Jump start to the new year - College of Engineering, Mathematics

advertisement

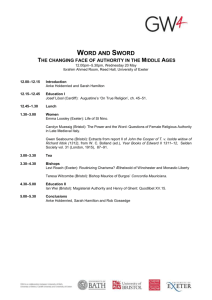

PRESS RELEASE PRESS RELEASE PRESS RELEASE Jump start the New Year in the South West! Two days free business and technical support is now available to plastics processors in the South West thanks to the University of Exeter’s EU-funded CALMARE project The New Year has begun brightly for the University of Exeter’s College of Engineering, Maths and Physical Sciences with a delivery of an Wittmann Battenfeld HM 45 injection moulding machine. Exeter University has been a Wittmann Battenfeld customer for some fifteen years. The new machine, specially set up for thermoset moulding, will further enhance the University’s general expertise in materials and mechanical engineering and will also play a leading role in the University’s new business technology centre, CALMARE, a new enterprise launched in the South West at the end of 2013. Part funded for two years by the European Regional Development Fund Programme 2007 - 2013, CALMARE (Centre for ALternative MAterials and REmanufacturing Technologies) will support South Western plastics processors with a range of material development and sustainability projects and services. These include materials testing, waste reduction and advising on design, redesign, remanufacturing and recycling. Paul McCutchion, Commercial Manager for the new centre says that ‘many SME (Small to Medium Enterprises) plastics manufacturers neither have the time nor resources to look into alternatives that could improve their products and processes, or may not know where to start. That is where we come in. Plastics processors of all kinds will definitely benefit greatly from these two days free work in 2014. Our CALMARE team, for example can visit companies on site or open up our facilities and manpower here for use. We can also work on new products and ideas, directly or with desk/feasibility research; undertake process improvement work and can also include workshops providing useful information on topics such as the impact of new legislation, or material developments.’ The CALMARE Centre is also there to help companies with ‘collaborative projects,’ says McCutchion, ‘such as implementation of cross network recycling solutions and development of new sustainable materials and processes.’ There is a large element of sustainable manufacturing involved in the Centre’s remit; part of the reason for turning to long standing technology partner and supplier, Wittmann Battenfeld. The X-AT (Exeter Advanced Technologies) Technical Services Manager Dave Baker notes that ‘over the years we have enjoyed great service and reliability across the board from Wittmann Battenfeld, not just for moulding but for energy efficient solutions in materials handling, temperature control, and granulation.’ The new Wittmann Battenfeld HM 45 moulding machine will therefore be greatly involved in some of the pioneering work being done at CALMARE in the areas of GRP, Composites and Thermoset recycling. ‘The new machine enjoyed a smooth commission,’ adds Baker, ‘and we are confident in creating pioneering work in thermoset-based recycling and moulding through the coming year.’ The CALMARE Centre already enjoys high-level support from UK plastics; trade associations and companies. The British Plastics Federation (BPF), for example, is involved; providing match funding and assisting the Centre in its mission to help plastics-based SMEs in the South West region. Tim Marsden, Senior Projects Executive at BPF says that ‘following our successful collaboration with the University of Exeter on a range of other projects, we were very pleased to lend our support to this exciting initiative. As the leading trade association for the plastics industry in the UK, one of our major concerns is upcoming UK and EU legislation issues and how they affect plastics SME businesses. So we are delighted that CALMARE has been set up and that one of its strengths will be raising opportunities in reusing and recycling plastics and composite materials.’ The £1.8m business technology centre is based at the University of Exeter and serves SME plastics manufacturers in the South West. Qualifying counties include Gloucestershire, Wiltshire, Dorset, Somerset, Dorset and Devon. For more details, please contact 01392 725821, email P.McCutchion@exeter.ac.uk or calmare@exeter.ac.uk or visit www.exeter.ac.uk/calmare For more details of Wittmann Battenfeld machinery and equipment contact the company at 01933 275777 www.wittmann-group.co.uk ENDS About the University of Exeter The University of Exeter is a Russell Group university and in the top one percent of institutions globally. It combines world-class research with very high levels of student satisfaction. Exeter has over 18,000 students and is ranked 8th in The Times and The Sunday Times Good University Guide league table, 10th in The Complete University Guide and 12th in the Guardian University Guide 2014. In the 2008 Research Assessment Exercise (RAE) 90% of the University’s research was rated as being at internationally recognised levels and 16 of its 31 subjects are ranked in the top 10, with 27 subjects ranked in the top 20. Exeter was The Sunday Times University of the Year 2012-13. The University has invested strategically to deliver more than £350 million worth of new facilities across its campuses in the last few years; including landmark new student services centres - the Forum in Exeter and The Exchange on the Penryn Campus in Cornwall, together with world-class new facilities for Biosciences, the Business School and the Environment and Sustainability Institute. There are plans for another £330 million of investment between now and 2016. www.exeter.ac.uk