Course objectives

advertisement

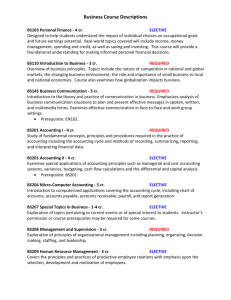

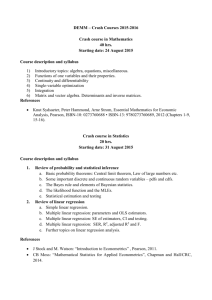

IE 201 – FINANCIAL ENGINEERING Designation as a ‘Required’ or ‘Elective’ course TYPE OF COURSE: Required for BSCME, BSME and BSIE Majors Course (catalog) description COURSE DESCRIPTION: IE 201 Financial Engineering, 3 Hours. Principles and techniques of economic analysis in engineering and management science. Basic probability theory and decision problems under risk and uncertainty. Prerequisite(s) PREREQUISITE(S): Math 181 Textbook(s) and/or other required material SAMPLE SOURCES AND RESOURCE MATERIALS: Engineering Economy by L. Blank and A. Tarquin, 7th edition, McGraw-Hill Science Publishers, 2011. Course objectives COURSE OBJECTIVES: This course introduces students to various aspects of financial analysis that are necessary for all engineering programs. It introduces such topics as interest rates, cash flows, project financial analysis, rate of return and alternatives comparison. Topics covered MAJOR TOPICS: 1 Economic decision making processes, concepts of cash flows, interest rate, equivalence, minimum attractive rate of return 2 The time value of money 3 Shifted uniform and gradient series 4 Nominal and effective interest rates 5 Present worth analysis 6 Annual worth analysis 7 Rate of return analysis (single alternative) 8 Rate of return analysis (multiple alternatives) 12 Examinations 13 Final exam Total Hrs 5 6 4 6 6 4 5 5 2 2 45 Class/laboratory schedule, i.e., number of sessions each week and duration of each session CREDIT HOURS: 3 hours TYPE OF INSTRUCTION: Type of Instruction Lecture/Discussion Recitation Contact Hours/Week 2 1 Contribution of course to meeting the professional component This course prepares students for financial transactions necessary for everyday life. It also prepares them to be able to sell a project to management in industry. It makes them aware that the financial end of a corporation, sometimes looked down on by engineers, is really very important and helping the company to make a profit is an important goal. Relationship of course to program outcomes As shown in the BSIE Course Outcomes Matrix: A Ability to apply knowledge of mathematics, science and engineering E Ability to formulate and carry out mathematical solutions H The broad education necessary to understand the impact of engineering solutions in global and societal context Comments on outcomes Following are possibly approaches to incorporating specific student learning outcomes into this course: A Use of mathematical calculators and computers to carry out calculations E Students are required to formulate engineering problems based on scientific and engineering principles H Students learn to measure the economical impact of different engineering solutions on large systems (e.g society, countries, public, etc.) These outcomes are what students are expected to gain from this course. Person(s) who prepared this description and date of preparation Pat Banerjee, Professor of Industrial Engineering, August 16, 2013. 250 ENGINEERING GRAPHICS AND DESIGN TYPE OF COURSE: requirement for the following programs: ME, IE, and CE MAJORS COURSE DESCRIPTION: Engineering design process, modeling and analysis. Product dissection, prototyping. Technical communication, AutoCAD, engineering graphics software, 3D views, multiview projection, dimensioning and tolerancing, standards. Team design projects. PREREQUISITE(S): Eligibility to register for ENG 160 English Composition I. SAMPLE SOURCES AND RESOURCE MATERIALS: Engineering Design: A Project Based Introduction, 4th Ed., Clive L. Dym, Patrick Little, and Elizabeth Orwin, John Wiley & Sons, 2013. COURSE OBJECTIVES: 1. Students will be able to analyze the engineering function of existing products. 2. Students will be able to specify human needs as engineering design requirements. 3. Students will be able to generate, analyze, evaluate, and select among engineering design solutions to meet specified requirements. 4. Students will be able to communicate technical ideas in writing and orally. 5. Students will be able to communicate technical ideas using accepted graphics standards and modern computer tools. 6. Students will be able to work productively on an engineering team. MAJOR TOPICS (LECTURE): Introduction to the Design Process Product Dissection, Reverse Engineering, Functional Analysis Communication: Technical Memos, Bibliographies Objectives, Metrics, Constraints, Customer Needs Generation, Assessment and Selection of Design Concepts Design Modeling and Analysis Proofs of Concept, Prototyping Communication: Oral Presentations Project Management, Work Breakdown Structures Communication: Technical Drawing. Views; Geometrical Dimensioning and Tolerancing; Standard Communication: Technical Reports Ethics issues Hrs 1 2 1 3 2 3 1 1 2 1 9 1 2 MAJOR TOPICS (LABORATORY): Hrs Team Project: Functional Analysis of Existing Device 8 Computer Applications 8 (Lab) Team Project: Design of a Device for a Client 14 TOTAL: 30 + 30 hours of lab sessions where a 2-Dimensional CAD package is used. During the lab sessions, students learn to use a commercial CAD package to apply the concepts covered in lecture. The CAD package used is AutoCAD. CREDIT HOURS: 3 hours Type of Instruction Contact Hours/Week Lecture 2 Instructor-led Laboratory 2 Contribution of course to meeting the professional component This course presents an introduction to the engineering design process. Students learn the role that ethics and economics play in the design process. As shown in Outcomes Matrix: c. Ability to design a system, component or process to meet desired needs d. An ability to function on technical teams f. Ability to understand professional and ethical responsibility g. Ability to communicate effectively h. The broad education necessary to understand the impact of engineering solutions in global and societal context. i. Recognition of the need for, and an ability to engage in life-long learning j. A knowledge of contemporary issues k. Ability to use techniques, skills, and modern engineering tools necessary for engineering Person(s) who prepared this description and date of preparation Michael J. Scott, August 23, 2014. Comments on outcomes c. Ability to design a system, component or process to meet desired needs. Students are introduced to the steps involved in the design process including identification of objectives, analysis of function, concept generation and selection, prototyping and proof-of-concept testing, and documentation. Students complete a major team design project and construct a device to fulfill a specified need. d. Ability to function on multidisciplinary teams. Students complete four different team projects, with students from the Mechanical, Industrial, and Civil Engineering programs mixed in four-person teams. Students complete a team contract, which is a graded assignment, and evaluate their own and their team members' contributions both at mid-project and after the assignment is completed. f. Ability to understand professional and ethical responsibility. In discussing the design process, students are introduced to the notion of ethics in design. g. Ability to communicate effectively. Students must demonstrate communication through engineering graphics, written reports and technical memos, and oral presentation. Students are required to work with the UIC Writing Center to improve their written communications. h. The broad education necessary to understand the impact of engineering solutions in a global and societal context. Design reports and product dissection reports include discussions of the context of the devices in question, with outside references cited as needed. i. Recognition of the need for, and an ability to engage in life-long learning. Students participate in a product dissection project and three team design projects that require particular knowledge outside the scope of the textbook and other materials that are standard for the class. They experience authentically the need to pursue novel information in any engineering design project. j. A knowledge of contemporary issues. The design project includes a required assessment of the environmental impact of their design, as measured by the embodied carbon and embodied energy of the materials chosen for the design. Students use a standard instrument for this assessment. The results are graded, and the environmental impact of the device is also scored in the final contest. k. Ability to use techniques, skills, and modern engineering tools necessary for engineering. Students use state-of-the-art software packages in order to perform engineering drafting. Students are encouraged to acquire personal versions of the AutoCAD software used in the class, which is free for student use. These outcomes are what students are expected to gain from this course. IE 342 – PROBABILITY AND STATISTICS FOR ENGINEERS Designation as a ‘Required’ or ‘Elective’ course TYPE OF COURSE: Required for BSIE Major Course (catalog) description COURSE DESCRIPTION: IE 342 Probability and Statistics for Engineers, 3 Hours. Probability, random variables, mathematical expectation, discrete and continuous distributions, estimation theory, test of hypotheses, and introduction to standard experimental design. Prerequisite(s) PREREQUISITE(S): Math 181 Calculus II, 5 Hours Textbook(s) and/or other required material SAMPLE SOURCES AND RESOURCE MATERIALS: Probability and Statistics for Engineers and Scientists, by Ronald E. Walpole, Raymond H. Myers, Sharon L. Myers and Keying E. Ye, 9th Ed., Prentice Hall, 2011. Course objectives COURSE OBJECTIVES: This course introduces students to various aspects of statistical analysis. The objective is to expose the students to elements of probability and probability distributions, and statistical inference. We try to keep a balance between theory (topics 1 to 5) and methodology (topics 6, 7 and 8). The students use differential and integral calculus to investigate different properties of random variables and their functions. They also learn how to apply statistical analysis to solve real-life problems. Many examples are used to show the applicability of the probability theory and statistical analysis. Topics covered MAJOR TOPICS: 1 Probability 2 Random variables and probability distributions 3 Mathematical expectation 4 Discrete probability distributions 5 Continuous probability distributions 6 Random sampling and sampling distributions 7 Estimation theory 8 Test of hypotheses 9 Class quizzes 10 Final exam Total Hrs 8 5 5 5 5 5 4 4 2 43 Class/laboratory schedule, i.e., number of sessions each week and duration of each session CREDIT HOURS: 3 hours TYPE OF INSTRUCTION: Contact Hours/Week Type of Instruction 3 Hrs Lecture/Discussion Outcomes A B E Comments on outcomes Ability to apply knowledge of mathematics, science and engineering. Students are able to use mathematical calculations in solving engineering problems. Also, students are able to formulate engineering problems based on scientific and engineering principles. Much of the course deals with the statistical aspects of data. An ability to design and conduct experiments, as well as to analyze and interpret data. Ability to analyze, interpret and determine significant parameters to aid in understanding data. Also, students develop the ability to analyze, interpret and determine significant parameters to aid in understanding data. An ability to identify, formulate, and solve engineering problems. Students develop the ability to understand what is needed, formulate problems mathematically and build on fundamental knowledge and apply it to new situations through completing homework assignments. Ability to use the techniques, skills, and K modern engineering tools necessary for engineering practice Demonstrate knowledge of computer usage in engineering analysis. Some homework requires use of computers. The students can use Microsoft Excel or any other statistical software in their projects. Extra sessions will be held (if necessary) to demonstrate the software. Person(s) who prepared this description and date of preparation Professor Nan Ratisoontorn, Assistant Professor of Industrial Engineering, August, 2013 These outcomes are what students are expected to gain from this course. IE 345 – REGRESSION APPLICATIONS AND FORECASTING IN ENGINEERING Designation as a ‘Required’ or ‘Elective’ course TYPE OF COURSE: Required for BSIE and BSME Major Course (catalog) description COURSE DESCRIPTION: IE 345 Regression Applications and Forecasting in Engineering. 3 Hours. Single and multiple regression analysis of variance, examination of residuals, introduction to time series analysis, and analytical forecasting techniques; application to engineering system. Prerequisite: IE 342 Probability and Statistics for Engineers. Prerequisite(s) PREREQUISITE(S): IE 342 Probability and Statistics for Engineers, 3 Hours Textbook(s) and/or other required material SAMPLE SOURCES AND RESOURCES MATERIALS: Introduction to Time Series Analysis and Forecasting by Douglas C. Montgomery, Cheryl L. Jennings and Murat Kulahci, 1st Ed., John Wiley & Sons, 2008. 1. Introduction to Forecasting and Regression: An applied Approach, by Bruce L. Bowerman, Richard T. O’Connell and Anne B. Koehler, 4th Ed., Thomson Books/Cole, Belmont, CA 2005. 2. Introduction to Time-Series Modeling and Forecasting in Business Economics, by Patricia E. Gaynor and Rickey C. Kilpartick, McGraw-Hill, New York, NY, 1994. 3. Statistics, Data Analysis and Decision Modeling, by Evans and Olson, Prentice Hall, Upper Saddle River, NJ, 2000. 4. Data, Statistics, and Decision Models with Excel, by Harnett and Horrell, John Wiley & Sons, New York, 1998. Course objectives COURSE OBJECTIVES: This course studies the essentials of effective regression analysis and forecasting methods. In a very general sense, all decisions are based upon forecasts. Many decision makers are unscientific methods of forecasting to arrive at decisions. However, if the decision maker possessed the knowledge of more scientific approaches, the effectiveness of his or her decisions should be enhanced. It is for these reasons that managers, engineers, economists, and analysts should study statistical regression and forecasting methods. This course tries to refine and stimulate your interest and success in regression analysis and forecasting. While this course covers a full range of regression analysis and forecasting methods, it concentrates on the most widely used methods of regression analysis and forecasting in engineering applications. These methods are important tools in production, marketing, finance, engineering, and economics. The emphasis of the course will be on the principles and applications of successful regression analysis and forecasting. The course will also stress the importance of communicating regression analysis and forecasting results through written report and verbal presentations. Data analysis and approaches to presenting results will also be introduced. Upon completion of this course, the students will be expected to be able to apply regression analysis and forecasting methods for solving engineering system problems. Topics covered MAJOR TOPICS: 1 Introduction 2 Time-Series Analysis 3 Simple Regression Analysis 4 Multiple Regression Analysis 5 Exponential Smoothing 6 Winters’ Exponential Smoothing 7 Box-Jenkins Methodology: Non-seasonal Models 8 Box-Jenkins Methodology: Seasonal Models 9 Examinations Total Hrs 1 5 7 9 7 5 3 3 8 48 Class/laboratory schedule, i.e., number of sessions each week and duration of each session CREDIT HOURS: 3 hours TYPE OF INSTRUCTION: Type of Instruction Contact Hours/Week Lecture/Discussion 3 Laboratory 0 Contribution of course to meeting the professional component This course studies the essentials of effective regression analysis and forecasting methods. While this course covers a full range of regression analysis and forecasting methods, it concentrates on then most widely used methods of regression analysis and forecasting in engineering applications. These methods are important tools in production, marketing, finance, engineering, and economics. The emphasis of the course will be on the principles and applications of successful regression analysis and forecasting. The course will also stress the importance of communicating regression analysis and forecasting results through written report and verbal presentations. Data analysis and approaches to presenting results will also be introduced. Upon completion of this course, the students will be expected to be able to apply regression analysis and forecasting methods for solving engineering system problems. Relationship of course to program outcomes As shown in the BSME Course Outcomes Matrix: A. Ability to apply knowledge of mathematics, science and engineering E. Ability to identify, formulate, and solve engineering problems G. Ability to communicate effectively K. Ability to use techniques, skills, and modern engineering tools necessary for engineering practice. Person(s) who prepared this description and date of preparation David He, Associate Professor of Industrial Engineering, January, 2011 Updated by Dr. David He, Professor of Industrial Engineering, August 2013 Comments on outcomes A. Use of fundamental knowledge of probability and statistics in regression analysis, engineering, problem formulation, modeling, and solution generation. E. Throughout the course, the students are required to analyze different engineering application problems, identify the problem parameters, formulate and modeling the problems, and find solutions to these problems using regression and forecasting methods to thermodynamic fundamentals, and finally how to express them in mathematical terms. G. Students are provided with opportunities to present their learning experience in oral and written format through their homework and projects. K. After this course, the students will be able to use effectively the regression analysis and forecasting tools to solve engineering problems. These outcomes are what students are expected to gain from this course. IE365 – WORK PRODUCTIVITY ANALYSIS Designation as a 'Required' or 'Elective' course TYPE OF COURSE: Required for BSIE and BSEM Majors Course (catalog) description COURSE DESCRIPTION: IE365 Work Productivity Analysis. 4 hours Operations analysis, man-machine relationship, motion study, micro-motion study, time study, predetermined time systems, performance rating, standard data techniques, work sampling, and wage payment plans. Prerequisite(s) PREREQUISITE(S): Credit or Concurrent Registration in IE 342 – Probability and Statistics for Engineers, 3 Hours Textbook(s) and/or other required material SAMPLE SOURCES AND RESOURCE MATERIALS: Methods, Standards and Work Design, Nibel, B.W. and Freivalds, A., 12th Edition, McGraw Hill, 2009. Course objectives COURSE OBJECTIVES: The course is designed to provide students with an opportunity to follow the evolution of Industrial Engineering and offers traditional tools of industrial engineers that have been developed for methods engineering and time study. Students get hands-on experience with some of these tools through laboratory projects. With the successful completion of the course, students will be equipped with a broad understanding of professional and ethical responsibility of a method engineer as well as a palette of traditional tools of methods engineers for productivity and quality improvements. Topics covered MAJOR TOPICS: 1. Introduction to motion and time study 2. Tools of methods analyst 3. Operations analysis 4. Worker-and-machine relationship 5. Motion and micromotion study 6. Job analysis and evaluation 7. Time study requirement 8. Elements of time study 9. Standard time and standard data 10. Basic motion times 11. Formula Construction 12. Work sampling studies 13. Follow-up method and uses of time standards 14. Lab meetings 15. Exams Total Hrs 3 4 3 3 4 3 3 3 4 4 3 2 2 30 4 75 Class/laboratory schedule, i.e., number of sessions each week and duration of each session. CREDIT HOURS: 4 Hours Type of Instruction: Contact Hours/Week Lecture-and-discussion 3 Laboratory 2 Contribution of course to meeting the professional component The course deals with the subject that industrial engineering has been most identified with: motion and time study, and productivity improvement. Through the course, students get a chance to view the evolution of industrial engineering and learn traditional methods engineering tools that have been developed for improving quality and productivity at large. Owing much to the peculiar subject matter, students are exposed to and better understand professional and ethical issues on ‘fair wage,’ ‘objective performance rating,’ and allocation of ‘proper allowances’ for standard time, to name a few. Relationship of course to program outcomes As shown in the BSIE Course Outcomes Matrix: B. Design and conduct experiments, as well as analyze and interpret data D. An Ability to function on technical teams. F. Understanding of professional and ethical responsibility G. An ability to communicate effectively J. A knowledge of contemporary issues Person(s) who prepared this description and date of preparation Hong Seo Ryoo (Assistant Professor) of Mechanical & Industrial Engineering, January 31, 2002 Rao Kodali (Lecturer), October 6, 2006 Houshang Darabi, Professor of Industrial Engineering, January 15, 2013 Comments on outcomes B. Through the use of exemplary problems in the text as well as through lab projects, students learn to analyze, simplify, and formulate problems and apply the techniques learned in course for their solution. D. Students participate in team projects where they work in groups of 3-4 to satisfy project requirements. F. Owing to the subject matter, students are exposed to professional and ethical issues centered on ‘fair wage,’ ‘objective performance rating,’ and allocation of ‘proper allowances’ for standard time throughout the semester. Chapters of text on standard time basically deal with this issue. G. Lab projects require technically written lab reports that are graded based upon not only the accuracy of results but also for the contents, the format, and the efficacy of presentation. Depending upon instructor, oral presentations may be required for some of the lab reports. J. Students are required to create a presentation on their choice of contemporary issue and share their findings with their classmates. These outcomes are what students are expected to gain from this course. ME 380 / IE 380 – MANUFACTURING PROCESS PRINCIPLES Designation as a ‘Required’ or ‘Elective’ course TYPE OF COURSE: Required for BSME AND BSIE Majors Course (catalog) description COURSE DESCRIPTION: Manufacturing Process Principles. 3 Hours. Introduction to basic manufacturing processes such as casting, bulk deformation, sheet metal forming, metal cutting. Interaction between materials, design, and manufacturing method. Economics of manufacturing. Prerequisite: CME 203. Prerequisite(s) PREREQUISITE(S): CME 203 Strength and Materials, 3 Hours. Textbook(s) and/or other required material SAMPLE SOURCES AND RESOURCES MATERIALS: Mikell P. Groover, Fundamentals of Modern Manufacturing. 3rd Edition. John Wiley & Sons, Inc., 2006. Course objectives COURSE OBJECTIVES: This course is designed to introduce students to engineering materials, manufacturing methods, and the importance of design and economic considerations in the selection of engineering materials and manufacturing processes to produce a desired part or a component. The course description is concerned mainly with the metals and manufacturing processes of metals, as outlined above, a course description which is a leftover-from-the 1960’s, when metals, then, were indeed the backbone of the manufacturing industry. However, since then, immense advances have been made in other materials, such as ceramics, polymers, and composite materials. Therefore, in order to be current in manufacturing industry and competitive in the domestic and global marketplace, metals, as well as engineering materials other than metals, namely, ceramics, polymers, and composite materials – metal matrix composites, ceramic matrix composites, and polymer matrix composites are presented to students. In addition to new engineering materials, manufacturing processes for these new engineering materials, such as plastic injection molding, filament winding, pultrusion are also presented to students. Accordingly, this course is aimed to maintain a fine balance between not overwhelming the students with details and yet not overlooking essentials that the students should be familiar with as they enter the business world. Topics covered MAJOR TOPICS: 1 Introduction to engineering materials and manufacturing processes 2 Metals and manufacturing processes for metals 3 Ceramics and manufacturing processes for ceramics 4 Polymers and manufacturing processes for polymers 5 Composite materials and manufacturing processes for composite materials 6 Metal casting 7 Powder metallurgy 8 Bulk deformation processes – rolling, forging, extrusion, and drawing Hrs 1-1/2 3 3 3 3 3 1-1/2 6 9 Sheet metalworking – cutting, bending, and deep drawing 10 Material removal processes by cutting tools – turning, drilling, and milling 11 Material removal processes by abrasives and non-traditional processes 12 Joining-welding, brazing, soldering, adhesive bonding and mechanical assembly 13 Examinations 14 Final examinations Total 47 3 6 3 6 3 2 Class/laboratory schedule, i.e., number of sessions each week and duration of each session CREDIT HOURS: 3 hours TYPE OF INSTRUCTION: Type of Instruction Contact Hours/Week Lecture/Discussion 3 Laboratory 0 Contribution of course to meeting the professional component Selection of engineering materials and manufacturing processes for an intended product do not only involve teams of engineers from various branches of engineering but in a broader sense they also involves purchasing, production, human resources, finance, sales, and marketing, complexity of the product, annual production rate, safety, quality, and environmental concerns. The shortcomings of traditional design-manufacturing engineering teams are compared with the benefits of concurrent engineering in addressing to Design for Manufacturability problems. Recycling of materials, conservation of energy, product liability suits, affordability, and social responsibility as engineers, safety, quality, and reliability, and affordability are stressed throughout the course. Relationship of course to program outcomes As shown in the BSME/BSIE Course Outcomes Matrix: a. Ability to apply knowledge of mathematics, science and engineering e. Ability to identify, formulate, and solve engineering problems j. Knowledge of contemporary issues. Person(s) who prepared this description and date of preparation Jeremiah Abiade, Assistant Professor of Mechanical and Industrial Engineering, January 15, 2014 Comments on outcomes a. Students are able to use mathematical calculations in solving engineering problems. Students learn theory and applications of engineering problems concerning manufacturing processes through out-of-class assignments and examinations. e. Ability to understand what is needed, ability to formulate problems mathematically, and ability to build on fundamental knowledge and apply it to new situations through out-of-class assignments. j. Knowledge of major technological issues facing society and the world and appreciation of the society’s concerns with security in technology. The textbook is supplemented by the latest information from the latest publications, conferences, and trade shows. The planned tour of a steel plant had to be scrapped because of the adverse economic affect of dumping steel imports on the domestic steel producers. These outcomes are what students are expected to gain from this course. IE/ME 394 – SENIOR CAPSTONE DESIGN Designation as a 'Required' or 'Elective' course TYPE OF COURSE: Required for BSME and BSIE Majors Course (catalog) description COURSE DESCRIPTION: IE/ME 396 Senior Design I. 4 Hours. Systematic approach to the design process. Creative problem solving. Design methodology and engineering principles applied to open-ended design problems with inherent breadth and innovation. Prerequisitie(s) PREREQUISITE(S): Senior standing with the department. Completion of core courses and consent of the instructor. Textbook(s) and/or other required material None. Course objectives COURSE OBJECTIVES: This course integrates the knowledge acquired in the various courses of the undergraduate curriculum to an open-ended design effort and applies the knowledge gained to the solution of a contemporary engineering problem. Students improve oral and written communication skills, gain familiarity with available technical literature, and experience the life cycle of a design project within a group environment. Many projects include practice in the use of computers and relevant support software while solving a design problem. Students work together as a team to accomplish common goals. Issues of professional ethics are also discussed. Topics covered MAJOR TOPICS: 1 Systematic approach to the design process; project management 2 Recognition/elicitation of customer needs 3 Translation of customer needs to functional specifications 4 Systematic aids to creativity 5 Student design projects: Formation of teams, development of design needs and specifications, Solution concept generation, analysis, concept selection, concept Development including analysis and optimization, detail design, Possible prototyping, design reviews, written formal reports 6 Engineering workplace issues: intellectual property, liability, ethics 7 Style and substance of reports and oral presentations 8 Presentations (in lieu of examinations) Total 60 Hrs 4 1 1 1 48 2 1 2 Class/laboratory schedule, number of sessions each week and duration of each session CREDIT HOURS: 4 Hours TYPE OF INSTRUCTION: Type of Instruction: Contact Hours/Week Lecture-Discussion 4 Laboratory 0 Contribution of course to meeting the professional component This course is a capstone design course, and is intended to expose students to many of the aspects of working in a professional environment. Students work in teams on projects for industry or other clients. It includes open-ended design, teamwork, communication, and customer interaction. Analysis of the designed system is required, with application of whatever technical content from the entire curriculum is relevant to the team’s problem. Process documentation with approval mechanisms at significant gates is also required. Relationship of course to program outcomes As shown in the BSME Course Outcomes Matrix, this course contributes to: C. Ability to design a system, component, or process to meet desired needs D. Ability to function on multi-disciplinary teams E. Ability to identify, formulate, and solve engineering problems F. Understanding of professional and ethical responsibility G. Ability to communicate effectively I. Recognition of the need for, and ability to engage in life-long learning Person who prepared this description and date of preparation Michael J. Scott, Assistant Professor of Mechanical Engineering, January 28, 2002; Constantine M. Megaridis, Professor of Mechanical Engineering, August 27, 2011. Michael Brown, Department of Mechanical Engineering, January 16, 2014 Comments on outcomes C. Project course with open-ended problems requiring creativity and new ideas. D. Semester projects are performed in teams of three undergraduates. E. Design projects require teams to determine which problems to analyze and solve. F. Ethical considerations inherent in design decisions. G. Teams give oral and written presentations at midterm and semester end. I. Many projects have clients or technical advisors from industry; interacting with professional engineers further along in their careers, students learn first-hand the need to keep current. The above outcomes are what students are expected to gain from completing this course. IE 442 – DESIGN AND ANALYSIS OF EXPERIMENTS IN ENGINEERING Designation as a ‘Required’ or ‘Elective’ course TYPE OF COURSE: Required for BSIE Major Course (catalog) description COURSE DESCRIPTION: IE 442 Design and Analysis of Experiments in Engineering, 4 Hours (1 hour for Lab using Minitab Software). Simple comparative experiments, single factor experiment, randomized blocks, Latin squares, and related designs, factorial design, regression model, response surface method and other approach to optimization, robust design, random factors, nested/split-plot designs, course project, and lab Session. Prerequisite(s) PREREQUISITE(S): IE342 – Probability and Statistics for Engineers, 3 Hours Textbook(s) and/or other required material SAMPLE SOURCES AND RESOURCE MATERIALS: 1. Design and Analysis of Experiments, 8th Edition, by Douglas C. Montgomery, ISBN 978-1-1181-4692-7, John Wiley, 2012. 2. Design and Analysis of Experiments: MINITAB Companion, 7th Edition, by Douglas C. Montgomery, Scott M. Kowalski, ISBN 978-0-470-16990-2, John Wiley, 2011. Course objectives COURSE OBJECTIVES: Develop the ability to appropriately analyze experimental data and communicate the results, the ability to translate industrial problems into an appropriate experimental design. Students also are given an introduction to techniques for variance reduction through robust parameter design. Topics covered MAJOR TOPICS: 1. Introduction to Probability and Sampling Distribution 2. Simple Comparative Experiments 3. Experiment with Single Factor 4. Randomized Blocks and Latin Squares 5. Factorial Design 6. 2k Factorial Design 7. Blocking and Confounding in 2K Factorial Design 8. Two-level Factorial Design 9. Response Surface Methods and Design 10. Robust Parameter Design 11. Experiments with Random Factors 12. Labs Training with Minitab 13. Course Projects 14. Exams Hrs 2 5 4 3 3 4 3 8 4 3 3 15 15 3 Total 75 Class/laboratory schedule, i.e., number of sessions each week and duration of each session CREDIT HOURS: 3 hours TYPE OF INSTRUCTION: Contact Hours/Week Type of Instruction 3 Hrs Lecture/Discussion Outcomes B Ability to design and conduct experiments, as well as analyze and interpret data. Comments on outcomes Students are able to design and conduct experiments, solving real problems, especially in engineering. Students are also able to analyze and interpret data based on scientific and engineering principles. Students use fundamental knowledge of design and analysis of experiments to solve real problems through class learning and course project. Person(s) who prepared this description and date of preparation Professor Lin Li, Assistant Professor of Mechanical Engineering, August 1, 2014 These outcomes are what students are expected to gain from this course. IE 446 – QUALITY CONTROL AND RELIABILITY Designation as a 'Required' or 'Elective' course TYPE OF COURSE: Required for BSIE Major Course (catalog) description COURSE DESCRIPTION: IE 446 Quality Control and Reliability. 3 Hours. Principles of statistical quality control including control by variable and by attribute, construction and use of control charts for variables, fraction defectives and number of defects and use of standard plans, reliability and life cycle testing. Prerequisite: IE 342. Prerequisite(s) PREREQUISITE(S): IE 342 Probability and Statistics for Engineers, 3 Hours Textbook(s) and/or other required material SAMPLE SOURCES AND RESOURCE MATERIALS: D. C. Montgomery, Introduction to Statistical Quality Control, 7th Edition, John Wiley & Sons, 2013. Course objectives COURSE OBJECTIVES: This course introduces students to concepts and methods of modern statistical quality control. Students learn to apply standard quality control tools. They learn the theoretical statistical concepts that justify the use of particular quality control tools in particular situations. They learn theory and methods for analyzing the performance of different quality control tools. The use of appropriate software for statistical and quality analysis is taught, and is necessary for successful completion of some homework assignments. Issues of ethics and professional responsibility and their relation to product quality are discussed. Topics covered MAJOR TOPICS: 1 Statistical and computational background 2 Concepts and history of quality control 3 Informal tools for quality control 4 Control charts for variables 5 Control charts for attributes 6 Theoretical performance of control charts 7 EWMA and CUSUM control charts 8 Process capability analysis 9 Acceptance sampling 10 Reliability concepts and measures 11 Measurement, tolerance, and specifications 12 Examinations Total Hrs 4 3 2 8 5 3 4 3 5 2 4 2 45 Class/laboratory schedule, i.e., number of sessions each week and duration of each session CREDIT HOURS: 3 Hours TYPE OF INSTRUCTION: Type of Instruction Contact Hours/Week Lecture-Discussion 3 Laboratory 0 Contribution of course to meeting the professional component This course shows how to use modern statistical quality control tools, such as control charts and process capability measures, to monitor quality characteristics of manufacturing processes. Students also learn the underlying basic probability and statistics so that they will choose appropriate quality control tools and will be able to implement specialized tools for non-textbook situations, as well as to analyze the theoretical performance of those tools. The importance of product quality in the contemporary global economy and the relationship between quality and professional ethics are also discussed. Relationship of course to program outcomes As shown in the BSIE Course Outcomes Matrix: A. Ability to apply knowledge of mathematics, science and engineering E. Ability to identify, formulate, and solve engineering problems F. Understanding of professional and ethical responsibility K. Ability to use the techniques, skills, and modern engineering tools necessary for engineering practice Person(s) who prepared this description and date of preparation Dr. Lin Li, Professor of Industrial Engineering, August 22, 2013 Comments on outcomes A. Students are able to use mathematical calculations in solving engineering problems and able to formulate engineering problems based on scientific and engineering problems. Use of fundamental knowledge of probability and statistics in statistical quality control, process capability and acceptance sampling are introduced. E. Students develop the ability to understand what is needed, are able to formulate problems mathematically and are able to build on fundamental knowledge and apply it to new situations. Throughout this course, the students are required to analyze different quality control and process environment application problems, identify the problem parameters, formulate and modeling the problems, and find solutions to these problems using statistical quality control methods. F. Essay assignment and class discussion on relationship between product quality, public safety, liability, and professional ethics. K. Students demonstrate the knowledge of computing tools in engineering analysis and technical approaches in engineering experimentation. After this course the students will be able to effectively use the computing tools to solve statistical quality control and reliability problems. These outcomes are what students are expected to gain from this course. IE 461 – SAFETY ENGINEERING Designation as a ‘Required’ or ‘Elective’ course TYPE OF COURSE: Required for BSIE AND BSEM Majors Course (catalog) description COURSE DESCRIPTION: Safety Engineering. 3 undergraduate hours; 4 graduate hours; Accident losses; standards and codes; hazards control; accident investigations; mechanical injuries; heat, pressure, and electrical hazards; fires and explosions; toxic materials and radiation; vibration and noise; course project for graduate level. Prerequisite(s) PREREQUISITE(S): IE 342 Probability and Statistics for Engineers, 3 hours; or consent of the instructor. Textbook(s) and/or other required material SAMPLE SOURCES AND RESOURCE MATERIALS: 1. Safety and Health for Engineers, 2nd Edition, R. Brauer. Wiley-Interscience, 2006, ISBN 978-0-471-29189-3. Course objectives COURSE OBJECTIVES: This course is designed to introduce students to the principles of health and safety engineering, with an emphasis on the application to the occupational setting. Both quantitative and qualitative tools are discussed. Topics covered MAJOR TOPICS: 1 Health Protection Fundamentals 2 Mechanical Hazards and Control 3 Electrical, Thermal, Pressure Hazards and Control 4 Fire, Explosion Hazards and Control 5 Ionizing/Non-ionizing Radiation, Noise Hazards and Control 6 Chemical, Biological Hazards and Control 7 Ventilation Control Systems and Personal Protective Equipment 8 Accident investigation, emergencies 9 Examination Total Hrs 6 7.5 4.5 3 7.5 6 4.5 3 3 45 . Class/laboratory schedule, i.e., number of sessions each week and duration of each session CREDIT HOURS: 3 hours TYPE OF INSTRUCTION: Contact Hours/Week Type of Instruction 3 Hrs Lecture/Discussion 0 Contribution of course to meeting the professional component This course provides a fundamental understanding of health and safety engineering with an emphasis as it pertains to the occupational environment. Identification of hazards and their associated methods of control are discussed. The underlying theme throughout the course is that worker health protection may be afforded through prevention by the anticipation, recognition, evaluation, and control of workplace hazards. Relationship of course to program outcomes: Outcomes A E F Comments on outcomes Ability to apply knowledge of mathematics, science and engineering. Students are able to integrate health protection principles, the physical environment, and engineering solutions. Also, students work in small groups to develop quantitative and qualitative control strategies for problems presented during lecture. For example, students develop control strategies for worker hazards in grain handling facilities in agricultural settings. An ability to identify, formulate, and solve engineering problems. Students are able to formulate quantitative problems for health protection evaluation and control, solve quantitative problems for health protection evaluation and control and utilize quantitative formulas and problems based on the content of the course and provide quantitative solutions to demonstrate their ability to apply standard equations used in practice. For example, students develop and solve explosion, thermal, radiation, and noise problems for comparison to thresholds of concern. Understanding of professional and ethical responsibility Students are able to understand their responsibility as engineers for the protection of worker health in the industrial environment as well as the surrounding community, the fact that society values these responsibilities, as demonstrated through professional work ethic, litigation, and legislation. Students develop this sense of responsibility to the public through lecture, conversation, and reading on the social, political, and economic implications of health protection. For example, we discuss the tension between engineers’ duties to employers and clients vs. duties to the general public. The broad education necessary to understand H the impact of engineering solutions in global and societal context. I A recognition of the need and ability to engage in life-long learning. Students were able to apply a framework with which they are able to approach health and safety concerns in any occupational environment. Students are able to integrate and apply their understanding of the physical environment, heath and safety hazards, and engineering solutions to an assortment of potential hazards, settings and applications. Students apply heath and fundamentals along with engineering control solutions to problems that extend to global and societal concerns. For example, students examine health and safety issues related the infectious diseases (TB or Legionellosis in Basic concepts lecture & assignment), learn to read regulations & Standards and Bureau of Labor Statistics Tables that describe rates of injury by occupation (S&H Regulations assignment), learn about disposal of hazardous waste and process safety relative to community and worker health impacts in US vs. developing countries. One lecture is devoted to ethics in engineering S&H practice and professional certification process, which includes the requirement for professional development and continuing education. Students are able to recognize the continuous development of health protection technology, continuous development of standards and legislation that affect heath protection. Students learn through lecture and safety control technologies along with new standards and laws that affect the practice of health protection. They also learn to research multiple sources of recommendations, guidelines and professional and legal standards relevant to design and performance. For example, students learn about the annual review of documentation for the continuous development of occupational exposure thresholds such as OSHA PELs, ACGIH TVLs & NIOSH RELs. One lecture is devoted to ethics in engineering S&H development and continuing education. Person(s) who prepared this description and date of preparation Professor Salvatore Cali, UIC Instructor, August 2013 These outcomes are what students are expected to gain from this course. IE 463 – FACILITIES PLANNING AND MATERIAL HANDLING Designation as a 'Required' or 'Elective' course TYPE OF COURSE: Required for BSIE Major Course (catalog) description COURSE DESCRIPTION: Facilities design functions, computer-aided plant layout, facility location, warehouse layout, Minimax location, deterministic and probabilistic conveyor models. Prerequisite(s) PREREQUISITE(S): IE 471 (Operations Research I), 3 hours Textbook(s) and/or other required material SAMPLE SOURCES AND RESOURCE MATERIALS: 1) Facilities Planning (4th edition), J. A. Tompkins, J. A. White, Y. A. Bozer, J. M. A. Tanchoco, John Wiley & Sons, 2010. Course objectives COURSE OBJECTIVES: This course introduces students to various aspects of facilities planning process. The objective is to provide the students with basic tools and methodologies used in this process, and to expose the students to the application of such tools. Both quantitative and qualitative tools (methods) are discussed. Topics covered MAJOR TOPICS: 1. Introduction 2. Computer-aided plant layout 3. Facilities location problems 4. Warehouse layout problems 5. Minimax layout and location problem 6. Deterministic and probabilistic conveyor models Total Hrs 3 8 8 8 8 10 45 IE 463 Instruction Notes on Relevant ABET Outcomes: A C E Ability to apply knowledge of mathematics, science and engineering. Students are able to use mathematical calculations in solving engineering problems and are able to formulate engineering problems based on scientific and engineering principles. They also use operation research techniques to formulate and solve facilities planning problems. For example, they apply Integer Programming to design an optimal layout of a facility. Ability to design a system, component, or process to meet desired needs. Students develop the ability to define and follow an iterative design procedure and think creatively. Also, students are supposed to decide and design the right layout and material handling equipment for their projects. Ability to identify, formulate, and solve engineering problems. Students develop the ability to understand what is needed, formulate problems mathematically and build on fundamental knowledge and apply it to new situations. In addition, operations research techniques are taught in the lecture portion of this course. The students select the right technique and interpret the mathematical solution of their model to provide answers for their engineering problem. For example, graph theory is used to investigate the adjacency of production departments of a facility. G Ability to communicate effectively. Students develop the ability to present effectively in senior design, write laboratory reports and course project reports, develop good interview skills, and create engineering drawings. In addition, students have to present their project results by two oral and two written presentations. J Students acquire the knowledge of major technological issues facing society and the world and develop an appreciation for the society’s concerns with security in technology. In the feasibility study phase of the term projects, the students are encouraged to select a facility, which is economically, technologically and operationally feasible. Knowledge of contemporary issues. Ability to use the techniques, skills, and K modern engineering tools necessary for engineering practice. Students develop the ability to utilize computers for engineering analysis purposes and technical approaches in engineering experimentation. Simulation software, LP packages and other mathematical programming software tools are used to find the optimal design of material handling systems, plant layout and location. Person(s) who prepared this description and date of preparation Houshang Darabi, Assistant Professor of Industrial Engineering, March 03, 2003. Houshang Darabi, Associate Professor of Industrial Engineering, September 5, 2013. These outcomes are what students are expected to gain from this course. IE 466 – PRODUCTION PLANNING AND INVENTORY CONTROL Designation as a 'Required' or 'Elective' course TYPE OF COURSE: Required for BSIE and BSEM Majors Course (catalog) description COURSE DESCRIPTION: IE466 Production Planning and Inventory Control. 3 undergraduate hours; 4 graduate hours. Principles of demand forecasting, production planning, master scheduling, job sequencing, design and control of deterministic and stochastic inventory systems, and material requirement planning Prerequisite(s) PREREQUISITE(S): IE342 Probability and Statistics (3 hrs), IE 345: Regression and Forecasting (3 hrs) and IE 471 –Operations Research (3 Hours) Textbook(s) and/or other required material SAMPLE SOURCES AND RESOURCE MATERIALS: Production and Operations Analysis (6th Edition), S. Nahmias, McGraw Hill, 2009 Course objectives COURSE OBJECTIVES: To teach students to apply basic optimization techniques to formulate and solve problems that arise in production systems. With the successful completion of the course, students are equipped with a general understanding of (integrated) production systems and a palette of optimization tools for solving commonly encountered production planning and control problems, including aggregate and disaggregate planning, job shop scheduling, and inventory control. Topics covered MAJOR TOPICS: 1. Introduction to production system 2. Forecasting techniques 3. Aggregate and disaggregate planning 4. Inventory system and control 5. Material planning requirement 6. Job shop scheduling 7. Integrated production systems: push vs. pull systems, JIT 8. Exams and/or quizzes Total Hrs 1 8 7 7 7 7 5 3 45 Class/laboratory schedule, i.e., number of sessions each week and duration of each session CREDIT HOURS: 3 undergraduate hours; 4 graduate hours. Type of Instruction Contact Hours/Week Lecture-and-discussion 3 Contribution of course to meeting the professional component Students are exposed to various bottleneck problems of various production systems and learn to formulate and solve them by using theoretical foundation of operations research and basic scientific/engineering principles. Through illustrative examples and discussions in class as well as problems from text and the literature, students get hands-on experience with optimization of commonly encountered production planning and control problems, including aggregate and disaggregate planning, job shop scheduling, and inventory control, and obtain a general understanding of (integrated) production systems. Contemporary issues and examples are presented and discussed in detail to provide students with insights as to how the class materials learned l are related and can be used for their solution. Through the course, students learn the merits and shortcomings of local vs. heuristic vs. exact solution procedures and, through illustrations and discussions, learn how simple tools learned in class may be extended and modified to solve real-world production system-related problems. Relationship of course to program outcomes As shown in the BSIE Course Outcomes Matrix: A. Ability to apply knowledge of mathematics, science and engineering E. Ability to identify, formulate, and solve engineering problems Comments on outcomes A. Use of linear algebra, calculus, optimization techniques, etc. to problems arising in production systems E. Supply chain modeling, production planning, and inventory control problems are described in class and also given to students as homework and exams. These problems are industrial engineering problems and the students learn how to formulate and solve those using analytical tools. Person(s) who prepared this description and date of preparation Hong Seo Ryoo (Assistant Professor) of Mechanical & Industrial Engineering, January 31, 2002 Nan Ratisoontorn, Visiting Assistant Professor of Industrial Engineering, June 12, 2013. IE 467 – DISCRETE EVENT COMPUTER SIMULATION APPLICATION Designation as a ‘Required’ or ‘Elective’ course TYPE OF COURSE: Required for BSIE and BSME Major Course (catalog) description COURSE DESCRIPTION: IE 467 Industrial Systems Simulation. 3 Hours. The solution of industrial problems by means of computer simulation. Simulation strategies. Simulation perspectives. In-depth study of some specific simulation programming languages, with projects. Prerequisite(s) PREREQUISITE(S): IE 342. Textbook(s) and/or other required material: Simulation with Arena, by Kelton and Sadowski, 5th Edition, McGraw-Hill, New York, 2010. Course objectives COURSE OBJECTIVES: The primary objective is to become proficient in the use of discrete event computer simulation as problem solving/system design technique. A systems approach to problem solving/system design will be stressed. Since proficiency with simulation can only be achieved from hands on experience, a computer simulation tool (Arena) will be applied to a progression of projects including manufacturing/production systems, transportation, service, bank system, etc. The course will also stress the importance of communication of simulation results through written report and verbal presentations. Data analysis and approaches to presenting simulation results will also be introduced. Upon completion of this course, the students will be expected to be able to model complex, real life industrial systems using computer simulation methods. Topics covered MAJOR TOPICS: 1 Introduction to discrete event simulation 2 Basic Modeling Concept 3 Terminating System Analysis 4 Transporters and Routings 5 Entity Flow and Conveyors 6 Non-Terminating System Analysis 7 Advanced Simulation Modeling Concepts 8 Arena Simulation Lab 9 Exams 10 Final Project Presentation Total Hrs 1 5 7 9 7 5 3 3 3 2 45 Class/laboratory schedule, i.e., number of sessions each week and duration of each session CREDIT HOURS: 3 hours Type of Instruction Lecture-and-discussion Laboratory Contact Hours/Week 3 6 Contribution of course to meeting the professional component The primary objective is to become proficient in the use of computer simulation as problem solving/system design technique. Since proficiency with simulation can only be achieved from hands on experience, a computer simulation tool (Arena) will be applied to a progression of projects including manufacturing/production systems, transportation, service, bank system, etc. Data analysis and approaches to presenting simulation results will also be introduced. Upon completion of this course, students will be expected to be able to model complex, real life industrial systems using computer simulation methods. Relationship of course to program outcomes As shown in the BSME Course Outcomes Matrix: A. Ability to apply knowledge of mathematics, science and engineering B. Design and conduct experiments, as well as analyze and interpret data D. Ability to function on multi-disciplinary teams E. Ability to identify, formulate, and solve engineering problems K. Ability to use the techniques, skills, and modern engineering tools necessary for engineering practice. Person(s) who prepared this description and date of preparation David He, Professor of Industrial Engineering, December 2013 Comments on outcomes A. Use of fundamental knowledge of probability and statistics in data analysis, problem formulation, modeling, and solution generation. B. Data collection and curve fitting for input analysis, simulation experiments in performance analysis, statistical inference of simulation output. D. The simulation projects and final simulation project required in this course encourage students to form their project teams to achieve a better learning experience in the class. E. Throughout the course, the students are required to analyze different industrial systems, identify the problems, formulate and modeling the problems, and find solutions to these problems using simulation. K. After this course, the students will be able to use effectively the industrial simulation tool to solve problems. These outcomes are what students are expected to gain from this course. IE 471 – OPERATIONS RESEARCH I Designation as a 'Required' or 'Elective' course TYPE OF COURSE: Required for BSIE and BSEM Majors Course (catalog) description COURSE DESCRIPTION: IE471 Operations Research I. 3 undergraduate hours; 4 graduate hours. Introduction to operations research, formulation of linear programming problems, simplex methods, duality theory, sensitivity analysis, network models, and mixed-integer linear programming. No graduate credit for industrial engineering majors. Prerequisite(s) PREREQUISITE(S): MATH 310, Applied Linear Algebra, 3 Hours Textbook(s) and/or other required material SAMPLE SOURCES AND RESOURCE MATERIALS: Introduction to Operations Research, Hillier and Lieberman, 8th edition, McGraw Hill, 2005, Course objectives COURSE OBJECTIVES: The course is designed to provide students with an opportunity to learn the theory and techniques of linear programming and its extensions. Students are expected to learn to formulate real-world problems as linear and mixed-integer programs through illustrations in class, via numerous problems from text and the literature, and also via an optional project opportunity. Students also learn to use Excel and CPLEX to solve linear programs. With the successful completion of the course, students will be equipped with the understanding of a palette of optimization tools: the simplex algorithm for linear programs and various algorithms for simple network models. Topics covered MAJOR TOPICS: 1. Introduction to operations research and linear programming 2. Model formulation, graphical interpretation and computer implementation 3. Simplex method 4. Theory of the Simplex method 5. Duality theory 6. Sensitivity analysis 7. Transportation and Assignment problems 8. Network models 9. Integer programming formulation 10. Project presentation 11. Exams Total Hrs 1½ 6½ 9 3 5 3 5 5-6* 4-5* 2* 3 45 *: The semester project is required for the course at the discretion of an instructor. **: If an instructor requires the final project, 5 hours are allocated for network models and 4 for integer programming. Class/laboratory schedule, i.e., number of sessions each week and duration of each session CREDIT HOURS: 3 undergraduate hours; 4 graduate hours. Type of Instruction Contact Hours/Week Lecture-and-discussion 3 Contribution of course to meeting the professional component The course is a gateway to optimization and presents a variety of basic operations research techniques for solving linear programming problems. Foremost, students understand the need for optimization. Through selectively chosen homework problems and the problems from the literature as well as extensive discussions in class and/or the final project opportunity (optional,) students learn to formulate and solve real-world problems as linear programs, network problems and mixed-integer linear programs. Students also learn to use computer software for solving linear programming problems and learn how to seek information outside of class materials. Relationship of course to program outcomes: As shown in the BSIE Course Outcomes Matrix: A. Ability to apply knowledge of mathematics, science and engineering E. Ability to identify, formulate, and solve engineering problems K. Ability to use the techniques, skills, and modern engineering tools necessary for engineering practice Person(s) who prepared this description and date of preparation Wei Chen (Associate Professor) & Hong Seo Ryoo (Assistant Professor) of Mechanical & Industrial Engineering, January 31, 2002 Pat Banerjee (Professor) of Industrial Engineering, October 15, 2007 Elodie Adida (Assistant Professor of Industrial Engineering), September 17, 2008 Houshang Darabi, Head of Undergraduate Studies, August 2013 Comments on outcomes: A. Use of linear algebra and calculus to learn the theory and methods for linear optimization problems. E. Through homework or/and an optional project. K. In addition to developing problem solving capabilities by hand in exam situations, students are required to use computer software and other mathematics applications for homework problems and their optional semester project. IE472 – OPERATIONS RESEARCH II Designation as a 'Required' or 'Elective' course TYPE OF COURSE: Required for BSIE and BSEM Majors Course (catalog) description COURSE DESCRIPTION: IE472 Operations Research II. 3 undergraduate hours; 4 graduate hours. Nonlinear programming problems, unconstrained optimization search techniques, Kuhn Tucker theorems, quadratic programming, separable programming, dynamic programming, Markov chain, and queuing theory. Prerequisite(s) PREREQUISITE(S): IE 471 – Operation Research I (3 Hours) Textbook(s) and/or other required material SAMPLE SOURCES AND RESOURCE MATERIALS: Introduction to Operations Research, Hillier and Lieberman, 9th edition, 2010 Course objectives COURSE OBJECTIVES: The course will continue to introduce the methods of operations research for improving design and operations of engineering system. The learning will emphasize the mathematical procedures of nonlinear programming search techniques, probabilistic models in operations research (e.g., Markov Chains and Queuing Theory), and dynamic programming. Students successfully completing this course are expected to be able to apply a variety of operations research techniques for solving nonlinear programming problems; to have a good command of probabilistic operations research methods and dynamic programming techniques; and to be familiar with computer software for solving nonlinear programming problems. Topics covered MAJOR TOPICS: 1. Introduction to Nonlinear Programming 2. Unconstrained Single Variable Problem 3. Unconstrained Multiple Variable Problem 4. Constrained Multiple Variable Problem 5. Quadratic Programming 6. Markov Chains 7. Queuing Theory 8. Dynamic Programming 9. Computer Lab 10. Review and Examinations (3 tests) Total Hrs 3 3 3 6 4½ 6 6 4½ 3 6 45 Class/laboratory schedule, i.e., number of sessions each week and duration of each session CREDIT HOURS: 3 undergraduate hours; 4 graduate hours. Type of Instruction Contact Hours/Week Lecture-and-discussion 3 Contribution of course to meeting the professional component The course extends OR I and presents more advanced topics of operations research, including nonlinear programming problems and probabilistic models. Through selectively chosen homework problems and the problems from the literature as well as extensive discussions in class and/or the final project opportunity (optional,) students learn the trade-off between realistic formulations of real-world problems and their solvability, learn to seek information outside of class materials, and realize the need for more sophisticated optimization tools and life-long learning for more accurate treatment of nonlinear problems and probabilistic models. Students also learn to use computer software for solving integer and nonlinear programming problems. Relationship of course to program outcomes As shown in the BSIE Course Outcomes Matrix: A. Ability to apply knowledge of mathematics, science and engineering E. Ability to identify, formulate, and solve engineering problems K. Ability to use the techniques, skills, and modern engineering tools necessary for engineering practice. Person(s) who prepared this description and date of preparation Hong Seo Ryoo (Assistant Professor) & Wei Chen (Associate Professor) of Mechanical & Industrial Engineering, January 31, 2002 Pat Banerjee (Professor) of Industrial Engineering, February 12, 2008 Nan Ratisoontorn, Visiting Assistant Professor of Industrial Engineering, June 12, 2013 Comments on outcomes A. Use of fundamental knowledge of mathematics such as linear algebra and calculus to learn the methods in Nonlinear Programming. Use the knowledge of statistics and probability to study the probabilistic models (Markov Chains and Queuing Theory) in operations research. E. Through homework and computer project assignments, students are required to demonstrate their understanding of the course material by implementing optimization algorithms for solving engineering problems. K. In addition to developing problem solving capabilities by hand in exam situations, students are required to use nonlinear programming software for homework problems and the optional semester project. The optional semester project provides students an opportunity to learn how to seek information outside of class materials. Through illustrative examples, students are exposed to the shortcomings of linear programming approach to real-world problems and the trade-off between realistic formulations of problems vs. their solvability and understand the need for more sophisticated optimization tools and life-long learning. These are the outcomes students are expected to gain from this course.