Supplemental Material

advertisement

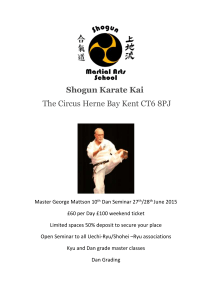

Supplemental Material to “The role of polarization-induced reorientation of DNA strands on bioFET sensitivity at high ionic strength” A. Device Fabrication The OCMFET can be considered as a modified floating gate transistor: the control capacitor is employed just for setting the operating point of the device. Noteworthy for avoiding the degradation of the organic semiconductor, the shape of the floating gate is elongated and all the biological events and procedures occur on one extremity, namely the sensing area, which is directly exposed to the environment, while the transistor area is protected. In Figure S1, the structure of the device is shown. The whole device is fabricated onto a flexible, transparent, 175 μm thick polyethylene terephthalate (PET, Goodfellow) substrate. The floating gate is patterned by means of a standard photolithography of a thermally evaporated aluminum film. The low operating voltages are reached by fabricating an ultra-thin, inorganic/organic gate dielectric, made by UV-grown alumina and Parylene C (Specialty Coating Systems) deposited by means of Chemical Vapor Deposition. The final thickness of the film is about 30 nm [1]. Source, drain, the top plate of the control capacitor and the sensing area are later patterned by photolithography of a thermally evaporated gold film. Gold was chosen as material for the sensing area as it is biocompatible and because standard functionalization techniques can be employed for the sensor specialization. Moreover, the characteristics of DNA strands on gold were widely investigated in several works [2][3][4][5]. A through-hole technique is performed in order to short circuit the sensing area and the floating gate. 6,13- Bis(triisopropylsilylethynyl)Pentacene (TIPS Pentacene, Sigma-Aldrich) was employed as p-type organic semiconductor. It was deposited onto the channel area (W/L = 950) by drop casting of a 0.5wt% solution of TIPS Pentacene in toluene; crystallization of the semiconductor was improved by letting the device dry at 90°C on a hot plate. B. Functionalization Procedure Before any biological procedure, the sensing area of the device was cleaned and sterilized with sodium hypochlorite. The functionalization of the sensing area with the DNA probes was performed by spotting a 100 nM solution of P24 in a 1 M potassium phosphate monobasic (KH2PO4, Sigma-Aldrich) buffer. After two hours, a 1 mM solution of 6-mercapto-1hexanol (MCH, Sigma-Aldrich) was spotted onto the sensing area. As demonstrated by Herne and Tarlov [2], MCH molecules act as spacer and prevent the probes folding. The device was then stored overnight in order to allow the selfalignment of the probes. 1 C. Hybridization Procedure Hybridization tests were performed at room temperature by spotting 100 nM solution of target sequences (T = 5’-CAC TAA GGG GCG GAA ACC-3’, Sigma-Aldrich) diluted in TE 1 M NaCl (10 mM Tris-HCl, 1 mM EDTA, 1 M NaCl, all reagents purchased by Sigma-Aldrich). References to Supplemental Materials [1] [2] [3] [4] [5] P. Cosseddu, S. Lai, M. Barbaro, A. Bonfiglio, App. Phys. Lett 100, 093305 (2012). T. M. Herne, M. J. Tarlov, J. Am. Chem. Soc. 119, 8916 (1997). R. Levicky, T. M. Herne, M. J. Tarlov, S. K. Satija, J. Am. Chem. Soc. 120, 9787 (1998). A. B. Steel, R. L. Levicky, T. M. Herne, M. J. Tarlov, Biophys. J. 79, 975 (2000). R. Lao, S. Song, H. Wu, L. Wang, Z. Zhang, L. He, C. Fan, Anal. Chem. 77, 6475 (2005). 2 FIGURE S1 FIG. S1. (a) Cross section and 3D cartoon of the low voltage OCMFET; the employed materials are reported in the palette; (b) electric symbol of the OCMFET. 3