msds for stampcrete high gloss clear sealer

advertisement

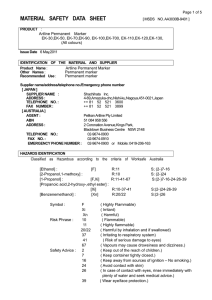

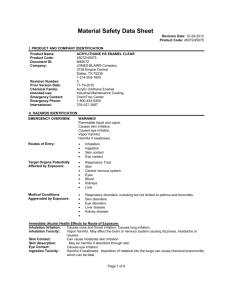

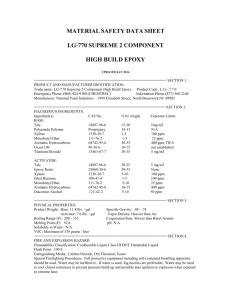

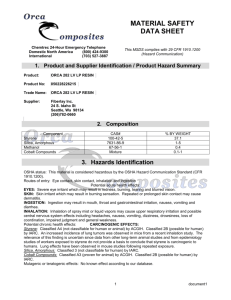

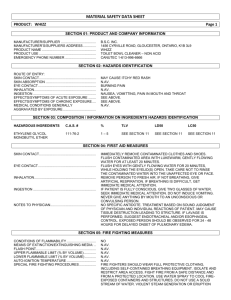

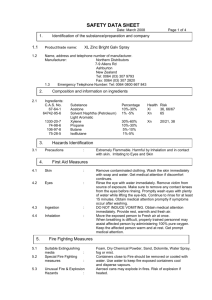

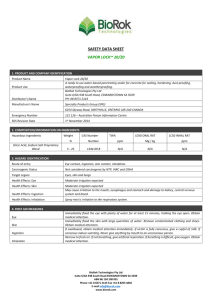

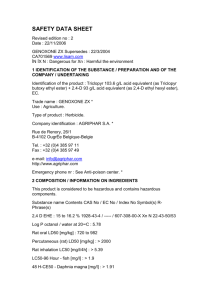

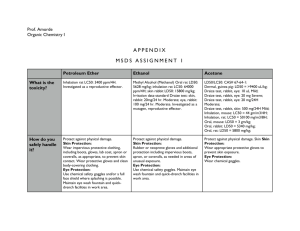

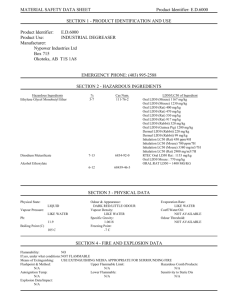

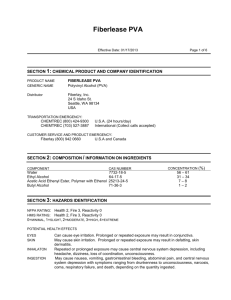

STAMPCRETE CLEAR ACRYLIC SOLVENT BASE HIGH GLOSS CONCRETE SEALER MATERIAL SAFETY DATA SHEET — 16 Sections SECTION 1 — CHEMICAL PRODUCT AND COMPANY IDENTIFICATION Product Identifier STAMPCRETE ACRYLIC HIGH [WHMIS Classification] GLOSS CLEAR SEALER Health 2 Flammability 3 Reactivity 0 Product Use CLEAR COATING FOR SEALING CONCRETE Manufacturer’s Name Solvents & Petroleum Service, Supplier’s Name Inc. STAMPCRETE Street Address 325 Commerce Blvd Street Address 1405 Brewerton Road City Syracuse Postal Code 13208 State New York Emergency Telephone 800 315 City Liverpool Postal Code 13088 State New York Emergency 4467 Telephone 800 451 9037 Date MSDS Prepared June 4, 2015 MSDS Prepared By Phone Number 412 726 Erwin Ratajczak 2986 SECTION 2 — COMPOSITION/INFORMATION ON INGREDIENTS Hazardous Ingredients (specific) Xylene, mixed isomers % 40 to 60% CAS Number 1330-20-7 LD 50 of Ingredient (specify LC 50 of Ingredient (specify species and route species) LD50 oral rat 4300 mg/kg LC50 inhalation gas cat 9500 ppm LD50 oral mouse 2119 mg/kg LC50 inhalation gas rat 5000 ppm Ethyl benzene 8 to 12% 100-41-4 LD50 dermal rabbit >5000 mg/kg LD50 oral rat 3500 mg/kg No data available –2– Cumene 0.22 to 0.3% 98-82-8 LD50 dermal rabbit 12300 LC50 inhalation vapor 10 g/m3 microliter/kg LD50 oral rat 2.9 g/kg LD50 oral rat 4000 mg/kg Aromatic 100 10 to 20% 63231-510-6 LD50 oral rat >5g/kg LC50 inhalation rat 1970 ppm/4 hours SECTION 3 — HAZARDS IDENTIFICATION Route of Entry ❐ ❐ Skin Skin Absorption ❐ Eye Contact ❐ Inhalation ❐ Ingestion Contact [Emergency Overview] WHMISSymbols] Health 2 Flammability 3 Reactivity 0 Potential Health Effects Skin Contact: Contact may cause mild skin irritation including redness, burning, drying and cracking of skin. Continued exposure may develop into dermatitis Skin Absorption: Eye Contact: Inhalation: ingestion: Solvents can penetrate the skin and cause systematic effects similar to those of inhalation symptoms. Contact with eyes may cause irritation including burning, watering and redness. High vapor concentrations are irritating to the eyes and respiratory tract. Also may cause headache dizziness and drowsiness Can cause gastrointestinal Irritation, nausea, Vomiting and diarrhea SECTION 4 — FIRST AID MEASURES Skin Contact Thoroughly wash exposed area with soap and water. Remove contaminated clothing. Launder contaminated clothing before reuse. If irritation develops and persists, seek medical attention. Eye Contact: Flush with water for at least 15 minutes while holding eye lids apart. Get medical attention immediately Inhalation: Move to fresh air. If required, give artificial respiration or administer oxygen by trained personnel. Avoid further over exposure. If symptoms persist, get medical attention. –3– Ingestion: Do not induce vomiting unless advised by a physician. Call nearest poison control center or physician immediately. Product Identifier SECTION 5 — FIRE FIGHTING MEASURES Flammable If yes, under which conditions? ❐Yes Vapor concentrations in enclosed are may ignite explosively. Product may ignite if heated in excess of it flash point. Vapors may travel to source of ignition and flash back. Closed containers may burst when exposed to extreme heat Empty containers may contain ignitable vapors. Means of Extinction For small fire use dry chemical powder extinguisher. For large fire, use alcohol foam water spray or fog Cool containing vessels with a water jet in order to prevent pressure build up, auto ignition or explosion. Flashpoint (° C) 24 degrees C Closed cup 75.2 F 37.8 degrees C open cup 100 degree F and Method Auto ignition 400 degrees C 752 degrees F Temperature (°C) Upper Flammable Lower Flammable Limit (% by volume) Limit (% by volume) 12.3% 1.9% Explosion Data — Explosion Data — Sensitivity to Impact Sensitivity to Static Discharge Hazardous Combustion Carbon monoxide, carbon dioxide and acrylic monomers Products [NFPA] Health 2 Flammability 3 Reactivity 0k SECTION 6 — ACCIDENTAL RELEASE MEASURES Leak and Spill Procedures Keep all sources of ignition and hot metal surfaces away from the spill or release. Use explosion proof non-sparking equipment. Stay upwind from area. Isolate danger and keep nonauthorized personnel out. Stop source of leak or spill if possible with minimum risk. Prevent spill from entering sewers, storm drain or any other unauthorized treatment system and natural waterways by diking ahead of the spill or leak. Always wear appropriate protective equipment including respiratory protection. Spilled material may be absorbed with an appropriate spill kit. Notify fire authorities and appropriate federal, state and local authorities if required. SECTION 7 — HANDLING AND STORAGE Employees who come in contact with this material must be trained in accordance with 1910.1200 of the Hazard Communication Standard. Open container slowly to relieve any pressure. Bond and ground all equipment when transferring from one vessel to another. Static charge can accumulate by flow and agitation. Ignition can occur by static discharge. The use of explosion proof equipment is required. The use of respiratory protection is advised when concentration exceed any established exposure limits and in confined spaces. Use good industrial and personal hygiene practice. Wash thoroughly after handling and do not wear contaminated clothing. Keep containers tightly closed. Use and store in a cool dry and well ventilated areas away from heat. Post no smoking or open flame signs. Keep away from incompatible materials. Protect containers from physical damage. Indoor storage should meet OSHA standards and appropriate fire codes. Empty containers from all residue, liquids and vapors. All containers should be disposed of in –4– an environmentally safe manner in accordance with all government regulations SECTION 8 — EXPOSURE CONTROL / PERSONAL PROTECTION Exposure Limits ❐ ACGIH TLV ❐ OSHA TLV Xylene ACGIH TWA 100ppm 8 hour Xylene TWA 100 ppm 8 hours TWA 434 mg/m3 TWA 435 mg/m3 STEL 150 ppm 15 minutes STEL 651 mg/m3 Ethyl benzene ACGIH TWA 100 ppm 8 hours TWA 100 ppm 8 hours TWA 435 mg/m3 Aromatic 100 ACGH TWA 19 ppm 8 hours STEL 100mg/m3 TWA100 ppm 8 hours TWA 435 mg/m3 Specific Engineering Controls (such as ventilation, enclosed process) Personal Protective Equipment Respiratory Protection: Engineering or administration controls should be implemented to reduce exposure. A NIOSH//MSHA approved respirator with organic vapor cartridge should be used under conditions where airborne concentrations are expected to exceed exposure limits. Use a positive pressure air supplied respirator if there is potential for uncontrolled release, exposure levels are not known, or any other circumstances where air purifying respirators may not provide adequate protection Ventilation: If current ventilation are not adequate to maintain airborne concentrations below the established exposure limits, additional ventilation or exhaust systems may be required. Where exposure mixtures may be present, explosion proof electrical systems safe for such locations must be used. Protective Gloves: Prevent prolonged and repeated contact by wearing gloves impervious to solvents. Eye Protection: Always wear safety glasses to reduce eye contact potential. Chemical goggles (ANSI Z87.1 or approved equivalent) are appropriate if splashing is likely. Eye wash stations must be available where eye contact can occur. Other Protective Clothing and Equipment: A source of clean water should be available for flushing skin Shower stations to should be available in case of larger spills. Contaminated clothing should be laundered before reuse. Work and Hygienic Practices: Efforts should be made to minimize contact and spills. Always wash hands before eating, drinking or smoking. Clean up spills promptly. Follow OSHA and company guidelines. –5– Product Identifier SECTION 9 — PHYSICAL AND CHEMICAL PROPERTIES Physical State Liquid Odor and Appearance Aromatic and clear liquid Odor Threshold (ppm) Not measured Specific Gravity 0.922 Vapor Density (air = 1) 3.8 Vapor Pressure (mmHg) 14.2 mm Hg @ 20 degrees C Evaporation Rate Lower than n-butyl acetate Boiling Point (° C) 143 to 147 degrees C Freezing Point (° C) Not applicable pH :Not applicable Coefficient of Water/Oil Distribution Not measured [Solubility in Water] negligible SECTION 10 — STABILITY AND REACTIVITY Stablility: Stable under normal conditions Conditions to Avoid: All possible sources of ignition Incompatibility (materials to avoid): Avoid exposure to strong oxidizing agents and reducing agents Hazardous Decomposition or BY Products: carbon monoxide, carbon dioxide and various oxides of carbon and nitrogen Hazardous Polymerization: Will not occur SECTION 11 — TOXICOLOGICAL INFORMATION This product contains ethyl benzene. A study conducted by the National Toxicology Program states that lifetime inhalation exposure of rats and mice to high concentrations of ethyl benzene (750 ppm) results in increases in liver tumors in mice. These effects were not observed in animals exposed to concentrations of ethyl benzene (75 ppm or 250 ppm). The study does not address the relevance of these results to humans. Prolonged or repeated skin contact with this product tends to remove skin oils, possibility leading to irritation and dermatitis. However, based on experience and available toxicological data, this product is judged to be neither a corrosive nor an irritant by OSHA criteria. This product will cause eye irritation when in contact with eyes. This product has a low order of acute oral and dermal toxicity, but minute amounts aspirated into the lungs during ingestion or vomiting may cause mild to severe pulmonary injury and possibly death. This product is judged to have an acute oral LD50 (rat) greater than 5 grams per kilogram of body weight and an acute dermal LD50 (rabbit) greater than 3.16 grams per kilogram of body weight. SECTION 12 — ECOLOGICAL INFORMATION This material is expected to be toxic to aquatic organisms. It may cause long term adverse effects in the aquatic environment. This material is volatile and will partition rapidly in air. It is not expected to partition in sediment and waste water solids.. There is no significant transformation due to hydrolysis and phot –6– SECTION 13 — DISPOSAL CONSIDERATIONS This is considered a RCRA hazardous waste due to the characteristics of D001 (ignitability). Waste is subject to land disposal restrictions in 40 CRF 268.40 and may require treatment standards. Consult state and local regulations to determine whether there are more stringent regulations than federal requirements. Container contents should be completely used and containers empty prior to discarding. Container residue is considered a RCRA hazardous waste and must be discarded in compliance with all applicable regulations. Larger empty containers such as drums, should be returned to a professional drum reconditioner. To assure proper disposal of smaller empty containers, consult with state and local regulations and disposal authorities. SECTION 14 — TRANSPORT INFORMATION Special Shipping Information Proper DOT Shipping Name Combustible liquid. Not regulated in containers 119 gallons (450 liters) or less and ground transportation. For containers greater than 119 gallons or air transport: UN1139, Coatings Solution, 3, III. SECTION 15 — REGULATORY INFORMATION Reportable Quantity (RQ), EPA regulation 40 CRF 302 (CERCLA Section 102: The RQ for xylenes is 100 pounds This product contains up to 60% XYLENE AND 20% Aromatic 100 The RQ for ethyl benzene 1000 pounds. This product contains up to 15% ethyl benzene. .Threshold Quantity (TPQ) , EPA regulation 40 CRF 355 (SARA Sections 301-304): No TPQ for product or any constituent greater than 1% or 0.1% Toxic Chemical Release Reporting, EPA regulation 40 CFR 372 (SARA Section 313): This product contains up to 60% xylene, 20% aromatic 100 and 15% ethyl benzene Hazardous Chemical Reporting, EPA regulation 40 CFR 370 (SARA Sections 311-312): EPA Classification Codes: Acute, Chronic, Fire. Toxic Substances Control ACT (TSCA): This product does not contain polychlorinated biphenyls (PCB’s) All components of this product are listed on the U.S. TSCA Inventory. –7– SECTION 16 — OTHER INFORMATION The information and recommendations are offered for the user’s consideration and examination. It is the user’s responsibility to satisfy itself that they are suitable and complete for its particular use. If the buyer repackages this product, legal counsel should be consulted to insure proper proper health and safety and necessary information is included on the container.