Abstract: Recovery of Lithium by Donnan Dialysis during Recycling

Abstract:

Recovery of Lithium by Donnan Dialysis during Recycling of Lithium Ion Batteries from Electric

Vehicles

Lithium ion batteries (LIBs) are a critical technology in electric vehicles (EVs). They are the sole battery at present whose weight and cost are low enough, and whose energy density and power density are high enough to power electric vehicles. This fact is not expected to change in the near and mid future (up to circa 2040-2050)[1].

The electrification of the world’s cars is highly desirable since EVs have no direct emissions of green-house gases, smog causing chemicals, or particulate matter. The International Energy Agency has outlined a roadmap to achieve 50% electrification of the world’s vehicle fleet by 2050. Such a massive undertaking will require a large amount of LIBs, and thus a large supply of lithium. Unfortunately, production forecasting shows that without recycling of used EV LIBs the world’s lithium producers will be unable to produce enough lithium to meet the demand from new EV LIBs beyond the mid 2020’s. [2]

The method to recycle LIBs that holds the greatest promise of recovering large amounts of lithium is by hydrometallurgy. The current hydrometallurgical method is to: deactivate and shred batteries; isolate fines; leach the fines with inorganic acids; recover cobalt, nickel, and manganese by solvent extraction; and recover lithium by precipitation with sodium carbonate. A waste stream of residual acid rich in sodium and lithium is generated. [3] This method suffers from an insufficient recovery of lithium (15 to 26% in industry [1], at most 80% in literature [4]). It also suffers from an insufficient purity of lithium (at most

99.18% in the literature [5]). Both are due to the precipitation with sodium carbonate process. A novel

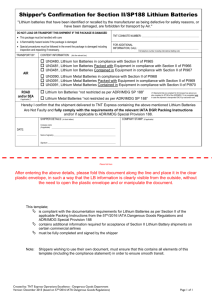

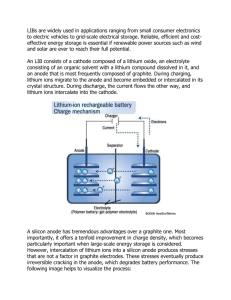

based on Donnan dialysis with cation exchange membranes (CEM). Lithium ions are extracted first with a monovalent CEM then ions of the other cathode metals (Co, Mn, and Ni) with a polyvalent CEM. Lithium is recovered by: neutralizing the acidic Li solution obtained from the first monovalent CEM ({1} in the figure); exchanging Li ions with K ions from a potassium bicarbonate solution pressurized with CO

2

with another monovalent CEM ({3} in the figure); depressurizing the Li enriched potassium bicarbonate solution, which results in the precipitation of lithium carbonate (the desired product); adding KHCO

3

to make up the K ions exchanged; re-pressurising; and recycling the entire solution past the monovalent cation exchange membrane ({3} in the figure).

Figure 1: proposed Li recovery process

A monovalent CEM and a polyvalent CEM were tested in Japan to determine the trans-membrane mass transfer coefficients at various salt and acid concentrations. The results from these investigations are presented.

References:

[1] A. Sonoc, J. Jeswiet, and V. K. Soo, “Opportunities to Improve Recycling of Automotive Lithium

Ion Batteries,” Procedia CIRP, vol. 29, pp. 752–757, 2015.

[2] H. Vikström, S. Davidsson, and M. Höök, “Lithium availability and future production outlooks,”

Appl. Energy, vol. 110, pp. 252–266, Oct. 2013.

[3] A. Chagnes and B. Pospiech, “A brief review on hydrometallurgical technologies for recycling spent lithium-ion batteries,” J. Chem. Technol. Biotechnol., vol. 88, no. 7, pp. 1191–1199, Jul.

2013.

[4] P. Zhang, T. Yokoyama, O. Itabashi, Y. Wakui, T. M. Suzuki, and K. Inoue, “Hydrometallurgical process for recovery of metal values from spent lithium-ion secondary batteries,”

Hydrometallurgy, vol. 47, no. 2–3, pp. 259–271, 1998.

[5] X. Chen, Y. Chen, T. Zhou, D. Liu, H. Hu, and S. Fan, “Hydrometallurgical recovery of metal values from sulfuric acid leaching liquor of spent lithium-ion batteries,” Waste Manag., vol. 38, pp. 349–

356, 2015.

Special Presentation on Summer Research in Japan Opportunity

The JSPS program is a 10 week summer research program in Japan. Graduate students from Canada,

France, Germany, Britain, Sweden, and the USA come and do research at laboratories of host researchers in Japan. The program is entirely supported by the Japanese government, including airfare and a generous maintenance allowance. The program begins with a one week culture and language training period and the researchers move to host institutions and concludes with a reunion of all researchers and presentation of results. The program offers a wonderful opportunity to experience Japan, both its top notch research facilities and its culture. If interested in going, come to this presentation to hear more about the JSPS summer program and apply before January 29 th .

Alexandru Sonoc was one of 5 Queen’s students who went to Japan in 2015. He will present some of his personal experience in Japan, talk a little about the program.