IMT 362 Metrology and Measurement System

advertisement

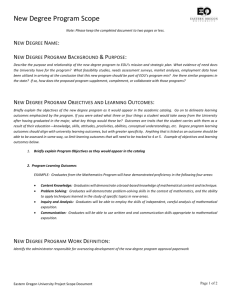

Department of Industrial & Manufacturing Engineering & Technology 1. Course Title: IMT 362 Metrology and Measurement System 3 Semester Hours 2. Description: Precision measurement and its relationship to Geometric dimensioning and tolerances (GD&T) and calibrations. Conduct Measurement Systems Analysis (MSA) for appropriate process measures. Statistical process control and quality assurance using automated gauges. Use of machine vision, Coordinate Measurement Machine, Robotic measurement arm, non-contact measuring systems. 3. Prerequisites: IMT341 (Intro. Mfg. Processes) and co-requisite IME 302 or IMT 262 or equivalent, or contents of instructor 4. Textbook: References: None 5. Course Objectives: Contributes to Student Outcomes Item Description EAC MFE A. To gain understanding of the fundamental precision measurement and its relationship to b, e, g, h, k Geometric dimensioning and tolerances (GD&T) and calibrations. B. To develop the ability to conduct Measurement Systems Analysis (MSA) for appropriate a, b, c, g, e, k process measures. C. To have a basic understanding how the measurement system performance impacts the b, c, e, g, h, i, k process capability which eventually impacts quality of the product D. To gain hands-on manufacturing laboratory experiences with Coordinate Measurement c, e, g, k Machine, Robotic measurement arm, or computer aided statistical process controller tools. 6. Topics: 1. Contributes to Course Objectives (5.) LECTURES Objectives Metrology overview ABC Blueprint/Interpreting views/lines/detail & assembly prints A Special view/Dimensioning/Dimensioning machined & Fab details A Statistics and metrology/Process capability study BC Gage Repeatability and Reproducibility BC Precision measuring tools – Micrometers/Verniers; Dial indicators/Gage blocks/fixed ACD gages; CMM/Faro Arm Surface metrology, surface roughness standards and measurement AC Geometric Dimensioning & Tolerancing AC Overview of DMAIC AC Lab projects Mobile gage and SPC lab (1) Mobile gage and SPC lab (2) Mobile gage and SPC lab (3) CMM fundamental measurement CMM complex dimension measurement Gage Repeatability and Reproducibility FARO Arm touch probe fundamental measurement FARO Arm touch probe Macro generation and measurement FARO Arm laser sensor Reverse Engineering 7. Class Schedule: Two 75 minutes classes per week Objectives D D D D D BD D D D 8. Contribution of Course to Meeting the Professional Component: Communications Mathematics Physical and Natural Science Social Science and Humanities Technical Content 0.5 hrs 0.0 hrs 0.0 hrs 0.0 hrs 2.5 hrs 9. Relationship of Course to MFE Student Outcomes: (based on 1 to 5 scales, 5 denotes very strong continuation to the student outcome and blank cell denotes that the course does not continue the related student outcome) Code A B c D E F G H I J K Student Outcomes, A Graduate from the Program Will Have: Manufacturing Engineering graduates will have an ability to apply knowledge of mathematics and science to manufacturing processes, materials, and design of manufacturing systems Manufacturing Engineering graduates will have an ability to design and conduct experiments, and to analyze and interpret data related to manufacturing processes, materials evaluation, and manufacturing systems Manufacturing Engineering graduates will have an ability to design, select, implement, and control a manufacturing system and its components or processes to meet desired needs Manufacturing Engineering graduates will have an ability to function on multi-disciplinary teams and the ability to apply a concurrent approach and project management to process and product development Manufacturing Engineering graduates will have an ability to identify, formulate, and solve manufacturing engineering problems through a hands-on approach that considers constraints, costs, benefits, and comparative processes and materials Manufacturing Engineering graduates will have an understanding of the professional and ethical responsibilities of a manufacturing engineer Manufacturing Engineering graduates will have an ability to effectively communicate technical concepts through appropriate methods Manufacturing Engineering graduates will have an understanding of the impact of manufacturing engineering solutions in a global, economic, environmental, and societal context Manufacturing Engineering graduates will have a recognition of the need to engage in lifelong learning Manufacturing Engineering graduates will have a knowledge of contemporary issues facing manufacturing engineers Manufacturing Engineering graduates will have an ability to use the proper techniques, skills, and modern engineering tools necessary for manufacturing engineering practice utilizing supporting technologies 10. Prepared by: Ye Li 11-20-2013 Reviewed By: Curriculum Committee Contribution 1.0 4.14 1.25 — 0.6 — 2.0 1.75 1.67 — 1.25