Understanding AS5034–2005 Installation and use of inert gases for

advertisement

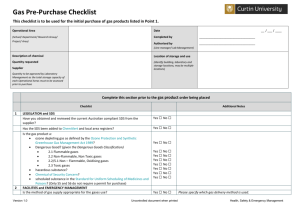

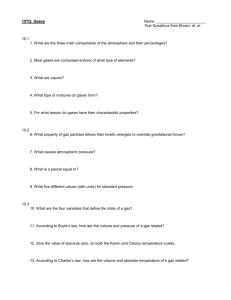

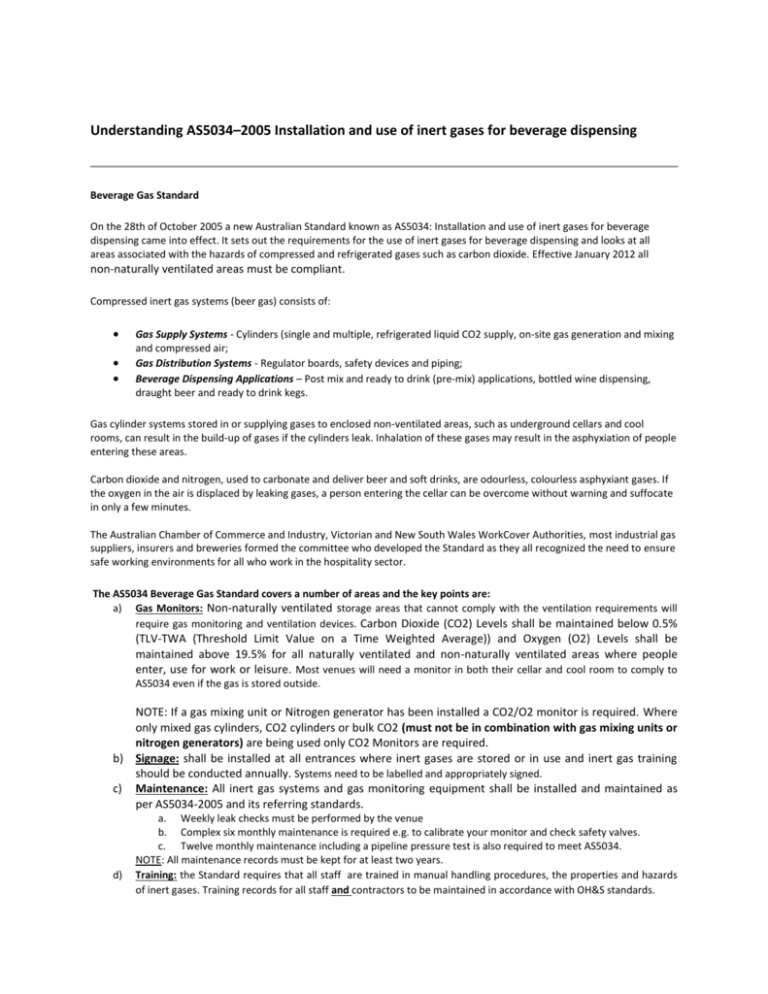

Understanding AS5034–2005 Installation and use of inert gases for beverage dispensing Beverage Gas Standard On the 28th of October 2005 a new Australian Standard known as AS5034: Installation and use of inert gases for beverage dispensing came into effect. It sets out the requirements for the use of inert gases for beverage dispensing and looks at all areas associated with the hazards of compressed and refrigerated gases such as carbon dioxide. Effective January 2012 all non-naturally ventilated areas must be compliant. Compressed inert gas systems (beer gas) consists of: Gas Supply Systems - Cylinders (single and multiple, refrigerated liquid CO2 supply, on-site gas generation and mixing and compressed air; Gas Distribution Systems - Regulator boards, safety devices and piping; Beverage Dispensing Applications – Post mix and ready to drink (pre-mix) applications, bottled wine dispensing, draught beer and ready to drink kegs. Gas cylinder systems stored in or supplying gases to enclosed non-ventilated areas, such as underground cellars and cool rooms, can result in the build-up of gases if the cylinders leak. Inhalation of these gases may result in the asphyxiation of people entering these areas. Carbon dioxide and nitrogen, used to carbonate and deliver beer and soft drinks, are odourless, colourless asphyxiant gases. If the oxygen in the air is displaced by leaking gases, a person entering the cellar can be overcome without warning and suffocate in only a few minutes. The Australian Chamber of Commerce and Industry, Victorian and New South Wales WorkCover Authorities, most industrial gas suppliers, insurers and breweries formed the committee who developed the Standard as they all recognized the need to ensure safe working environments for all who work in the hospitality sector. The AS5034 Beverage Gas Standard covers a number of areas and the key points are: a) Gas Monitors: Non-naturally ventilated storage areas that cannot comply with the ventilation requirements will require gas monitoring and ventilation devices. Carbon Dioxide (CO2) Levels shall be maintained below 0.5% (TLV-TWA (Threshold Limit Value on a Time Weighted Average)) and Oxygen (O2) Levels shall be maintained above 19.5% for all naturally ventilated and non-naturally ventilated areas where people enter, use for work or leisure. Most venues will need a monitor in both their cellar and cool room to comply to AS5034 even if the gas is stored outside. NOTE: If a gas mixing unit or Nitrogen generator has been installed a CO2/O2 monitor is required. Where only mixed gas cylinders, CO2 cylinders or bulk CO2 (must not be in combination with gas mixing units or nitrogen generators) are being used only CO2 Monitors are required. b) Signage: shall be installed at all entrances where inert gases are stored or in use and inert gas training should be conducted annually. Systems need to be labelled and appropriately signed. c) Maintenance: All inert gas systems and gas monitoring equipment shall be installed and maintained as per AS5034-2005 and its referring standards. d) a. Weekly leak checks must be performed by the venue b. Complex six monthly maintenance is required e.g. to calibrate your monitor and check safety valves. c. Twelve monthly maintenance including a pipeline pressure test is also required to meet AS5034. NOTE: All maintenance records must be kept for at least two years. Training: the Standard requires that all staff are trained in manual handling procedures, the properties and hazards of inert gases. Training records for all staff and contractors to be maintained in accordance with OH&S standards. What is the problem? Gas cylinder systems stored in enclosed non-ventilated areas, such as underground cellars and cool rooms, can result in the build-up of gases if the cylinders leak. Inhalation of these gases may result in the asphyxiation of people entering these areas. What are the risks? Carbon dioxide and nitrogen, used to carbonate and deliver beer and soft drinks, are odourless, colourless asphyxiant gases. If the oxygen in the air is displaced by leaking gases, a person entering the cellar can be overcome without warning and suffocate in only a few minutes. Hotel staff have been killed in cellars after breathing in leaking carbon dioxide and/or nitrogen. The most recent was a 53 year old at the Royal Mail Hotel in Victoria in 2011 How can I be sure my venue is compliant with AS5034? Not sure if your hotel / club is AS5034 Compliant? CMA will conduct compliance audits to determine if your venue complies with AS5034. This audit is free of charge, all you need to do is call CMA today to arrange for a consultant to visit your venue.