Microsoft Word template

advertisement

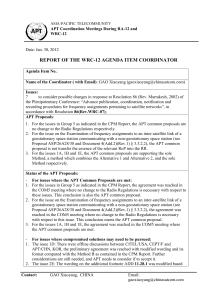

ME 440 – C/NC Machine Tools Solution of Assignment 4 Student Name* ID#* Fall 2014 Introduction In this assignment, an APT program to machine a Wankel (rotary) engine rotor is considered. First part of the assignment defines various geometric entities while the second part concentrates on the development of the APT program that specifically employs these entities to describe the motion of the cutting tools. Part A: The geometric entities are illustrated in Figure 1. Y L2 C2 C5 C4 L1 P1 C1 C3 P0 X Z P0 P1 X PL2 PL1 Fig. 1 Geometric entities to be used in the APT program. Part B: The listing of the APT program using the geometric entities introduced in Part A is given in the Appendix. Notice that no attempt is made to improve the efficiency of the program (i.e. the machining operations) for the sake of not obscuring its clarity. As can be seen from Table 1, there are five sections to the program that defines the cutter’s motion. –1– Student Name* ID#* ME 440 – C/NC Machine Tools Solution of Assignment 4 Fall 2014 Table 1. Machining operations Section Machining Operation 1 Rough machining of the outer profile 2 Surface finishing of the outer profile 3 Surface finishing of the top surface 4 Rough finishing of the hole at the center 5 Surface finishing of the hole at the center Once the drive-, part-, and check surfaces are determined correctly, defining contouring motion is quite straightforward. Similarly, the time required to complete the machining operation could be expressed as c1c2 k T 2 (1) In Eqn. (1), c1, c2, k, , are the experimental parameters. It is critical to note that climbmilling is to employed in all finishing operations for the given problem as it leads to a much better surface-finish than its counterpart,. Unfortunately, a serious mistake about how the contouring motion is defined for up- and climb-milling has been detected in some of your solutions. As mentioned in one of the lectures; a milling tool, by design, can cut material when it is rotated in only one particular direction (that direction is usually clockwise). Hence, if it spins in the opposite direction (i.e. counter-clockwise); the tool will not be able to remove any material as the cutting edges do not directly face the workpiece. Consequently, programmers do have a control over the milling operation by simply changing the direction of the feed/cutter motion (not the direction of the spindle rotation!). As a rule of thumb, one must examine the cross-section of the cutting tool: when the cutting edges are opposing the feed, the resulting operation becomes up-milling. So beware! As a final note, a new statement called INDIRV (which stands for “IN DIRection of a Vector) is utilized in the APT program to resolve the ambiguity that might occur at the startup of a contouring motion. In this statement, the direction of the contouring motion is specified by a vector which has projections i, j, k along the X-, Y-, and Z axes respectively. For instance, INDIRV/1,0,0 means the direction is along +X axis; INDIRV/-1,0,0 means the direction is along –Xaxis; INDIRV/0,1,0 means the direction is along +Yaxis; INDIRV/1,1,0 means the direction is along the line which makes 45o with the X axis. –2– Student Name* ID#* ME 440 – C/NC Machine Tools Solution of Assignment 4 Fall 2014 Part C: Some advantages of the APT programming are as follows: It is a programming environment enabling the use of many advanced features of highlevel languages (e.g. arithmetic operations, arrays, conditionals, branching, etc.) The APT vocabulary is in English and most commands are easy to remember. With APT, one can handle very sophisticated machining jobs. All APT programs are portable. As you have already discovered, there are some major disadvantages associated with the APT programming: For simple machining tasks (just like the one we have here), the APT programming seems to be relatively more complicated than its counterpart. Due to the success of advanced CAD/CAM packages which can generate NC programs directly, the APT programming is becoming obsolete. Hence, the commercial APT development tools are quite scarce in metal cutting industry. [*] REMARK: If this is a group project, ONLY the name of the group (which you’ve selected) is written. Names of the contributing group members, their student ID numbers along with their signatures must be included to the last page of the report: The group members who contributed to the preparation of this report are as follows: Name Student ID # Signature –3– Student Name* ID#* ME 440 – C/NC Machine Tools Solution of Assignment 4 Fall 2014 APPENDIX: APT Program Listing $$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$ $$ $$ $$ ME 440: C/NC MACHINE TOOLS (FALL 2005/2006) $$ $$ *** SOLUTION OF HW#4 *** $$ $$ $$ $$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$ PARTNO WANKEL ROTOR MACHIN/MAZAK,9,OPTION,2,0 $$ POSTPROCESSOR NAME & OPTIONS UNITS/MM $$ $$ DEFINITION OF GEOMETRIC ENTITIES (SEE TEXT) $$ P0 = POINT/0,0,50.0 P1 = POINT/49.0,58.0,50.0 C1 = CIRCLE/CENTER,165.03,58.0,RADIUS,155.0 C2 = CIRCLE/CENTER,-9.015,-42.485,RADIUS,155.0 C3 = CIRCLE/CENTER,-9.015,158.485,RADIUS,155.0 C4 = CIRCLE/CENTER,49.0,58.0,RADIUS,50.0 C5 = CIRCLE/CENTER,49.0,58.0,RADIUS,60.0 L1 = LINE/XAXIS,58.0 L2 = LINE/YAXIS,49.0 PL1 = PLANE/XYPLAN,-20.0 PL2 = PLANE/XYPLAN,-2.0 $$ $$ MACRO FOR ROUGHING OUTER PROFILE (UP-MILLING) $$ A – AXIAL DEPTH; R – RADIAL DEPTH $$ ROSFC = MACRO/A,R THICK/A,R,R GO/C3,PL1,C1 TLRGT,TLOFPS,GOFWD/C3,PAST,C2 GOLFT/C2,PAST,C1 GOLFT/C1,PAST,C3 RAPID;GOTO/P0 TERMAC $$ $$ MACRO FOR FINISHING OUTER PROFILE (CLIMB-MILLING) $$ A – AXIAL DEPTH $$ FOSFC = MACRO/A THICK/A,0,0 GO/C1,PL1,C3 TLLFT,TLOFPS,GOFWD/C1,PAST,C2 GORGT/C2,PAST,C3 GORGT/C3,PAST,C1 RAPID;GOTO/P0 TERMAC –4– Student Name* ID#* ME 440 – C/NC Machine Tools Solution of Assignment 4 Fall 2014 $$ $$ MACRO FOR FINISHING TOP SURFACE (CLIMB-MILLING) $$ R – RADIAL DEPTH $$ TOPSFC = MACRO/R THICK/0,R,R GO/ON,L1,PL2,C5 TLLFT,TLONPS,GOLFT/C5,PAST,L1 GOFWD/C5,PAST,L1 GOFWD/C5,ON,L1 RAPID;GOTO/P0 TERMAC $$ $$ MACRO FOR ROUGH-CUTTING OF THE CENTER HOLE (UP-MILLING) $$ A – AXIAL DEPTH; R – RADIAL DEPTH; F – FEEDRATE $$ RCUTCH = MACRO/A,R,F THICK/A,R,R GO/ON,L1,PL1,ON,L2,40 $$ PLUNGING INDIRV/-1,0,0 $$ RESOLVES AMBIGUITY IN DIR. TLRGT,TLOFPS,GOFWD/ON,L1,C4,F GORGT/C4,PAST,L1 GOFWD/C4,PAST,L1 GOFWD/C4,ON,L1 RAPID;GOTO/P1 TERMAC $$ $$ MACRO FOR SURF. FINISHING OF THE CENTER HOLE(CLIMB-MILLING) $$ A – AXIAL DEPTH; F – FEEDRATE $$ FCUTCH = MACRO/A,F THICK/A,0,0 GO/ON,L1,PL1,ON,L2,40 $$ PLUNGING INDIRV/1,0,0 $$ RESOLVES AMBIGUITY IN DIR. TLLFT,TLOFPS,GOFWD/ON,L1,C4,F GOLFT/C4,PAST,L1 GOFWD/C4,PAST,L1 GOFWD/C4,ON,L1 RAPID;GOTO/P1 TERMAC $$ $$ DEFINITION OF MACHINING CONDITIONS $$ CUTTER/19.05 TOLER/0.01 SPINDL/600,CLW COOLNT/ON –5– Student Name* ID#* ME 440 – C/NC Machine Tools Solution of Assignment 4 $$ $$ DEFINITION OF CUTTER MOTION $$ FROM/P0 $$ $$ ROUGH-CUTTING OF OUTER PROFILE $$ FEDRAT/100 CALL/ROSFC,A=10.0,R=32.0 $$ REMOVE CORNERS (A = 10 MM) CALL/ROSFC,A=10.0,R=14.0 $$ DITTO CALL/ROSFC,A=10.0,R=0.5 $$ ROUGH CUTTING PERIMETER CALL/ROSFC,A=0,R=32.0 $$ REMOVE CORNERS (A = 20 MM) CALL/ROSFC,A=0,R=14.0 $$ DITTO CALL/ROSFC,A=0,R=0.5 $$ ROUGH CUTTING PERIMETER $$ $$ SURFACE FINISHING OF OUTER PROFILE $$ FEDRAT/70 CALL/FOSFC,A=10.0 CALL/FOSFC,A=0 $$ $$ SURFACE FINISHING OF TOP SURFACE $$ CALL/TOPSFC,R=12.0 CALL/TOPSFC,R=0.5 CALL/TOPSFC,R=0 $$ $$ ROUGH-CUTTING OF THE CIRCLE AT CENTER $$ RAPID;GOTO/P1 CALL/RCUTCH,A=10.0,R=0.5,F=100 CALL/RCUTCH,A=0,R=0.5,F=100 $$ $$ SURFACE FINISHING OF THE CIRCLE AT CENTER $$ CALL/FCUTCH,A=10.0,F=70 CALL/FCUTCH,A=0,F=70 RAPID;GOTO/P0 SPINDL/OFF COOLNT/OFF END FINI –6– Fall 2014