Island e Beam case study

advertisement

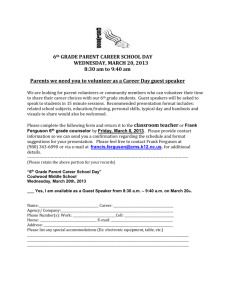

The Science of Success Edgecam enables Island e-Beam, LLC, to eliminate outsourcing while improving efficiency and part quality Understanding the science behind the products made at Island eBeam, LLC, may sometimes require an advanced degree — which is one reason why not many companies do what it does. As one of about a dozen businesses worldwide that manufacture electron beam sources and thermal evaporation equipment, Island e-Beam, LLC, of Bradenton, Florida, is filling a fruitful niche. About The Company: “We have a very diverse customer base that ranges from the low end to the high end,” says David Ferguson, owner of Island e-Beam, LLC. Name: Island e-Beam, LLC “On the high end, you have our OEMS that build complete PVD Business: manufacturing of electron beam (physical vapor deposition) systems, along with military and sources and thermal evaporation equipment aerospace applications,” he explains. “On the low end, you have the decorative and art industry.” Having spent his manufacturing career working for businesses that make similar products, Ferguson opted to branch out on his own in 2009, the year Island e-Beam, LLC, opened its doors. Website: islandebeam.com Benefits Achieved: The science behind the company’s products entails physical vapor • Eliminated outsourcing deposition, or PVD, by which electron beam sources are used within vacuum chambers to deposit thin coatings of vaporized materials • Increased part quality onto a range of items. • Toolpath remains associative to the High-voltage electricity (10kV) is used to accelerate a stream of CAD model electrons that have been generated by heating up a tungsten filament. That stream of electrons is captured, focused, and directed onto the material to be evaporated. Comments: Vaporization converts the material from a solid, into a vapor — and, “While machining with Edgecam is fast, I’m finally, back into a solid at the substrate in the form of thin layer of material, usually measured in angstroms. One angstrom is a unit of not as concerned with the time involved as I am with the part being correct. With length equal to one-billionth of a meter. Edgecam, the parts are correct.” The PVD process can be as simple as a single material coating, or as complex as a 180-layered beam-splitter coating. David Ferguson Owner After having grown tired of outsourcing the parts required to build his electron beam sources to local machine shops, Ferguson began to look at bringing the work in house. “The quality wasn’t there, the delivery wasn’t there, and the price wasn’t there,” Ferguson says of his outsourcing woes. “Inevitably, the parts would come in and the tolerance would be off, the tapped holes wouldn’t be right. We would usually just fix it here and be done with it because it was just easier that way.” Furthermore, the electron beam sources are made of materials that some machine shops don’t like to cut, including OFHC copper, stainless steel, mild steel, molybdenum, tantalum, tungsten, titanium, and others. “We only use vacuum-compatible materials to make the parts,” Ferguson says. “Not everyone wants to machine those materials, which is another reason why we wanted to bring the work in house.” To bring the work in house, Ferguson — who had never before worked with CNC machines — purchased a Haas VF-2 milling center. Following a lengthy struggle with his former CAM software, Ferguson also acquired the Edgecam computer-aided-manufacturing (CAM) solution by Vero Software to program the new Haas. “It was a constant battle,” Ferguson says of his former CAM solution. “Every time we would try to generate toolpath, there was always a glitch, and their tech support never fixed the problems.” When Edgecam representative Silverhawk Solutions showed Ferguson what the software could do, he was pleased with the solution’s functionality and ease of use. "Steve Harrison of Silverhawk Solutions came in and gave me a demonstration,” Ferguson says. “Some of the parts that we make are complex and, now that we can just drag in a solid, using the Edgecam software has been the easiest solution.” To create its solid models, the company utilizes computer-aideddesign solutions AutoCad, by Autodesk, and SOLIDWORKS, by Dassault Systèmes. Given that Edgecam is “CAD neutral,” it offers error-free interoperability with any CAD system. Without the need for data translation, Edgecam toolpath remains associative to the original design, retaining the integrity of the designer’s vision. With Edgecam’s ease of interoperability, the company’s solid models are easily imported into Edgecam, where the software automatically identifies features to be machined. “The parts we make are generally the same,” Ferguson says. “The only thing that varies is the size of the pockets, which is where you put the material to be vaporized.” Still, while the parts are alike, the task of hand programming would be difficult, if not impossible, and subject to human error. “We ran one job that probably had 1,000 lines of code, and I can’t imagine trying to program that by hand.” Dimensionally, a small electron beam source is 5"L x 6”W x 4” H and weighs about 6 pounds, while a large electron beam source is up to 12”L x 8”W x 5”H and 40 pounds. “Just to be able to machine a pocket with an angled wall in Edgecam is a great feature,” Ferguson says. “We’re not a production machine shop by any stretch. While machining with Edgecam is fast, I’m not as concerned with the time involved as I am with the part being correct. With Edgecam, the parts are correct.” Among the latest upgrades to the software is Edgecam Workflow, an easy-to-use interface that simplifies the task of managing a job. By approaching a job comprehensively — from cutting tools to stock management, fixtures and machining strategies — Workflow assists programmers in making the best choices for managing every step of the process. “As soon as we had Edgecam, we were very quickly able to machine a part with minimal hiccups,” says Ferguson, who implemented the solution in April of 2013. “The results were immediate. I’m very pleased with the Edgecam software, and with the support I have received. Steve Harrison and his team at Silverhawk Solutions have been great, with superb tech support whenever we need it.”