Short Spec

advertisement

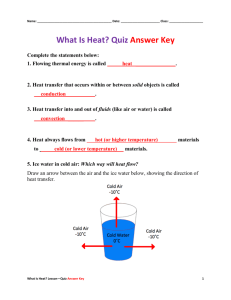

AVANTI SYSTEMS USA - TRANSVERTO MONOBLOCKTM SHORT-FORM PORT CHESTER, NY GUIDE SPECIFICATION SECTION 10 22 05 GLASS PARTITION SYSTEMS - TRANSVERTO MONOBLOCKTM CSI 3-PART SHORT-FORM GUIDE SPECIFICATION: USE FOR OUTLINE OR DD SPECIFICATION ISSUES. EDIT TO SUIT PROJECT PART 1 GENERAL 1.01 SUMMARY NOTE: Delete items below not required for project. A. Section includes, but is not limited to, fabricating, furnishing, delivering, erecting and installing the following work: 1. Full height double-glazed partition system. 2. Integral operable blinds (option) 3. LCD privacy glazing; see Section 08 88 36 4. Accessories required for a complete working installation. B. Related Documents and Sections: Examine Contract Documents for requirements that directly affect or are affected by Work of this Section. A list of those Documents and Sections include, but is not limited to the following: 1. Drawings and general provisions of the Contract, including General and Supplementary Conditions and Division 01 General Requirements, and Division 02 through 49 Specification Sections, apply to this Section 1.02 SUBMITTALS A. Product Data: Submit manufacturer’s printed product literature indicating product characteristics, performance criteria, product use limitations, requirements and recommendations, and Manufacturers' Instructions. B. Shop Drawings: Submit shop drawings indicating plans, elevations, and details showing type and thickness of metal and glass, glazing, anchoring, and joining, electrical wiring and power requirements, hardware, trim, and accessories. Provide Field Measurements. C. Samples: 1. Initial for Selection: Submit two (2) complete full range sets of color chips. 2. Final Selection: Submit two (2) 12 inch (30 cm) square samples for acceptance. NOTE: Prototype corner section(s) indicating joinery and edge conditions available upon request. D. Manufacturer's Certificates NOTE: Delete the following Article if LEED is not applicable or otherwise; edit to meet project LEED requirements. E. Sustainable Design (USGBC LEED®) Submittals: Refer to Section 01 81 15, LEED Design Requirements. 1. LEED 2009 (v3) Credits. Complete online LEED forms and submit other required materials as follows: a. Materials and Resources (MR) Credits: 1). MR Credit 3: Materials Reuse - 5% (c3.1) or 10% (c3.2) [ DD ] [ OUTLINE ] ISSUE APRIL 04, 2014 GLASS PARTITION SYSTEMS 10 22 05 - 1 AVANTI SYSTEMS USA - TRANSVERTO MONOBLOCKTM SHORT-FORM GUIDE SPECIFICATION PORT CHESTER, NY 2). MR Credit 4: Recycled Content - 10% (c4.1) or 20% (c4.2) (post-consumer + 1/2 pre-consumer) 3). MR Credit 7 (MRc7): Certified Wood b. Indoor Environmental Quality (EQ) Credits: 1). EQ Credit 4.2 (EQc4.2): Low-Emitting Materials - Paints & Coatings 2). EQ Credit 8.1 (EQc8.1): Daylight & Views - Daylight 75% of Spaces 3). EQ Credit 8.2 (EQc8.2): Daylight & Views - Views for 90% of Spaces 2. LEED v4 Credits. Complete online LEED forms and submit other required materials as follows: a. Materials and Resources (MR) Credits: 1). MR Credit 1 (MRc1): Building Life-Cycle Impact Reduction; Option 3 - Building and Material Reuse 2). MR Credit 3 (MRc3): Building Product Disclosure and Optimization - Sourcing of Raw Materials; Option 1 3). MR Credit 4 (MRc4): Building Product Disclosure and Optimization - Material Ingredients; Option 2 - REACH Optimization b. Indoor Environmental Quality (EQ) Credits: F. 1). EQ Credit 2 (EQc2): Low-Emitting Materials 2). EQ Credit 7 (EQc7): Daylight 3). EQ Credit 8 (EQc8): Quality Views 4). EQ Credit 9 (EQc9): Acoustic Performance LEED Closeout Documentation: NOTE: Edit below to meet project LEED requirements. 1. LEED 2009 (v3). Submit completed LEEDTM submittal Worksheet Templates for the following credits: a. MRc3, MRc4, MRc7 and EQc4.2, EQc8.1, EQc8.2 2. LEED v4. Submit information and documentation to complete LEEDTM Worksheet Templates for the following credits: a. MRc1, MRc3, MRc4 and EQc2, EQc7, EQc8, EQc9, EQc9 1.03 A. QUALITY ASSURANCE Regulatory Agency Approvals: Comply where required by authorities having jurisdiction (AHJ). 1. Glazing: GANA (GM), GANA (LGRM), and CPSC 16 CFR 1201 2. Accessibility: ADAAG (28 CFR Part 32) and ICC / ANSI 117.1 B. Qualifications: Manufacturer to have minimum five (5) years documented experience; Installer to have minimum two (2) years documented experience. C. Source Limitations: Obtain Glass Partition System materials from one manufacturer. 1.04 A. 1.05 A. DELIVERY, STORAGE, AND HANDLING Comply with manufacturer’s instructions and recommendations, GANA (GM), GANA (LGRM), and Division 01 requirements. SITE CONDITIONS Ambient Conditions: Do not deliver or install product until building is enclosed and HVAC system has been operating at occupancy levels in accordance with ANSI/ASHRAE 55; Acclimate product to installation location at least 48 hours before installation. PART 2 PRODUCTS GLASS PARTITION SYSTEMS 10 22 01 - 2 [ DD ] [ OUTLINE ] ISSUE APRIL 04, 2014 AVANTI SYSTEMS USA - TRANSVERTO MONOBLOCKTM PORT CHESTER, NY 2.01 A. SHORT-FORM GUIDE SPECIFICATION MANUFACTURERS Basis of Design Product by Manufacturer: Transverto MonoblockTM by Avanti Systems USA, 200 William St. Suite 306; Port Chester, NY 10573; Toll Free Tel: 877-282-6843; Tel: 914-9349093; Web: www.avantisystemsusa.com NOTE: Delete one of the following two paragraphs coordinating with project requirements of Divisions 00 and 01 for product options and substitutions. 1. Substitutions permitted under provisions of Section 01 25 00, Substitution Procedures. a. Submit Document 00 43 25, Substitution Request Form (During Procurement) b. Submit Document 00 63 25, Substitution Request Form (During Construction) 2. Substitutions: Not permitted. 2.02 DESCRIPTION A. Regulatory Requirements: Provide tempered or laminated safety glass for locations subject to human impact as required by authorities having jurisdiction (AHJ). B. Sustainability Characteristics: 1. Fully demountable system for ease of reuse or recycling 2. Assembly components (glass, aluminum and stainless steel) contain recycled material and are infinitely recyclable. 3. No adhesives used (no VOC) with dry joint glazing NOTE: Delete the following if LEED is not applicable or otherwise; edit to meet project LEED requirements. C. LEED Characteristics: 1. LEED 2009 (v3) a. MRc3: Avanti Transverto Monoblock's components easily disassemble and reassemble to "Use as salvaged... or reused materials." b. MRc4: Avanti Transverto Monoblock's glazing contains a calculated total 35% "Recycled content." The aluminum frame channels and stainless steel hardware metals contain a total LEED reportable recycled content of 25%. c. MRc7: Avanti wood doors, doorframes, and glazing channel frames are FSC-certified. d. EQc4.2: Avanti Transverto Monoblock glass, and powder-coated, plated or anodized metals, are classified by USGBC as "inherently nonemitting sources." e. EQc8.1: Avanti Transverto Monoblock glass wall assembly borrowed light brings daylight deeper into the floor plate. f. Avanti Transverto Monoblock glass wall assemblies provide direct outdoor lines of sight. EQc8.2: 2. LEED v4 a. MRc1: Avanti Transverto Monoblock can be easily disassembled for salvage and reuse. b. MRc3: Avanti can meet credit requirements in three Option 2 categories: FSC Certified Wood; Materials Reuse; and Recycled Content. c. MRc4: Option 2, submit product's REACH Optimization report d. MRc8 (Healthcare): Avanti Transverto Monoblock contributes to one flexibility method (3 required); "Use demountable partitions for 50% of applicable areas." [ DD ] [ OUTLINE ] ISSUE APRIL 04, 2014 GLASS PARTITION SYSTEMS 10 22 05 - 3 AVANTI SYSTEMS USA - TRANSVERTO MONOBLOCKTM SHORT-FORM GUIDE SPECIFICATION 2.03 A. PORT CHESTER, NY e. EQc2: Avanti Transverto Monoblock glass, and powder-coated, plated or anodized metals, are classified by USGBC as "inherently nonemitting sources." f. EQc7: Avanti Transverto Monoblock glass wall assembly borrowed light brings daylight deeper into the floor plate. g. EQc8: Avanti Transverto Monoblock glass wall assemblies provide direct outdoor lines of sight. h. EQc9: Avanti Transverto Monoblock products contribute with system acoustic ratings of 45+ dB reductions. PERFORMANCE / DESIGN CRITERIA Performance Criteria: 1. Acoustical: Sound reduction tested in accordance with BS EN ISO 140-4 or ASTM E90 and ASTM E336, and rated in accordance with BS EN ISO 717-1 or ASTM E413. a. Transverto MonoblockTM - Glass Wall Acoustic Rating: (US Equivalent) STC: 45 dB (Rw) 45 b. Transverto MonoblockTM - Solid Wall Acoustic Rating: (US Equivalent) STC: 47 dB (Rw) 47 c. Acoustic Rating: (US Equivalent) STC: 36 dB (Rw) 36 Acoustic Rating: (US Equivalent) STC: 37 dB (Rw) 37 Aluminum/Glass Door - d. Wood (Timber) Door - 2. Fire Resistance (BS 476 Part 22; ANSI/NFPA 80): 30/0 (EU) a. Steel Frame Option: NOTE: 30/30 = CPSC 16 CFR 1201, Cat. I & II Design Criteria: 1. Structural Live Load - Deflection: Maximum L/120 2. Structural Stability: BS 5234, BS 6180; or IBC 1621.1.2, ASCE 7 9.6.2.8 a. Seismic: 2.04 60 min. (US) 30 minutes integrity (resistance to the passage of flames or smoke) and 30 min. insulation (stops the transfer of radiant heat) 3. Impact Safety Resistance: B. 60/60 (EU) 20 min. (US) IBC Section 1705.2 MATERIALS A. Aluminum Extrusions: ASTM B221, 6063-T6 alloy and temper B. Stainless Steel Fittings: ASTM A276, Type 304 C. Wood: FSC certified Hardwood; Species, [ Cherry ] [ Ash ] [ Oak ] [ Beech ] [ Maple ] [ As selected by Architect from manufacturers full range. ] D. Glass: 1. Fully Tempered (FT) Clear Glass: ASTM C1048, Type 1, Class 1, Quality q3. 2. Laminated Glass: ASTM C1172; two (2) layers clear glass; [ clear ] [ translucent ] interlayer. NOTE: Privacy glass can be provided as tempered glass or laminated glass Select switch and color required and delete the paragraphs not required. 3. Lunar LCD Privacy Glazing: UL approved liquid crystal display switchable privacy glass; 110 VAC, 60 Hz; [ single ] [ 3 way ] switches; and electric hinges; see Section 08 88 36. a. Color: [ Neutral ] [ Grey ] [Green ] [ Bronze ] [Blue ] [ As selected by Architect. ] GLASS PARTITION SYSTEMS 10 22 01 - 4 [ DD ] [ OUTLINE ] ISSUE APRIL 04, 2014 AVANTI SYSTEMS USA - TRANSVERTO MONOBLOCKTM SHORT-FORM PORT CHESTER, NY GUIDE SPECIFICATION E. Glazing Gaskets: Molded or extruded [ rubber (ASTM C1115) ] [ neoprene (ASTM C864) ] [ EPDM ] F. Fasteners: Type best suited to application, and acceptable to glass partition system manufacturer. G. Wood Doors: See Section [ 08 14 00 ] [ 08 17 53 ] [ 08 17 54 ] . H. Door Hardware: See Section 08 71 00. 2.05 FULL HEIGHT DOUBLE GLAZED PARTITION SYSTEM - TRANSVERTO MONOBLOCKTM NOTE: Transverto Monoblock full height glass partition system 3/8 inch glass partitions are available up to 9 feet high and 1/2 inch glass partitions up to 12 feet high. System is relocatable with frameless dry jointed system. A. Transverto MonoblockTM full height, relocatable, double dry glazed glass partition system as manufactured by Avanti Systems USA. NOTE: Aluminum framed or frameless glass can be specified as part of this section. 1. Configuration: [ Straight wall ] [ As indicated by Drawings. ] 2. Single Glazed: NOTE: Select from the following paragraphs and delete items not required. a. [ Tempered ] [ Laminated ] Clear Glass Thickness: b. Laminated LCD Privacy Glazing Thickness: 1/4 inch (6 mm) 9/16 inch (14 mm) 3. Solid Panels: [ Gypsum wallboard ] [ Chipboard ] and CW 75 light-gage metal framing with laminated facing of [ vinyl-foil ] [ Plastic Laminate ] [ melamine ] [ FSC-certified veneered wood ] . 4. System Framing (AV-TM drawing number): a. Head and Sill Framing (AV-TM01) b. Intermediate Vertical Framing Connection - Glass/Glass (AV-TM02) c. (AV-TM03) Intermediate Vertical Framing Connection - Solid/Glass d. Floor Termination Framing - Solid/Wall (AV-TM04) e. Wall Termination Framing - Solid/Wall (AV-TM05) f. (AV-TM06) Wall Termination Framing - Glass/Wall g. T Connection Framing - Glass/Glass (AV-TM07) h. T Connection Framing - Solid/Glass (AV-TM08) i. Intermediate Framing - Solid/Glass (AV-TM09) j. Door Jamb Framing - Glass/Door Jamb (AV-TM10) k. Door Jamb Framing - Solid/Door Jamb (AV-TM11) l. Door Head Framing - Glass/Door Head (AV-TM12) m. 90 Degree Corner - Solid/Solid (AV-TM13) n. Vertical Framing at Round Column/Glass (AV-TM14) o. Vertical Framing at Round Column/Solid (AV-TM15) p. Solid Panel Connection (AV-TM15) q. Solid End Wall Termination Framing (AV-TM16) r. 90 Degree Corner - Solid/Glazed (AV-TM17) s. Doorframe at Ceiling (AV-TM18) t. T Connection Framing - Solid/Glass (AV-TM19) [ DD ] [ OUTLINE ] ISSUE APRIL 04, 2014 GLASS PARTITION SYSTEMS 10 22 05 - 5 AVANTI SYSTEMS USA - TRANSVERTO MONOBLOCKTM SHORT-FORM GUIDE SPECIFICATION PORT CHESTER, NY u. 135 Degree Corner Framing - Glass/Solid (AV-TM20) v. (AV-TM21) Ceiling Termination - Solid/Ceiling w. Doorframe Termination at Wall (AV-TM22) x. T Connection of Two Doorwings and Glass Wall (AV-TM23) y. Solid Wall Connection to Window Mullion (AV-TM24) z. Glass Wall at Floor (AV-TM25) aa. Solid Wall Connection (AV-TM26) bb. Typical Accessories: Glazing pocket PVC seals; foam seals; mineral sound Insulation 5. Integral Operable Blinds: [ Manual; ] [ Motorized; ] 1 inch aluminum horizontal slat blinds a. Controls: [ Wall switch ] [ Remote: [ 110 VAC ] [ Battery pack ] ] 2.06 A. 2.07 GLASS PARTITION DOORS Door Assembly: [ LCD ] [ Pivot ] [ Sliding ] [ Hinged ] Glass [ Flush Wood (timber frame) ] [ Acoustic Double-Glazed ]; See Section [ 08 17 53 ] [ 08 17 54 ] . FINISHES A. Aluminum: AAMA 2604, polyester powder coating; [ Stock color RAL 9006 Metallic Silver. ] [ Custom color as selected by Architect from manufacturer's full color range. ] B. Stainless Steel: Satin finish C. Wood Doors: Manufacturer's standard [ stain and ] [satin ] [ gloss ] polyurethane finish as selected by the Architect from manufacturer's full color range. D. Wood Doors: Finish specified in Section [ 08 14 00 ] [ 08 17 53 ] [ 08 17 54 ] . PART 3 EXECUTION 3.01 A. EXAMINATION AND PREPARATION Examination, Preparation, and Acceptance of Conditions in accordance with Division 01 requirements, manufacturer's instructions, approved Shop Drawings, and as follows: 1. Carefully examine installation areas with Installer present, for compliance with requirements affecting Work performance. NOTE: Transverto Monoblock can be installed on floor substrates that vary +/- 1 inch (25 mm). a. Ensure finished floor under glass partition system is level plus or minus 1 inch in 10 feet (25 mm in 3 m) non-cumulative. b. Verify concealed overhead structural supports meet project requirements. 2. Proceed with installation only after unsatisfactory conditions have been corrected. 3. Broom sweep and vacuum clean surfaces thoroughly prior to installation. 3.02 A. INSTALLATION Install in accordance with Division 01 requirements, manufacturer's instructions, approved Shop Drawings, GANA (GM), GANA (LGRM), and as follows: 1. Securely anchor assembly to structure with components installed plumb and level, in proper plane, free from warp and twist. NOTE: Delete paragraph below if integral operable blinds are not used. 2. Integral Operable Blinds: Power, switching and controls; see Division 26, Electrical. NOTE: Delete paragraph below if LCD glazing is not used. 3. Switchable Privacy Glazing: Power, switching and controls; see Division 26, Electrical. B. Tolerances: GLASS PARTITION SYSTEMS 10 22 01 - 6 [ DD ] [ OUTLINE ] ISSUE APRIL 04, 2014 AVANTI SYSTEMS USA - TRANSVERTO MONOBLOCKTM PORT CHESTER, NY SHORT-FORM GUIDE SPECIFICATION 1. Maximum Variation from Plumb or Level: 1/8 inch in 3 feet (3 mm in 1 m) or 1/4 inch in any 10 feet (6 mm in 3 m), whichever is less. 2. Maximum Misalignment of Members Abutting End to End: 1/16 inch (1.6 mm). 3.03 A. FIELD QUALITY CONTROL Non-Conforming Work: Repair or replace as directed by the Architect; see General and Supplementary Conditions, and Division 01, General Requirements. 1. Remove and replace glass that is broken, chipped, cracked, abraded, or otherwise damaged, including natural causes, accidents and vandalism, during construction period. 3.04 ADJUSTING, CLEANING, AND PROTECTION A. Adjust doors for smooth operation throughout full operating range. B. Waste Management: Comply with Division 01requirements; recycle shipping pallets, cardboard protection, and scrap metal. C. Cleaning: Clean metal and glass surfaces to remove foreign materials; clean glazing to GANA Bulletin 01-0300. D. Touch-up, clean, repair or replace damaged products prior to Substantial Completion. E. Protect installed work from construction operations until date of Final Completion or Owner occupancy, whichever occurs first. END OF SECTION NOTE: Avanti Systems is a European award winning innovating glass partition company that offers an extensive range of partitioning and storage wall options for commercial and office interiors. In line with a commitment to innovative design and product research, Avanti Systems ensure that all products developed by the company meet the rigorous standards laid down by the regulatory bodies. Furthermore, wherever possible, our R&D program incorporates material from sustainable sources and recyclable materials. A design-led and innovative company that works hand in hand with architects and contractors to produce the best possible results every time and on every job. In essence we look to fulfill a clients brief to the letter and do not simply resort to off the shelf solutions. This specification includes Avanti Transverto Monoblock full height, floor to ceiling moveable wall assembly, which is available as double glazed with straight partition walls. NOTE: Be sure to obtain the latest version of this Guide Specification. This Guide Specification is not a completed document ready for use. It must be edited, deleting, adding, or modifying text, as required to suit project requirements. The professional stamping and the contracting parties of the Contract Documents are responsible for the accuracy of issued project specifications, including any use of this AVANTI SYSTEMS USA Guide Specification. AVANTI SYSTEMS USA SHALL NOT BE LIABLE FOR DAMAGES ARISING OUT OF THE USE OF THIS GUIDE SPECIFICATION. [ DD ] [ OUTLINE ] ISSUE APRIL 04, 2014 GLASS PARTITION SYSTEMS 10 22 05 - 7