1.5.2 Co-composting facility siting considerations

advertisement

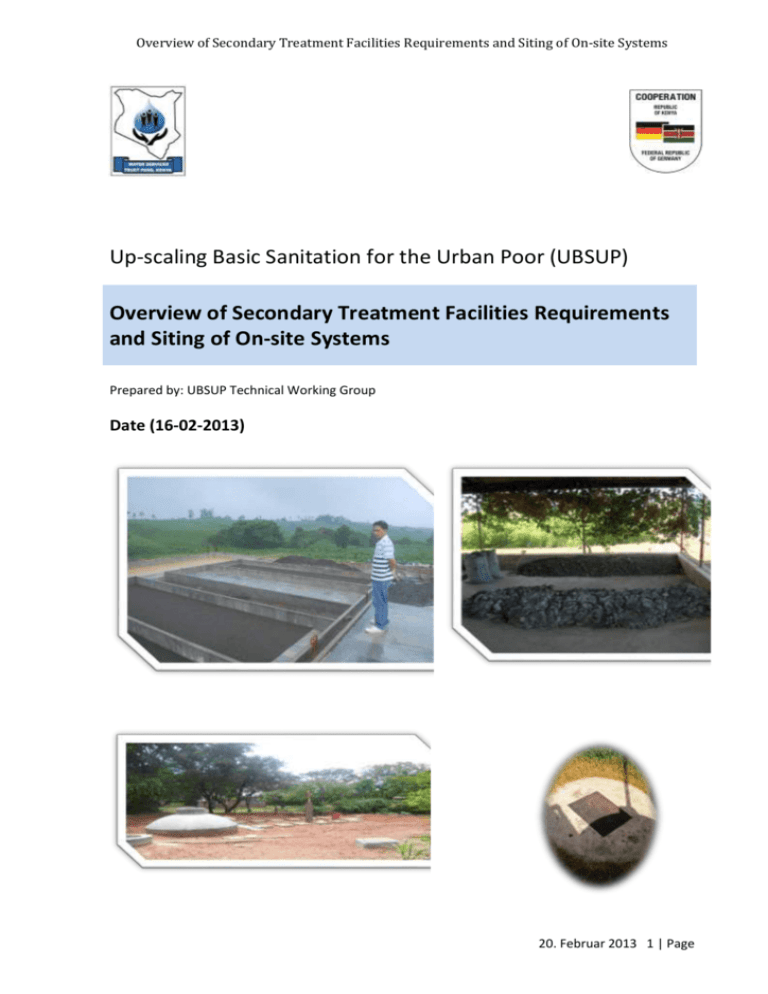

Overview of Secondary Treatment Facilities Requirements and Siting of On-site Systems Up-scaling Basic Sanitation for the Urban Poor (UBSUP) Overview of Secondary Treatment Facilities Requirements and Siting of On-site Systems Prepared by: UBSUP Technical Working Group Date (16-02-2013) 20. Februar 2013 1 | Page Overview of Secondary Treatment Facilities Requirements and Siting of On-site Systems Table of Content EXECUTIVE SUMMARY 4 1.1.1 What Is a Septic Tank? 1.1.2 Septic Tanks siting Considerations 1.2.0 SOAKAWAY 1.2.1 What Is a Soak away? 1.2.2 Soak-away siting considerations 1.3.0 CONSERVANCY TANK 1.3.1 What is a conservancy tank? 1.3.2 Conservancy tank siting considerations 1.4.0 Unplanted Drying Beds 1.4.1 What Is an Unplanted Drying Bed? 1.4.2 Unplanted Drying bed siting considerations 1.5.0 Co-composting Facility 1.5.1 What is co-composting? 1.5.2 Co-composting facility siting considerations 1.6.0 DEWATS 1.6.1 What Are DEWATS? 1.6.2 DEWATS siting considerations 1.7.0 SUMMARY OF CONSIDERATIONS IN SITING DIFFERENT SANITATION FACILITIES 1.8.0. References 6 7 7 7 8 8 8 9 9 9 11 11 11 13 13 13 14 15 17 20. Februar 2013 2 | Page Overview of Secondary Treatment Facilities Requirements and Siting of On-site Systems Acronyms and Abbreviations BoQ Bill of Quantities DEWATS Decentralised Waste Water Treatment EPP Ecosan Promotion Project FBO Faith Based Organizations GIZ Deutsche Gesellschaft für Internationale Zusammenarbeit GmbH IO International Organizations KARI Kenya Agricultural Research Institute KeBS Kenya Bureau of Standards MDGs Millennium Development Goals MoA Ministry of Agriculture MoF Ministry of Finance MPHS Ministry of Public Health and Sanitation MWI Ministry of Water and Irrigation NEMA National Environmental Management Authority NGO Nongovernmental organisation O&M Operation & Maintenance UBSUP Up-scaling of Basic Sanitation for the Urban Poor UDDT Urine diversion dehydrating toilet UDT Urine diverting dry toilet WASREB Water Services Regulatory Board WHO World Health Organisation WRMA Water Resource Management Authority WSP Water Services Providers WSTF Water Services Trust Fund 20. Februar 2013 3 | Page Overview of Secondary Treatment Facilities Requirements and Siting of On-site Systems EXECUTIVE SUMMARY This document describes the different technical options for secondary treatment with the specific objective of providing guidelines and criteria for siting the facilities. The secondary facilities that have been considered in this document are the facilities that have been identified to have potential of adoption by UBSUP. These facilities are: Septic tanks Soak away pits Conservancy tanks Co- composting beds DEWATS Proper siting of these facilities ensures protection against water sources contamination i.e. wells and streams. The safety and effectiveness of a well and streams depends greatly on its location in relation to sanitation facilities. It is important to maintain safe distances between private ground water wells and possible sources of contamination. The Possible sources of contamination and minimum distances from wells include: Septic Tanks and conservancy tanks, 50 feet from well Livestock yards, Silos, Septic Leach Fields (including soak away pits) , 50 feet from well Petroleum Tanks, Liquid-Tight Manure Storage and Fertilizer Storage and Handling (including drying and composting beds), 100 feet from well Manure Stacks, 250 feet from well Source:EPA Ground water can become unusable if it becomes polluted and is no longer safe to drink. Contaminated ground water can be the result of: Microbial contamination (fecal contamination from feedlots) High concentrations of naturally-occurring contaminants, such as arsenic and radon (depends highly on the geology of the land surrounding the well) Local land use practices (fertilizers and pesticides) 20. Februar 2013 4 | Page Overview of Secondary Treatment Facilities Requirements and Siting of On-site Systems Problems with the integrity of nearby on-site septic systems The diagram below gives a schematic illustration of the siting distances Source: Southern Idaho Public Health; 2012; www.siphidaho.org 20. Februar 2013 5 | Page Overview of Secondary Treatment Facilities Requirements and Siting of On-site Systems 1.1.0 SEPTIC TANKS 1.1.1 What Is a Septic Tank? A septic tank is basically a vessel buried underground, the purpose of which is the collection, storage, and, to some limited extent, treatment of sewage. On a simple hierarchy of sewerage facilities, the septic tank falls between the 'long-drop pit latrine', the function of which is to store and bury human waste, and a piped connection to an fully functioning sewage treatment works, the function of which is to convert human waste products into mostly harmless end products. A typical septic tank system normally operates by gravity, and consists of a tank and a soakaway drain. Untreated wastewater from a property flows into the septic tank, where the solids separate from the liquids. Some solids, such as soap scum or fat, will float to the top of the tank to form a scum layer. Heavier solids, such as human and kitchen wastes, settle to the bottom of the tank as sludge. Self forming bacteria in the tank help the system "digest" these solids or sludge where a natural process of anaerobic decomposition occurs in the tank which reduces the amount of solid matter and provides some treatment of the waste. The remaining liquids flow out of the tank to a percolate into the soil (soakaway) and eventually taken up through the root system of plants or added to the groundwater. Baffles built into the tank hold back the floating scum from moving past the outlet of the tank. But what you may not know is that an improperly sited, designed, installed or operated septic tank system can pollute drinking and surface water, and cause many problems, especially environmental. Because septic tank systems are underground, they are often ignored by people who own or use them. However because septic tank systems are generally out of sight they should not be out of mind. The effluent from a septic tank still contains about 70% of the polluted matter in the sewage, and hence there is a need for further treatment of the liquid from the tank. Septic tank care is crucial to maintain a healthy septic system. The septic tank is a passive system. There is nothing electrical or mechanical involved. Although the septic system is actually quite self-sufficient, there are things you can to help the system work efficiently. Microbes in your septic system will naturally break down the organic material that drains into 20. Februar 2013 6 | Page Overview of Secondary Treatment Facilities Requirements and Siting of On-site Systems your septic tank. The broken down material and water will naturally drain out of the septic tank and into the ground underneath it. Some solids cannot drain out of the septic tank. This is normal. Regular septic tank care requires you to pump out these solids every three to five years. The size of your septic tank, the amount of use, and the kind of products you stick in your drains will determine how often your septic tank will need to be pumped. 1.1.2 Septic Tanks siting Considerations Septic tank 50 feet from surface water Septic tank 50 feet from all well Septic tank 5 feet from foundation Septic tank and drain field to be 6 feet apart Avoid low lying areas Avoid areas where root may grow towards the septic tank 1.2.0 SOAKAWAY 1.2.1 What Is a Soak away? The soak away or percolation trench is an underground soil treatment system, which receives partially treated sewage from the septic tank. The soil on a site must be suitable for a soak away to work properly. It is noted here that the effluent from a septic tank is by no means fit (in terms of health) for discharge into a water course (e.g., a river, vlei1 or an aquifer) or onto the ground where it could be accessible to animals, humans included. 1 The word vlei is used predominantly in South Africa. It is an Afrikaans word derived from Dutch "vallei". In Afrikaans, however, its meaning changed into "shallow minor lake", mostly of a seasonal or intermittent nature. Wikipedia 20. Februar 2013 7 | Page Overview of Secondary Treatment Facilities Requirements and Siting of On-site Systems Not all sites are suitable for septic tank and soak-away systems. Of primary concern is the type and porosity of the soil at the site. Soils that are too coarse or too fine can limit the effectiveness of the treatment system. Also the depth of the seasonally high water table or bedrock can also cause problems. Some of these problems may possibly be overcome by altering the design of the septic system. It is good practice to carry out percolation tests on the ground soil to ascertain its suitability for a soak-away and generally you cannot improve an unsuitable site to the point where a soil treatment system will work In areas with high water table within a 600mm of the ground surface a soak-away may be typically installed close to the surface of the ground, but care must be exercised as it is possible that the polluted water may break through the ground surface. In other areas there may be clay ground present close to the ground level, and where this occurs then it is very unlikely that the use of a soak-away will prove satisfactory. The size of your septic tank soak-away is determined by the size of not only your septic tank but the size of your dwelling as well. You cannot simply construct a soak-away to the specifications that you wish. There are other considerations including where the soaka-way is built. It cannot be built near any open water such as a river or a vlei because of the possibility of seepage from the soil into the water. This would result in contamination of the water source which could lead to many problems including health concerns. 1.2.2 Soak-away siting considerations Soak-away pits to be sited 50 feet from all temporary surface water (ditches and canals) Soak-away to be 100,200, 0r 300 feet from surface water (stream, lakes, or rivers) depending on soil type They should be 100 feet from all wells Soak-away to 10 feet from foundations and 20 feet from basements They should be at least 5 feet from property lines Areas where vehicles may compact such as drive ways, parking and roads should be avoided Steep slopes should be avoided; slopes less than 20% are preferred. Avoid areas where tree may grow towards and impact on the soak-away Avoid low lying areas where there are runoffs or storm water drains or where water may pond temporarily. Avoid areas with high water tables. 1.3.0 CONSERVANCY TANK 1.3.1 What is a conservancy tank? A conservancy tank is any covered tank without an overflow which is used for the reception and temporary retention of sewerage and that requires routine emptying at intervals. 20. Februar 2013 8 | Page Overview of Secondary Treatment Facilities Requirements and Siting of On-site Systems 1.3.2 Conservancy tank siting considerations Conservancy 50 feet from surface water Conservancy tank 50 feet from all well Conservancy tank 5 feet from foundation Avoid low lying areas Avoid areas where root may grow towards the conservancy tank Every conservancy tank shall comply with the following requirements: Such tank shall be provided with a fresh air inlet and an intercepting trap, Such tank shall be constructed with 215mm brick or 150mm reinforced Concrete walls on a foundation slab of mass concrete not less than 150mm thick The tank shall be at ground level and shall be provided with one or more airtight manhole covers to allow access to the tank for cleaning it. The floor of the tank shall be graded to a point, which is vertically below one of the manholes referred to in paragraph (b) and a sump not less than 300mm or more than 450mm² in plan and not less than 150mm or more than 225mm deep shall be constructed at such point. Such tank shall be impervious to liquid. The owner of the property served by such tank shall provide and maintain at his own expense a suitable road or other means of access to enable the vehicle used by the WSP to empty such tank to reach and empty such tank. Such owner shall pay the local WSP for the clearance of such tank in accordance with such tariff as may from time to time be prescribed by the local WSP No industrial, trade or manufacturing waste, refuse or effluent shall be discharged into any conservancy tank. 1.4.0 Unplanted Drying Beds 1.4.1 What Is an Unplanted Drying Bed? An Unplanted Drying Bed is a simple, permeable bed that, when loaded with sludge, collects percolated leachate and allows the sludge to dry by evaporation. Approximately 50% to 80% of the sludge volume drains off as liquid. The sludge however, is not stabilized or treated. 20. Februar 2013 9 | Page Overview of Secondary Treatment Facilities Requirements and Siting of On-site Systems Feacal sludge drying beds (Source: Olufunke Cofie 2002) The bottom of the drying bed is lined with perforated pipes that drain away the leachate. On top of the pipes are layers of sand and gravel that support the sludge and allow the liquid to infiltrate and collect in the pipe. The sludge should be loaded to approximately 200kg TS/m2 and it should not be applied in layers that are too thick (maximum 20cm), or the sludge will not dry effectively. The final moisture content after 10 to 15 days of drying should be approximately 60%. A splash plate should be used to prevent erosion of the sand layer and to allow the even distribution of the sludge. When the sludge is dried, it must be separated from the sand layer and disposed of. The effluent that is collected in the drainage pipes must also be treated properly. The top sand layer should be 25 to 30cm thick as some sand will be lost each time the sludge is manually removed. 2 2 Source; Sandec/Eawag. 20. Februar 2013 10 | Page Overview of Secondary Treatment Facilities Requirements and Siting of On-site Systems Structural Principle of a drying bed 1.4.2 Unplanted Drying bed siting considerations In regions with frequent rainfall, covering the drying beds with a roof may be considered. Drying beds 100 feet from surface water Drying beds 100 feet from all well 1.5.0 Co-composting Facility 1.5.1 What is co-composting? Co-Composting is the controlled aerobic degradation of organics using more than one feedstock (Faecal sludge and Organic solid waste). Faecal sludge has a high moisture and nitrogen content while biodegradable solid waste is high in organic carbon and has good bulking properties (i.e. it allows air to flow and circulate). By combining the two, the benefits of each can be used to optimize the process and the product. 20. Februar 2013 11 | Page Overview of Secondary Treatment Facilities Requirements and Siting of On-site Systems 3 For dewatered sludges, a ratio of 1:2 to 1:3 of dewatered sludge to solid waste should be used. Liquid sludges should be used at a ratio of 1:5 to 1:10 of liquid sludge to solid waste. There are two types of Co-Composting designs: open and in-vessel. In open composting, themixedmaterial (sludge and solid waste) is piled into long heaps called windrows and left to decompose. Windrow piles are turned periodically to provide oxygen and ensure that all parts of the pile are subjected to the same heat treatment. Windrow piles should be at least 1m high, and should be insulated with compost or soil to promote an even distribution of heat inside the pile. Depending on the climate and available space, the facility may be covered to prevent excess evaporation and protection from rain. In-vessel composting requires controlled moisture and air supply, as well as mechanical mixing. Therefore, it is not generally appropriate for decentralized facilities. Although the composting process seems like a simple, passive technology, a well-working facility requires careful planning and design to avoid failure. 3Source; Sandec/Eawag. 20. Februar 2013 12 | Page Overview of Secondary Treatment Facilities Requirements and Siting of On-site Systems Co-composting facility (Open Windrow System) in Kumasi (Source IWMI, 2003) The effluent that is collected in the drainage pipes must also be treated properly. The top sand layer should be 25 to 30cm thick as some sand will be lost each time the sludge is manually removed. 1.5.2 Co-composting facility siting considerations In regions with frequent rainfall, covering the co-composting facility with a roof may be considered. Co-composting facility to be 100 feet from surface water Co-composting facility to be 100 feet from all well 1.6.0 DEWATS 1.6.1 What Are DEWATS? DEWATS stands for “Decentralized Wastewater Treatment Systems”. DEWATS represents a technical approach rather than merely a technology package. DEWATS applications are designed to be low-maintenance: most important parts of the system work without technical energy inputs and cannot be switched off intentionally. DEWATS applications provide state-of-the-art technology at affordable prices because all of the materials used for construction are locally available. DEWATS applications provide treatment for both domestic and industrial sources Systems can be designed to handle organic wastewater flows from 1-1000 m3 per day Systems are built to be reliable, long lasting and tolerant towards fluctuations in loads DEWATS applications do not require sophisticated maintenance Without considering facilities for necessary chemical pre-treatment of wastewater from industries, DEWATS applications are designed with four basic technical treatment modules which are combined and configured to provide a custom solution for a given sanitation/wastewater challenge: Primary treatment: sedimentation and floatation 20. Februar 2013 13 | Page Overview of Secondary Treatment Facilities Requirements and Siting of On-site Systems Secondary anaerobic treatment in fixed-bed reactors: baffled upstream reactors or anaerobic filters Tertiary aerobic treatment in sub-surface flow filters Tertiary aerobic treatment in polishing ponds DEWATS applications are designed and dimensioned in such a way that treated water meets requirements stipulated in environmental laws and regulations. Advantages of DEWATS technology: Provides treatment for domestic and industrial wastewater Low initial investment costs as no imported materials or components are needed Efficient treatment for daily wastewater flows of up to 1000m3 Modular design of all components Tolerant towards inflow fluctuations Reliable and long-lasting construction design Low maintenance costs Main DEWATS modules for physical and biological wastewater treatment: 1. Settler 2. Anaerobic Baffled Reactor 3. Anaerobic Filter 4. Planted Gravel Filter 1.6.2 DEWATS siting considerations The site size to dictate the layout of the site plan and DEWATS Modules. Establish the availability of an area to reuse or discharge the treated waste water . The soils MUST have the adequate depth and bearing capacity. The topography of the area should have adequate slopes to allow flow by gravity within and to the DEWATS. DEWATS should be sited above Groundwater, surface water and flood plain elevations Local Land use should allow the establishment of DEWATS. 20. Februar 2013 14 | Page Overview of Secondary Treatment Facilities Requirements and Siting of On-site Systems 1.7.0 SUMMARY OF CONSIDERATIONS IN SITING DIFFERENT SANITATION FACILITIES No 1 Facility Septic Tank Siting Consideration Septic tank 50 feet from surface water Septic tank 50 feet from all well Septic tank 5 feet from foundation Septic tank and drain field to be 6 feet apart Avoid low lying areas Avoid areas where root may grow towards the septic tank 2 Soak Away Pits Soak-away pits to be sited 50 feet from all temporary surface water (ditches and canals) Soak-away to be 100,200, 0r 300 feet from surface water (stream, lakes, or rivers) depending on soil type They should be 100 feet from all wells Soak-away to 10 feet from foundations and 20 feet from basements They should be at least 5 feet from property lines Areas where vehicles may compact such as drive ways, parking and roads should be avoided Steep slopes should be avoided; slopes less than 20% are preferred. Avoid areas where tree may grow towards and impact on the soak-away Avoid low lying areas where there are runoffs or storm water drains or where water may pond temporarily. Avoid areas with high water tables. 3 Conservancy Tanks Conservancy 50 feet from surface water Conservancy tank 50 feet from all well Conservancy tank 5 feet from foundation Avoid low lying areas Avoid areas where root may grow towards the conservancy tank Every conservancy tank shall comply with the following requirements: Such tank shall be provided with a fresh air inlet and an intercepting trap, Such tank shall be constructed with 215mm brick or 150mm reinforced Concrete walls on a foundation slab of mass concrete not less than 150mm thick The tank shall be at ground level and shall be provided with one or more airtight manhole 20. Februar 2013 15 | Page Overview of Secondary Treatment Facilities Requirements and Siting of On-site Systems No Facility Siting Consideration covers to allow access to the tank for cleaning it. The floor of the tank shall be graded to a point, which is vertically below one of the manholes referred to in paragraph (b) and a sump not less than 300mm or more than 450mm² in plan and not less than 150mm or more than 225mm deep shall be constructed at such point. Such tank shall be impervious to liquid. The owner of the property served by such tank shall provide and maintain at his own expense a suitable road or other means of access to enable the vehicle used by the WSP to empty such tank to reach and empty such tank. Such owner shall pay the local WSP for the clearance of such tank in accordance with such tariff as may from time to time be prescribed by the local WSP No industrial, trade or manufacturing waste, refuse or effluent shall be discharged into any conservancy tank. 4 Unplanted Drying Beds In regions with frequent rainfall, covering the drying beds with a roof may be considered. Drying beds 100 feet from surface water Drying beds 100 feet from all well 5 Co-Composting Facility In regions with frequent rainfall, covering the co-composting facility with a roof may be considered. Co-composting facility to be 100 feet from surface water Co-composting facility to be 100 feet from all well 6 DEWATS The site size to dictate the layout of the site plan and DEWATS Modules. Establish the availability of an area to reuse or discharge the treated waste water. The soils MUST have the adequate depth and bearing capacity. The topography of the area should have adequate slopes to allow flow by gravity within and to the DEWATS. DEWATS should be sited above Groundwater, surface water and flood plain elevations Local Land use should allow the establishment of DEWATS. 20. Februar 2013 16 | Page Overview of Secondary Treatment Facilities Requirements and Siting of On-site Systems 1.8.0. References 1. Olufunke, C., Doulaye, K., Silke Rothenberger, Daya Moserand Chris Zurbrügg (2009) Co Composting of Faecal Sludge and Organic Solid Waste for Agriculture: Process Dynamics. 2.BORDA;’Demand-based Technical Solutions to Reduce Water Pollution by Small and Medium Enterprices and Settlement in Densely Populated Areas 3. http://www.grassrootswiki.org/index.php/Co-composting 4. http://www.iwapublishing.com/template.cfm?name=isbn9781780404769_ 20. Februar 2013 17 | Page