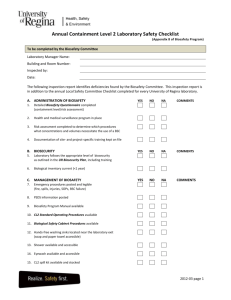

Biosafety Program: Users Manual

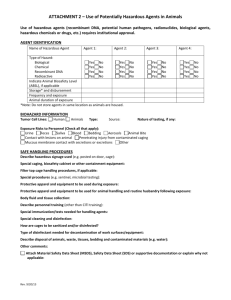

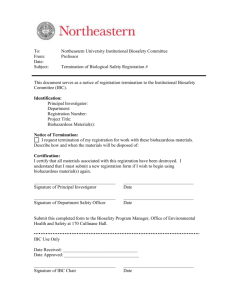

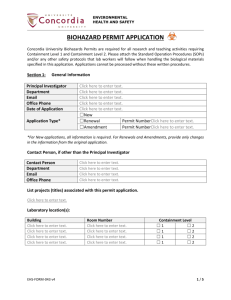

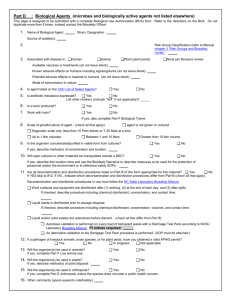

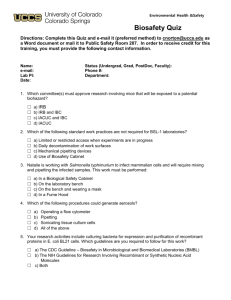

advertisement