Hazardous Materials: Recognizing and Identifying the Hazards

advertisement

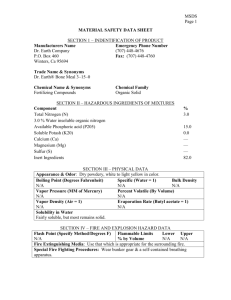

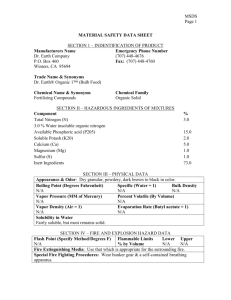

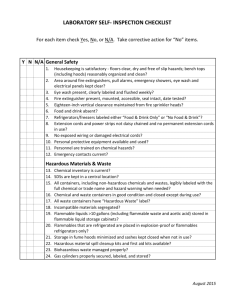

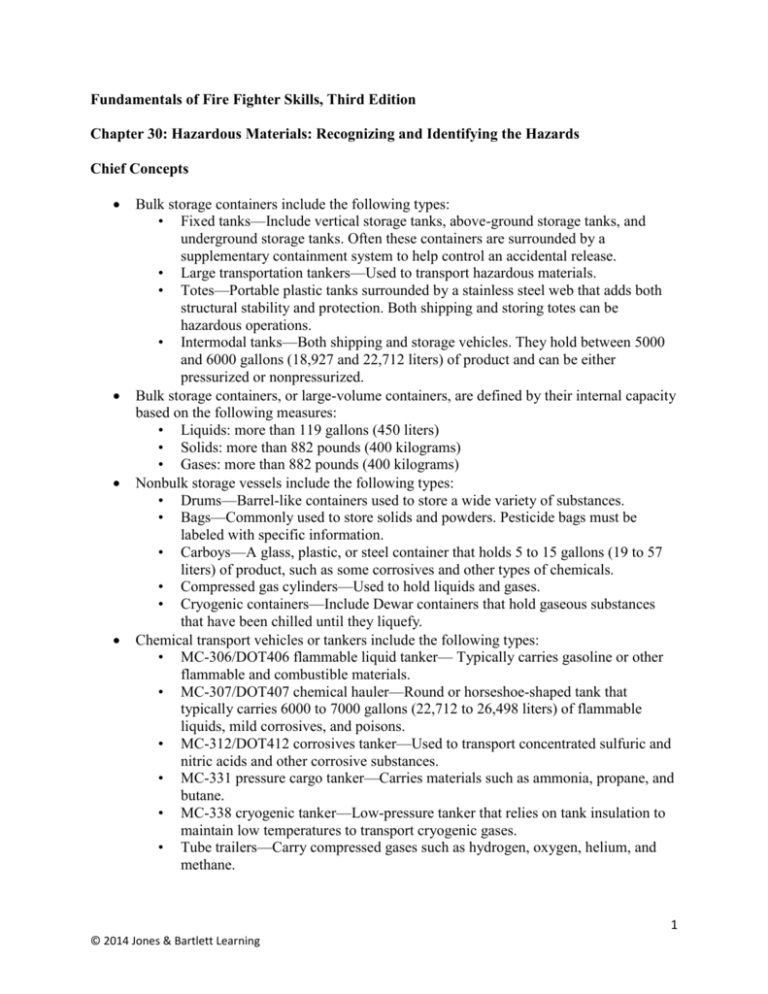

Fundamentals of Fire Fighter Skills, Third Edition Chapter 30: Hazardous Materials: Recognizing and Identifying the Hazards Chief Concepts Bulk storage containers include the following types: • Fixed tanks—Include vertical storage tanks, above-ground storage tanks, and underground storage tanks. Often these containers are surrounded by a supplementary containment system to help control an accidental release. • Large transportation tankers—Used to transport hazardous materials. • Totes—Portable plastic tanks surrounded by a stainless steel web that adds both structural stability and protection. Both shipping and storing totes can be hazardous operations. • Intermodal tanks—Both shipping and storage vehicles. They hold between 5000 and 6000 gallons (18,927 and 22,712 liters) of product and can be either pressurized or nonpressurized. Bulk storage containers, or large-volume containers, are defined by their internal capacity based on the following measures: • Liquids: more than 119 gallons (450 liters) • Solids: more than 882 pounds (400 kilograms) • Gases: more than 882 pounds (400 kilograms) Nonbulk storage vessels include the following types: • Drums—Barrel-like containers used to store a wide variety of substances. • Bags—Commonly used to store solids and powders. Pesticide bags must be labeled with specific information. • Carboys—A glass, plastic, or steel container that holds 5 to 15 gallons (19 to 57 liters) of product, such as some corrosives and other types of chemicals. • Compressed gas cylinders—Used to hold liquids and gases. • Cryogenic containers—Include Dewar containers that hold gaseous substances that have been chilled until they liquefy. Chemical transport vehicles or tankers include the following types: • MC-306/DOT406 flammable liquid tanker— Typically carries gasoline or other flammable and combustible materials. • MC-307/DOT407 chemical hauler—Round or horseshoe-shaped tank that typically carries 6000 to 7000 gallons (22,712 to 26,498 liters) of flammable liquids, mild corrosives, and poisons. • MC-312/DOT412 corrosives tanker—Used to transport concentrated sulfuric and nitric acids and other corrosive substances. • MC-331 pressure cargo tanker—Carries materials such as ammonia, propane, and butane. • MC-338 cryogenic tanker—Low-pressure tanker that relies on tank insulation to maintain low temperatures to transport cryogenic gases. • Tube trailers—Carry compressed gases such as hydrogen, oxygen, helium, and methane. 1 © 2014 Jones & Bartlett Learning • Dry bulk cargo tanks—Commonly seen on the road and carry dry bulk goods such as powders, pellets, fertilizers, and grain. Railway tank cars can carry volumes up to 30,000 gallons (113,562 liters) and have the potential to create large leaks or vapor clouds. There are three basic railcar configurations: • DOT 111 nonpressurized railcars—Carry general industrial chemicals, consumer products, flammable and combustible liquids, and mild corrosives. • DOT 105, DOT 112 pressurized railcars—Transport materials such as propane, ammonia, ethylene oxide, and chlorine. • Special-use railcars—Include boxcars, flat cars, corrosive tank cars, and highpressure compressed gas tube cars. Pipelines often transport hazardous materials. They may be located either underground or above ground. The DOT marking system is characterized by a system of labels and placards. The DOT’s ERG is also part of this system and offers a certain amount of guidance for fire fighters operating at a hazardous materials incident. Labels, placards, and other markings on buildings, packages, boxes, and containers often enable fire fighters to identify a spilled or released chemical. Placards are diamond-shaped indicators (10¾ inches [27.3 centimeters] on each side) that must be placed on all four sides of highway transport vehicles, railroad tank cars, and other forms of transportation carrying hazardous materials. Labels are smaller versions of placards (4-inch [10 centimeters] diamond-shaped indicators) and are used on the four sides of individual boxes and smaller packages being transported. Nine DOT chemical families are recognized in the ERG: • DOT Class 1: Explosives • DOT Class 2: Gases • DOT Class 3: Flammable combustible liquids • DOT Class 4: Flammable solids • DOT Class 5: Oxidizers • DOT Class 6: Poisons (including blood agents and choking agents) • DOT Class 7: Radioactive materials • DOT Class 8: Corrosives • DOT Class 9: Other regulated materials The ERG is a preliminary action guide for hazardous materials incidents. It is divided into four colored sections: • Yellow section—Used when the UN number is known or can be identified. • Blue section—Lists chemicals alphabetically by name. • Orange section—Contains the emergency action guides. • Green section—Organized numerically by UN identification number and provides the initial isolation distances for specific materials. The NFPA hazard identification system is designed for fixed-facility use. The NFPA 704 hazard identification system uses a diamond-shaped symbol of any size, which is itself broken into four smaller diamonds, each representing a particular property or characteristic. The blue diamond at the nine o’clock position indicates the health hazard posed by the material; the top red diamond indicates flammability; the yellow diamond at 2 © 2014 Jones & Bartlett Learning the three o’clock position indicates reactivity; and the bottom white diamond is used for special symbols and handling instructions. Additional reference sources for hazardous materials include material safety data sheets (MSDS), shipping papers, and staffed national resources such as CHEMTREC and the National Response Center. The MSDS provides basic information about the chemical makeup of a substance, the potential hazards it presents, appropriate first aid in the event of an exposure, and other pertinent data for safe handling of the material. MSDSs may be kept in a three-ring binder or a file cabinet, or a computer system. Industries that routinely use radioactive materials include food testing labs, hospitals, medical research centers, biotechnology facilities, construction sites, and medical laboratories. Radioactive materials are not detected by sight, smell, taste, or other senses. If you have any suspicion that the incident involves radiation, it will be necessary to call a hazardous materials team or some other resource with radiation detection capabilities. 3 © 2014 Jones & Bartlett Learning