Laboratory Work № 2 “Engineering Materials/Classification

advertisement

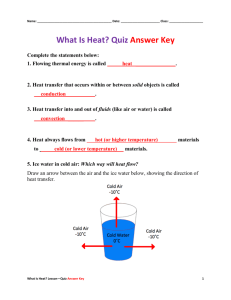

Laboratory Work № 2 “Engineering Materials/Classification/Properties/Use/Advanced Materials” WATCHING Task 1 Watch an episode about Glass Block manufacturing and match the beginnings with their endings. 1. 2. 3. 4. 5. Glass blocks are Glass blocks Production begins with A blast of ambient air Entering the machine each peace passes over series of burners 6. In the squeeze station 7. Every block 8. Glass blocks come a. in many shapes, sizes and patterns. b. an automated press forces the top head and bottom head together. c. must meet precise standards for both size and shape. d. popular for creating walls, windows and stunning design features. e. four ingredients – recycled glass pieces, sand, soda ash and limestone. f. insulate from heat, cold and noise. g. that keep the glass temperature constant. h. cools down the molting glass drastically. USE OF ENGLISH Task 2 Choose the correct word from the brackets. 1. A strong hard building material composed of sand, gravel, cement and water. (concrete/ceramics/clay). 2. A rectangular block of clay baked by the sun or in a kiln; used as a building or paving material. (glass/polymer/brick). 3. A waterproofing agent applied to roofing materials during manufacture. Based on natural oil or a petroleum component called bitumen, which liquefies when heated and is impervious to water. (biomaterial/composite/asphalt). 4. A smooth, hard and brittle transparent material. (glass/fiberglass/silicon). 5. Rocks from which metals can be extracted. (iron/ore/steel). 6. A type of steel not needing a protective coating as it doesn’t rust. (zinc/lead/stainless steel). Task 3 Complete the abstract with the words given in the table. industries distribution computers production steelmaking raw material ore substances cotton transported Compiler: Lanberg E. S. 1 Laboratory Work № 2 “Engineering Materials/Classification/Properties/Use/Advanced Materials” Materials are (1) … which are used to make different products with different properties used as inputs to (2) … or manufacturing or simply to create something new. Basically materials are the pieces required to make something else, from buildings and art to stars and (3) … . A material can be anything: a finished product in its own right or an unprocessed (4) … . Raw materials are first extracted or harvested from the earth and divided into a form that can be easily (5) … and stored, then processed to produce semifinished materials. These can be input into a new cycle of production and finishing processes to create finished materials, ready for (6) …, construction and consumption. An example of a raw material is (7) …, which is harvested from plants, and can then be processed into thread (also considered as a raw material), which can then be woven into cloth, a semifinished material. Cutting and sewing the fabric turns it into a garment, which is the finished material. (8) … is another example – raw materials in the form of (9) … are mined, refined and processed into steel, the semifinished material. Steel is then used as an input in many other (10) … to make finished products. Task 4 Use the word given in capitals at the end of each line to form a word that fits in the space in the same line. Solid materials can be grouped into three basic classifications: metals, ceramics and polymers. This classification is based primarily on chemical makeup and atomic as well as (1) … structure. More engineering components are made of metals and alloys than of any other class of solid. But increasingly, polymers are (2) … metals, because they offer a combination of (3) … more attractive to designers. The best properties of materials can be combined to make composites which often combine two or more materials from these three basic classes. In hightechnology (4) … , a new classification called advanced or smart materials emerges. These materials are semiconductors, biocompatible materials, and nano-engineered materials. Natural materials like wood or leather should also be mentioned, since they offer properties that, even with the (5) … of today’s materials scientists, are hard to beat. MOLECULE REPLACE PROPER APPLY INNOVATIVE Task 5 Read the text. Look carefully at each line. Some of he lines are correct, and some have a word which should not be there. If a line correct put a tick (√) by the number. If a line has a word which should not be there, write the word beside it. Carbon nanotubes Compiler: Lanberg E. S. 2 Laboratory Work № 2 “Engineering Materials/Classification/Properties/Use/Advanced Materials” (1)__________ The structure of a nanotube consists from of a single sheet of graphite, one (2)__________ atom in thickness which is rolled into a tube. At least one end of the tube is (3) __________ capped with a fullerene hemisphere. The each nanotube is a single (4) __________ molecule is composed of millions of atoms. The length of the molecule is (5) __________ thousands of times greater than its in diameter. Nanotubes are extremely (6) __________ strong than and stiff and relatively ductile. For single-walled nanotubes, (7) __________ tensile strengths range between 50 and 200 GPa, which is the strongest (8) __________ known material so far yet. Nanotubes have unique electrical properties and (9) __________ are efficient conductors of heat. Because of their unique one properties, (10) _________ nanotubes are more extremely useful as reinforcement in composite (11) _________ materials and will be the applicable in many ways in nanotechnology, electronics, optics and other fields of materials science. READING Task 6 Read the text. Complete the table with the advantages and disadvantages of the materials mentioned int the text. When I choose a material for a bike frame, I have to think about the properties of the material. How elasticis it? If you bend or stretch it, will it go back to itsoriginal shape? If it does, it has high elasticity. How strong is it? There are two kinds of strength. The first is how much force you need to bend it to a point where it can’t go back to its original shape. The second is the amount of force you need to break it. Steel is the least expensive choice. There's a wide range of standard gauge tubes available. It's strong and it has good elasticity but it's heavy. Aluminium is light and strong but it’s flexible. The more it bends, the quicker it breaks. So aluminium bike frames use large diameter tubes. That limits the amount of bending. Titanium has a great strength-to-weight ratio. It’s got good elasticity so when it bends it tends to return to its original shape. It's corrosÍon.resistant so you don’t need to paint it. But it’s expensive – fifteen times the price of steel! The professionals use carbon fibre. It's very light and it’s very strong. You can shape it any way you like. But carbon-fibre frames are hand-made so they’re very expensive. Material Steel Aluminium Titanium Carbon fibre Advantages (1) ..., (2) …, (3) … (5) …, (6) … (8) … (10) …, (11) …, (12) … Disadvantages (4) … (7) … (9) … (13) … Task 7 Read the text. Six sentences have been removed from it. Choose from the sentences A-H, the one which fits each gap (1-6). There is one extra sentence. Compiler: Lanberg E. S. 3 Laboratory Work № 2 “Engineering Materials/Classification/Properties/Use/Advanced Materials” GLASS For centuries, glass has served as a universal packaging container, holding precious commodities like wine and olive oil. Today, manufacturers use glass to hold everything from soda and peanut butter to champagne and perfume. (1) … The glass in many items, from your soda bottle to your computer, can be recycled over and over while retaining its strength. Just the Facts 1. Americans generated 12.2 million tons of glass in the municipal solid waste (MSW) stream in 2009. 2. About 23 percent of the glass was recovered for recycling. 3. Recovery increased from 750,000 tons in 1980 to more than 2.8 million tons in 2009. 4. Soft drink, beer, food, wine, and liquor containers represent the largest source of glass generated and recovered for recycling. 5. Glass in durable goods, such as furniture, appliances, and especially consumer electronics, round out the sources of postconsumer glass. The glass containing your soda today might be the glass containing your spaghetti sauce tomorrow. That's because glass, especially glass food and beverage containers, can be recycled over and over again. In fact, 90 percent of recycled glass is used to make new containers. (2) ... Glass makers have always known the material's recyclability, but glass recycling has grown considerably in recent years. This growth is due to both increased collection through curbside recycling programs and glass manufacturers' increased demand for recycled glass. Today, most glass manufacturers rely on a steady supply of recycled crushed glass, known as "cullet," to supplement raw materials. (3) … Sand is the only material used in greater volumes than cullet to manufacture glass. Using cullet saves money and helps the environment, because: 1. Cullet costs less than raw materials. 2. Cullet prolongs furnace life since it melts at a lower temperature. 3. Cullet demands less energy from power sources like electricity, natural gas, and coal. 4. Less energy used means reduced emissions of nitrogen oxide and carbon dioxide, both greenhouse gases. Collection and Processing Although all glass is made of silica and soda, the type and quantity vary slightly with different types of glass. These differences frequently cause manufacturing problems due to different melting points and chemical incompatibility. (4) ... Glass separated by color, whether this takes place at the curbside or drop-off facility or at a materials recovery facility, yield glass cullet of higher economic value. Sorting also can help reduce common contaminants, such as ceramic cups, plates and pottery, clay garden pots, crystal and opaque drinking glasses, heat-resistant ovenware, lead collars from wine and champagne bottles, stones and dirt, light bulbs, metal caps, lids and neck rings, and mirrors. (5) … Compiler: Lanberg E. S. 4 Laboratory Work № 2 “Engineering Materials/Classification/Properties/Use/Advanced Materials” In the materials recovery facility, workers remove large contaminants by hand and sort the glass by color where possible. (6) ... Magnets pull out metal, and air currents remove lightweight material such as paper. Some cullet suppliers use sophisticated equipment such as lasers to sort colors of crushed glass and further remove small contaminants. Scientists continue to develop mechanisms to improve materials sorting, and, therefore, the quality of the cullet. A. In addition, since neither brown nor amber glass is used to manufacture clear glass, it is important to sort glass by color. B. Then, glass is typically crushed and travels by conveyor belt through a series of refinements. C. Finally, sorting can keep broken glass from contaminating other recyclables, like newspapers. D. To make glass, manufacturers mix sand, soda ash, limestone, and cullet; heat the mixture to a temperature of 2,600 to 2,800 degrees F; and mold it into the desired shape. E. Other uses for recycled glass include kitchen tiles, counter tops, and wall insulation F. Glass manufacturers and consumers continue to appreciate glass for its aesthetic value but also recognize its practicality. G. Glass container manufacturers need a steady supply of quality cullet to make glass containers. Compiler: Lanberg E. S. 5