Sarment - JMS International Trading

Sarment

Address: 12 Caffrey Crescent, Port Willunga, South

Australia 5173

Phone: +61 8 85566550 m. 0419810208

Email: h2oasisenergy@live.com.au

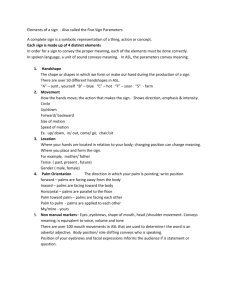

Palm Oil … Reflections on Opportunities.

For the past 4 years I have been focused on developing Solar Distillation and enveloping this technology into sustainable agriculture systems. I was asked to also have a look at Palm Oil and

Mangoes by a business associate who dealt with Malaysian clients.

In the following pages I express and condense my views to explain ways to improve the processing and recover a greater quantity of biofuel from the Full Fruiting Bodies (FFB) as well as ways to make use of every part of the tree (Leaf Fronds, Palm Oil Trunks, Palm Hearts and

Roots). The detailing of all these processes can come latter and I am confident that with the cooperation of Wilmar International a very precise set of reports will be produced.

What follows challenges the existing practices but also corrects the problems of the past – replacing deforestation with reforestation – and gaining credibility with the public.

Sarment – Palm Oil – Imperata – Rubber - Biofuels

Whole Bunch Processing

Enter the world of Sarment which has recently been introduced to unique technology

– Flash

Détente and Counter Current Extraction.

There are now over 70 Flash Détente units around the globe, which includes Bordeaux. The Counter Current Extraction is more an Australian speciality and I was involved in its development on recovering extra beverage wine from pressed grape skins.

Processing the entire Palm Oil Full Fruiting Body will yield more oil and convert all cellulose to

RTP Green Fuel and Biochar and recover other valuable commodities (lignin and glycerine) in the conversion to Biodiesel. The process is clean with no solid wastes and will even recover potable water from the Palm Oil FFB . After the initial start-up the process will be selfsustaining in electricity and heating.

2 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

By processing whole Palm Oil FFB there is an immediate gain in Oil production of 1.6 % . This is due to the oil content in the Empty Fruiting Bodies. In traditional processing the Palm Oil

Fruitlets are processed and the EFB is discarded.

The inclusion of the EFB will also add to the RTP Green Fuel and/or Paper Pulp as it simply adds to the biomass.

3 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

The Whole Bunch Processing will also contribute to a major reduction of POME.

Currently a palm oil mill produces an average of 0.65 tonne of raw palm oil mill effluent

(POME) from every ton of FFB processed.

Oil and grease contents in the fresh raw POME has been recorded at 2861 mg / L.

This is equivalent to 1.86 kg of oil and grease per tonne of FFB processed. All this will be recovered using Counter Current Exchange.

Mesocarp Fibre

Palm Fruit is pressed for oil extraction, with Mesocarp Fibre and Palm Kernel Nut as left over biomass.

The Mesocarp Fibre is then separated from Palm Kernel Nut by cyclone separator.

Mesocarp fibre is an elongated cellulose with 30-50mm length which constitute 15.7% of

FFB.

Mesocarp fibre contain less than

6%

oil residue and calorific value at 19000kJ/kg. It also contain of 2.2% Nitrogen.

180kg of Mesocarp Fibre is generated per 1000 kg of FFB.

Sarment will recover this oil - another increase in yield of 10.8 kg. I have read that this oil is of a higher quality than CPO.

Palm Kernel Meal

Kernel press cake can, after extraction of oil from the kernels, be used as livestock feed. It is rich in carbohydrate (48%), protein (19%) and oil (5-8%). The feed analysis for PKM supplied to

New Zealand indicates an oil content of 8%.

It is a highly fibrous and medium grade protein feed, hence most suited to ruminant or rabbit feeding ( Pickard, 2005 ). Palm kernel resulting from mechanical extraction contains 5-12% oil and solvent-extracted palm kernel meal contains 0.5-3% oil ( Chin, 2001 ). Most of the palm kernel meal production goes to animal feeding ( FAO, 2012 ).

My estimate of PKM is 80 kg per 1000kg FFB. This is deducted from 73kg of Shells plus 67 kg of Kernels minus 60 kg of PKO.

In the Sarment process the PKM component will contribute a minimum of 8% and therefore the recovery of this oil would add another 6.4 kg.

4 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

The result of WHOLE FFB processing…..

Source

CPO

EFB

POME reduction

PKO

PKM

Traditional

225kg

-

-

60kg

-

Sarment

225kg

10.8kg

1.8kg

60kg

6.4kg

TOTAL 285kg 304kg

This is an increase of 19kg of oil or a 6.7% increase in production.

5 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

Sime Darby report a CPO extraction rate of 21.86% and PKO at

4.96% from 10,523,534 MT of FFB processed in FY2013/14.

http://www.simedarby.com/Operational_Statistics.aspx

These extraction rates are somewhat lower than my calculations. My data is a ‘best fit’ from internet sources. I am dependent on the internet, as I do not have access to research and industry databases. Wilmar International can easily access data to make amendments.

An explanation of the lower yields may be that they represent the amount of oil after processing.

In the refining of palm oil, bleaching clay dosages of 0.5 -1% are generally used.

From, Malaysia alone, with a production of 9 million tons of oil in 1999, a total of

70,000 tons of spent bleaching clay is estimated to be generated yearly.

Spent bleaching clay contains about 30 - 40% of oil by weight of spent bleaching clay and this constitutes a major loss in oil as well a major cost from the clay since the spent clay is currently disposed untreated. In addition, the use and disposal of the spent bleaching clay is becoming a potential problem in the producing countries because of the rapid growth of the industry and currently, oil - laden spent bleaching clays are mainly disposed of in landfills or in waste dumps, as the spent clays are considered nontoxic.

This leads to the thought that oil is lost during processing. The Counter Current Exchange process will extract oil and other valuable commodities. There are developments which will easily be installed into the Sarment process and will improve oil processing. E.g. Supercritical

Fluid Extraction (SFE).

The present study shows that the extraction of palm oil by using SC-CO

2

can potentially replace the conventional screw-press extraction, clarification and

vacuum drying processes. Notably the palm oil produced by SC-CO

2

meets all the specifications of CPO for commercial trading. http://www.researchgate.net/profile/Cheng_Hock_Chuah/publication/227760030_CHARACTERIZATION_AND_SUPERCRITICAL_CARBO

N_DIOXIDE_EXTRACTION_OF_PALM_OIL_%28ELAEIS_GUINEENSIS%29/links/00b7d515256c643e4d000000.pdf

6 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

Biodiesel

The process for converting the Crude Palm Oil and Palm Kernel Oil through to biodiesel is very similar and therefore there should be no problem in using blended oil. An alkali catalyst is added

– followed by transestrication with ethanol – produces yields of 93.6% (CPO) and 95.8%

(PKO).

I have read the following reference and I am confident that Wilmar International well understand the economics of biodiesel. https://books.google.com.au/books?id=jgrFBAAAQBAJ&pg=PA198&lpg=PA198&dq=kg+cpo+per+litre+biodiesel&source=bl&ots=Uqa8NPnp

9U&sig=xTqLQRIhzVoq9Ni0bLvhrFcGa8c&hl=en&sa=X&ved=0CFAQ6AEwB2oVChMI3r7V9buTxgIVlYG8Ch1C_QDl#v=onepage&q=kg

%20cpo%20per%20litre%20biodiesel&f=false

The opportunity to incorporate the latest technology developing from around the world e.g.…

The Hong Kong Polytechnic University

Catalyst for Green Biodiesel Production from Unrefined Feedstock

A durable catalyst developed for green biodiesel production from low grade feedstock through one-step catalysis http://www.polyu.edu.hk/ife/corp/cntimgs/techsearch/2_ABCT_02_0315.pdf

The Sarment process yields more oil and that ultimately lowers the cost of production. Additionally, as a low pollution process and the parallel production of RTP Green Fuel the next generation mill should also benefit from carbon trading.

7 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

Empty Fruiting Body

By incorporating EFB in the processing we solve another problem (mulching) and after the RTP processing we will be able to return Biochar to the plantations

“The utilization of EFB for mulching (30 to 80 t/ha), unfortunately, also has some disadvantages. High transportation and distribution costs, long degradation time (up to one year), water pollution by the rest oil (about 1.25 %) and its attractiveness for beetles and snakes have been a number of downsides that hardly are solved” http://cdm.unfccc.int/filestorage/9/C/W/9CWFUYV8XQ03PRB4D2OAGNTLM7K1ZI/Enclosure%201.pdf?t=QVZ8bHljNGszfDBTOSFEePXamppM9QQ9_r9M

Producing biochar from oil palm biomass can potentially lead to a healthier environmental, societal and economic growth for the oil palm industry speci fi cally, and enhances sustainability in worldwide context. http://www.researchgate.net/profile/Robert_Bachmann2/publication/270831179_Biochar_from_oil_palm_biomass_A_review_of_its_potential_a nd_challenges/links/54d1efc00cf25ba0f0421624.pdf

After oil extraction and recovery of other valuable products (e.g. glycerine) the RESIDUAL BIOMASS and processing SOLIDS (e.g. filter cake) can be processed by RTP

This consolidates the Sarment Whole Bunch Processing by producing additional Biofuel.

8 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

Convert all waste products to RTP Green

Fuel.

In less than two seconds, Rapid Thermal Processing (RTP™) technology converts biomass into a liquid asset.

This RTP technology is a fast thermal process in which biomass, usually forest residuals or agricultural by-products, is rapidly heated to approximately 500°C in the absence of oxygen. A circulating transported fluidized bed reactor system similar to the one used in the UOP Fluid

Catalytic Cracking (FCC) technology is at the heart of the process.

A tornado of hot sand vaporizes the biomass, which is then rapidly quenched, typically yielding

65wt% to 75wt% RTP green fuel. This pourable liquid can then be used as fuel for industrial heat or electrical generation, or it eventually can be further upgraded to produce transportation fuels.

RTP green fuel: a clean-burning, sustainable cost-effective fuel oil and coal substitute

RTP green fuel has virtually no sulphur and is produced in a nearly carbon-neutral way, making it ideal for companies wishing to reduce their carbon footprint. It can be adapted for use in a wide variety of industries including electrical generation, forestry, refining and petrochemicals, pulp and paper and most energy-intensive heavy industry.

RTP also produces char and a non-condensable gas, both of which can be used to provide process energy in the reheater to maintain the RTP process and/or in the dryer to condition the biomass.

This makes the RTP process virtually self-sustaining.

The Sarment process will yield approximately 304 kg of Blended

Palm Oil and 370 kg of RTP Green Fuel from a tonne of FFB.

9 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

In comparison to the conventional mill - Direct Combustion is used but it is messy and inefficient pathway to gaining energy.

RTP versus Direct Combustion

Direct combustion delivers considerably less useable energy per unit of feedstock than RTP. Burning residuals results in more variable energy production than burning more consistent, energy-dense RTP green fuel. And with direct combustion, once feedstock conversion begins, the energy must be used immediately on-site, unlike RTP green fuel, which can easily be stored for later use or transported (or SOLD) to another facility.

Envergent Technologies

This worldwide success is the direct result of Envergent Technologies’ rich heritage; the biofuel pioneer is a joint venture between two recognized technology leaders —

Ensyn Corp. and UOP, a Honeywell Company.

To date, Ensyn has designed and built seven commercial RTP plants in the

United States and Canada. These plants currently process biomass for use in the manufacture of more than 30 commercial products ranging from food flavorings to adhesive resins for construction. Co-products are also used in a variety of commercial thermal applications. RTP has produced more than 30 million gallons of product for commercial use. http://www.envergenttech.com/files/rtp-from-envergent-2010.pdf

10 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

The dynamics of focusing on Biofuel appears to be qualified by the following.

A proposed scheme to plant palm oil biofuel trees, funded by China and supported by the

Indonesian government, is expected to cover an area of 4.4 million acres on the island of

Borneo. http://www.global-greenhouse-warming.com/palm-oil-biofuel.html

G7: End of fossil fuel era? - BBC News

By Roger Harrabin BBC environment analyst

G7 leaders meeting in Germany agreed on the need to move away from fossil fuels

The G7 has called for a transformation of electricity generation towards clean sources by 2050.

They said fossil fuel emissions should not be allowed in any sector of the economy by the end of the century. http://www.bbc.com/news/science-environment-33055651

11 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

Imperata cylindrica

Imperata wastelands can be used to expand Palm Oil Plantations without any more rainforest deforestation.

A NTHROPIC S AVANNA

Imperata cylindrica occupies at least 200 million hectares in tropical Asia.

These Imperata wastelands have resulted from slash & burn practices.

The clearing of Rainforests to make way for Palm Oil is one of the key factors.

My plan is to use the Imperata Biomass to produce biofuels and paper pulp.

This will involve the complete harvesting of the Imperata – both the above ground foliage and the rhizomes that grow to a depth of 60cm.

This harvesting will eradicate Imperata and condition the soil in preparation for plantings of Palm Oil seedlings, food crops, and a variety of Rainforest species.

12 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

Subsequently, to protect the land from erosion and regrowth of weeds an environment friendly matting would be put in place.

A proportion of the biofuel and paper pulp will be used in the making of this matting.

13 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

14 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

Objective: Eradication of 20 million hectares.

Over the next 20 years these Imperata grasslands could then be transformed into Rainforest,

Palm Oil Plantations, and Sustainable Food Production.

At the end of 20 years the Imperata would be reduced to zero and in its place would be a sustainable community for both humans and wildlife.

LAND USE Hectares

Palm Oil 9,000,000

Rainforest Conservation 8,000,000

Sustainable Food Production 2,000,000

Infrastructure & Community 1,000,000

Imperata cylindrica Eradicated 20,000,000

In the 23

rd

year the Palm Oil Plantations will be producing 77,886,416 litres of

Biodiesel , and 21,369,382 litres of RTP Green Fuel which would generate

110,409,187,092 kWh of electricity. Plus paper pulp - 3,949,520 tonne - to produce environmental matting and other paper products.

Realistically, I cannot guarantee the accuracy of my model (and like all models variances can be limited by inputting better data). The processing of Imperata and eradicating the weed leaves a legacy of palm oil plantations and rainforest.

This Land Use transformation increases the Carbon stock by 470% and additional environmental benefits are derived from biofuel and biochar production. In the arena of ‘carbon trading’ this will be a bonus for the project.

Starting the project in the region of Riau – where the annual slash and burn creates a toxic smoke haze over Singapore, Malaysia and Thailand – could see other benefits. In 1997 the smoke haze cost the Singaporeans $9 billion in associated health costs. Each year Riau emits the equivalent of 58% of Australian Greenhouse Emissions.

This alone is a commercial opportunity and will help restore the reputation of the Palm Oil

Industry.

15 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

After 25 years a Palm Oil plantation will need to be replanted.

In the past the palm oil trunks were cut down piled up and burnt. These days they are left to rot – this is deemed a better environmental practice.

By processing Palm Oil Trunks using SARMENT technology would produce a range of products – sugar, building laminates, ethanol, butanol, carbon dioxide, and RTP Green

Fuel.

Palm Oil Trunks contain 102 g/kg SUGAR which compares to Sugar Cane 115 g/kg.

From my ‘rough’ modelling this indicated that there were over 3 million hectares to be replanted over the next 10 years.

The replanting is the equivalent of 20 times of all the wine grape vineyards in Australia.

My model is based on these selected data and I realise that palm oil trees are now being selected for shorter trunks and new plantations can be a mix of rubber trees and oil palms. There are sure to be errors in my modelling, but it is clearly evident that palm oil trunks should be processed!

Selected criteria

Each Palm Oil Trunk is 10m in length, 80cm in diameter and 80% moisture content.

The dry weight of each log equals 700 kg.

The sap sugar content is 15%.

A hectare of Palm Oil Trunks will yield 13.2 kl of Ethanol.

•

This is higher than in the previous document and comes about from using a bigger log size than Mori et al and I prefer to use the sugar cane conversion as it reflects industrial practice.

•

The 135 kg of sucrose found in 1 ton of b&c are transformed into 70 litres of ethanol . The practical sucrose-ethanol conversion efficiency is, therefore, 76% (compare with the theoretical 97%).

http://en.wikipedia.org/wiki/Sugarcane

16 | P a g e

Malaysia to peak in

2020 at 5.6

million hectare

Indonesia to increase to 10 million hectare in 2020 and keep expanding at 2.2

% per year

Sarment – Palm Oil – Imperata – Rubber - Biofuels

Replanting Palm Oil – “The Next Decade”

For the next ten years this replanting presents a great opportunity to produce sugar, ethanol,

RTP Green Fuel, building products, stock feed, plant derived plastic packaging, and paper.

At the same time the replants will increase the yield of oil per hectare through use of better

Palm Oil seedlings and their growth boosted with irrigation and fertilizer systems.

Then in 20 to 25 years’ time this plantation will be replanted...... again increasing

the yield of oil per hectare through use of better Palm Oil seedlings …..

.

Then in 20 to 25 years’ time it can again be replanted........

Ad infinitum…

17 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

18 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

From my modelling I have only the data from Mori et al to work with. The sugar content is derived from a dry weight of a trunk and equals 25.4%. For sugarcane I have removed 85% of the water to achieve a dry weight and determined the sugar content to be 27.8%.

Taking the high end of average sugarcane yields at 70 tonne of cane stalk per hectare will produce

4.9 kl of ethanol per hectare.

Palm Oil Trunks will yield 13.2 kl of ethanol per hectare every 20 to 25 years .

At replanting, a hectare of the palm oil trunks is equivalent to 2.7 hectares of Sugarcane.

In the next decade (2012 – 2022) this equates to 8 million hectares of Sugarcane.

This is equivalent to a third (34%) of the world’s current hectares of sugarcane and a 25% increase in the ‘hectares’ of sugarcane.

Sugarcane is the world's largest crop. In 2010, FAO estimates it was cultivated on about

23.8 million hectares, in more than 90 countries

http://en.wikipedia.org/wiki/Sugarcane

The energy extracted would be far greater for Palm Oil Trunks -as after the sugar is extracted – sugarcane yields 130 kg of dry bagasse which is 25% of the 522 kg of Palm Oil Trunk used to produce RTP Green Fuel and Biochar.

2022 to 2032 will offer even larger quantities of Palm Oil Trunks. Logically each decade will have an increase in the hectares to be replanted until new plantings cease.

This document is meant to arouse interest in approaching Palm Oil from a different perspective.

There may be some flaws in my model based on the scarcity of data.

From the number of institutions that work alongside the Palm Oil Industry it would be easy for them to qualify my model.

There is little doubt in my mind that what I have produced is understated and the values could be considerably higher.

19 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

Rubber Plantations Replanting.

Akin to the palm oil trees at the end of their lives – Rubber Trees - are cut down and the trunks are processed to recover rubberwood.

Apart from latex, the rubber tree also produces a large quantity of biomass. It is estimated that a standing tree can produce up to 2.1 m 3 of biomass, including the trunk, branches, twigs, and leaves. https://www.ncsu.edu/bioresources/BioRes_10/BioRes_10_2_2526_Ratnasingam_RWSM_Propects_Rubberwood_Biomass_Energy_6653.pdf

A 30-year old cultivated rubber tree is about 30 m tall with an average branch-free bole of 3 m.

The diameter at breast height (dbh) may reach about 30 cm. The stem tends to taper. The constantly tapped portions of the stem may develop, with age, a latex-smeared cortex.

Available log volume for diameters above 15 cm ranges from 52 m

3 ha

-1

to 162 m

3 ha

-1

(assessed for nine cultivars by Gan et al. 1985); in assessments a figure of 100 m

3 ha

-1

is normally used.

The utilizable wood volume per hectare depends upon numerous factors such as clone, site and management. Sawn timber recovery lies between 25 and 45 percent. http://www.fao.org/docrep/004/ac126e/ac126e03.htm

From the wastage at the mill and including the biomass left to rot in the plantation. This would include foliage and branches. My contention is that there is recoverable latex in this biomass.

This is after a discussion with a person who had worked in a rubber plantation and said there was latex in the leaves.

The Sarment Process would recover this latex prior to producing

RTP Green Fuel and Biochar.

There are over 7 million hectares of rubber plantations worldwide. At 3% replanting this equals

210,000 hectares producing rubberwood, latex and RTP Green Fuel each year.

20 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

The Sarment Process can handle a range of inputs – Palm Oil FFB,

Imperata cylindrica, Palm Oil Trunks, and Rubberwood Biomass.

This allows for more flexibility in processing over the present day Palm Oil Mills. It would be remiss IF I didn’t mention two more applications for the Sarment Process.

1.

Jatropha

China and India are planting Jatropha to offset fossil fuel diesel.

In normal processing of the Jatropha seeds the leftover meal is toxic to animals.

Based on CSIRO documents, and with adaptation of wine processing machinery we can denature the toxins. This is only relevant if the meal was used for feeding animals. Toxins are obliterated during RTP processing.

Some people say commercial Jatropha plantations will not survive without a mechanized system simply because you cannot get the labour and even if you get them, you cannot pay them. http://www.jatropha.pro/harvesters.htm

Using South Australian Agricultural Engineering for the development of machine harvesting coupled with Sarment processing technology will develop a system to be sold (or provision of contract services) worldwide.

Jatropha will see enormous growth: 5 million hectares are expected by 2010.

The number and size of Jatropha projects currently being developed is increasing sharply. This is the case in almost all regions of the world which are suitable for Jatropha cultivation. It is predicted that each year for the next

5-7 years approximately 1.5 to 2 million hectares of Jatropha will be planted.

This will result in a total of approximately 5 million hectares by 2010 and approximately 13 million hectares by 2015. http://www.jatropha-alliance.org/fileadmin/documents/GEXSI_Global-Jatropha-Study_FULL-REPORT.pdf

21 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

Over the past decade China has quietly emerged as the world’s third largest biofuel producer. Concerned over rising food prices, in June 2007 China’s central government banned the use of grain-based feedstocks for biofuel production and reoriented the country’s bioenergy plans toward perennial crops grown on marginal land.

One such crop, Jatropha curcas, has emerged as a high potential biodiesel feedstock because of its adaptability to the diverse growing conditions where

China’s marginal land is abundant. Provincial governments in Southwest

China, for instance, have drafted ambitious plans to increase Jatropha by over one million hectares in the next decade. http://worldagroforestry.org/downloads/Publications/PDFS/WP07259.pdf

The data above is a bit old but it indicates the potential to provide harvesting and processing services for China et al. It may be an avenue to form joint ventures. Any mechanical harvesting may be served by harvesting both foliage and seed pods this will add to the lignocellulose biomass and hence potential RTP Green Fuel.

22 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

2.

Palm Oil Leaf Fronds

This represents another valuable source of “Biomass”.

“A study conducted by the Malaysian standard organization, SIRIM Bhd, revealed that 2.65 million hectares of oil palm trees could yield up to 7 million tons of oil palm trunks and 26.2 million tons of oil palm fronds annually. Oil palm fronds are a rich source of fibre for the manufacture of MDF and other panel products.” http://worldtimber.wordpress.com/2009/09/03/malaysia-rubberwood-clones-forest-plantation-log-prices/

2,650,000 hectares of palm oil trees

143 oil palms per hectare

378,950,000 oil palm trees

26,200,000 tons of oil palm fronds / year

10 tons of oil palm fronds / hectare

0.07 tons of oil palm fronds / tree

69.14 kg of oil palm fronds / tree

“There are about 145 oil palm trees per hectare. About 25 pieces of fronds can be obtained from a single tree. The average weight of each frond is about 8 kg (Supranto et al, 1999). Hence, about

200 kg of fronds can be obtained in a year per tree. Moreover, about 30 tons of fronds can be produced in one hectare in a year.” http://www.isesco.org.ma/english/publications/Solar%20Drying%20system%20final/Chapter12.pdf.

Oil palm frond (OPF) has been identified as a potential feed for herbivore livestock. The average weight of OPF pruned from a mature plant is 13.3 kg and total OPF production is about 5500 kg/ha/year. The dry matter (DM), crude protein (CP), ash, ether extract (EE), crude fibre (CF), acid detergent fibre (ADF), lignin, calcium (Ca) and phosphorus (P) content of OPF has been shown to be 349, 70, 50, 24,323, 536, 276, 4 and 9 g/kg respectively. The gross energy and metabolizable energy (MJ/kg DM) of OPE is 17.2 and 6.5 respectively. These data indicate that OPF, a low cost byproduct available throughout the year, could be more widely used as a roughage source for ruminants and other herbivorous livestock. http://www.asap.asn.au/livestocklibrary/2000/Dahlan_0263.pdf

23 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

Palm oil, the most widely consumed vegetable oil in the world, is produced across a whopping 17 million hectares worldwide, an area larger than Uruguay.

http://www.wri.org/blog/2014/06/new-palm-oil-production-maps-mark-milestone-transparency

This equates to 170 million tonnes of OPF Biomass… or 510 million… or 94 million (3 Research Papers 3 different results)!

Compared to the Australian annual grape production for wine at 1.7 million tonnes I can comprehend that there is a very large processing opportunity.

24 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

Oil Palm Fronds & Sarment Process

The simplest way is to MACERATE the fronds as soon as possible after detachment from the

Palm Oil trees.

The shredded material will then be run through a Hot Water COUNTER CURRENT

EXTRACTOR (CCE) to remove all soluble components. The reason for using only water will become apparent in the next few pages.

After CCE the shredded leaf fronds need to be pressed out to lower their moisture content.

Either Continuous Belt Press or Screw Press will be able to complete the task.

After this processing we have 2 products….

1.

Fibrous Dry Frond Chips (FDFC) – “Solids”

2.

Leaf Frond Extract (LFE) –

“Liquids”

The FDFC have at least 3 options.

1.

Sold for Stock Feed

2.

Sold for Paper Making

Leaves and empty fruit bunches have a high content of cellulose and can be processed into pulp. The pulp can blended with other types of pulp to be used for the production of paper. Several types of papers such as kraft, printing, industrial and newsprint papers can be produced. The cellulose fibre that is similar to coconut coir can also be used for mattresses, fibre boards, and agricultural mats and in the automotive industry.

3.

Feedstock for RTP Green Fuel.

25 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

Animal Feed

Oil palm fronds are a low-protein, high-fibre material that has been shown to be palatable and to have a good feeding potential for many classes of herbivore livestock, including cattle, buffaloes, sheep, goats, deer and rabbits ( Dahlan et al., 2000 ; Dahlan et al., 1994 ).

From the Sarment processing of other products we are well placed to make superior quality pellets. Animal nutritionists can add to a FDFC base extra protein (Imperata rhizomes contain

14% crude protein); carotenoid & Vitamins A and E, Rumen Bypass Fat - C16 Palmitic Acid

(recovered from Palm Oil refining); and Yeast (Palm Oil Trunks).

26 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

If all the FDFC were to be used to produce RTP Green Fuel this would add significant volumes.

BIOMASS of Oil Palm Frond

Biomass post PRESSING

Dry Matter Content

100,000,000

fresh tonne

31,000,000

tonne

31%

Allocation...

Animal Stock feed

RTP Green Fuel & Biochar

0%

100%

RTP Green Fuel from OIL PALM FRONDS

BIOMASS for RTP

RTP Conversion

31,000,000

tonne

70%

21,700,000

tonne

ELECTRICITY from OIL PALM FRONDS

Energy RTP Green Fuel conversion to kWh

Total kWh

18,600

kJ/kg

5.2

kWh/kg

112,117,390,000

kWh

112,117,390

MW

112,117

GW

ELECTRICITY from OPF comparison with CHINA

5,463,800,000

MW

2.05%

With whatever direction – animal feed or RTP Green Fuel? – the WATER has to be removed otherwise the rot sets in and the chance to recover valuable products is lost.

27 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

Leaf Frond Extract (LFE)

The palm oil fronds are full of water – at least 55%. The Sarment process will extract this water and can further process this to separate other soluble components.

My view is that we can commercialise this source of water. In my mind, Leaf Frond Water, is equivalent to mineral waters such as Evian and desalinated Deep Ocean water from Hawaii.

As per the processing of Palm Oil FFB we can deploy Spinning Cone Column, Centritherm, and

Sintered Stainless Steel Filtration to produce water with unique purity and taste.

Botanique nonpareille

One tonne of OPF could yield

1,000

bottles…..

28 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

Leaf Analysis used in determining fertilizer regimes would indicate that there would be recovery of some of the plants nutrients.

Nutrient Units Optimum

N

P

K

Mg

Ca

S

Cl

B

Cu

Zn

% DM

% DM

% DM

% DM

% DM

% DM

% DM mg/kg mg/kg mg/kg

2.6

0.165

1.05

0.325

0.625

0.3

0.6

20

6.5

15

There is always a possibility that the LFE could be ‘fermented’ with bacteria to develop a richer nutrient broth for both plant, animal, and human nutrition. This could lead to a probiotic enriched version of Botanique nonpareille.

Palm oil, particularly virgin or “red” palm oil, is a traditional fat that has been a part of the human diet for at least 5000 years.

It is logical to blend in at least

25ml into Botanique nonpareille NUTRITION.

Red palm oil not only supplies fatty acids essential for proper growth and development, but it is packed with an assortment of vitamins, antioxidants, and other phytonutrients important for good health. Red palm oil gets its name from its characteristic dark red colour. The colour comes from carotenes such as beta-carotene and lycopene.

Carotenes are valuable nutrients and powerful antioxidants. They are also important because our body can convert them into vitamin A, an essential nutrient.

Carotenes in fruits and vegetables can supply the needed vitamin A if an adequate amount of fat is also consumed. Carotenes require fat for conversion into vitamin A.

29 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

Red palm oil provides a perfect solution. It supplies the needed fat and vitamin A precursors.

Red palm oil is the richest dietary source of provitamin A carotenes (beta-carotene and alphacarotene). It has 15 times more provitamin A carotenes than carrots and 300 times more than tomatoes.

Just one teaspoon a day of red palm oil supplies children with the daily recommend amount of vitamin A.

Nursing mothers are encouraged to supplement their diet with palm oil to enrich their milk with the vitamin. Studies show that adding red palm oil into the diet can double or triple the amount of vitamin A in mother’s milk.

In addition to beta-carotene, alpha-carotene, and lycopene it contains at least 20 other carotenes along with vitamin E, vitamin K, CoQ10, squalene, phytosterols, flavonoids, phenolic acids, and glycolipids. Palm oil is one of the richest natural sources of vitamin E. In addition to ordinary vitamin E, it also contains the highest amount of a super potent form of vitamin E known as tocotrienol. There are four tocotrienols. Palm oil contains all of them. These tocotrienols have up to 60 times the antioxidant activity of ordinary vitamin E. The combination of vitamin E, tocotrienols, carotenes, and other antioxidants makes palm oil a super antioxidant food.

The Botanique nonpareille SIX PACK will supply a person’s daily needs and should be supported by the WHO.

30 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

There is no real “stopping point” in this document and I could easily continue on by showing how other technologies can be incorporated, BUT this may only overcomplicate the situation. I hope I have achieved a vision for fully sustainable production of biofuels.

There are many passionate people concerned about deforestation of rainforest and what I have shown is a commercial pathway to restoring rainforest. Imperata cylindrica is ranked the 7 th

World’s Worst Weed and Sarment technology could be applied to the other Top Ten.

Water hyacinth contains Cellulose 16%; Hemicellulose 55%; Lignin 6% and Crude Protein 12% by weight – therefore this noxious weed could be processed for Animal Feed and RTP Green Fuel. I emphasise that the Sarment Process removes and recovers the moisture content (water and oil) to make the biomass stable for pyrolysis.

Both H

2

Oasis Energy and Solar(chi)tecture, my companies, are focused on solutions for desertification . Therefore the scope to find millions of hectares to provide food and biofuels for future generations becomes much easier.

In the wings I have a number of companies and individuals that will provide support. In particular there is Della Toffler Pacific who are proposing using a trial unit valued at €600,000, the debate will be, do we take Palm Oil FFB to Italy?

Obviously I am keen to discuss this with Wilmar International.

The processing of Whole FFB is being proposed by others which only verifies the Sarment

Process. I remain confident that my ideas are far more versatile.

Yours sincerely,

Rod Bourchier

31 | P a g e

Sarment – Palm Oil – Imperata – Rubber - Biofuels

Rod Bourchier

Diploma of Agricultural Science +

“Think outside the Square”

“The more you see – the more opportunities you will find.”

“Do not cloud your perspective”

Born in 1948

Commenced winemaking at Penfold’s Magill Estate under the tutelage of Max Schubert renowned creator of ‘Grange’ – Australia’s most famous wine.

1972 - Shared the winemaking responsibilities for Grange and all other premium red wines in the new red wine cellars at Penfolds Barossa Valley winery.

1973 – Established the Karrawirra label collected over 70 medals in 12 months.

1974 -1985 Chief Winemaker at Yalumba (presently Australia’s largest Family Owned Winery). This was a period of transition from fortified wines to table wines.

General Manager and Winemaker at Baileys (1986), Echuca Estates (2000 to 2003), and Southern Vales

(1990 to 1993).

Production Director of Intervin joint venture number 392 in the Soviet Union. Commenced construction of a Bottle Fermented Sparkling Wine (US$200 million) facility that would have produced

25 million bottles of Pinot/Chardonnay in its first year.

Established VinovatioN consulted for Australian Wine Estates, Tandou, Cimicky, Morning Sun

Estates and Lovely Valley Beverage Company and acted as a Consultant to Shaw Wallace and Co. in

India

Completed with BDO a major report for the establishment of a 15,000 tonne winery in Swan Hill.

Working on joint venture projects in Mauritius focussing on sugar cane.

2008 Established H

2

Oasis Energy to commercialise my Solar Distillation Patents. With the South

Australian Government I participate in the Growing Global Companies programme and have completed a Strategic Marketing Plan course and the Leadership in Action residential .

“

Our Solar Distillation Irrigation Matting (ultiMAT) creates the water to make plants grow. It only needs a source of saline water – oceans or groundwater –and sunshine to be able to operate.

At the same time it holds the soil in place and captures rainfall - important factors in arresting desertification. The pure water generated can sustain plant growth on previously useless land. As populations grow and 'peak oil' kicks in H

2

Oasis Energy can open up new areas for both food and biofuel crops. Our designs can also provide safe drinking water - which is important since a child dies every 8 seconds from water borne disease

”

2015 – Vision to establish highly sustainable Agricultural Systems

32 | P a g e