3.1.3 GAS SUPPLY, GAS SYSTEMS AND PIPES (WILL BE

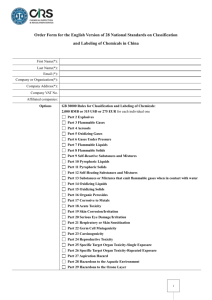

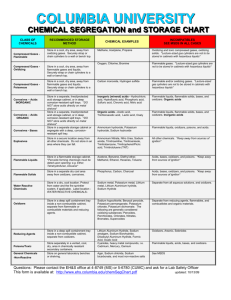

advertisement

3.1.3 GAS SUPPLY, GAS SYSTEMS AND PIPES (WILL BE REWRITTEN BY ROBERTO) The gas supplies system will be installed outside the GIF++ building in two separate rooms: one for neutral gases (Ar, CO2, N2, He, SF6, CF4) and one for flammable gases or gases with very low vapour pressure (iC4H10, CH4, Ar/H2, CF4, C2H2F4, nC5H10). The latter will be heated in order to ensure enough pressure at the input of gas systems and it will also contains several zones classified as zone 2 and therefore instrumented with ATEX certified equipment. All gases will be connected to automatic change-over panels based on pressure measurement. If possible, for gases that are liquid at ambient temperature, the change-over mechanism will be based on weight otherwise the modification will be implemented in a second phase. One line for each gas will be installed from the gas supply zone up to the GIF++ service area. The pipes for gases with low vapour pressure will be heated (iC4H10, C2H2F4, …). Several panels will be available for the primary gas distribution to all mixers and analysis devices. The consumption of all gases will be monitored at the mixer level. The gas systems will be built following the standard used for the LHC experiments. All system will be running on one dedicated PLC. PVSS is used as software for the control interface. Data about gas systems status and important values will be also available on the network. At least three gas mixers will be built and ready for the first operational phase of the GIF++ facility. They will be designed in order to accommodate as much as possible the requests from all the users. The gas re-circulation rack from the old GIF facility will be verified and used for the cosmic trigger setup. In a second phase, other two or three gas recirculation rack will be built in order to satisfy the different detector groups. Since flammable gases will be used, a flammable gas detection system will be installed. As usual, detection point will be located near the primary gas supply panels, in the mixers using flammable gas and inside the facility. The flammable gas leak alarm will be propagated to the CCC and Fire-brigade using the standard procedure. The concentration of a flammable gas in the gas mixture will be monitored using infrared analysers. One analysis rack with O2 and H2O analysers will be available and it is intended to be used for all the gas systems. An automatic system will scan all the selected lines. After a first period of commissioning, a gas chromatograph will be also included in the gas analysis rack. Several gas distribution panels will be available in the preparation zone and inside the facility (typically about 3 in the preparation zone and 5 in the irradiation area). Each panel is sub-divided in two parts: one for lines that do not contain flammable gases and lines that might contain flammable gases.