Stevenson et al revised supplementary info 2

advertisement

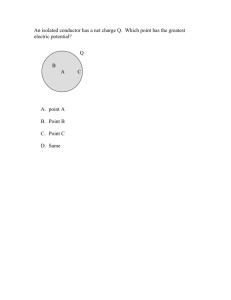

Fabrication of free-standing ordered fluorescent polymer nanofibres by electrospinning J.R.Y. Stevenson,1 S. Lattante,2 P. André,1,3 M. Anni2 and G. A. Turnbull1 1 Organic Semiconductor Centre, SUPA, School of Physics and Astronomy, University of St Andrews, St Andrews, KY16 9SS, UK Dipartimento di Matematica e Fisica “Ennio de Giorgi”, Università del Salento, Via 2 per Arnesano 73100, Lecce, Italy 3 RIKEN, Wako, Saitama 351-0198, Japan Supplementary Information The effect of solution concentration and electrospinning voltage on fibre thickness Nanofibres were deposited for solutions of concentrations 10% to 25% and the results are shown in table S1. No fibres were deposited for solutions of 5% and 30% concentrations; in these cases the solution viscosity was outside the range that would support a stable jet and only droplets were emitted from the tip. We found that an increase in both the applied voltage and in the solution concentration (from 10% to 25%), yields an increase in average fibre diameter from 290 ± 50 nm (10%, 17 kV) to 1200 ± 200 nm (25%, 26 kV). The 25% solution shows a large increase in the diameter compared to the other concentrations because this solution was much more viscous. Upon evaporation from an equivalent volume there will be a higher mass of material left behind and therefore a thicker fibre. In addition the viscosity increases with concentration, resulting in a reduced mobility of polymer chains to rearrange into thinner fibres.1, 2 Furthermore at the higher concentrations the solvent will evaporate off sooner, resulting in a more mechanically resistant jet. The increase in diameter with voltage has been seen in studies on other materials and was attributed to an increased draw of solution from the tip. 3 The 15% solution gave reasonably low fibre diameter (380 ± 70 nm at 20 kV) and was relatively insensitive to spinning conditions and so was subsequently selected for deposition with the parallel plate setup (results in tables S2, S3). Concentration 10% 15% 20% 25% Voltage (Kv) 17 20 26 17 20 26 17 20 26 17 20 26 Mean thickness (nm) Median thickness (nm) Standard deviation (nm) 290 - 390 - 380 430 400 460 - 830 510 1200 300 - 380 - 380 430 400 430 - 790 400 1200 50 - 90 - 70 90 50 130 - 190 120 200 Table S1. The measured thickness of random fibre samples. A dash indicates no fibres were obtained for those parameters. Separation 0.7 cm 1 cm 2 cm 4 cm Voltage (Kv) 17 20 26 17 20 26 17 20 26 17 20 26 Mean thickness (nm) Median thickness (nm) - 510 710 440 670 690 - 540 - - 680 - - 510 680 450 680 690 - 520 - - 660 - Standard deviation (nm) - 90 160 50 100 130 - 120 - - 120 - Table S2. Measured diameters of aligned fibres. A dash indicates no fibres were obtained for those parameters. Concentration 10% 15% 20% 25% Plate (cm) 0.7 separation 0.7 (suspended) 1.0 2.0 4.0 Voltage (kV) 17 20 26 17 20 26 17 20 26 17 20 26 Voltage (kV) Order parameter 0.004 0.007 0.054 0.019 0.051 0.011 0.063 0.030 0.058 Order parameter 17 20 26 20 17 20 26 17 20 26 17 20 26 0.33 0.35 0.56 0.09 0.28 0.28 0.23 0.12 - Table S3. The order parameter measured for each sample. A dash indicates no fibres were produced for that configuration. “0.7 (suspended)” refers to the order parameter of the suspended free-standing fibre sample. Aligned samples with lower order parameters were due to relatively poor quality and less dense samples being produced at the given electrospinning settings (1cm separation, 17kV and 4cm separation). Calculated transverse field distributions for the experimental configuration in fig. 1(b) Figure S1. (i) to (v): x-component of electric field in a series of horizontal (x-y) planes at heights 5, 45, 85, 125, 165 mm below the needle tip (tip to collector plate separation is 170 mm). (vi) The ycomponent of the electric field for the plane 165 mm below the tip. The square seen in each image is a representation of the 10 cm x 10 cm top plate. Electric field in units of V/m with positive field directed in the positive x or y directions. Full set of plate modelling images FIG. S2. (a), (b), (c), (d) x-component (horizontal) of the electric field in the x-z plane, around the parallel collection plates (shown in outline) for plate separations of (a) 0.7 cm, (b) 1 cm, (c) 2 cm and (d) 4 cm. FIG. S3. (a), (b), (c), (d) z-component (vertical) of the electric field in the x-z plane, around the parallel collection plates (shown in outline) for plate separations of (a) 0.7 cm, (b) 1 cm, (c) 2 cm and (d) 4 cm. Emissive properties of the nanofibres FIG. S4. (a) Fluorescence image taken of the ordered fibres excited at 540 nm, (b) photoluminescence excitation (PLE) and photoluminescence spectra for suspended fibres and rhodamine B in toluene solution. PLE was recorded at an emission wavelength of 650 nm, and emission scans for an excitation wavelength of 520 nm. References 1. B. Cramariuc, R. Cramariuc, R. Scarlet, L. R. Manea, I. G. Lupu and O. Cramariuc, J Electrostat. 71, 189 (2013). 2. J. F. Zheng, A. H. He, J. X. Li, J. A. Xu and C. C. Han, Polymer 47, 7095 (2006). 3. P. Heikkilä and A. Harlin, Eur. Polym. J. 44, 3067 (2008).