iv. vector control

Performance of ANN Based Indirect Vector Control

Induction Motor Drive

Rani S & Victore George

I. INTRODUCTION

E-mail : rany.ktm@gmail.com

Abstract – Induction motors are extensively used in industrial and household appliances consume about 60% of the total consumed electrical energy. The need for energy conservation is increasing the requirements for saving the electrical energy. It is therefore important to optimize the efficiency of motor drive systems if significant energy savings are to be obtained. This paper proposes a new control scheme based on artificial neural networks to obtain certain torque and speed operating point there exist only one set of voltage amplitude and frequency that operates the machine at optimum efficiency. In this paper indirect field oriented (IFOC) control is used. This is one of the most effective vector control of induction motor due to the simplicity of designing and construction. methods of their speed control have either been expensive or highly inefficient. Various methods have been designed to achieve the best performance of the motor and the approaches used can be classified into three different types. The first, so called “loss model controller”. The second type, named “search controller”.

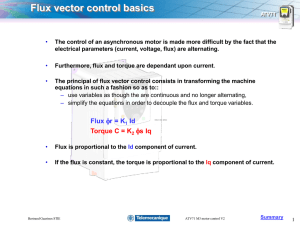

II. FIELD ORIENTED CONTROL

The vector control of ac drives has been widely used in high performance control system. Indirect field oriented control (IFOC) is one of the most effective vector control of induction motor due to the simplicity of designing and construction. In this system, the flux coordinates reference frame is locked to the rotor flux

The efficiency of Induction Motor when operate at rated speed and load torque is high. Unfortunately for variable load operation the application of the motor at rated flux will cause the iron losses to increase excessively; hence its efficiency will reduce dramatically. In order to reduce the iron losses the flux level should be set lower than rated flux, but this will increase the copper loss. Therefore, to optimize the efficiency of the induction motor drive system at partial load, it is essential to obtain the flux level that minimizes the total motor losses. vector rotating at the stator frequency as shown in Fig.2.

This results in a decoupling of the variables so that flux and torque can be separately controlled by stator directaxis current and quadrature-axis current respectively. It is also known as decoupling, orthogonal or trans-vector control.

The FOC block used here gets the value of the flux and voltage frequency ratio to give gating pulses to the inverter which controls the voltage being fed to the induction motor and hence the efficiency optimization is obtained to achieve the task of energy saving. The feedback is again send to the speed controller for the

In air conditioning system, the induction motors are often used to drive a compressor at constant speed operation. However, because the typical load profile of this load is that the load torque varies with speed, therefore implementation of a variable speed drive for it is potential to increase energy saving . Because of their easy implementation and low cost, indirect field oriented induction machine drives are finding numerous industrial applications. Most of the industrials motors are used today are in fact induction motors. Induction motors have been used in the past mainly in applications requiring a constant speed because conventional optimization purpose. Point to another through the adequate optimal trajectory and the other which is in charge of keeping the motor at a maximum efficiency operating point in the steady state for a given speed and torque. The first part acts when a modification in the reference speed is produced. Its function consists of determining the necessary optimal trajectory, starting from the present state of the motor and the aimed speed, creating the adequate reference signals. Once the desired speed is reached, the motor changes into steady state with minimum stator current for the new load torque.

From this moment, the second algorithm acts.

ISSN (Print) : 2319 – 2526, Volume-2, Issue-5, 2013

49

International Journal on Advanced Computer Theory and Engineering (IJACTE)

The search for the maximum efficiency operating point is based on and consists of an iterative algorithm, which applies small increments to the reference signal while reference signal is in charge of maintaining the required torque and speed. A step followed by a decrease in the consumed active electric power means that it acts in the correct direction and must be repeated.

Otherwise, a successive step will be reversed. A special algorithm that selects the most convenient state of the three-phase inverter among the eight possible ones achieves the closeness of the stator current space vector to its reference signal in both transient and steady states.

In this way, the inverter, in spite of being a voltagesource one, acts as a current source that permits us to ignore the voltage equations of the motor model as mentioned.

Like the human brain the ANN can be trained to solve the lost complex non-linear problems with variable parameters. The ANN has been successfully applied to identify and control the currents of an induction machine. There have been several applications of ANN in AC drive systems such as adaptive flux control, current control, speed control, and field-oriented control. It is expected that ANN as an artificial intelligence tool will guide to new modern techniques in power electronics and motion control systems. As mentioned earlier speed and torque estimation two other applications for the ANN in motion control.

Fig.1: Vector drive with ANN based feedback signal processing.

Fig. 2 : Neural network system to calculate commanded voltage and frequency.

III. ANN MODEL

Artificial Neural networks are relatively crude electronics models based on the neural structure of the human brain. The fundamental processing element of a neural network is a neuron. A neural net is based on layers of neurons. The outputs are the operating speed and torque of the artificial neural networks is valuable on several counts including their adaptability, nonlinearity, and generalization capabilities. The ANN is the simulation of human brain nervous system and is constructed of artificial neurons And their interconnections.

50

Fig. 3 : ANN with separate hidden layers for speed and torque estimation.

A unique property of a neural network is that it can still perform its overall function even if some of the neurons are not functioning. That is, they are very robust to error or failure. Neuron is a fundamental processing component of a neural network. Once the network is structured, network is ready to train. For this initial weights are chosen randomly. Here, neural network is used for compute the appropriate set of voltage and frequency to achieve the maximum efficiency for any value of operating torque and motor speed. NN have the two inputs, motor torque and speed and have two outputs, optimum voltage and frequency.

The two layer feed forward structure of NN model is used in this paper. It has two hidden layers; one is of tan-sigmoid function. Since the optimum voltage and frequency are highly non-linear function of motor speed and load torque so we preferred the tan-sigmoidal function and other is of pure linear function. The two inputs of NN model is firstly feed to the layer of tansimoidal function and output of this layer is broadcast to the layer of linear neurons.

Fig. 4: Neural network model.

ISSN (Print) : 2319 – 2526, Volume-2, Issue-5, 2013

International Journal on Advanced Computer Theory and Engineering (IJACTE)

The back-propagation training algorithm is used for this network. The training is automated with Mat lab

Simulation program developed for this purpose, which train the network using the back propagation method. At the end of training of network the value of weight and bias are set. The torque and speed should vary with in a practical limit corresponding the value of voltage and frequency is calculated and saved in a data file in matrix form.

IV. VECTOR CONTROL

The vector control of ac drives has been widely used in high performance control system. In the case of induction machines, the control is usually performed in the synchronously rotating reference frame. In vector or field oriented control both the magnitude and phase alignment of vector variables are controlled The stator current of induction machine are separated into flux- (I sd

) and torque producing (I sq

) components by utilizing transformation to the d-q coordinate system, whose direct axis (d) is aligned with the rotor flux space vector. This means that the q-axis component of the rotor flux space vector is always zero. ѱ rq

=0 d ѱ rq

=0

dt machine model as shown. The controller makes two stages of inverse- transformations, as shown, so that the control currents i ds

* and i qs

* corresponds to the machine currents i ds

and i qs

, respectively. In addition, the unit vector assures correct alignment of i ds

current with flux vector ѱ r

and i qs

perpendicular to it. Note that the transformation and inverse transformation including the inverter ideally do not incorporate any dynamics, and therefore, the responds to i ds

and i qs

is instantaneous.

Fig.5: Vector control implementation principle with machine d e -q e model.

In Fig.5 the machine model is represented in synchronously rotating reference frame. Vector control implementation can be explained with this fig. The inverter is omitted from the figure, assuming that it has unity current gain that is, it generates the currents i a

, i b

, and i c

as dictated by the corresponding command currents i a

* i b

* and i c

* from the controller.

A machine model with internal conversions is shown in right. The machine terminal voltage i a

, i b

and i c are converted into i ds s and i qs s components by three phase to two phase transformation. These are then converted to synchronously rotating frame by the unit vector component cosθ e

and sinθ e

before applying to the d e -q e

51

Fig. 6: Complete block diagram of vector control.

Fig.6 shows the basic structure of the vector control of the AC induction motor. To perform vector control, follow these steps:

Measure the motor quantities (phase voltages and currents)

Transform them to the 2-phase system using a

Clarke transformation

Calculate the rotor flux space vector magnitude and position angle

Transform stator currents to the d-q coordinate system using a Park transformation

The stator current torque- (isq) and flux- (isd) producing components are separately controlled

The output stator voltage space vector is calculated using the decoupling block

An inverse Park transformation transforms the stator voltage space vector back from the d-q coordinate system to the 2-phase system fixed with the stator

ISSN (Print) : 2319 – 2526, Volume-2, Issue-5, 2013

International Journal on Advanced Computer Theory and Engineering (IJACTE)

Using the space vector modulation, the output 3phase voltage is generated

S ѱ rq

= 0

V. CONCLUSION

This paper has presented an ANN-based scheme for induction motor drive leading to energy saving. The proposed scheme uses information on speed and torque of the motor to generate the appropriate voltage amplitude and frequency that save the energy. An ANN model has been configured and trained on a set of data generated, based on the motor equivalent circuit, using a

Matlab computer program. The model uses two hidden neuron layers. By using this technique we can obtain the stable operating point. The corresponding values of voltage and frequency at this point will operate the machine at optimum efficiency.

VI. REFERENCES

[1] Toshiaki Murata, Takeshi Tsuchiya and

Ikuo Takeda, “Vector Control for Induction

Machine on the Application of Optimal Control

Theory,” IEEE Trans. on Industrial Electronics, vol. 37, no. 4, pp. 283-290, 1990.

[2]

B.K.Bose, “Modern Power Electronics and AC

Drives”.

[3] Performance of ANN based indirect vector control induction motor drives. © 2007 JATIT, www.jatit.org.

[4] M.G. Simoes and B. K. Bose, “ Neural network based estimation of feedback Signals for vector controlled induction motor drive”, IEEE

Trans. Ind Apl., vol- 31 pp 620-629, May/June

1995.

[5] F.J.Nola, “Power factor Control System for AC

Induction Motor, “U.S.Patent 4 8, Oct 4,1977

[6] Alexander Kusko, Donald Galler,”Control

Means For Minimization of Losses in AC and

DC Motor Drives”, IEEE Trans. Ind. Appl., vol.

LA-19, No. 4, July/August 1983

[7] Iordanis Kioskeridis, Nikos Margaris, “Loss

Minimization in Induction Motor Adjustable-

Speed Drives”, IEEE Trans. Ind. Electron, vol.

43, No. 1, February 1996

[8] Iordanis Kioskeridis, Nikos Margaris, “Loss

Minimization in Scalar Controlled

Induction Motor Drives with Search Controllers,

“IEEE Trans. Ind.Electron, vol. 11, No. 2, March

1996

[9] K.M.Hasan, Li Zhang, B. Singh, “Neural

Network Control of Induction Motor Drives for

Energy Efficiency and High Dynamic

Performance”.

[10] D.M.Breathauer, R.L.Doughty and R.J.Puckett,

“The Impact of Efficiency on the Economics of

New Motor Purchases, Motor Repair, and Motor

Replacement, “IEEE Trans. Ind. Appl., vol. 30,

Nov./Dec. 1994, pp. 1525-1537.

[11] H.A.Al-Rashidi, A.Gastli, A.Al-Badi,

“Optimization of Variable Speed Induction Motor

Efficiency Using Artificial Neural Network”.

[12] Howard Demuth, Mark Beal, “Neural Network

Toolbox For Use With Matlab”, User Guide, The

Math Work Inc. June 1992

[13]

Dan W. Patterson, “Introduction to Artificial

Intelligence and Expert System”.

52

ISSN (Print) : 2319 – 2526, Volume-2, Issue-5, 2013