11, 2010 10 Bristol-Myers Squibb: Empowerment and Metrics Turn Plants Around. Pharmaceutical Manufacturing Magazine, 2005. http://www.pharmamanufacturing.com/articles/2005/231.html