HW 9.doc

advertisement

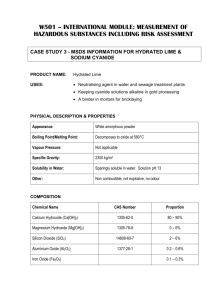

1) http://www.testmasters.com/assets/docs/limesoftening.pdf, accessed 11/18/2013 An example of a water softening bar chart is above. This chart can be used to determine the amount of lime and soda ash to add to water to soften (remove metal ions). The recipe is: 1 equivalent of lime per equivalent CO2, 1 equivalent lime per equivalent calcium hardness, 2 equivalents of lime per equivalent of magnesium carbonate hardness, 1 equivalent of lime per magnesium non-hardness, and one 1 equivalent of soda ash (sodium carbonate) per equivalent of non-carbonate hardness. In the bar graph above, the lime requirements would be = 12.9(1) + 179(1) + 14(2) + 77(1) = 296.9 mg/L as CaCO3 (assuming no excess lime), and 77(1) = 77 mg/L as CaCO3 2) Cyanide detox of water – oxidative treatments. Compare three different methods Cyanides can be used in many chemical and metallurgical processes as simple salts or cyanide complexes. Cyanide is highly toxic, and has tight compliance limits in wastewater. Alkaline chlorination Alkaline chlorination is used by most electroplating shops that generate dilute cyanide bearing wastewater. Alkaline chlorination can be achieved by either directly adding chlorine gas and sodium dioxide to the water, or by direct addition of sodium hypochlorite. The gaseous chlorine has been estimated to be about half as costly, but is perceived to be more dangerous due to the handling of chlorine gas. Assuming the use of sodium cyanide, the first stage reaction using sodium hypochlorite is NaCN + NaOCl NaCNO + NaCl, and the second stage is 2NaCNO + 3NaOCl + H2O 3NaCL + N2 + 2NaHCO3 Stable cyanide complexes (ferrocyanides) are typically unaffected by chlorinates and cannot use this method of destruction. Cyanides complexed with copper, nickel, and precious metals react more slowly than free cyanide and requires excess chlorine. Concentrated wastes (such as spent plating solutions) cannot use alkaline chlorination due to the potential for chlorine gas. http://www.nmfrc.org/bluebook/sec623.htm Ozone Oxidation Ozone oxidation can be used for cyanide destruction. The operating costs are less than alkaline chlorination, but the equipment is more expensive due to the expense of an ozone generator. An advantage to ozone over chlorine is that while chlorine can combine with organics to produce toxic compounds, ozone will not. Ozone can also destroy zinc, copper, and cyanide complexes. Chemical Precipitation Ferrocyanide (Fe(CN)6 4- is a less-toxic cyanide because it tends not to release free cyanide. Ferrous sulfate can be used to precipitate cyanide, which can be removed in a subsequent sedimentation process. 3) Reductive treatments for cr(vi) detoxification of water, compare at least three different methods Hexavalent chromium is frequently used in industrial processes, but is highly toxic and has tight compliance discharge limits. Ion Exchange Ion exchange removes chromium ions from the aqueous phase by replacing them with the anion present in the ion exchange resin such as chlorides or hydroxides. Ion exchange units typically require pretreatment to remove organics, suspended solids, and other contaminants that can foul the resin. Ion exchange units minimize the need for handling and on-site storage of chemicals and wastes. Conversion to Trivalent Chromium and Precipitation To convert hex chrome to trivalent chrome, acid (usually sulfuric) is added to wastewater to produce a low pH (between 1 and 2). Then, reducing agents such as sulfur dioxide, sodium bisulfate, or sodium metabisulfate are added. For example: 3SO2 + 2H2CRO4 + 3 H2O <-> Cr2(SO4)3 + 5H2O. When the reaction is complete, a sudden drop in ORP will occur. Once the reaction is complete, lime is added to increase and maintain a pH of 8 or higher and to precipitate chromium hydroxide. The precipitate chromium hydroxide is non-toxic and can be easily removed and disposed. Cr2(SO4)3 +3Ca(OH)2 <-> 2Cr(OH)3 + 3CaSO4) Bioabsorbtion Some biological materials have the ability to accumulate heavy metals. Algae, bacteria, and fungi have shown to be potential metal bioabsorbents. Biological materials have benefits of Low cost, high versatility, high uptake, high tolerance of organics, and regeneration. In a paper by Sukumar “reduction of hexavalent chromium by rhizopus oryza”, the reduction ability of a specific organism was tested at a laboratory scale. At optimum conditions, there was a 91.15% conversion of hex chromium to trivalent chromium. Based on the high removal chromate removal, bioabsorbtion may be a feasible, economical technique for chromate removal. Sukumar, M. Reduction of hexavalent chromium by Rhizopus Oryza. African Journal of Environmental Science and Technology. Vol 4(7)( pp 412418, July 2010. http://www.water.siemens.com/en/applications/wastewater_treatment/chrome-removal/Pages/default.aspx http://www.hubbardhall.com/chemical-apps-wastewater-chrome-reduction.htm http://www.sensorex.com/docs/AppNoteChromeWaste.pdf 4) 1000 word essay summarizing progress on project Paper mostly done at this point. Needs to be reviewed for punctuation/grammar/readability.