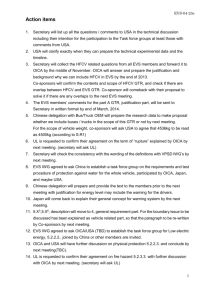

EVS-04-05e

advertisement

Summary of discussion points on OICA draft, 3rd EVS meeting EVS-04-05e Clause Items Summary of discussion at the 3rd EVS meeting [not fully discussed comments in red] General issue SOC for REESS testing Currently proposed by OICA at 50% SOC, Japan made a counterproposal to perform tests at 95% SOC (Reference document - EVS-03-16e.doc). Japan made a presentation summarizing the SOC applied in battery tests in various standards which indicated that 80-100% SOC is commonplace. China and US agreed that 50% SOC is not sufficient. OICA will reconsider this proposal. Japan indicated their presentation would be made available on the IG website(Reference document - EVS03-22e.xls). 3. Definitions 3.3. 3.31. Cell Rupture Clarification is required for the definition of (fuel) cell and rupture. OICA will look how terms are used in document and will modify definitions if appropriate. 3.9. Electric power train Korea Comment [Need for a definition of a traction motor?] 5.1.1.2.4. Isolation resistance 5.1.1.2.4. 1. Electric power train consisting of separate Direct Current or Alternating Current buses. UL comment [How is the use of a wiring harness proof of meeting the criteria in a) below? How is it determined that the protections are robust enough to last over the vehicle service life as noted in item b) below? How are motor housings electronic converter cases or connections determined to Page1 of 8 Comments from OICA Summary of discussion points on OICA draft, 3rd EVS meeting EVS-04-05e meet this criteria?] UL comment [How is it determined whether or not isolation resistance requirements can be maintained over time? This statement seems a bit ambiguous. There should always be two levels of protection from electric shock and they should be still functional after testing.] 5.1.1.2.4. 2. Electric power train consisting of combined DC- and ACbuses Korea Comment [Note: FMVSS 305 requires the isolation monitoring system in the case there the lower level of isolation resistance is used.] 5.2.2. Protection against electric shock UL comment [Does this mean that Isolation Resistance does not need to be met if there are multiple parts of the high voltage bus exposed? I think that the statement needs to be re-worded to clarify the intent.] UL comment [The requirements in 5.2.2.1 currently limit the voltage within 1 minute to the values noted in 5.2.2.1. Is there a peak limit value of voltage prior to the 60 seconds?] 5.2.2.2. Low electrical energy The US questions the value cited for minimum energy causing a safety concern (i.e. 0.2 J). The IG chairman agreed with OICA to organize a teleconference to address this topic specifically. All member of the IG are welcome to participate. 5.2.2.3. Physical protection The US requested OICA to quantify the likelihood of occurrence of the direct contact scenarios described by NHTSA. OICA will provide more data for this. 5.2.2.4.2. Electrical power train consisting UL comment [There should be no evidence of fire or explosion without consideration of time frame. What Page2 of 8 Summary of discussion points on OICA draft, 3rd EVS meeting EVS-04-05e of combined DC- and AC buses about safety of first responders?] Korea comment [Note – comment about measurement of isolation loss in RESS – diagrams in the test section may not cover this adequately] 5.2.3.3. Fire hazard UL comment [There is no requirement for RESS exposure to water such as what may occur is located towards the bottom of a vehicle and driven through flooded viaducts. Why hasn’t this been considered, as there is evidence of field problems due to flooding of EVs in the US? Recommend including the immersion test or something similar from SAE J2464. It may be good to consider partial flooding as a potential field incident that could occur to an RESS located in a vehicle in a location that may be subject to flooding exposure such as underbody locations.] 7.1.5. Test conditions and test procedure regarding post-crash 7.1.5.2.6. Electrolyte leakage 7.2.2. Vibration test 7.2.2.1. Purpose US comment [Very much agree – but that is not called out in 7.2.2.3] 7.2.2.2. Installation -wording “REESS” US comment [Explain – cells and connectors are not representative nor acceptable in these tests – only exception believed appropriate is where the RESS were divided into more than one unit on the vehicle and in that case both/all units would be tested] Korea comment [note – what is an appropriate coating? – specification needed? Gas sampling to detect electrolyte vapor? Difficult to measure on vehicle. Treat gas emissions in the environmental restrictions on hazardous substances? How is leakage measured?] Page3 of 8 Summary of discussion points on OICA draft, 3rd EVS meeting 7.2.2.2. - wording “Test device” 7.2.2.3.2.2. Test procedures EVS-04-05e US comment [Call out stiffness requirements in engineering terms – ratios and ranges.] The vibration test procedure from UN 38.3 is used by OICA however different values for the vibration profile are used to make it representative of battery real-life application. The US requested more information on how representative this profile is of application in a vehicle and also why a test duration of 3 hours is chosen. OICA will provide data on this. US comment [Regarding an observation period of 1h, 10 days or more, latent failures are issue] US comment [Regarding the test environment, device must be tested for normal functionality via cycle testing] 7.2.3. Thermal shock and cycling test 7.2.3.1. Purpose US comment [It is an environmental stress test used in evaluating product reliability as well as in manufacturing to catch early-term, latent defects by inducing failure through thermal fatigue. As a safety performance test it should be used to “stress the system” as done in development, As the OEMs are performing 40 cycle tests the acceptance criteria should be no less than 25 cycles – the 5 cycle test called out is meaningless. The test should be done with the case/enclosure open or removed and the RESS should be test cycled for functionality] 7.2.3.3. Procedures Following discussions, OICA will provide data supporting their suggested temperature range i.e. -40 to +60C, other standards (ISO, SAE) use higher upper Page4 of 8 Summary of discussion points on OICA draft, 3rd EVS meeting EVS-04-05e temperatures. Questions also arose about the rationale for the number of temperature cycles (only 5), the upper temperature limit at +60 C instead of +80 C and the duration of the observation period. NHTSA research will perform tests starting with 25 cycles – the results will be shared with the IG as far as available. US comment [Regarding an observation period of 1h, 24 hour min] Korea comment [what about presence of smoke? – what about heat rise? Observation time interval - 1hr? Longer?] 7.2.4. Mechanical shock test 7.2.4.3.2. Test procedure Korea comment [Table 3 Values for category 1-1 vehicles: May be a challenge to conduct this test for heavy battery systems – subject to test equipment capabilities] 7.2.5. (5.3.4.2.) Mechanical integrity test Korea comment [Need to address test procedures to be acceptable for self-certification environment] 7.2.5.2. Installation -wording REESS US comment [Complete RESS only – this makes no sense in sub-component] 7.2.5.3.2. Crush test US comment [Inadequate. Crush test, along with mechanical Shock, have been the subject of extensive debate, and little data. Therefore, this has been the subject of one of NHTSAs research projects that is defining this more completely. ] 7.2.6. Fire resistance test 7.2.6.3.2. Test procedure The US considered the test duration (60 + 70 seconds) is too short to be representative of realistic fire scenario. OICA commented that the duration represents scenario Page5 of 8 Summary of discussion points on OICA draft, 3rd EVS meeting EVS-04-05e where persons inside a burning vehicle have time to evacuate. The OICA proposal is based on the established UN R34 gasoline pool fire. ALLIANCE only observed bonfire tests where battery underwent a benign controlled burn. NHTSA is sponsoring research on battery fire including gas release analysis and will have the updated information later. Japan commented that an EV would probably have a similar risk in a fire compared to diesel ICE however the risk from high pressure gas (eg in H2 vehicle) is a bigger concern. Discussion on this issue will continue as research data becomes available. Korea comment [For a component based test, 7.2.6.3.2.2. Component based test A or 7.2.6.3.2.3. Component based test B. can be chosen.] [7.2.6.3.2.2. Component based test A a. Install the Tested-Device on the fire resistance test device by the horizontal to the ground. b. Install 5 or more temperature sensors in the whole area of the Tested-Device can be represented with the height of 25mm±10mm from the bottom of the TestedDevice's external surface by the vertical direction. c. Heat the entire lower part of battery equally and directly through fuel combustion. d. Increase the temperature to 800°C within 30 seconds, cease the heating 2 minutes after reaching 800°C. Complete the test after 2 hours passes. However, the temperature shall not exceed 1,100oC. e. Check if there is any explosion on the TestedDevice during the test. Page6 of 8 Summary of discussion points on OICA draft, 3rd EVS meeting EVS-04-05e 7.2.6.3.2.3. Component based test B The Tested-Device shall be placed on a grating table positioned above the pan, in an orientation according to the manufacturer’s design intent. The grating table shall be constructed by steel rods, diameter 6-10 mm, with 4-6 cm in between. If needed the steel rods could be supported by flat steel parts.] 7.2.7. External short circuit protection 7.2.7.3. Procedures 7.2.9. Over-discharge protection test 7.2.9.3. Procedures 7.2.10. Over-temperature protection test 7.2.10.3. Procedures Discussion arose concerning the chosen resistance of the short (i.e. 5mΩ). OICA will include a rationale for this choice. OICA propose this test with the over-discharge protection system installed in order to demonstrate the functionality of this system. Korea questioned the suitability of this test (discharge down to 25% nominal voltage) for super capacitors or flywheels. The IG will decide what REESS devices will be included in GTR and OICA will then propose any required modifications for tests. The US questioned the rationale for the 1 hour observation time. OICA enquired as to a counterproposal but this would not be agreed during this meeting. It was questioned why a specific temperature e.g. 60 C or higher is not suggested in this test. OICA indicated Page7 of 8 Summary of discussion points on OICA draft, 3rd EVS meeting EVS-04-05e that this may be design restrictive but they would consider specifying a temperature. Others Hydrogen emissions Japan suggested inclusion of this requirement to cover emissions from aqueous electrolyte (open) type batteries e.g. lead acid. While not currently commonplace this type of battery may be used for traction purposes. OICA will introduce this as part of the draft. The EU questioned the need for international harmonisation efforts if technology will only be applied in some markets. Page8 of 8