case_study - National HE STEM Programme

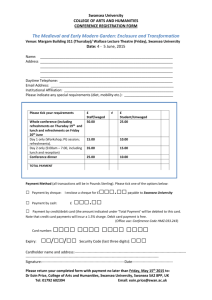

advertisement

Title: The Steel Academy: development of key Author(s): Richard Thomas, Assistant Dean, Faculty of Applied Design & Engineering Institution: Swansea Metropolitan University Abstract: The aim of the Steel Academy project was to provide an integrated “skills escalator” for the metals industry in South Wales, by capitalising on the strengths of two universities in the region, integrating existing provision developing new programmes to fill gaps. This was achieved, with additional side benefits not originally anticipated. As a result there now exists a single, integrated provision in materials engineering, oriented towards the metals industry, from sub-degree to doctoral level, with strong employer engagement. Background and Rationale: One of the Welsh government’s key priority areas in its economic development strategy is the Advanced Manufacturing and Materials sector, which forms a significant part of the Welsh economy. The sector is broad and includes a considerable amount of work for the aerospace and automotive industries. Historically, the production and processing of metals has dominated manufacturing industry in Wales and, whilst copper and aluminium production have declined, the manufacture of steel remains a major component of the sector, with other metals, such as titanium and nickel also playing an important role. To support this large metals manufacturing activity, several universities and colleges provided a range of metallurgical courses, both full-time and part-time, in both further and higher education. However, with two or three decades of decline and restructuring within the industry, the educational provision also declined, to the extent that for many years only one institution, Swansea University, offered metallurgical education in Wales. The university has retained strong links with the industry and offers a full-time BEng programme in Materials Science and Engineering, a part-time Integrated Graduate Development Programme at Masters level and a very strong and highly regarded MRes/EngD programme. Part-time metallurgical education had been provided by West Glamorgan Institute of Higher Education, but this programme had been terminated in the late 1980s. Recent discussions with Tata Steel and Celsa Manufacturing identified that the industry was facing a serious skills shortage. An ageing workforce and the lack of any opportunity to train and educate metallurgical technicians or develop existing staff to graduate level in metallurgy on a part-time basis meant that companies engaged in the steel industry were facing a potentially serious shortage of skills as current staff approached retirement. To meet this challenge, the School of Logistics and Manufacturing Engineering at Swansea Metropolitan University and colleagues from the Materials Science department at Swansea University to find a solution to this problem. Implementation: The first stage was to engage with employers to establish more precisely the nature and scope of the problems faced by the industry. It became apparent that whilst companies can recruit well qualified graduates in Materials Science and Engineering from universities, a development period of, typically, two years is necessary before these graduates begin to make an effective contribution to the organization. This is not uncommon in many disciplines and many larger companies have graduate development schemes to help with this. However, The companies, particularly Tata Steel, identified a need to supplement recruitment of graduates from full-time university programmes with an additional route. There was a need to develop technician-level education and a corresponding opportunity for individuals following this route to further their education to graduate level or beyond. During the course of these discussions, the idea of a “skills escalator” emerged. This skills escalator would comprise an integrated educational provision, which would start at further education level – level 3 and possibly level 2 - and at the upper end would provide EngD/Phd opportunities. This idea was very well received by industrial partners, but It quickly became apparent that no single educational institution in South Wales was in a position to meet every aspect of this emerging need for workforce development. However, it was agreed that by working in partnership, the majority of the skills escalator could be addressed by two institutions – Swansea University and Swansea Metropolitan University – working in partnership. It was agreed to prioritise university provision and then to work with a suitable partner further education college to address the lower level needs. It was decided that each institution would concentrate on its strengths. For Swansea University, this meant their existing full-time degree programme, the IGDS and MRes/EngD programmes, which are well-established and clearly addressing important needs. Swansea Metropolitan University already had a strong, well-regarded part-time BEng programme, with pathways in Mechanical Engineering and Manufacturing Systems Engineering, both of which drew students from the steel industry, making the university well placed to address the part-time undergraduate and sub-degree need. With Swansea Metropolitan University taking the lead in the development of a part-time programme in Materials Engineering, consultation took place with steel manufacturers, other industry bodies and with colleagues at Swansea University. It was decided, firstly, to develop a completely integrated suite of programmes with different entry and exit points. Higher National Certificate (HNC), Higher National Diploma (HND) and Foundation Degree (FD) qualifications were embedded within the overall envelope of the BEng in Materials Engineering, enabling students to complete intermediate qualifications, if they wished. They may choose to leave with one of these qualifications or to pursue the BEng programme fully. Students who leave with a sub-degree qualification would be able to return subsequently to “top up” the qualification to BEng (honours). The curriculum for the programme was designed with input from both industrial partners and academic colleagues at Swansea University. IT was decided that Levels 4 and 5 of the programme would cover the broad range of materials science and engineering, whilst Level 6 would enable students to specialise in metallurgical studies. At the same time, the increasing application of composite materials in a range of industries, but particularly the aerospace industry, prompted the team to include an alternative route for specialization in polymers and composites at Level 6, broadening the provision beyond the original vision for meeting the needs of the steel industry to embrace another growing aspect of the advanced manufacturing and materials sector. The structure for the programme is shown in Table 1 below. Module Level 4 Mathematics Engineering Science 1 Physical Science for Materials Introduction to Materials and Manufacturing Computer Aided Engineering Design Workshop and Study Skills Level 5 Structure and Properties of Materials Manufacturing with Materials Materials in Service Manufacturing and Quality Systems Engineering Management Group Project Level 6 Metals Major Project 40 Metallurgy of Steel 20 Metallurgy of Non Ferrous Alloys Welding Engineering Non Destructive Testing Credits 20 20 20 20 20 20 20 20 20 20 20 20 20 Polymers and Composites Major Project 40 Engineering with 20 Polymers Composite Materials 20 20 20 Finite Element Analysis Non Destructive Testing 20 20 Table 1: Steel Academy part-time BEng Materials Engineering In addition to developing the curriculum itself, close attention was paid to the delivery model. Swansea Metropolitan University has, for many years, delivered a successful part-time BEng programme in Mechanical and Manufacturing Systems Engineering. It was decided to integrate delivery of the new BEng Materials Engineering as closely as possible with this existing provision, particularly as some of the Level 4 and 5 modules were common. The current model for delivering this programme is with lectures being held on Fridays from 1 to 7 p.m, over an extended academic year of 42 weeks. This has been well-received by both employers and employees as it minimizes the amount of time the students need to spend away from the workplace and also reduces the overall time needed to complete the degree, without compromising the actual delivery hours. With this agreement in place, the programme was put through the university’s validation process and an initial cohort of eight students was recruited. The first sixty Level 4 credits were delivered during this initial phase of the project. Whilst Swansea Metropolitan University led the development, validation and delivery of the BEng programme, colleagues at Swansea University worked on the development of electronic material to support learning in specific aspects of materials and steel technology. Although the existence of a part-time BEng portfolio in Mechanical and Manufacturing Engineering and a proven delivery model were helpful in the development of the new Materials Engineering programme, it was still necessary to put the programme through a full validation process. It was encouraging to note the extremely positive and supportive comments made by external members of the validation panel, which served to reinforce the impression that the premise of the development of this programme was sound. In parallel with this activity, colleagues at Swansea University led the development of a work based learning (WBL) programme in metallurgy, which aimed to deliver 10 credit modules in a range of metallurgical subjects, as a series of short courses to staff employed in industry. This provision became known as the METAL programme and was implemented in parallel with the BEng programme during the 2011/12 academic year. A close correspondence with the BEng programme was designed in, to enable appropriate candidates who complete modules on the METAL programme to enrol on the BEng and, potentially, count credits obtained on the WBL programme. The aim of this project was to develop a provision that addressed an important need in a key industrial sector, with particular attention to gaps that existed in current provision. As a result, a major curriculum development has taken place at Swansea Metropolitan University, allied to developments at Swansea University, along with, important spin-off benefits, as discussed below. Evaluation: Quantitative analysis of this project would be difficult at this stage. At the time of writing the report, the first cohort of students is just completing the first 60 credits of study. However, each student has participated in a structured interview to assess their experience during their first academic year. The background of students on the programme varies from those with three good A levels, recruited by Tata specifically for development into graduate-level metallurgists or process technologists, through students with Higher National qualifications in chemistry to one student with a Higher National Certificate in Mechanical Engineering, who decided to change discipline to Materials Engineering because of the career opportunities it offers within the company. Students were asked about their experience of the programme in terms of intensity of study and delivery of the lectures, timing and scheduling and the quality of teaching. Although each student was interviewed separately, by the project manager rather than by a member of the teaching team, the response was remarkably consistent. Although the students found the study quite intensive they felt that they were prepared to undertake this kind of study because of the potential career benefits and also felt that, at least at this stage, it was demanding but not beyond what they could cope with. They were uniformly happy with the extended academic year, with Friday afternoon and evening lectures, which they felt had actually improved the likelihood of them getting release from work to attend as it minimized disruption to their various departments. The team were particularly gratified to see the comments on the quality of teaching. The students made positive comments on the sympathetic approach taken by the lecturers and the evident industrial experience of the team, which they felt helped them to contextualize the lecture material and thus increase the immediate relevance of the material to their work roles. Examination success rates will be monitored to evaluate student performance and the effectiveness of the teaching and learning. An interesting evaluation comes from the employers’ perspective. Tata Steel have been particularly pleased with the programme and have decided to increase the number of students from the company for the second cohort. Although Swansea Metropolitan University has recruited students from Tata onto its Mechanical and Manufacturing Engineering programmes for many years, the relationship with the company has not been particularly strong. As a result of this programme a very close working relationship has developed, with regular meetings to ensure that design and delivery of the programme was appropriate. The relationship is now developing further to embrace other opportunities to work together to help the company develop the well-educated workforce it feels it needs to ensure its future success and a specific recruitment pathway has been created to take good A-level students onto a technical trainee programme, which includes the BEng Materials Engineering. Other companies who participated in discussion early in the programme did not feel that they were at a stage where they could candidates for the programme at this stage, nevertheless wished to engage with it at a lower level. This led to the development of a major short course programme in the metallurgy of steel for Celsa Manufacturing, with four courses delivered during the last year and further presentations scheduled for next year. Another intensive short course programme was developed and delivered for Texturing Technology Limited, which dealt with subjects such as roll grinding and electroplating. Alongside the developments at Swansea Metropolitan University, colleagues at Swansea University secured funding from the European Social Fund to develop a series of 10 credit work based learning course (at Level 4), which Tata and other companies have been using to develop employees. The examination success rate has been high and several of the participants who have successfully completed 60 credits of study will be progressing to the BEng programme in the next academic year. A close working relationship has been developed between the two universities, with joint progress meetings held and representatives from each institution sitting on the steering groups for the various projects that comprise the Steel Academy. Finally, work has begun with a partner further education college to try to establish a metallurgy/materials programme at Level 3 to address the final remaining gap in provision. Discussion, Learning and Impact (Success): The overall outcome of this project is the establishment of a single, integrated “skills escalator” for the metals industry, jointly developed and delivered, by Swansea Metropolitan University and Swansea University, which provides an educational resource from sub-degree to doctoral level for industry. The programme builds on existing full-time degree, MRes/EngD and Integrated Graduate Development Scheme in Materials Science and Engineering at Swansea University and the part-time BEng programmes in Mechanical and Manufacturing Engineering at Swansea Metropolitan University, along with subject expertise in both institutions to develop part-time Higher National, Foundation Degree and BEng (honours) degree programmes in Materials Engineering, offered on an extended academic year, with a schedule designed to minimize disruption to work commitments. The programme was designed and validated during the funding period, a cohort of students was recruited and the first 60 credits of study completed. Alongside this, additional spin-off benefits have been achieved - the ESDFfunded METAL work based learning programme, and the realization by companies that, even if they are not currently in a position to place students on an extended academic programme, there is an opportunity to benefit from the expertise at either university by means of generic or specifically tailored short courses, which may be credit-bearing and allow students to progress to the academic programme. Some of these short courses may even give the students entry at an advanced level. Apart from the obvious benefits to industry of having such a comprehensive opportunity, within an integrated framework, to develop employees to the very highest level, other key additional benefits have been realized. The close working relationship between the relevant departments of both universities has benefitted both the universities and the participating companies and the strength of the relationship developed with key employers is already having benefits for both universities and companies. The opportunity to secure additional funding from ESF to develop a work based learning programme has added to the comprehensiveness of provision and a further application for ESF funding to establish a work-based learning programme at Level 4 and above in welding engineering has been submitted by Swansea Metropolitan University and Neath Port Talbot College. The development of an additional specialism in polymers and composites has also proved to be worthwhile. Whilst this was originally developed in anticipation of a growing need in the Welsh aerospace sector in a few years’ time, it attracted the attention of two English further education colleges with significant He provision and partnerships have been developed to assist them in the establishment of a similar skills escalator approach to address needs in aerospace, marine and defence industries in their regions. If anything, the overall impact of this project has exceeded expectations. The original aim was achieved and several significant, additional outcomes which were not part of the original basis for the project have been realized. An important aspect of the project is the impact it has had on participating universities, both in terms of improving relationships with each other and with key employers in the metals sector, with whom an excellent working relationship has been established. Further work to establish a Level 3 provision has begun, but is at an early stage. Further Development and Sustainability: It is planned to continue to offer the part-time BEng/FD/HN programme at Swansea Metropolitan University on the same basis as the part-time programmes in Mechanical and Manufacturing Engineering, a programme that has been running successfully for around fifteen years. There seems to be a growing demand for the metals-orientated programme in South Wales, and the demand for a polymers and composites version will be assessed on a year-by-year basis. Work undertaken with partner FE institutions who will be offering a degree with this particular specialism will also inform any provision of this nature in South Wales. Continued input from employers will be facilitated through a faculty management position, with specific responsibility for industrial engagement and an industrial advisory, which has recently been established and includes representatives from employers, the automotive and aerospace forums and Sector Skills Councils. One major employer is developing a recruitment route to train new metallurgical specialists, who will pursue the degree as part of their development programme. Professional body accreditation is currently being pursued with the Institute of Materials, Minerals and Mining. Whilst the programme developed at Swansea Metropolitan University will remain a part-time provision (in order not to compete with the full-time programme at Swansea University), full-time students are already benefitting from relationships with the extended range of companies that are engaged in this project. For example, students have undertaken study visits to some of these companies, there are new opportunities for full-time students to undertake industry-based or related project work and material developed for delivery on the part-time programme can be used to inform relevant aspects of the full-time Mechanical Engineering programme. Along with the HE STEM Legacy project, this project has had a major impact on the teaching team at Swansea Metropolitan University, broadening the range of engagement with employers, expanding horizons and providing fresh stimuli for development of the curriculum and engineering education research. Outputs: The outputs of this project are principally a new, integrated part-time BEng/FD/HN programme in Materials Engineering, with options enabling specialism in metals or polymers and composites. This new provision addresses an important gap in the skills escalator developed as a wider output from this project. Further important outputs from the project are the close working relationships established between universities and employers in the South Wales region, with the specific aim of developing programmes which are academically sound, but address a genuine and urgent industrial need. Finally, opportunities have emerged to develop a whole raft of spin-off benefits have been developed, which include a range of generic Level 4 work based learning modules in the science and technology of metals, specific short courses, custom made for individual organizations, bids for European funding to enable the development of further work based learning programmes and the potential for a Level 3 programme in materials engineering at a partner FE college. In summary, the comparatively modest investment from the HE STEM programme has enabled the development of a sustainable route for the enhancement of the workforce in the metals and materials industries to graduate level, and has catalysed the development of a wide range of related activities which are well on the way to establishing a comprehensive academic provision from Level 2 to doctoral level, with genuine partnerships between universities and employers and a strategy for long term development and delivery.