this release

advertisement

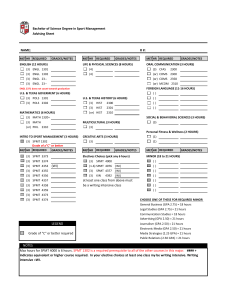

PRESSEMITTEILUNG 22.01.2015 Pfedelbach Oil Spill Response Limited relies on the absolute reliability of the SPMT Light from SCHEUERLE to mobilize subsea well intervention equipment If absolute reliability is required, companies around the world place their trust in vehicles from the TII Group, which is comprised of SCHEUERLE, NICOLAS and KAMAG as well as the TII Energy. In particular, this reliability is important to ensure an effective response when responding to oil spill incidents. Oil Spill Response Limited selected vehicles from SCHEURLE to mobilize critical subsea well intervention equipment that would be called upon in the event of a subsea well blowout. Following the Macondo incident, the Subsea Well Response Project (SWRP), a consortium of nine leading upstream companies designed and developed advanced capping, dispersant and containment equipment for deployment worldwide. Oil Spill Response Limited was identified to make this equipment available to industry and now owns, stores and maintains four capping stacking systems in four international locations – Brazil, Norway, Singapore and South Africa. In the event of an incident, subscribers to OSRL’s Subsea Well Intervention Services can mobilize the equipment which is stored at the bases in a response ready state. The capping stacks can be mounted on a well up to depths of 3,000 metres and can either completely seal off the escaping oil or at least reduce the flow until a relief borehole addresses the situation. In order to reliably transport the capping stack to the ship when required, OSRL uses the transversely-coupled SCHEUERLE SPMT Light vehicle. The 120 t capping stack is permanently loaded on the vehicle ready to be mobilised when required. "The SPMT Light, which was designed among other equipment for heavy load transportation for internal use in plant and steel construction as well as special assignments such as for Oil Spill Response Limited, is employed here in a very sensitive situation. In the event of an incident, it has to function perfectly and our customers know that they can fully rely on this", according to Jannick Mathieu, Area Manager Sales at TII Sales, the sales arm of the TII Group. 1/4 The 120 t rescue head is positioned permanently on the SCHEUERLE SPMT Light ready to be mobilized immediately when needed. The proven hydraulic pendulum axle, which was developed by SCHEUERLE, provides stability when transporting the capping stack 2/4 The SCHEUERLE SPMT Light, with its 86 t load-bearing capacity, is often used for in-plant transports as seen here transporting a 50 t bridge girder at Sibau Genthin, Germany. Breman Machinery, Netherlands: using a longitudinally coupled SCHEUERLE SPMT Light for transporting a 40 t stator. 3/4 SPMT Light The essential feature of the SPMT Light series is the compact design of the vehicle modules. The platform dimensions of 6,000 x 2,438 mm with 4 pendulum axles guarantee optimum flexibility for smaller transport assignments, e.g. in production halls. Payloads of up to 86 t are possible. Naturally, the SPMT Light also has the well-known advantages of a conventional SCHEUERLE SPMT such as the robust design of the bogie units and the electronic multi-directional steering complete with all known steering programs. Fixing points on the topside of the platform top allow the mounting of cargo control posts for the transportation of long materials. Press Contact: Christopher Rimmele +49 (0)7941 / 691-225 christopher.rimmele@tii-group.com 4/4