Demonstrating the Production and use of Eco paper bags for

advertisement

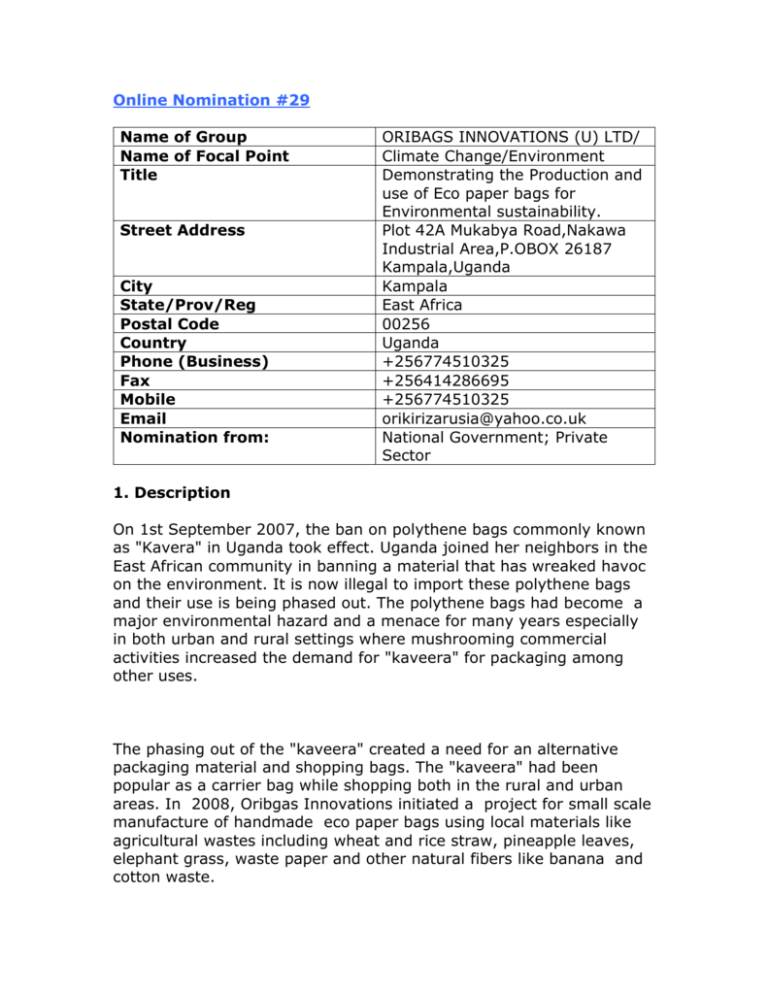

Online Nomination #29 Name of Group Name of Focal Point Title Street Address City State/Prov/Reg Postal Code Country Phone (Business) Fax Mobile Email Nomination from: ORIBAGS INNOVATIONS (U) LTD/ Climate Change/Environment Demonstrating the Production and use of Eco paper bags for Environmental sustainability. Plot 42A Mukabya Road,Nakawa Industrial Area,P.OBOX 26187 Kampala,Uganda Kampala East Africa 00256 Uganda +256774510325 +256414286695 +256774510325 orikirizarusia@yahoo.co.uk National Government; Private Sector 1. Description On 1st September 2007, the ban on polythene bags commonly known as "Kavera" in Uganda took effect. Uganda joined her neighbors in the East African community in banning a material that has wreaked havoc on the environment. It is now illegal to import these polythene bags and their use is being phased out. The polythene bags had become a major environmental hazard and a menace for many years especially in both urban and rural settings where mushrooming commercial activities increased the demand for "kaveera" for packaging among other uses. The phasing out of the "kaveera" created a need for an alternative packaging material and shopping bags. The "kaveera" had been popular as a carrier bag while shopping both in the rural and urban areas. In 2008, Oribgas Innovations initiated a project for small scale manufacture of handmade eco paper bags using local materials like agricultural wastes including wheat and rice straw, pineapple leaves, elephant grass, waste paper and other natural fibers like banana and cotton waste. Oribags innovations is a private enterprise operating in Uganda,Kampala. Our vision is to be the leading producer of environmentally friendly products/services in the region. The company derives its experience from its founders in particular Mrs.Orikiriza Rusia Bariho who started making beads from local materials while still a student in 2005 .This initiative grew out of research and development started since 2007. These paper bags have become a good alternative to the environmentally hazardous polythene bags and have demostrated potential for employment creation for many Ugandans especially women and youth. The project has since been supported by the Uganda Industrial Research Institute (UIRI)- a government research body under its incubation programme.Despite the limited capacity, the project has demonstrated sound environmental responsibility and the potential of small innovative projects for employment creation. Oribags purchases these materials locally from farmers and other groups and proceses them at an incubation centre at the Uganda Industrial Research Institute .Currently, products are marketed locally. In the near future, we intend to export some of the products to other countries in East Africa,to America and Europe.The company hopes to acquire its own home with in five years. 2. Main Partners Our key stake holders include the Uganda Industrial Research Institute (UIRI) that has supported and incubated us for product improvement and marketing.UIRI provided seed funding for this project in addition to technical assistance under its business incubation programme.UIRI has also sponsored us for various trade fairs where we have marketd the eco paper bags and created environmental awareness. The Uganda Women Entrepreneurs Association Limited (UWEAL) has made graet contributions for constant entrepreneurship and business oriented trainings. UWEAL has also served as a constant inspiration and motivation by recognizing the company’s entrepreneurial efforts through its “Rising star Award.” The New vision and DFCU Bank: The 2010 nationwide search for women achievers has given Oribags additional capital through its prize of Ugshs. 2,000,000 when Orikiriza Rusia Bariho one of the company proprietors was awarded as the second best woman Achiever of the year. NTV Uganda-a national media group: by featuring the company and its works in its latest environmental programme “Eco Talk”: Technologies that save the environment”. 3. Achievements The project has created awareness all over the country. We have so far atteed over 15 exhibition fairs in the country and in the neighbourhood countries in Rwanda and Southern Sudan. The project creates direct employment each year. Currently the project employs, 10 workers who are youth and women. With increase capacity, the initiative hopes to employ 20 workers by 2012. Most of these youth are out of school youth who cannot afford to go to college. Some are unemployed mothers who are idle at home, and thus, decided to create additional income by working with Oribags. Oribags also creates increase in income of women who augment their monthly wages when they enter into reselling the eco paper bags. We normally give a standard 10% discount for women who become resellers. These women will either sell at the suggested retail price or overprice a little. As it continues to expand, this project will help to provide employment to its suppliers and the people in the community. With increased capacity the project has potential of creating employment for over 300 people. The project also outsources tasks which are not directly related to paper bags making. Thus, it will time overtime provide jobs for carpenters, painters, graphic artists, photographers, printers, drivers, freight forwarders to support daily operations. Currently Oribags purchases raw materials from 4 farmers who own families of 7 people each. The project currently employs 10 people who also support their families .We have so far trained 4. Sustainability Oribags is focused on building a team of hard working talented individuals and communities to keep the project focused on this most productive and profitable industry. The local availability of raw materials provides great sustainability for this project. Our raw materials are locally available and through our production is on the other hand a recommeded method of proper waste disposal by recycling. Traditionally the challenge is that no single firm in Uganda is commercially involved with primary packaging production technologies through exploitation of indigenous raw materials such as waste paper,cotton waste, banana fiber, pineapples peels, baggase and sisal. The Government’s commitment on ban of low density polythene bags commonly known as “Kaveera”as packaging materials provides great an opportunity to gain wider audience as local innovative manufactures of biodegradable and environemntally friendly packaging bags. The project builds the capacity of local entrepreneurs especially youth and women, through training.Over 1000 youth and women have been trained in this technology.It is hoped that in futre this project can be owned by various communities to produce products for themdselves.this requires adquate capacity building. 5. Innovation The project utilizes locally available materials which rather are considered as waste like waste paper, pineapple crowns, and rice straws to output products of high value. Also it involves local participation of grassroots communities to develop the products. It also presents a novel method of proper waste disposal through reuse and recycling. The project also aims at introducing, implementing and promoting innovative approaches for environmental sustainability while putting commercial considerations into account. The project is innovative in terms of addressing new issues or themes, utilizing new methods and technologies and/or involving new and disadvantaged target groups to alleveiate poverty from communities. 6. Replicability Oribags recognizes primary packaging production to be a new niche and the best prospect for Uganda in the medium to long term. It is against this background that efforts are being geared to this project so as to specialize in producing complete ready-made primary packages for end-users. This industry has great prospects to grow as local production of these materials is abundant. The whole of the country is engaged in agriculture and there for materials is available country wide. Small paper plant can be established in each of the districts.Our neighboeirng country Rwanda already passed a ban on the use of polythene bags. Our recent exhibition in Kigali Rwanda indicated great need for this technology. The project has potential of replication in all the East African Countries. But first in Uganda, replication is possible through · Establishment eco paper bags pilot plant that will serve as training plant for private and public actors for paper and paper bags making that should beat 40tonnes of pulp per day and employ over 50 people · Diversification of products · Commercialisation of products on small scale · Exploration of export markets in the East African region,Europe and America · Training of over 1000 youth and women in paper making technology as an entrepreneurial skill. All these can be achieved through · Acquisition of modern paper bags making equipment and machinery.Currently the production process is labour intesive · Assistance with the capacity building and training in modern paper making technology · Support to influence the Ugandan market realise the need for environmentally friendly packaging bags. · Financial assistance to demostrate the project to a wider market · Market study for products in other neighbouring countries, · feasibility study of the project in other districts of Uganda, · Availability of skill and manpower, · Lobby more government support to grow the project and create more awareness 7. Contribution Women and youth Empowerment – mostly women and youth work with Oribags. This year,the project employs 10 people.With increased capacity,the project hopes to create employment for 20 people by 2012. We have also conducted training for over 1000 women and youth in in this skill and setting up small businesses .The project also provides additional income to women farmers who supply materials for processing. Employment for Especially abled –some processes of Paper bags making do not require physical prowess. In Oribags, we can employ specially abled persons such as vertically challenged or deaf-mute people since most of the training done are demonstrations. Gender Sensitive –The project hires people regardless of their sexual orientation. We employ men, women, orphans or even those affected by HIV/AIDS. As long as they can do the job, they’re hired. Direct Employment - At present, the project is employing 10 regular staff including 2 Plant workers. It plans to hire additional 10 staff when it sets up apaper bags factory . Most of these are out of school youth who cannot afford to go to college. Some are unemployed mothers who are idle at home, and thus, decided to create additional income by working for us. The company will also create increase in income of women wanting to augment their monthly wages when they enter into Oribags as resellers. The company will give a standard 10% discount based on its retail price when they become resellers. These women will either sell at the suggested retail price or overprice a little. As it continues to expand, the project will help to provide employment to its suppliers and the people in its community. The company outsources tasks which are not directly related to paper bags making. Thus, it will time overtime hire carpenters, masons, painters, graphic artists, photographers, printers, drivers, freight forwarders to support its daily business operations. Oribags provide skills to its workers which can never be taken away from them. A week’s training at the plant will produce a skilled worker who can do most of the techniques used in producing paper bags. Previously out-of-school youth, have been able to set aside some money and enrol in vocational schools in the evening while working at the plant by day. Also we have often connected them to benefit from short course trainings provided by UIRI, our incubator. Unemployed mothers who used to ask milk-money from their in-laws can now buy their own milk for their babies, and set aside money for their daily needs. The constant quest for excellence by the company has also imparted to its workers the values of: orderliness, efficiency, teamwork, punctuality and thriftiness. The project produces environmentally friendly products, the biodegradable paper bags. Also the project promotes the proper methods of disposal of waste through reuse and recycling 8. Awareness At present, our major arm of creating awareness is through trade fairs and exhibitions which we normally attend courtesy of UIRI’s support. They are staged mostly in Kampala, but some are held outside like in Mbale, Mbarara and Jinja. Recently UIRI also sponsored us for international exhibition in Kigali, Rwanda. The project has also organised various awareness workshops targeting the entire population promoting the use of biodegradable paper bags. We have also hosted many visitors who visit the small production plant time over time thus creating awareness.. As usual we intend to consolidate our participation in exhibitions both locally and internationally and this is possible with support from Uganda Industrial Research Institute and the south south cooperation. The project has created more awareness through television presentations. Recently the project was aired on NTV Uganda,a regional television on its environmental program “ eco talk” technologies that save the environment. The project intends to develop its own website through which we outreach more people. The project has also featured in various media including, the new vision, the daily monitor in Uganda. Having acquired the necessary capacity we intend to acquire an advertising van in the city Kampala always moving around advocating for the use of biodegradable packaging bags as paper bags made by Oribags branded “made in Uganda.” Oribags will also strengthen its public relations and marketing department. 9. Other The project is now seeking partnership,nationally, regionally and internationally to advance and upscale this project.The technology is feasible and this has already been demostratated.Though this project is still nascent,it has created impact and has demostrated great environmental rensponsibility and if supported it has potential to contribute graetlt to sustainable development including employment creation.Currently the project requires about $600,000 to up scale this project and create more impact.The production is currently very labour intensive. we currently use rudimentally methodsin the production process.these funds will assist as aquire modern equipment and machinery to boost this innovation.