Plating process pre-treatments. General overview 0

advertisement

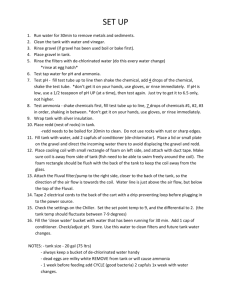

Plating process pre-treatments. General overview 0 - Introduction We want to discuss here about the plating process pre-treatments. Often the plating process is seen as a long series of problems and problems. The main point is that very often the basic points to get a good plating result are underestimated in their importance. A little care and some fixed rules on the item preparation before plating can solve more than 70% of the most common problems. The plating phase is a fixed step for the main part of jewellery articles, and it is clear that a good finishing aspect is given by a good plating job done. The following list contains the right steps that should be observed for all the articles after the polishing operations in the right sequence. All single tanks/steps will be explained here more in details. 1. Ultrasonic cleaning 2. First rinse tank 3. Electrolytic degreasing 4. First rinse tank 5. Washing tank 6. Neutralization tank 7. First rinse tank 8. Washing tank 9. Plating tank ( rhodium, gold…etc. ) 10. First rinse tank 11. Washing tank 12. Drying operations 1 – Ultrasonic cleaning After the normal manual polishing operations on semi-finished articles, the pieces must be treated on an ultrasonic washing machine in order to remove all traces of polishing pastes. It’s important to know that the better is the polish finishing, the better will be the plating result later. A bad polished article will never be nice and attractive, even after a perfect plating deposition. In a few words the ultrasonic action consists of the creation of high frequency waves in a stainless-steel tank filled up with water and detergents. On side-vertical walls and/or on bottom of this tank many PZT elements (piezoelectricelectrostrictive) are soldered, which vibrate at the frequency of 33 and more KHz. Vibration waves spread with uniform distribution into the entire volume of the tank and, reaching the surface of the pieces to clean, creating compression and decompression actions, these oscillating waves generate a lot of micro-bubbles (CAVITATION), that implode at high energy. The cavitation phenomenon is well known in hydraulic physics and it’s used to pulp, to comminute and to remove mechanically every kind of dirt at molecular level. Moreover, the relatively high temperature, normally used into an ultrasonic tank, is because the most common polishing pastes melt at a temperature near to 50-60°C, so the removal action will be easier and more effective at high temperature. Detergents are also used, to dissolve the molecules of dirty and oils present on the pieces and to prevent oxidation. 2 - First rinse tank When the items come out from any tank, some liquid is still present on the metallic surface. This liquid film is called “drag-out” and if not rinsed or washed properly, before entering in a new plating tank, it could be one of the main causes of contamination or pollution for the following solutions. Moreover, after the ultrasonic tank it is important to remove the detergents still present on the pieces surface, because sometimes the detergents used into ultrasonic machine are not perfectly compatible with the chemicals presents in the following tanks. To do that, it’s sufficient to wash the articles into a tank containing water. This step, in plating, is commonly called “first rinse”. In the jewellery sector plating often the first rinse tank does not require filtration or water recirculation. 3 - electro-degreasing tank After the first rinse, the pieces are ready for the following step: the electro-cleaning, commonly called “degreasing”. The electro - degreasing step, while cleaning the surface from greases and oils, is the main factor for the ACTIVATION of metal surfaces. In a few words, the electro-cleaning step prepares the metal surface of the articles for the following electrodepositions such as rhodium, gold, silver etc. For these reasons, without a well done electrodegreasing step, the precious metal deposition can not achieve a good result. The metallic surfaces are activated because during the electro-cleaning step, the gas quickly developed on the articles surface generates thousands and thousands of micro localized explosions that wil take to a surface perfectly cleaned and perfectly electro-conductive. Different chemicals are used in electro-cleaning: the formulas of electrolytic degreasing solution are often made by alkaline solutions composed of potassium hydroxide, phosphates, carbonates and surfactants, but the right choice must be done in relationship to different factors as the types of the articles or the types of plating baths to be used later. A good electro-degreasing solution for standard jewellery purpose should be not too aggressive, rich of complexing agents and with medium content of surfactants. Potassium hydroxide is necessary to attack the molecules of dirt and to dissolve them; furthermore it is the main factor for the solution conductivity. Complexing agents guarantee that dissolved molecules are not re-deposited then during the electro-cleaning process. The surfactants are very important to dissolve grease and oils and they act as a soap. As in the ultrasonic tank, also after the electrodegreasing tank it is necessary to wash the articles in a first rinse tank, to remove the 80 % of the drag-out (remember that the drag-out is the liquid film remaining on the surface of articles when put out from a tank). 4- Washing tank and the principle of operation for a water treatment unit coupled to a plating plant Following to another first rinse immediately after the electrolytic solution is the “washing tank”. In these tank, the water is not still as in the first rinse tank, but it is circulating, because all the washing tanks of plating line/plant are connected to a water treatment plant in order to always guarantee a perfect water quality. It’s important to know,that in plating process the water quality is a huge factor of importance for the final result. As everybody knows, there are different types of water. Distilled water, demineralized water, line-tap water, fresh water. But which one is the right water for plating purposes? And why? Even if in the normal speech we say that the required water is deionized or demineralized, the right water for plating purpose is water without organic contaminants and with low saline content. This is the reason why a common water treatment plant is made of columns of active carbon (to catch and trap the organic impurities) and ionic-exchange resins, to catch any saline impurities and low finally its conductivity. A good water for plating uses, normally has a conductivity under 5 microsiemens. As the plating solutions, and especially the precious metal based plating solutions, are very sensitive to organic pollution or saline pollution, the best choice in terms of costs/properties is the deionized water. What is Deionization? The deionization process removes all ions from a solution. Cationic exchanging resins remove all the cations (positively charged ions such as Sodium, Calcium, and Magnesium) and anionic exchanging resins remove all the anions (negatively charged ions such as sulfate, bicarbonate, and chloride). The cationic exchanger is operated in front of the anion exchanger and converts the salts to acids. CaSO4 + 2R CaR2 + H2SO4 NaCl + R H-R-Na + HCl Calcium and Sodium are captured by resins and the ending result is an acidic water because H2SO4 and HCl are now presents The anion exchanger removes then acid from solution: H2SO4 + 2R R2SO4 + 2H2O HCl + R HO-RCl +H2O The acids come out from the Cationic process are captured by the Anionc resins. In this way the water in exit will be without salts and will have neutral pH 5 - Neutralization step A neutralization step is done in a tank containing a liquid compatible with the following plating solution but chemically opposite to the previous solutions. As explained before, the electrolytic solution is an alkaline solution, and all the alkaline solutions are difficult to wash completely. For that reason we have the neutralization tank, containing an acidic solution which neutralizes completely all the alkaline residues that may stay attached to the surface. In this way the articles, after the neutralization are perfectly performed, cleaned and ready for the further electro-deposition process. After the neutralization tank, for all reasons explained before, the process will continue again with another first rinse tank, and another washing tank. Finally we arrived to the Galvanic process. Independently of what this process should be (rhodium, gold, silver, etc..) in all cases the perfection of end result will be achieved because a perfect preparation was performed earlier. 6 - Common problems caused from a not well done preparation (when the precious plating bath is considered in good conditions) 6.1 Problems generated by a poor ultrasonic degreasing step 6.1.1 not uniform deposition during the plating process 6.1.2 black or yellow patches after the plating process 6.2 Problems caused by electrolytic degreasing step 6.2.1. 6.2.2. 6.2.3. 6.2.4. 6.2.5. 6.3. Problems caused by improper first rinses or washing 6.3.1. 6.3.2. 6.3.3. 6.4 not uniform deposition parts of the articles without deposition plating deposition with low penetration power white clouds on the articles after the plating deposition oxidation on the articles baths contamination white clouds on the articles after plating deposition black, brown or yellow patches on the articles Problems caused by water 6.4.1 baths contamination 7 - Conclusion In conclusion with this general overview we wanted to demonstrate that to get a perfect plating result, a perfect pre-treatment steps have to be properly followed. All the plating plants must be equipped with a water treatment plant in order to maintain an high quality water, necessary for long life baths and quality in the articles